I've created a conditional G-code macro that prints a model to help tune pressure advance. It's based on the model used in this post, which I happen to like very much. It's a fast and native solution, starts from your printer directly and requires no slicer or other software.

The macro is a work-in-progress, but offers a lot of configurability already. I will probably make a number of improvements as I use it myself, but I wanted to share this with you at this stage for feedback and educational purposes (i.e. my education).

I can't guarantee that this code will work properly on your machine. I have a simple cartesian model with XYZE axes. Also, I've tested this on my printer with a self-compiled post-beta 5 firmware 3.4.0, since I ran into some rounding issues in the output of earlier RRF firmwares, though this has been fixed by @dc42 and I've seen mentioned that this fix is part of the beta 6 release.

I've kept the variable names as descriptive as possible. However, let me know if you need explanation on how to use this:

; This macro generates a test print to determine the best pressure advance factor (M572 S-parameter)

; It uses the test print described in this forum post:

; https://forum.duet3d.com/topic/6698/pressure-advance-calibration

; Author: Schmart

; WARNING: all dimensions, size units and speeds are in mm and mm/s

; Reference for conditional G-code:

; - https://duet3d.dozuki.com/Wiki/GCode_Meta_Commands

; Wishes for conditional G-code:

; - Canceling or stopping running conditional G-code

; - Simulation; logging what commands would be executed/generated without actually executing them

; - Dumping the variables (names and values) in a macro, perhaps also treating variable in a meta-way, e.g. {#var} for count, {var[0].name} and {var['layer_height'].value}

; - Assigning an object or array to a variable. E.g. var axis = move.axes[0]; echo {var.axis.letter}

; - Custom subroutine/function definition, e.g. def print_line(var a, var b)

; - ceiling(), pow() and sq() functions

; TODO:

; - Many optimizations still remaining

; - Perhaps the most important variables (bed and print temperature, filament diameter, extrusion multiplier, PA stepping)

; can be made into macro parameters, e.g. M98 P"0:/macros/4 - Print Tuning/Pressure Advance" B40 P204 D1.75 X0.95 S0.02 P0.002

; Starting value for pressure advance

var pa_start = 0.0

; Pressure advance increment for each (whole) millimeter print height

; e.g. if var.height = 20, var.pa_start = 0.1 and var.pa_stepping = 0.004, then

; the PA test range is from 0.1 to (0.1 + 20 * 0.004) => 0.1 to 0.18.

var pa_stepping = 0.01

; The extruder to apply the pressure advance factor to

var pa_extruder = 0

; These values specify the center of the print bed

; The default bed center is at (0,0)

var x_center = 0

var y_center = 0

; Print temperatures

var print_temperature = 205

var standby_temperature = 120

var bed_temperature = 40

; Height of the test print

var height = 20

var layer_height = 0.20

; Number of fast segments

var fast_segments = 3

; Slow segments are at the beginning and the end, and in between fast segments, e.g. SLOW FAST SLOW FAST SLOW

var slow_segment_length = 10

var fast_segment_length = 20

; Definition of speeds

var first_layer_speed = 20

var travel_speed = 80

var fast_segment_speed = 60

var slow_segment_speed = 10

; Number of perimeters around the object as a stable base

var skirt_loops = 6

; Height of the skirt in layers

var skirt_layers = 2

; The tool number to print with

var tool_number = 0

; Extrusion width is calculated here, but can also be set with a literal value

; Note that 1.05 and 1.125 are common factors that result in 0.42mm or 0.45mm width respectively

var nozzle_bore_diameter = 0.40

var extrusion_width = {var.nozzle_bore_diameter * 1.125}

var filament_diameter = 1.78

var extrusion_multiplier = 0.93

; Firmware retraction settings

var retract_length = 0.5

var retract_restart_length = 0

var retract_speed = 40

var deretract_speed = 40

var retract_z_lift = 0

; Flow math

var filament_flow = {pi * var.filament_diameter * var.filament_diameter / 4}

var regular_flow = {(var.extrusion_width - var.layer_height) * var.layer_height + pi * var.layer_height * var.layer_height / 4}

