Problem solved! This has taken months. I checked grub screws, belt teeth…. I had noticed that now and then the hot end juddered when moving to position, but not all the time. The person I bought the machine from had cable tied the hot end cable harness to 1 of the Z motor arms. It was hanging loose and tidied up the harness, as it does tend to flop about on my other machine.

When close to the bed (within 10mm) and only in specific positions it held the arm causing the belt to slip! Also G29 failed most of the time as the probe was not triggered due to the arm being held back. The judder now solved, G29 completes and bed leveling showing a decent graph.

Thanks for your help. (I have learned lots of G code and Duet wiring though)

Gary

Best posts made by Gary

-

RE: G29 on delta below bedposted in My Duet controlled machine

-

RE: Delta z height AC Predatorposted in Duet Hardware and wiring

Hi, Sorted at some point the X belt had twisted with the non-toothed side running on the stepper. I didn’t even notice when checking the stepper grub screws. I couldn’t see the belt twist as it’s slightly recessed on the machine, but I noticed when looking closely at the carriage and tabs. Really noticeable when you manually move the carriage up and down. It makes sense now as when I did a HomeDelta quite often, but not all the time, the interface would report not all axis homed and they weren’t. I just thought it was an annoying “feature” that would sometimes happen and I would have to click Home again. The board was turning the stepper the 490mm distance I have in my HomeDelta and not triggering the end stop giving the error. Also when doing probing from high up the results were inconsistent – belt slippage. Down low with slow probes it was okay. After a Home the X and Y values were not zero on the interface and when touching bed the hot end was not centred on the bed. Now to change the belts and somehow fix the bed which got smashed at the edge when the Perspex lid hit it!

M665 L440.000:440.000:440.000 R226.630 H455.788 B185.0 X0.093 Y0.750 Z0.000

M666 X-0.012 Y-0.045 Z0.057 A0.00 B0.00

Latest posts made by Gary

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

@dc42 Thanks for the info about the polarity. That now makes sense! I bought some PMV20XNER MOSFETs, but the size of them is way beyond my capability.

I tried to PM you, but I get then message "This user has restricted their chat messages. They must follow you before you can chat with them"

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

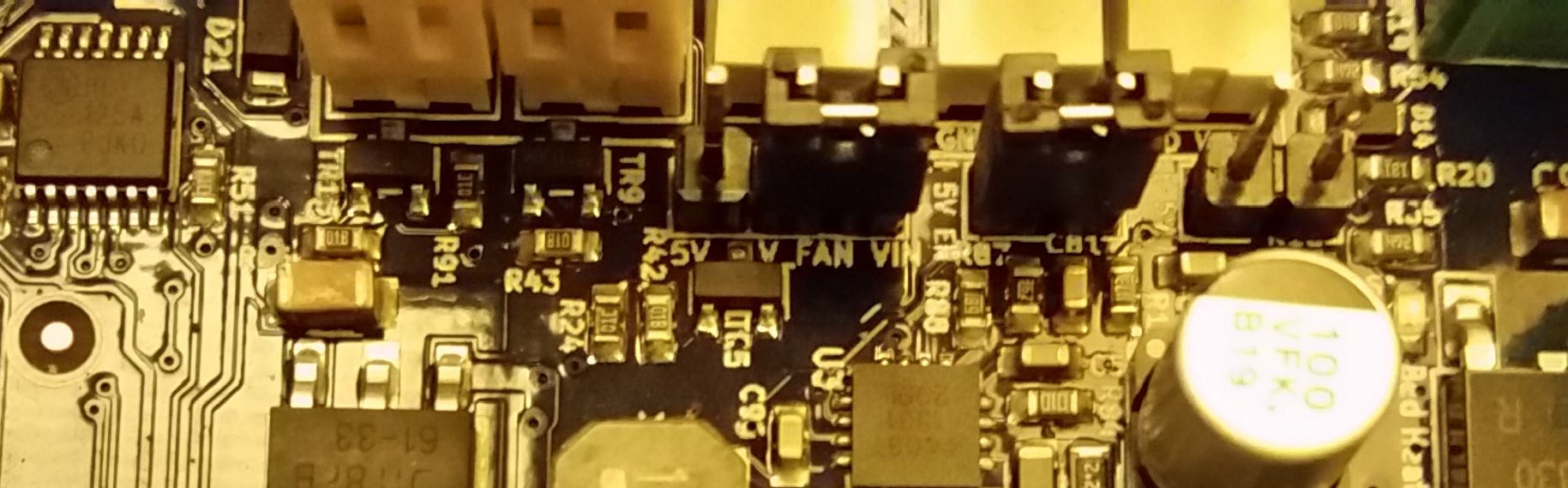

@bearer Thanks I will check as I have now visually blown P3. Also P1 stopped working. So all 3 now not working! Is there anywhere in the UK that I can send the board to get it fixed?

