Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?

-

I just noticed something when trying to screw the arms back to the slide arms at the top (these are what connect with the end stops).

It looks like three of the arms have M3? bolts that do not tighten back on the slide arms - they just spin and spin but don’t tighten. Is this a sign that the slide arms are defective?

-

Hi, there is a floating 'nut' located inside of the slider. That nut has likely slipped out. I had that same exact problem. If your luck is holding it may not have actually fallen out. But you'll likely have to disassemble the carriage assy, use tweezer to reposition the nut while you thread the bolt into it, provided its still inside. On one of my sliders, the plastic cracked and I was forced to glue it together using a clamp.

Your rod-end bearings appear to be superior quality compared to what AC sold me.

good luck.

3mm

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Thanks for the tips. If I measure the arms from end to end (including the chrome eyeholes at each end), all arms measure to the same 279mm. Does that seem right?

I’ll have to get the M3 bolts to address the bed angle. I think you’re 100% on the money with those horrible bed mounts. Will advise. Thanks again.

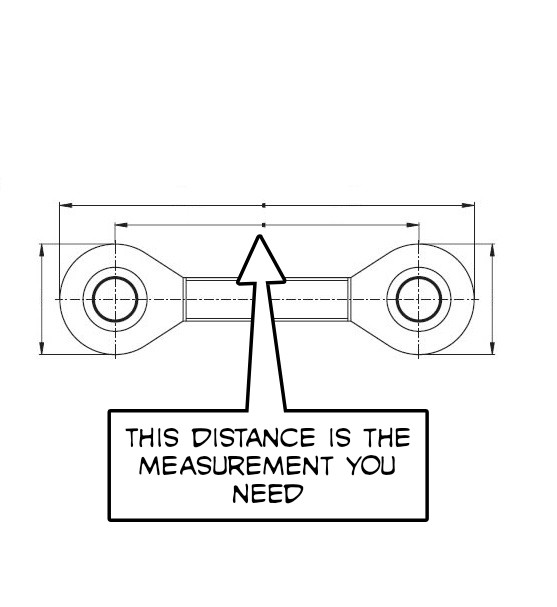

The measurement you need is from center to center of the eye holes. I haven't measured all of mine but i doubt they are all exactly 268mm since my bed still calibrates to a slight dish.

-

Juice's diagram is perfect. Hole center to hole center.

Mindbender9: If they are indeed anything but 271 (your current M665 L setting), that can cause numerous problems. Measure hole-hole carefully, and if they are not 271:

-

Put the actual measure in M665 in config.g

-

Delete config_override.g entirely.

-

Reboot (or power cycle) the printer

-

Re-run M32 a couple of times, and then M500

Post your config_override.g ...

Seems like we are getting closer.

-

-

Measuring Eyehole to Eyehole, the arms are 270-271mm in length.

@3mm - You were right on the money regarding the floating nuts. I was able to reattach all of the arms after removing the sliders like you mentioned. Thanks again.

@Danal - I set all three sliders and endstops to the same position equally. One slider arm was slightly off by 1mm compared to the other two, but now they're all evenly set.

I want to recheck the three main pillars again before performing a test calibration. Just to be safe.

Thanks guys for all of the help. Believe me, I am very grateful for all of the tips and direction you're sending my way. I would be (more) lost if you guys weren't jumping in to help.

Much appreciated as always!

-

How did you make the measurement? I need to measure mine more precisely, my bed calibrates to an upward tilt on the Y tower side but i'm pretty sure they are perpendicular.

-

Hi @Juice

If you mean the arms, I disassembled them from the Nozzle/Hot-End and the slider assemblies. Then I measured each using a ruler, and they were all uniform in length.

But I more or less used your diagram (thank you for that) and eyeballed to center position in each eye.

Getting the arms reattached took a little work.

-

Ok thanks mindbender. I just finished measuring mine, i made a jig and measured as best i could with a steel ruler and all but 1 came out to about 266.5mm, not quite the 268 that they are supposed to be. Anycubic QC needs some work. The one arm is longer and fits the jig a fair bit tighter than all the others, it may be .1-.2 mm longer. Does anyone have any suggestions on what i should do in this situation?

-

@juice - How long has it been since you've purchased the AC Kossel? If it's still under warranty, you could pursue getting a replacement part for that single arm.

On second thought, trying to get tech support from Anycubic3D wasn't easy. You might have better luck going through the seller for a replacement part under warranty.

Otherwise, several people have recommended carbon fiber aftermarket arms/ball ends as being one of the best upgrades for a delta printer. When I get my printer to work, I might look at replacement arms as a future purchase.

-

@juice said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Ok thanks mindbender. I just finished measuring mine, i made a jig and measured as best i could with a steel ruler and all but 1 came out to about 266.5mm, not quite the 268 that they are supposed to be. Anycubic QC needs some work. The one arm is longer and fits the jig a fair bit tighter than all the others, it may be .1-.2 mm longer. Does anyone have any suggestions on what i should do in this situation?

