Latest posts made by ScaraMan

-

PT100 DAUGHTER BOARD, Reading 2000 c for Heat Bedposted in Duet Hardware and wiring

Hi

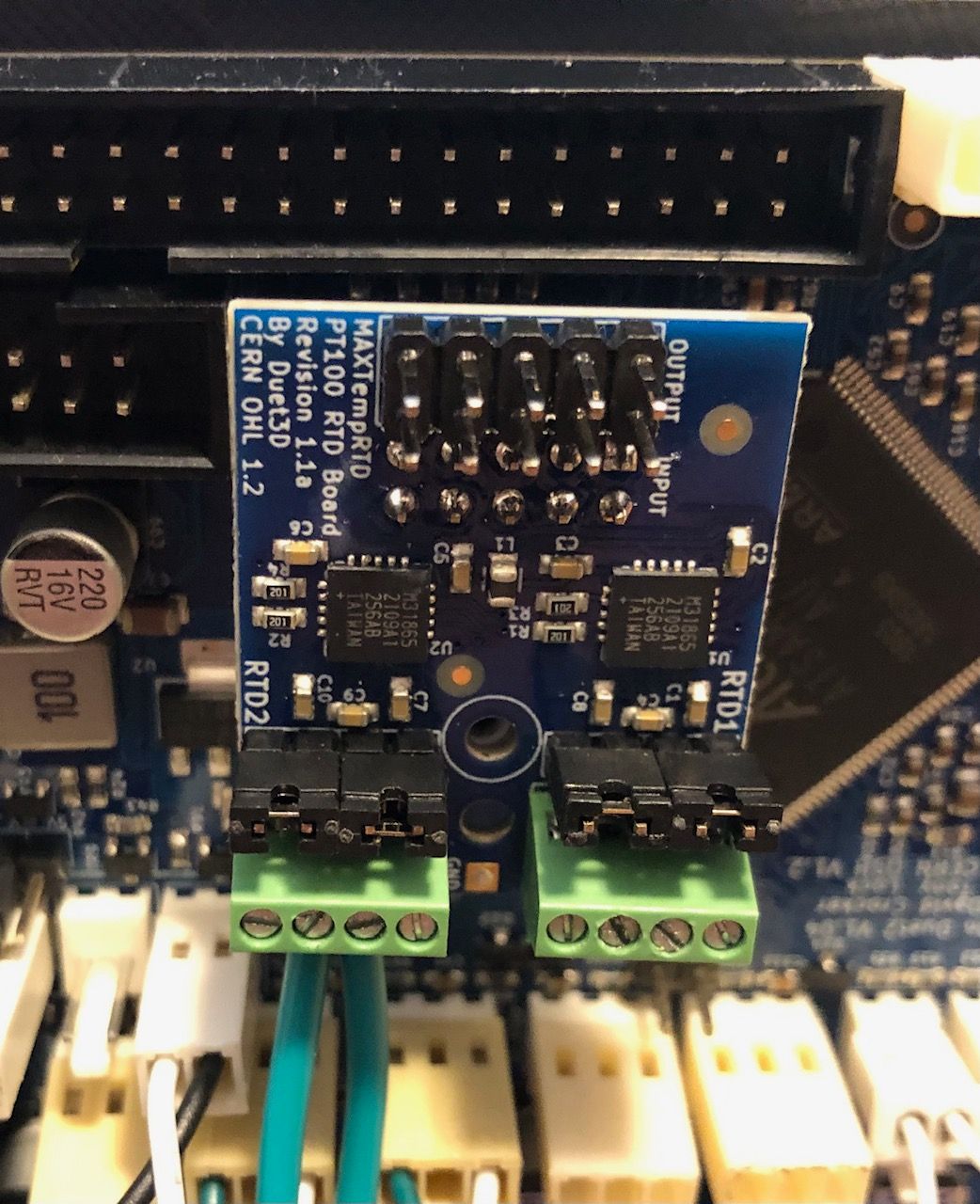

I recently purchased the PT100 Daughterboard latest version with jumpers.

I have some issues.

The reason why I bought this board, was to connect the Ultimaker 2 heatbed to the Duet wifi.

That’s all, but when I connect it reads 2000 C for the Bed, I am using rep rap firmware2.x

I followed the instructions on the web on how to configure firmware.

The 2 wires for power go to heatbed connector on Duet wifi , and the other 2 wires I have connected to PT 100 motherboard (2 and 3 on the first connector )

The jumpers are there on both connectors.

