@cj19944 Just used an external 5v power supply and all is working okay thanks again.

Best posts made by cj19944

-

RE: Hobby servo for probe shutting down duet.posted in Duet Hardware and wiring

-

RE: Hobby servo for probe shutting down duet.posted in Duet Hardware and wiring

@cj19944

All this did was just not shut the machine down. -

RE: Hobby servo for probe shutting down duet.posted in Duet Hardware and wiring

@dc42 i have taken it from the 5v .i05 rail should i use another pin.

Thanks

Latest posts made by cj19944

-

RE: Machine stallingposted in Duet Hardware and wiring

@cj19944 I turned arc welder of in cura and this resolved the issue thanks for your help.

-

RE: Machine stallingposted in Duet Hardware and wiring

@jay_s_uk Hi I just increased that to 120 and still no change. Could it be something to do with the g code? Thanks

-

RE: Machine stallingposted in Duet Hardware and wiring

@jay_s_uk ```

; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Fri May 06 2022 00:13:26 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"L3D" ; set printer name M302 S120 R110 ; Wait a moment for the CAN expansion boards to start G4 S2 ; Network M552 P192.168.1.210 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S0 ; physical drive 0.2 goes backwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M569 P122.0 S0 R0 T3:3:3:5 M584 X0.0 Y0.1 Z0.2 E0.3:122.0 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X320.00 Y320.00 Z320.00 E492.45:224.6 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X3000 Y3000 Z600.00 E1200.00:9000 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X2800 Y2800 Z2800 E1200:4100 I60 ; set motor currents (mA) and motor idle factor in per cent M84 S200 ; Set idle timeout ; Axis Limits M208 X-500 Y-500 Z0 S1 ; set axis minima M208 X535 Y500 Z1450 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io1.in M574 Y1 S1 P"io2.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io2.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io7.out" ; create servo pin 0 for BLTouch M558 P9 C"io4.in" H10 F240 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.785 ; set Z probe trigger value, offset and trigger height M557 X-450:450 Y-450:450 S100 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"pt1000" ; configure sensor 0 as PT1000 on pin temp0 M950 H0 C"out0" T0 ; create nozzle heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H0 S280 ; bed ; set temperature limit for heater 0 to 280C M308 S1 P"temp1" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out9" T1 ; create bed heater output on 1.out0 and map it to sensor 1 M307 H1 R0.332 K0.297:0.000 D3.05 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H1 ; map heated bed to heater 1 M143 H1 S150 ; set temperature limit for heater 1 to 150C ; dyze M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as PT100 on pin spi.cs2 M950 H2 C"out1" T2 ; create nozzle heater output on out1 and map it to sensor 2 M307 H2 R0.978 K0.093:0.000 D15.87 E1.35 S1.00 B0 V28.2 ; disable bang-bang mode for heater and set PWM limit M143 H2 S480 ; set temperature limit for heater 2 to 150C M308 S3 P"spi.cs1" Y"rtd-max31865" ; configure sensor 3 as PT100 on pin spi.cs1 M950 H3 C"out2" T3 ; create nozzle heater output on out2 and map it to sensor 3 M307 H3 R0.932 K0.093:0.000 D15.34 E1.35 S1.00 B0 V48.3 ; disable bang-bang mode for heater and set PWM limit M143 H3 S480 ; set temperature limit for heater 3 to 150C M308 S4 P"spi.cs0" Y"rtd-max31865" ; configure sensor 4 as PT100 on pin spi.cs0 M950 H4 C"out3" T4 ; create nozzle heater output on out3 and map it to sensor 4 M307 H4 R1.251 K0.124:0.000 D14.53 E1.35 S1.00 B0 V28.4 ; disable bang-bang mode for heater and set PWM limit M143 H4 S480 ; Fans M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 C"noctua" S1 H-1 ; set fan 1 name and value. Thermostatic control is turned off M950 F2 C"!out4" Q500 ; create fan 2 on pin !out4 and set its frequency M106 P2 C"pump" S1 H T25 ; set fan 2 name and value. Thermostatic control is turned on M950 F3 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P3 C"water fan1" S1 H-1 M950 F4 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P4 C"water fan2" S1 H-1 ; Tools M563 P0 S"slice head" D0 F0 T0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"dyze head" D1 H2:3:4 F0 T1 ; define tool 1 G10 P1 X-49 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; Custom settings are not defined thanks for the reply -

