Yes, it is a kinematic mount with ball screws. According to my logic, I wanted to use the "B" position too. Many thanks for your help

Best posts made by bernie-mix

-

RE: Set up three Z-axis location - M671posted in Duet Hardware and wiring

-

RE: motor phase A may be disconnected reported by driver(s) 5posted in General Discussion

Okay, I found out for myself why: In the M584, I incorrectly addressed the extruder stepper!

Wrong line:

M584 X0.3 Y0.4 Z0.0:0.1:0.2 E0.5correct line:

M584 X0.3 Y0.4 Z0.0:0.1:0.2 E20.0WOOHOOO - it works

-

RE: Set up three Z-axis location - M671posted in Duet Hardware and wiring

At the rear is a magnetic spherical recess, front right is magnetic v-groves (45° to X and Y axis) and front left a a plane round magnet

Latest posts made by bernie-mix

-

RE: Set up three Z-axis location - M671posted in Duet Hardware and wiring

@fcwilt

In my opinion, this is the only way the bed can expand in all directions without rotating around the spherical recess -

RE: Set up three Z-axis location - M671posted in Duet Hardware and wiring

At the rear is a magnetic spherical recess, front right is magnetic v-groves (45° to X and Y axis) and front left a a plane round magnet

-

RE: Set up three Z-axis location - M671posted in Duet Hardware and wiring

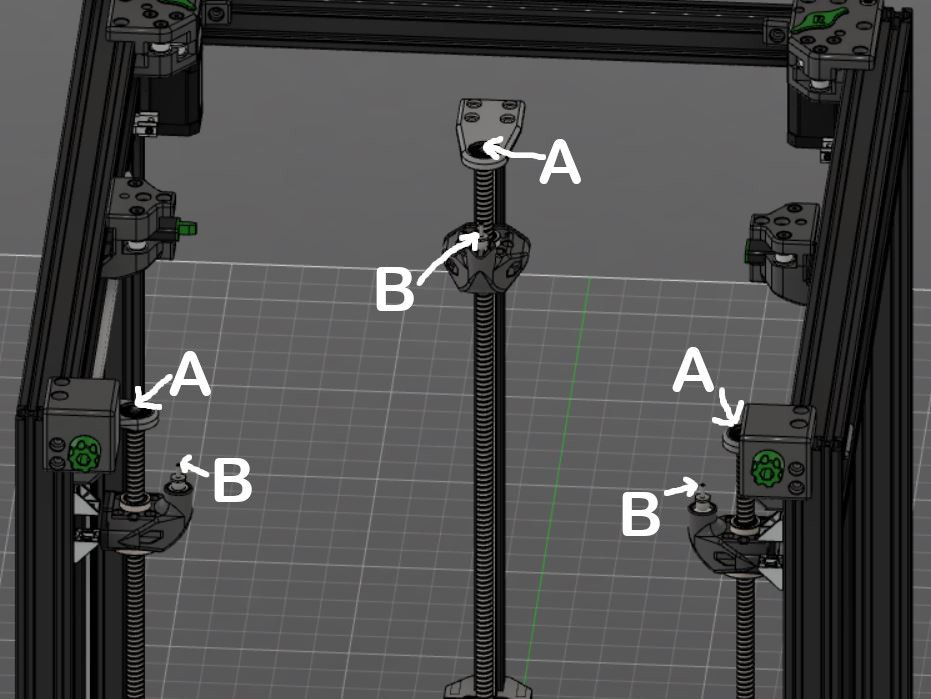

Yes, it is a kinematic mount with ball screws. According to my logic, I wanted to use the "B" position too. Many thanks for your help

-

Set up three Z-axis location - M671posted in Duet Hardware and wiring

Hey guys,

Set up three Z-axis location - M671- in RRF3 on Duet 3 MB6HC:

Which coordinates should I enter? The real ones of the leadscrews (A) or the ones where the bed actually rests (B)?

-

RE: Tool board remote heater auto tune not implementedposted in Tuning and tweaking

Will that be built in at some point?

-

RE: motor phase A may be disconnected reported by driver(s) 5posted in General Discussion

Okay, I found out for myself why: In the M584, I incorrectly addressed the extruder stepper!