(I bought pre-wired connectors, but I didn't see that although the connectors were compatible at the hot end the polarity was reversed to the fan. I wouldn't have thought that switching the fan polarity would have blown anything - the fans would just spin the wrong way).

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

@Phaedrux Hope it's clear enough.

Getting:

ErrorInput file contains unsupported image format

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

@Phaedrux Yeah. Nothing physically obvious. What also confused me was the 2 Fans on the WebGUI. I didn't notice that one was Tool Fan and the other Fan 0, which are the same. I thought one was the heatsink fan, which thinking about it now wouldn't make sense as it's not speed controllable. Thanks for your help.

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

@Phaedrux Tried the following:

fan0 Molex into fan2 header

config.g changes

;Fans

; M106 P0 S0 I0 F500 H-1 ; Disable FAN0: Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S0 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off;Tools for p0

; M563 P0 D0 H1 F0

M563 P0 D0 H1 F2It seems to work!

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

@Phaedrux I've taken molex off fan header connections and attached direct to 24v. All fans/wiring okay. My mistake about speed - it's just a quiet - ish fan.

That's maybe something if m106 and the sliders have no effect?

send M106 P1 H-1 and heatsink fan comes on. No change to WebGUI controls

M106 P1 S0 fan stops (WebGUI speed sliders - no effect)

M106 P1 S1 fan on (WebGUI speed sliders - no effect)

M106 P0 S1 no change to part cooling fan - still off -

RE: Fan Problem - Blown Board?posted in Duet Web Control

@Phaedrux MOSFETs look okay. Do you know if the WebGUI fan speed slider issues the M106 command?

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

@Phaedrux M563 P0 D0 H1 Same as my other machine which works and dozuki says you can omit for tool0. Added F0 and rebooted - no change. M106 P0 S1 does not turn the fan on. Vin jumper selected as in working machine. I cannot figure it out. Thanks for trying to help. Strange that heatsink fan starts when over 45C, but WebGUI hs no effect on it either below or above 45C.

-

RE: Fan Problem - Blown Board?posted in Duet Web Control

I'm still commissioning the machine, so most of the config is from my other machine. Main problem is that the WebGUI fan speed sliders have no effect (also M106 no effect). Hotend fan kicks in at 45C. Fan seems slow, but it's hard to tell. (firmware 2.05.1)

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Tue Feb 26 2019 21:31:01 GMT+0000 (Greenwich Mean Time)

;made by Gary 22/07/2020; General preferences

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M552 S1 ; connect to WiFi; Delta Settings

M665 L440.49 R227 H456.747 B185.0 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 A0.00 B0.00 ; Put your endstop adjustments here, or let auto calibration find them; Network

M550 P"P1" ; Set machine name

M551 P""

M552 P192.168.0.16 ; Set password

;M552 P0.0.0.0 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards (BMG extruder clone - MT-1703HSM168RE 0.9deg step 180917 1.68A)

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation (20teeth pulley) "E3D MT-1704HSM168RE 0.9deg step 190102, 400 steps/rev 1.68A"

M92 X160.00 Y160.00 Z160.00 E837 ; Set steps per mm

M566 X1000 Y1000 Z1000 E1000 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z12000.00 E10000 ; Set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z3000.00 E3000.00 ; Set accelerations (mm/s^2)

M906 X1000.00 Y1000.00 Z1000.00 E1100.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

;M906 X1344.00 Y1344.00 Z1344.00 E1344.00 I30 ; Set motor currents (mA) and motor idle factor in per cent (reduced to 80% of max Amps)

;M84 S30 ; Set idle timeout

M84 S600; Retraction

M207 S4.0 F5000 R-0.025 T2500 Z0.5 ; Firmware retraction; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe (standard AC Predator microswitch probe, clips just under nozzle)

M558 P4 H25 F120 T6000 ; Set Z probe type to switch(P4) and the dive height + speeds

G31 P500 X0 Y0 z17.225 ;Z22.446 ;17.249 ;.656 ; Set Z probe trigger value, offset and trigger height

M557 R115 S20

;G29 S1 ; Load the heightmap; Heaters

M307 H0 A137.8 C533.3 D1.5 V24.3 B0 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S240 ; Set temperature limit for heater 1 to 240C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools for p0

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

M572 D0 S0.1 ; Pressure Advance

;M591 D0 P2 C4 S1 ; Activate filament sensor

M404 N1.75 ; Set for print monitor

M592 D0 A0.07772 B-0.00029 ; Nonlinear extrusion. Set parameters for extruder drive 0; Miscellaneous

T0 ;select tool 0 gary added

M501 ; Load saved parameters from non-volatile memory