Be sure and set M665 L to 266.5, even if it seems to make things worse at first; getting that right is foundational to getting all the other settings.

With regard to the difference, I wouldn't count on getting anything better from Anycubic. Also, I was getting decent prints with stock arms where one was .9mm longer. So... accept it until you upgrade it... If you can, "pair" the arms as best as possible to a given carriage. Longest two together, etc.

-

@mindbender9 said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

and eyeballed to center position in each eye.

Tip for the future: When measuring center-center between holes that are identical, measuring to the same end (e.g. "right" or "top") of each hole is equivalent, and much more precise than eyeball center.

Having said that, I would NOT take your machine apart again.

And, just checking basic assumptions: You have M665 L271, correct?

-

@mindbender9 I've had my printer for 2 months now and i suppose i could see if they'd send me a new rod, but I think i'll just put my efforts into upgrading to magnetic ones. We both have the same model with rods that are not the 268mm that they are quoted as being. Who knows what length of rod i'll end up with.

@Danal Do you have magnetic arms on your anycubic kossel? If so, did they fit the effector and carriages without any modifications?

Thanks -

@danal said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

Having said that, I would NOT take your machine apart again.

LOL - No argument here.

And, just checking basic assumptions: You have M665 L271, correct?

Yes, config.g still has M665 L271 set. I'm working on the bed issues and will remove the stock bed mounts and pursue the direct attached method.

Thanks for the help! I'll start up a test print when I get home from work.

-

@juice said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

@Danal Do you have magnetic arms on your anycubic kossel? If so, did they fit the effector and carriages without any modifications?

I did mod my printer to have mag ball "Haydn Huntley - Blue Eagle Labs" rods. I actually ordered them from either Amazon or Ultibots, I don't remember. I have a linear, NON plus, so I used 218mm. For a plus, they will be different. I printed adapters for the existing effector, and printed adapters for the carriages that more-or-less completely replace the plastic part of the carriage. Found both on Thingiverse.

The effector is not on the printer right now because I am trying something different (also mag ball).

This one mod made the most difference in print quality of anything I did. I highly recommend it.

-

danal said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

@juice said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

@Danal Do you have magnetic arms on your anycubic kossel? If so, did they fit the effector and carriages without any modifications?

I did mod my printer to have mag ball "Haydn Huntly" rods. I actually ordered them from either Amazon or Ultibots, I don't remember. I have a linear, NON plus, so I used 218mm. For a plus, they will be different. I printed adapters for the existing effector, and printed adapters for the carriages that more-or-less completely replace the plastic part of the carriage.

This one mod made the most difference in print quality of anything I did. I highly recommend it.

I mod'd my 'AC kossel linear plus' (although that is what I bought, it isn't what I received), but in any case I got the Hayden diagonal-rod mag-ball rod arms from UltiBots.

MindBender, I recommend that you work to establish a relationship with a quality robotics vendor and UltiBots is a good one in my estimation.

Solve the problems, get yourself a Smart-Effector and mag-ball terminated diagonal-rods, that'll fix the parts problems, the bowl-shaped bed and all the messing around trying to figure out what those cheeseballs over at AnyCubic sent ya. And with the Smart-Effector solution...everything snaps together, so-to-speak. Plus you get a in-built build area illumination 3x bright white LEDs, everything has connectors for easy removal/re-connection, and a slick z-probe auto-sensing height-sensor (everything in this art requires tweaking) and it works really well too. One of the points alot of folks miss about the Smart-Effector is that its a low mass unit, compared to the heavy effector that AnyCubic implemented. Low mass is very tastey in delta printing.

That's my two centavos here in LA, Ca, United States of Mexico!!

3mm

-

I've decided to stick with my original rods since before i undertook the upgrade, the machine was printing good, 20 mm calibration cubes printed within 0.1 mm deviation, so i guess the small difference in that one rod isn't enough to make a huge difference in print quality.

What would make a huge difference is the 3mm difference in rod spacing between effector and carriages that i didnt notice during the upgrade!! I upgraded to robotdiggs carriages and they have 20mm spacing while the anycubic effector has 43mm. I spent 2 days scratching my head over why i couldn't get good calibration even though everything seemed to be within good tolerance. Then I realized that i never measured the effector. Luckily i have a spare one that does have 40mm spacing and now i can use my V6 without any modifications...although i do lose 37mm in build height. Anyway, first calibration with new effector got me 0.031 deviation, and that's without a probe. Now, on to the minor things so i can get printing again.

