Ringing in Y axis (Linear guide system, coreXY design)

-

@JayT yes, ringing is common. It happens more in Y on coreXY as you're moving the whole of x axis about

-

@JayT Have you tried tweaking the motor currents?

-

YEs, we initially used 2000mA, reduced it down to 1600mA.

- Tried to use Pulse dir pins with external driver as well. no luck.

- I am using 0.9deg motors (as with 1.8degree there was vertical ribbing in Y axis).

- I had built cartesian system, even then Y always had ringing. this wasn't the problem with 300bed side. Then we moved to Corexy for 500 bed size, but ringing appear despite slow speeds.

-

@JayT said in Ringing in Y axis (Linear guide system, coreXY design):

@jay_s_uk : RRF3.5.0 RC3.

NOTE: I use the same in 300 bed sized machine. It's not giving any problems.

@JayT said in Ringing in Y axis (Linear guide system, coreXY design):

@jay_s_uk : RRF3.5.0 RC3.

NOTE: I use the same in 300 bed sized machine. It's not giving any problems.

Yes, you are right, I also have the same and it works fine.

-

@JayT there are at least two possible sources of this resonance:

-

The combination of the heavy Y axis and the belts. Increasing the belt tension will increase the frequency of this resonance and may also reduce its amplitude somewhat.

-

If the tool head is heavy and its centre of mass is displayed from the Y axis by much distance then there will be resonance due to torsional rotation of the tool head about the Y axis. The frequency and seriousness of this will depend on the moment of inertia of the tool head about the Y axis, and how stiff the Y axis metalwork is. To reduce the amplitude of this resonance you will need to reduce toolhead moment of inertia (e.g. if using a direct drive extruder then switch to one with lower mass) or make the Y axis stiffer so that it better resists twisting.

On my E3D tool changer with Hemera tools, #2 is by far the most significant.

I suggest you upgrade to firmware 3.5.0-rc.3 and then use an accelerometer and the Input Shaping Plugin in DWC to measure the frequency of the ringing and tune input shaping to mitigate it.

-

-

- Based on suggestion, I tried latest firmware 3.6 RC3.

NOTE: Tool head is Biqu. (not much heavy, with 3dpinted ducts for part cooling). - Attached is an image with the top one printed using DAA & bottom one is how base printing without DAA appears. There is absolutely no difference after input shaping. (I manually calculated distance between 2 lines using vernier (except the corner one) ).

- Jerk is 5.

- DAA: speed is 120mm/s, acceleration 800mm/s2, and distance is 2mm between 2 lines, so that 60Hz for DAA. We used ZVD mode.

- In the top cube, I also modified acceleration to 1500 mm/s2, but no difference.

Can you suggest here further?

- Based on suggestion, I tried latest firmware 3.6 RC3.

-

@JayT best off getting an accelerometer and measuring it properly.

And ZVD is not the most aggressive input shaper, see the data evaluation info here about the different shapers https://docs.duet3d.com/en/User_manual/Tuning/Input_shaping_plugin#data-evaluation

maybe try ei2 or ei3 -

@jay_s_uk :

@dc42 :

Thank you for suggestions. I used EI2 & EI3 methods input shaping modes with 20Hz, and it indeed reduced ringing, also with reduced print speed, it further goes down. I am reading on connecting accelerometer to find exact frequency.Can you suggest where should I fit my accelerometer for Y-Axis? (on the extruder ? ) , NOTE: The accelerometer doesn't have axis marked.

Can you mark in the picture above to suggest? -

@JayT the closer to the nozzle the better. There are mounts you can print that let you mount an accelerometer directly to the nozzle (just for data capture)

-

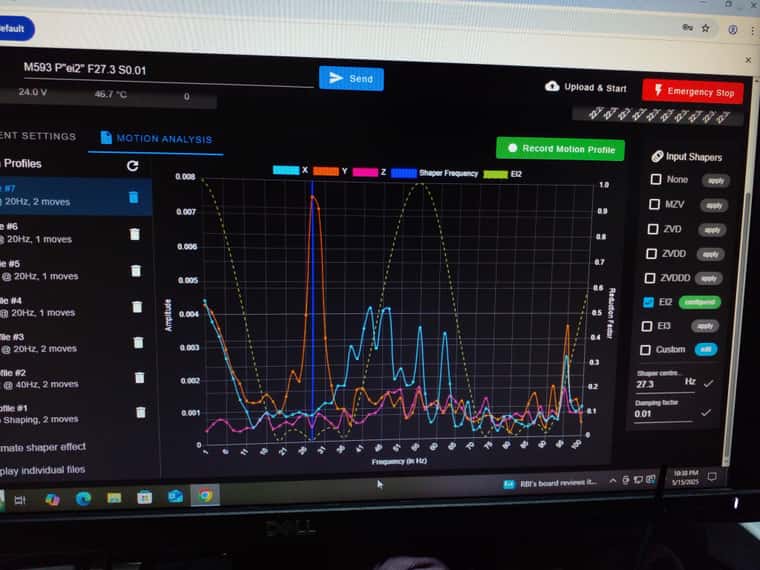

Hi Jay, I tried 20Hz, result was better. And I used following accelerometer curve to detect the exact frequency. as per this 27.4 shaper frequency, but that does not remove ringing for me like 20Hz. Can you suggest further on how to proceed here or how to analyze this graph?

Also What is the role of damping factor ? At 20Hz with 0.05 i get better result I feel. but I need to find proper frequency & damping factor to make its smooth.

Damping factor 0.01

EI2

Mounted above BLtouch mount. -

Below is result at 20-22Hz frequency, where many lines reduce, speed is 60mm/s, so the lines are closer. However, I am not able to remove these lines in the picture.

How do I capture this frequency in input shaping method?

This is with damping factor 0.05 though, with 0.01 lines are more prominent i felt.

-

@JayT as the ringing is so severe, you are unlikely to cancel it completely. You could try other input shapers such as ZVDD and ZVDDD.