var bridge_flow = {pi * var.nozzle_bore_diameter * var.nozzle_bore_diameter / 4}

var line_spacing = {var.extrusion_width - var.layer_height * (1 - pi / 4)}

var regular_flow_ratio = { var.extrusion_multiplier * var.regular_flow / var.filament_flow}

var purge_line_flow_ratio = { 2.0 * var.regular_flow_ratio }

echo "extrusion_width: " ^ var.extrusion_width

echo "layer_height: " ^ var.layer_height

echo "filament_flow: " ^ var.filament_flow

echo "bridge_flow: " ^ var.bridge_flow

echo "regular_flow: " ^ var.regular_flow

echo "line_spacing: " ^ var.line_spacing

echo "regular_flow_ratio: " ^ var.regular_flow_ratio

;M37 S1 ; Enter simulation mode

; Set firmware retraction

M207 S{var.retract_length} R{var.retract_restart_length} F{60 * var.retract_speed} T{60 * var.deretract_speed} Z{var.retract_z_lift}

T{var.tool_number} ; Select tool

M106 S0 ; Turn off part cooling fan

M568 P{var.tool_number} S{var.print_temperature} R{var.standby_temperature} A1 ; Set tool to standby temperature

M190 S{var.bed_temperature} ; Wait for bed temperature to reach setpoint

M116 P{var.tool_number} ; Wait for temperatures associated with the selected tool to be reached

; Make an inventory of axes that have not yet been homed

var axes = ""

echo "Total number of axes: " ^ {#move.axes}

while {iterations < #move.axes}

if {!move.axes[iterations].homed}

set var.axes = {var.axes ^ move.axes[iterations].letter}

; Home applicable axes

echo "Axes to be homed: " ^ var.axes

G28 {var.axes}

;G28 XYZ ; Home the X, Y and Z axes

;G28 XY ; Home the X and Y axes

;G28 Z ; Home the Z axis

G21 ; Set units to millimeters

M83 ; Use relative distances for extrusion

; Calculate object width

var width = {var.fast_segments * var.fast_segment_length + (1 + var.fast_segments) * var.slow_segment_length}

; Calculate starting coordinates and other constant(s)

var x_start = {var.x_center - 0.5 * var.width + var.skirt_loops * var.line_spacing}

var y_start = {var.y_center - 0.5 * var.line_spacing + var.skirt_loops * var.line_spacing}

var travel_feedrate = {60 * var.travel_speed}

var first_layer_feedrate = {60 * var.first_layer_speed}

; Absolute position for purge line in X and Y space, 50 mm behind model

G90 ; Use absolute coordinates

G1 X{var.x_start} Y{var.y_start + 50} F{var.travel_feedrate}

; Set heater to final temperature and wait

M568 A2

M116 P{var.tool_number}

; Absolute position of nozzle at first layer height

G1 Z{var.layer_height} F{var.travel_feedrate}

; Relatively print two fat purge lines

G91 ; Switch to relative coordinates

G1 X{var.width} E{var.width * var.purge_line_flow_ratio} F{var.first_layer_feedrate}

G1 Y{-(2 * var.line_spacing)} F{var.travel_feedrate}

G1 X{-var.width} E{var.width * var.purge_line_flow_ratio} F{var.first_layer_feedrate}

G10 ; Retract to prevent oozing

; Move to the start of the model in X, Y and Z space

; The skirt code also moves to the start, but the skirt can be disabled.

; Also, the skirt code does not set Z, and there may be no purge line for which Z is set. Safety first.