I upgraded to robotdiggs carriages and they have 20mm spacing while the anycubic effector has 43mm. I spent 2 days scratching my head over why i couldn't get good calibration even though everything seemed to be within good tolerance. Then I realized that i never measured the effector. Luckily i have a spare one that does have 40mm spacing and now i can use my V6 without any modifications...although i do lose 37mm in build height. Anyway, first calibration with new effector got me 0.031 deviation, and that's without a probe. Now, on to the minor things so i can get printing again.

Stick with it mindbender, you'll get yours running well too! -

-

@juice said in Beginner Needs Help - Anycubic Kossel Plus + Duet WiFi -- HOW?:

I've decided to stick with my original rods since before i undertook the upgrade, the machine was printing good, 20 mm calibration cubes printed within 0.1 mm deviation, so i guess the small difference in that one rod isn't enough to make a huge difference in print quality.

Deviation is part of the story. Here's another part:

Bottom is stock AKL rods. Top is Haydn magnetic. Otherwise identical. Even same G-Code file.

Middle is a different experiment, not relevant to this discussion.

-

@danal The parts that i printed before i started my upgrade weren't as good as your top print but were much better than your bottom print, even better than the middle one. That was with the old trigorilla board, i have yet to do any prints with the duet. That said, i am sure that having those sweet magnetic arms would be beneficial, its just that if i can get good quality prints with the arms i have, i'll hold off on the upgrade until i have some money burning a hole in my pocket.

Ok, made my first print with the duet upgraded anycubic kossel. Looks pretty good to me. X & Y dimensions need tweaking though.

-

So more weird results.

I've attached the DC42 IR Sensor to the hot-end (effector?) and connected the sensor to the Duet following the instructions. I've changed my M558 P-value to P1 and followed the first half of the instructions on David's webpage for the IR sensor (Link).

-

If I put an object right near the bottom of the sensor, the LED lights up solid. I take my hand away, the LED turns off. Nice.

-

On the Duet device webpage, the Z-Probe value remains at a value of 280 no matter what the Z-height is. It fluctuates between 279-280, and that's it.

-

With 12V power applied, I enter M558 P1 then I enter G31 P500 Z1.0 on the G-Console. After setting the Z-height manually with 2 sheets of paper, I raise the nozzle 5mm up as instructed, then G92 Z0 to set Z=0.

-

Following the instructions, I enter G30 S-1 and the nozzle buries itself into the bed again HARD. Here's a screenshot of the Console:

- If I press "Home All" the assembly raises itself up to the top but doesn't click the end-stops. I then get an error:

G28 Error: G0/G1: insufficient axes homed Error: Homing failedHere's the config files:

- config-override.g (I commented the weird values out again):

; This is a system-generated file - do not edit ; Delta parameters ;M665 L271.000 R152.869 H301.792 B85.0 X6.799 Y4.280 Z0.000 ;M666 X2.286 Y-0.607 Z-1.679 A0.00 B0.00 ; Heater model parameters M307 H0 A90.0 C700.0 D10.0 S1.00 V0.0 B1 M307 H1 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H2 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H3 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H4 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H5 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H6 A340.0 C140.0 D5.5 S1.00 V0.0 B0 M307 H7 A340.0 C140.0 D5.5 S1.00 V0.0 B0- config.g:

; Configuration file for Duet WiFi (firmware version 1.20 or newer) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P1 ; Set firmware compatibility to look like RepRapFirmare ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 R134 L270 B85 H285 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them ; Network M550 Pduettest M552 S1 ; Enable network M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Z-Probe M558 P1 X0 Y0 Z0 H5 F1000 T5000 ;I1 ; Set Z probe type to DC42 and the dive height + speeds G31 X0 Y0 Z1.0 P500 ; Set Z probe trigger value, offset and trigger height M557 R130 S20 ; Define mesh grid ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z80 E96 ; Set steps per mm M566 X1200 Y1200 Z1200 E1200 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E1200 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Set active high endstops ; Heaters M305 P0 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M143 H0 S120 ; Set temperature limit for heater 0 to 120C M305 P1 T100000 B4267 C0 R4700 ; Set thermistor + ADC parameters for heater 1 M143 H1 S275 ; Set temperature limit for heater 1 to 275C ; Fans M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Automatic saving after power loss is not enabled M501 ; Custom settings are not configuredhomedelta.g:

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool on Sun May 13 2018 19:16:40 G91 ; relative positioning G1 S1 X290 Y290 Z290 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 X-5 Y-5 Z-5 F1800 S2 ; go down a few mm G1 S1 X10 Y10 Z10 F360 ; move all towers up once more (second pass) G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning ;G1 X0 Y0 F6000 ; move X+Y to the centreEntering the command "G30 S-1" is hanging me up. I've tried to do an auto-calibration and the nozzle took a number of measurements in the air above the bed ranging from 3mm - 130mm.

Can anyone make sense of this? I have not resolved the bed angle issue yet, but this is something else entirely. Please help! Thanks!

-