I am only using 1 connector for the heatbed only, not for my hotend ( since that is a e3d v6 no pt100 sensor )Can you please tell me how to fix this issue ??

How to properly configure ??Currently under the Heater section in config file I have this

M305 P0 X200 ; set thermistor + ADC parameters for heater 0

M143 H0 S65 ; set temperature limit for heater 0 to 80C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S260 ; set temperature limit for heater 1 to 260C -

RE: Need help to connect Herkulex smart servos to the Duet wifiposted in Duet Hardware and wiring

hi

Yes, I have all those documents already, and have used the servos connected with Arduino uno and Arduino due.

I just want to know how can I use them with the Duet wifi ???

a sketch would be appreciated for the connections,

or since I know how to connect them to the Arduino board, is it possible to use the Arduino with the duet wifi ?? if so how ?? -

RE: Need help to connect Herkulex smart servos to the Duet wifiposted in Duet Hardware and wiring

here are the electrical specifications

Working Voltage: 7~12VDC(Optimized 7.4V)

Rated Current: 450mA @ 7.4V : 1.7kgf.cm

Communication Link: Full Duplex Asynchronous Serial(TTL Level), Binary Packet, Multi Drop

Multi control through Servo ID: 0 ~ 253, 254(Broadcast only)

Maximum Baud Rate: 0.67Mbps

Feedback: Position, Speed, Temperature, Load, Voltage etc.

Various Control Algorithm: PID, Feedforward, Trapezoidal Velocity Profile, Velocity Override, Torque Saturator & Offset, Overload Protection, Neutral Calibration, Dead Zone -

Need help to connect Herkulex smart servos to the Duet wifiposted in Duet Hardware and wiring