G90 ; Use absolute coordinates

G1 X{var.x_start} Y{var.y_start} Z{var.layer_height} F{var.travel_feedrate}

G91 ; Switch to relative coordinates

G11 ; Advance/unretract/deretract in preparation to print

; Routine for printing the test object

var layers = {floor(var.height / var.layer_height)}

echo "Total number of layers: " ^ var.layers

while {iterations < var.layers}

; Track current layer

var layer = {iterations + 1}

; Current height in mm

var z = {var.layer * var.layer_height}

; Calculate pressure advance factor

var pa = {var.pa_start + floor(var.z) * var.pa_stepping}

; Set pressure advance

M572 D{var.pa_extruder} S{var.pa}

; Output some statistics while printing

echo "Layer " ^ iterations ^ " (" ^ {iterations + 1} ^ " of " ^ {var.layers} ^ " at " ^ {var.z} ^ "mm)"

echo "Pressure advance: " ^ {var.pa}

; Pre-calculate feedrates for first layer and other layers

var slow_segment_feedrate = {60 * (var.layer == 1 ? var.first_layer_speed : var.slow_segment_speed)}

var fast_segment_feedrate = {60 * (var.layer == 1 ? var.first_layer_speed : var.fast_segment_speed)}

; Print skirt

if {iterations < var.skirt_layers}

G90 ; Use absolute coordinates

; Move to absolute XY start coordinates

G1 X{var.x_start} Y{var.y_start} F{var.travel_feedrate}

G91 ; Switch to relative coordinates

; Print all loops of the skirt

while {iterations < var.skirt_loops}

var skirt_loop = {var.skirt_loops - iterations}

var x = {var.width + 2 * var.skirt_loop * var.line_spacing}

var y = {var.line_spacing + 2 * var.skirt_loop * var.line_spacing}

; Print one full skirt loop

while iterations < 2

var direction = {iterations == 0 ? 1 : -1}

G1 X{var.direction * var.x} E{var.x * var.regular_flow_ratio} F{var.fast_segment_feedrate}

G1 Y{var.direction * var.y} E{var.y * var.regular_flow_ratio} F{var.fast_segment_feedrate}

; Travel to the start of the next skirt loop

G1 X{var.line_spacing} Y{var.line_spacing} F{var.travel_feedrate}

; Print two perimeters back and forth of alternating slow and fast segments

while iterations < 2

var direction = {iterations == 0 ? 1 : -1}

; Slow starting segment (X)

G1 X{var.direction * var.slow_segment_length} E{var.slow_segment_length * var.regular_flow_ratio} F{var.slow_segment_feedrate}

; Remaining fast and slow segments (X)

while iterations < var.fast_segments

G1 X{var.direction * var.fast_segment_length} E{var.fast_segment_length * var.regular_flow_ratio} F{var.fast_segment_feedrate}

G1 X{var.direction * var.slow_segment_length} E{var.slow_segment_length * var.regular_flow_ratio} F{var.slow_segment_feedrate}

; Print the side perimeter (Y)

G1 Y{var.direction * var.line_spacing} E{var.line_spacing * var.regular_flow_ratio} F{var.slow_segment_feedrate}

