I've spent another whole day on this and nearly a whole roll of filament... changed nozzle diameter, cleaned/disassembled/reassembled the extruder 3x, changed extrusion multiplier, z height calibration, advanced settings, changed to more powerful heatsink fan, etc.

I suspect it has to do with my Triangle Lab chinese clone all metal heat break. Going to throw in the towel on this and just placed my order for genuine E3D V6 (Volcano) hot end, titanium heat break, copper heat block, hardened steel nozzle, E3D Nema 17 pan cake motor. Lesson learned on trying to save $ on critical parts!

In my research, it seems others are having issue with the chinese all metal heat breaks as well (particularly the Volcano all-metal version), although Trianglelab is supposed to be fine.

My goal of making my Ender Pro print as good as my Prusa mk3s is proving to be much more costly, challenging, and time consuming than just hitting print on the Prusa Mk3s...

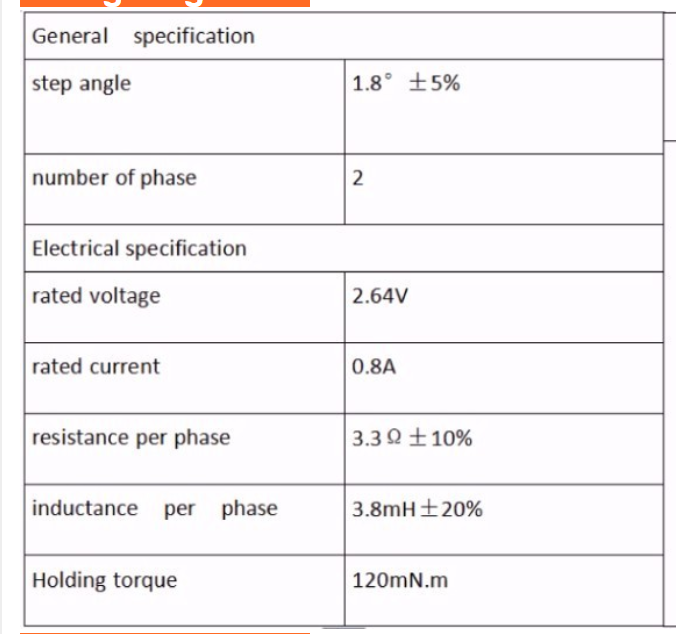

The new extruder motor is 0.9 degrees whereas my old one is 1.8 degrees. Besides of course recalibrating its esteps, do i need to configure or set it up any differently when I install the new 0.9 degree motor?