My new accidental Bed surface discovery

-

This is probably old news to some of you but the other day my Boro glass broke while a large PETG print was cooling on it. New glass was ordered and going to take 2 weeks to get here. Out of desperation I bought a ceramic glazed Pizza stone. My bed is 330cm dia and the 13" pizza stone fits right in. A little hair spray and I have been printing both ABS and PETG with great results. I'm not even sure I am going to go back to the glass when it gets here.

I have a mains powered bed so I have no idea how this would work on anything else and no I have not tried to cook pizza on it but the thought has crossed my mind.

Anyone else ever try this or have any accidental discoveries they would like to share?

I would love to find a nozzle or coating for my e3d Volcano to resist the plastic fuzz from building on it during prints.

-

Why not? What is the thickness, how much heavier and how flat. Estimations would suffice.

-

@jackatom74 said in My new accidental Bed surface discovery:

I would love to find a nozzle or coating for my e3d Volcano to resist the plastic fuzz from building on it during prints.

I had good experience with a DIY silicone sock made from a mold remixed off thingiverse. It was my first try, think I made it thicker than was supposed to be (3mm ?) and the hole surrounded the nozzle pretty closely. Lasted 6-8 months I think, damaged it when swapped over to a real V6 and did not fit. The E3D sock was much thinner, did not come close enough around the nozzle, and lasted only a month or so.

-

If you have an aluminium heat spreader between the bed heater and the glass, then you don't need to use borosilicate glass. Ordinary float glass from your local glazier will work just as well. It's generally very flat, although occasionally you might get a slightly warped piece.

-

@3dpmicro Its 8mm and of acceptable flatness, and maybe a little heavier than my 4mm boro glass. the prints are sticking well and once they cool coming right off without a fight.

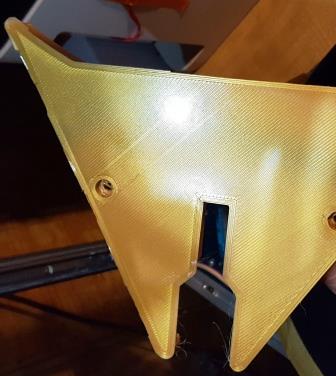

Below is one of the corners for my printer I printed last night.

PETG@245C, bed temp at 105C and then I dial it back every 3 layers until I get to 85C