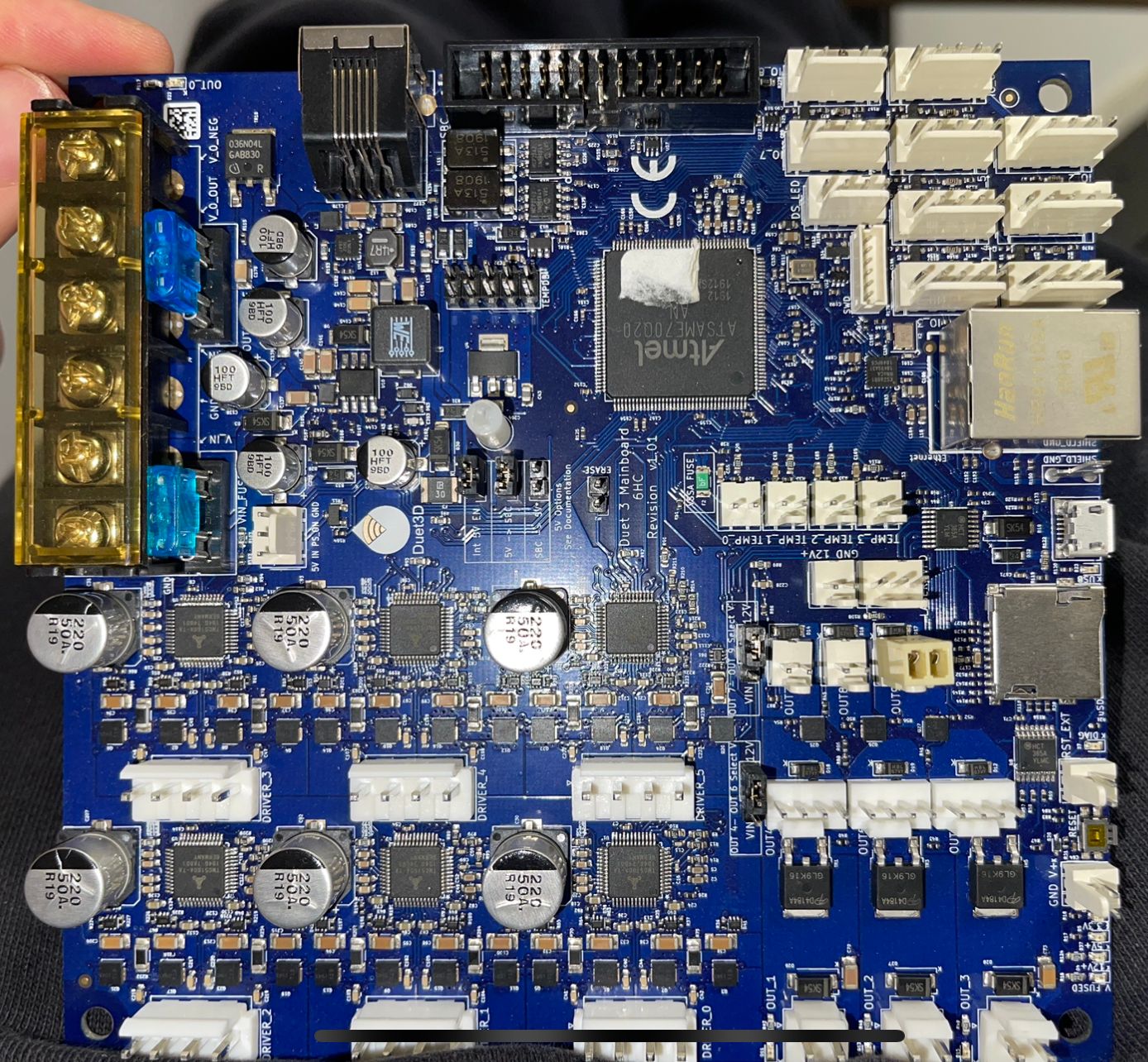

Machine stallingposted in Duet Hardware and wiring

Hi, I Have a medium 3d printer running on stepper motors and duet 3 6hc, which is stalling at certain areas in the print, I though it was due to 24v being to low so I upgrade to the new duet 3 and a 48 power supply 1000w, I think the steppers only need about 134 watts and there is 5 in total. It is definitely a lot better since I upgrade to 48v, I will add a video to show the stalling. If anyone has some recommendations it would be much appreciated .

-

RE: I need a chamber heater, any recommendations?posted in Duet Hardware and wiring

@TRATOON i have used these finned strip heaters, in a heated chamber build before got up to 90 degrees c https://www.ebay.co.uk/itm/291050095804

I first got some out of and old stratus printer but i did not know the name of them at the time. -

RE: Fried Duet 3 ioposted in Duet Hardware and wiring

@Phaedrux i dont see any chips that are broken but i have replaced the duet now maybe ill get another use out of it , i also had to replace the bl touch as that got fried anyway thanks for your help.