Wrong line:

M584 X0.3 Y0.4 Z0.0:0.1:0.2 E0.5correct line:

M584 X0.3 Y0.4 Z0.0:0.1:0.2 E20.0WOOHOOO - it works

-

motor phase A may be disconnected reported by driver(s) 5posted in General Discussion

Hello Friends,

I exchanged my Duet 2 Wifi for a brand new Duet 3 + Toolboard1LC. Now I'm configuring and most of it already works (homing x / y / z, heat up hotend - Bed heater is not connected so far)

But when I wanted to adjust my extruder, the error message comes up:Warning: motor phase A may be disconnected reported by driver(s) 5

Warning: motor phase B may be disconnected reported by driver(s) 5The Stepper Motor on driver 5 (Toolboard) is a Nema17. I can measure the motor coils with a multimeter directly on the toolboard, so the motor has no cable break.

M122 says

=== Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v0.6 or 1.0 (standalone mode) Board ID: 08DJM-956L2-G43S4-6JTD6-3SS6K-KA7AH Used output buffers: 2 of 40 (12 max) === RTOS === Static ram: 154604 Dynamic ram: 162504 of which 148 recycled Exception stack ram used: 320 Never used ram: 75640 Tasks: NETWORK(ready,292) ETHERNET(blocked,444) HEAT(blocked,1256) CanReceiv(suspended,3424) CanSender(suspended,1488) CanClock(blocked,1436) TMC(blocked,192) MAIN(running,4528) IDLE(ready,76) Owned mutexes: === Platform === Last reset 00:10:24 ago, cause: power up Last software reset at 2020-06-21 18:37, reason: User, spinning module GCodes, available RAM 75584 bytes (slot 0) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x04435000 BFAR 0x00000000 SP 0xffffffff Task MAIN Error status: 0 MCU temperature: min 18.2, current 35.7, max 35.7 Supply voltage: min 24.0, current 24.1, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.3, under voltage events: 0 Driver 0: standstill, reads 37392, writes 15 timeouts 0, SG min/max 0/0 Driver 1: standstill, reads 37393, writes 15 timeouts 0, SG min/max 0/0 Driver 2: standstill, reads 37393, writes 15 timeouts 0, SG min/max 0/0 Driver 3: standstill, reads 37394, writes 15 timeouts 0, SG min/max 0/0 Driver 4: standstill, reads 37394, writes 15 timeouts 0, SG min/max 0/0 Driver 5: standstill, reads 37396, writes 14 timeouts 0, SG min/max 0/0 Date/time: 2020-06-21 19:27:40 Slowest loop: 3.52ms; fastest: 0.22ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 1.3ms, write time 0.0ms, max retries 0 === Move === Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 0ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 7.45ms; fastest: 0.03ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 1 of 8 - Ethernet - State: active Error counts: 0 0 0 0 0 Socket states: 5 2 2 2 2 0 0 0 === CAN === Messages sent 2500, longest wait 3ms for type 6012 === Linux interface === State: 0, failed transfers: 0 Last transfer: 624274ms ago RX/TX seq numbers: 0/1 SPI underruns 0, overruns 0 Number of disconnects: 0 Buffer RX/TX: 0/0-0and config.g is