Hi Guys,

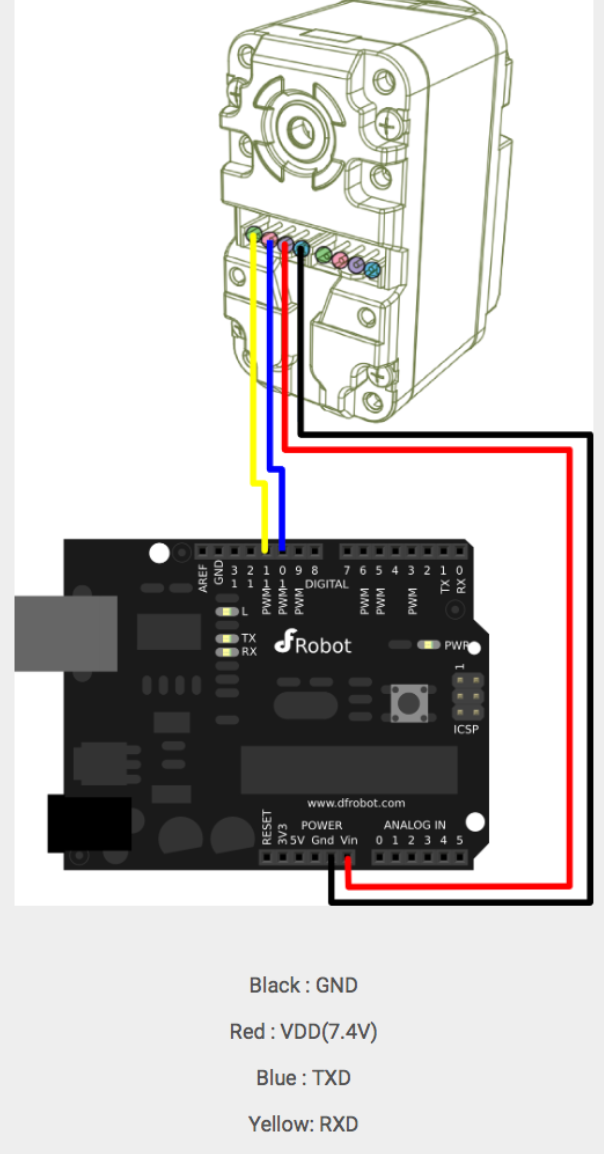

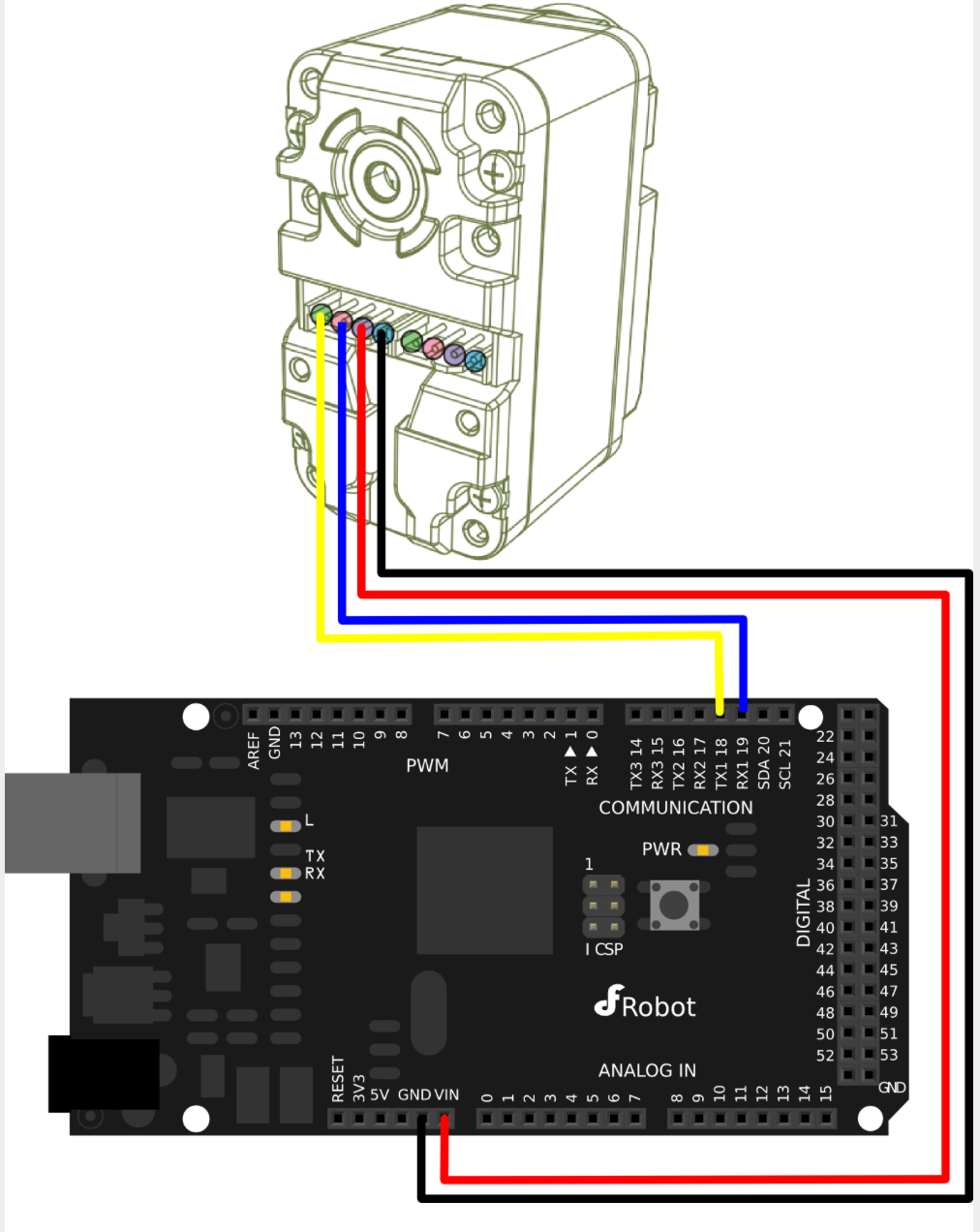

I have attached an image showing how the Herkulex smart servo is connected with an Arduino uno board ( RX is pin 11, and TX is pin 10 ), how can I connect the servo to the Duet wifi ??

-

RE: How to connect Smart Servo to the Duet Wifiposted in General Discussion

Hi

I appreciate your help, thanks.

In order for the servos run, they require 7.4 VDC

I will have to use a drop down converter from 24V TO 7.4

If you have an example of the wiring or a simple sketch , that would be very

Much appreciated -

How to connect Smart Servo to the Duet Wifiposted in General Discussion

Hi

I am currently building a Scara Robot and planning to use the Duet Wifi

as my hardware controller for the stepper motors X,Y and Z.

I am planning to use 2 smart servos Herkulex DRS -101 for my Robot Gripper since I already have them, and was wandering how can I implement these to work with the Duet Wifi board ???

The servos can be daisy chained

-

RE: Using a 4th (Rotary) Axisposted in CNC

@dc42 Hi David, I am trying to get in contact with you concerning SCARA.