; Move one layer up

G1 Z{var.layer_height} F{var.travel_feedrate}

G10 ; Retract

G91 ; Relative positioning

G1 F3000 Z20 ; Move gantry up 20mm

G90 ; Absolute positioning

G28 X ; Home X axis

;M104 S0 ; Turn off nozzle heat block

M568 P{var.tool_number} S0 R0 A2 ; Set required heater temperature off

M140 S0 ; Turn off bed

M106 S0 ; Turn off part cooling fan

M18 ; Disable stepper motors

;M37 S0 ; Leave simulation mode

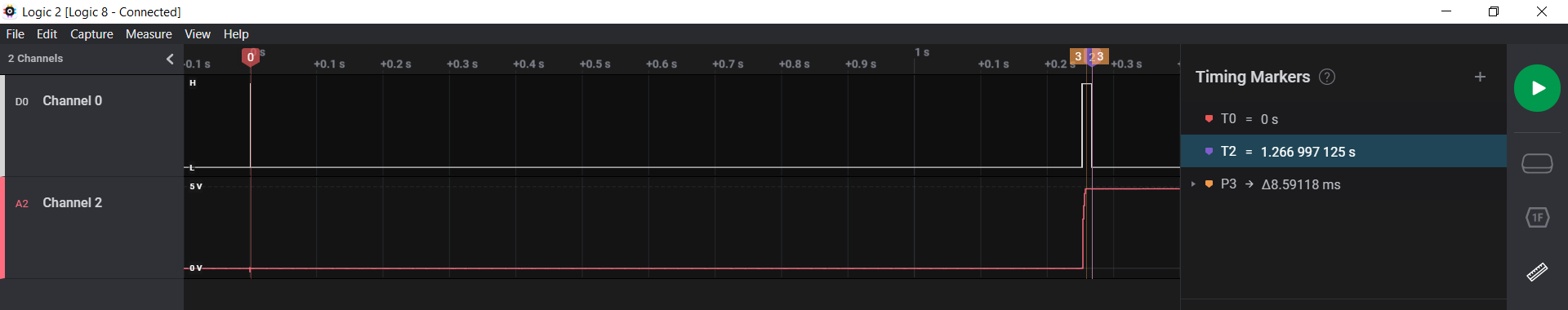

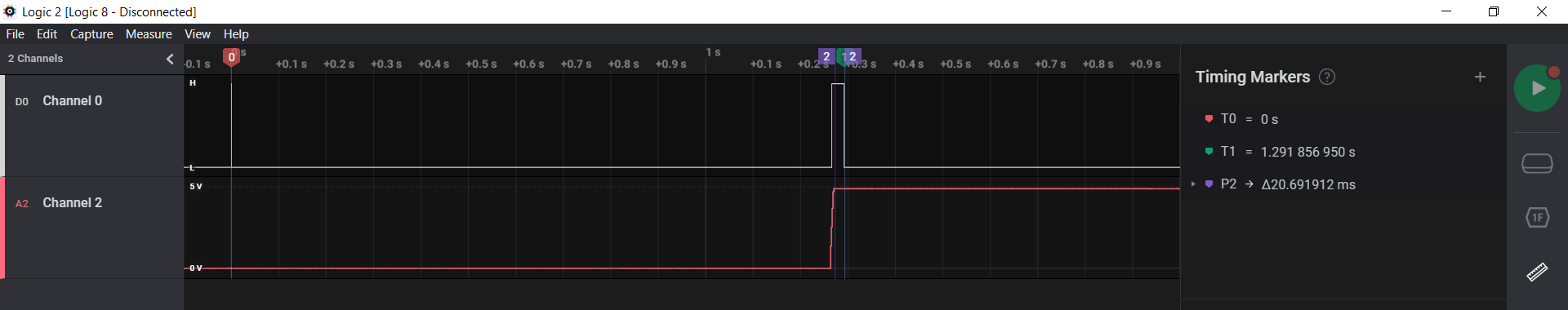

Photo of one print in progress and one done:

Lastly, I'm so happy with the concept and speed, that I'm now toying with the idea to make macros for:

- Tuning bridge parameters (with flow, temperature and part cooling as variables)

- Layer adhesion (with temperature and part cooling are variable)

- Tuning the extrusion multiplier

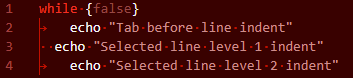

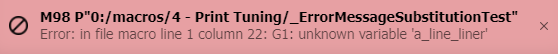

EDIT: The code didn't look right when it contains words like "doesn't" and "haven't" in comments. This results in random "{0}" inserted and illegal G-code.

).

). also actually tries to print this. Wrapping the parent code between

also actually tries to print this. Wrapping the parent code between