@littlehobbyshop said in Duet Web Control 2.0 released:

This is very nice, I like the modern layout with the burger menu and collapsible categories.

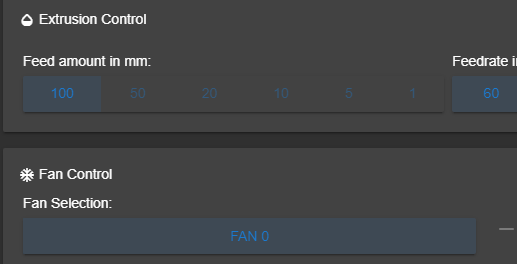

Quick access to the height map is good too.The dark mode is great but personally I think the blue text could do with being a little brighter:

Maybe it's just me.

A bold white font would be ideal, imo. Is there any way to change the color/size?