; General preferences M80 ; turn on ATX Power supply G4 P2000 ; stay tuned G90 ; send absolute coordinates... M83 ; ...but relative extruder moves G21 ; Set units to Millimeters M550 P"BLVmgnCube" ; set printer name M584 X0.3 Y0.4 Z0.0:0.1:0.2 E0.5 ; set drive mapping to each axis M669 K1 ; Select CoreXY mode - New format ; Network M552 S1 ; enable network M552 P192.168.178.13 ; Static IP Address M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0 goes forwards - Z Axis Left (1) M569 P0.1 S1 ; physical drive 1 goes forwards- Z Axis Back 2) M569 P0.2 S1 ; physical drive 2 goes forwards- Z Axis Right (3) M569 P0.3 S0 D3 ; physical drive 3 goes forwards- X Axis, activate Stealthchop M569 P0.4 S0 D3 ; physical drive 2 goes backwards- Y Axis, activate Stealthchop M569 P20.0 S0 D3 ; physical drive 5 goes forwards - Extruder 1 ; Set up three Z-axis location M671 X-35.0:180.0:394.0 Y55.0:355.0:55.0 S8 ; leadscrews at 1 - left, 2 - back and 3 - right M92 X159.96 Y159.96 Z800 E400 ; set steps per mm M350 X16 Y16 Z16 E16 I1 ; configure micro-stepping with interpolation M566 X800.00 Y800.00 Z200.00 E240.00 ; set maximum instantaneous speed changes (mm/min) M203 X20000.00 Y20000.00 Z1000.00 E1200.00 ; set maximum speeds (mm/min) M201 X3000.00 Y3000.00 Z800.00 E800.00 ; set accelerations (mm/s^2) M906 X1400 Y1400 Z1400 E600 I30 ; set motor currents (mA) and motor idle factor in percent*100 M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X317 Y290 Z350 S0 ; set axis maxima ; Endstops M574 X1 S1 P"20.io1.in" ; X min active high endstop switch M574 Y2 S1 P"0.io3.in" ; Y max active high endstop switch ; Z-Probe - BLTouch - *CURRENT* M574 Z1 S2 ; set endstops controlled by probe M558 P9 C"^20.io0.in" H5 F2000 T6000 ; set Z probe type to bltouch and the dive height + speeds (bltouch NEEDS pullup) G31 P100 X0 Y27.24 Z0 ; set Z probe trigger value, offset and trigger height ;G30 ; Probe Z ; Configure Heaters and Sensors M308 S0 P"0.temp0" Y"thermistor" T100000 B3950 ; Configure bed temperature sensor M950 H0 C"0.out0" T0 ; Define heater 0 (bed heater) - bed_heat pin and Temp Sensor 0 M143 H0 S110 A2 ; set temperature limit for heater 0 to 110c M140 H0 ; Map heated bed to heater 0 M308 S1 P"20.temp0" Y"thermistor" T100000 B3950 ; Configure extruder 1 temperature sensor M950 H1 C"20.out0" T1 ; Define heater 1 (hot-end E0) to use the "20.out0" pin and Temp Sensor 1 M143 H1 S265 A2 ; set temperature limit for heater 1 to 265C ;M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor ;M308 S3 P"temp3" Y"thermistor" T10000 B3988 A"Coolant" ; Configure coolant sensor ; Configure Fans M950 F0 C"20.out2" Q100 ; Define Fan_0 for use - Parts Cooler on Printhead - 4010 fan M950 F3 C"0.out9" Q100 ; Define Fan_3 for use - X/Y Stepper cooling fan M950 S0 C"20.io0.out" ; Define GPIO port 0 on IO4, servo mode - BLTouch Z-Probe M950 J0 C"^!0.io1.in" ; Input 0 uses 0.io1.in pin, pullup enabled ; Fans M106 P0 S0 ; set fan 0. Parts Cooler on Printhead ;Set PID values M307 H0 A161.7 C312.8 D1.0 V23.3 B0 ; disable bang-bang mode for the bed heater and set PWM limit M307 H1 A561.8 C236.5 D5.8 V23.3 B0 ; disable bang-bang mode for the extruder heater and set PWM limit ; Tools M563 P0 S"Extruder 1" D0 H1 F0 ; define tool 0. Fan 0 operates with an active hot-end G10 P0 X0 Y0 Z0 R0 S0 ; set tool 0 axis offsets active and standby temperatures to 0C ;Display M575 P1 S1 B57600 ; setup for PanelDue ; Emergency Stop ;M574 S1 P"^!0.io1.in" ; Define Emergency endstop - emergency stop switch condition ;M581 P0 S1 T0 ; Define action to be taken with activation of emergency stop switch ; Miscellaneous T0 ; select first toolI took the config.g from a template for my printer and only adjusted the in/outputs.

Please tell me that I only have a bug in config.g and not that the toolboard is broken.

Thanks for your help -

RE: Attempting to extrude with no tool selected - During Printposted in Tuning and tweaking

@dc42

I have grounded my printer frame with the ground of 220V power outlet. Should I disconnect this grounding and instead connect the frame to the negative of the power supply output? Or must this connection persist and additionally the negative output connect to the frame?