I have posted a link on the forum , can you please have a look at it, I need your opinion.

Thank youhere is the link

https://forum.duet3d.com/topic/14114/scara-robot-want-to-know-if-duet-wifi-is-the-right-choice?_=1580465871679 -

SCARA Robot - want to know if DUET WIFI is the right choiceposted in General Discussion

Hello all ,

I have built a Scara robot similar to JJRobots , with improved design modifications- for testing only. Once I have a board that can

Make it work , I will port it to a more high end build SCARA.

I have tried using marlin firmware to control it, but I never succeed

I am using an Ultimaker 2 controller board to run the motors and end stops only .For now. It can home the arms when I use pronterface but after that it goes

Crazy , I have tried several times, changing home offsets, scara offsets, but never work according to my setup. I give up. !

I want to know if I should get the Duet wifi for my SCARA .

I am already using the DUET wifi for my printer and I am very pleased.

I came across the Scarlett SCARA , and I noticed he’s using the DUET and works fine. I have attached a TOP VIEW with some dimensions of the SCARA and a picture, any help would be much appreciated. Thanks !

-

Have to run G code file twice to begin print at correct heightposted in General Discussion

Hi guys

I have this issue where I send the g code file to the duet wifi, and all is well until it starts to print. The nozzle tip is quite a few mm above the heatbed, I cancel, start another, then its perfect. Any clue why this is ?

I have posted below, config, home all, home z, and a snippet from the beginning of the code file

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.3 on Wed Nov 27 2019 02:27:21 GMT-0500 (EST); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"ALPHA 300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1600.00 E311.00 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E4200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X1050 Y1050 Z1250 E1050 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y300 Z190.19 S0 ; set axis maxima; Endstops

M574 X1 Y1 Z2 S0 ; set active low end endstops; Z-Probe

;M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

;M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S80 ; set temperature limit for heater 0 to 80C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S260 ; set temperature limit for heater 1 to 260C; Fans

M106 P0 S1 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned OFF

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned ON

M106 P2 S1 I0 F500 H-1 ; set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned OFF; Tools

M563 P0 S"NOZZLE " D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

————————————————————————————————————————

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2.1.3 on Wed Nov 27 2019 02:27:21 GMT-0500 (EST)

G91 ; relative positioning

G1 H2 Z5 F300 ; lift Z relative to current position

G1 H1 X-305 Y-305 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 H2 X5 Y5 F6000 ; go back a few mm

G1 H1 X-305 Y-305 F360 ; move slowly to X and Y axis endstops once more (second pass)

G1 H1 Z195.19 F300 ; move Z up stopping at the endstop

G90 ; absolute positioning

G92 Z190.19 ; set Z to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 S2 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning————————————————————————————————————————

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v2.1.3 on Wed Nov 27 2019 02:27:21 GMT-0500 (EST)

G91 ; relative positioning

G1 H2 Z5 F300 ; lift Z relative to current position

G1 H1 Z195.19 F300 ; move Z up until the endstop is triggered

G90 ; absolute positioning. added extra line could remove for testing

G92 Z190.19 ; set Z position to axis minimum (you may want to adjust this); Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 H2 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning————————————————————————————————————————

;FLAVOR:RepRap

;TIME:44156

;Filament used: 9.62041m

;Layer height: 0.2

;Generated with Cura_SteamEngine 3.6.0

T0

M190 S60

M104 S210

M109 S210

M82 ;absolute extrusion mode

G90 ; Absolute Position

G28 ; Home ALL axis

G1 X30 Y30 Z170

G92 E0 ; Reset extruder

G1 X30 Y30 F4000 ;move X/Y to front of printer

G1 Z15.0 F9000 ;move the platform to 15mm

G4 5000

G92 E0 ;zero the extruded length

G1 F200 E50 ;extrude 10 mm of feed stock

G4 10000

G92 E0 ;zero the extruded length again

G4 1000

M83 ;relative extrusion mode

G1 F1500 E-6.5

;LAYER_COUNT:401

;LAYER:0

M107

G0 F7500 X165.65 Y76.023 Z0.16

;TYPE:SKIRT

G1 F1500 E6.5

G1 F900 X165.918 Y75.542 E0.00552

G1 X166.252 Y75.104 E0.00553

G1 X166.647 Y74.72 E0.00553

G1 X167.093 Y74.396 E0.00553

G1 X167.581 Y74.141 E0.00552