The G2/G3 arc command can be specified using either the R parameter to describe the radius or the I/J parameter to describe the center of the arc.

If using the R parameter, unless you describe an arc of exactly 180 degrees, there are exactly 2 arcs which can fit the description, one goes through an angle under 180 degrees and one goes through an angle under 180 degrees. Both clockwise. (Counterclockwise arcs suffer the same issue, of course.)

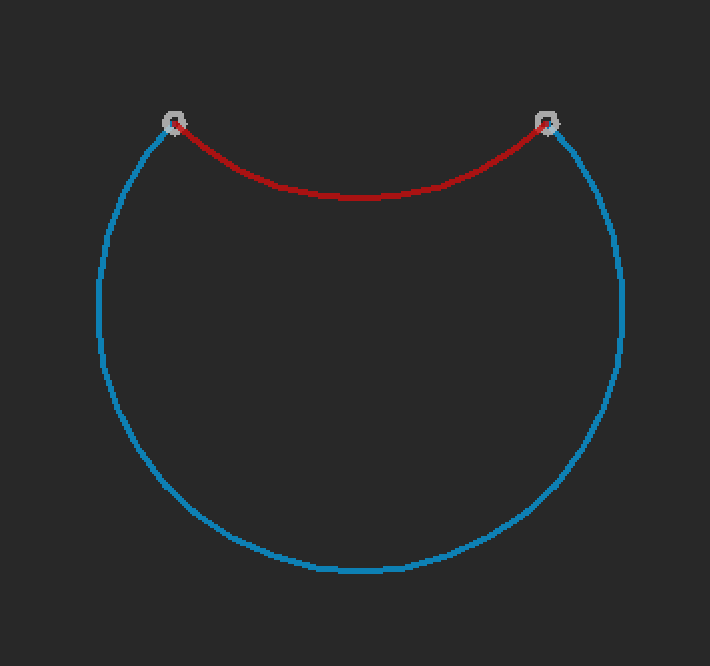

For example, moving between the two white circles (left to right) here spaced 10 units apart with a counterclockwise arc of radius 7.07, one can construct the shorter (red) arc which traverses 90 degrees or the longer (blue) arc which traverses 270 degrees. Both have the same radius, both start and end at the right points.

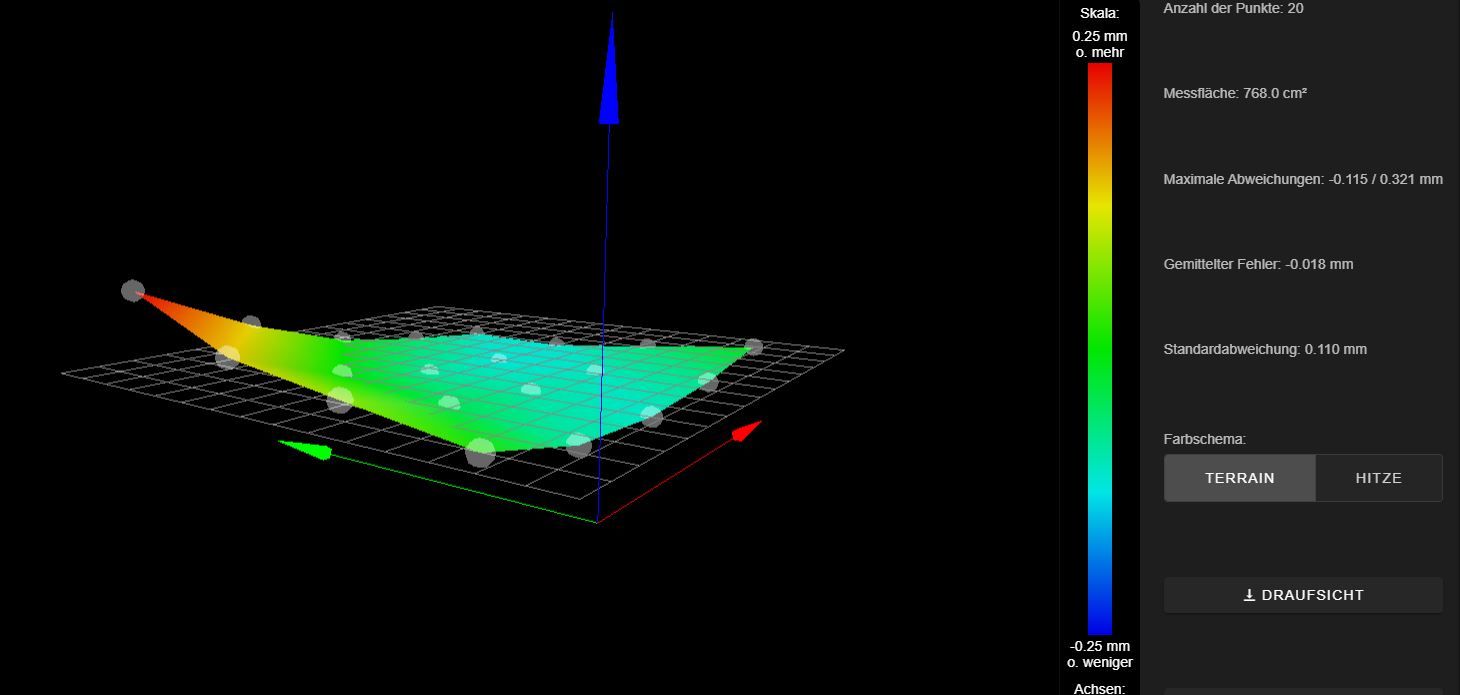

It appears as though RRF always chooses the longer of the two arcs. At least it does on my machine for the path I just constructed. I would have expected the shorter, since now it appears there is no way to traverse an arc under 180 degrees.

Is this the intended behavior? It seems like one should never use the R parameter for arcs given this ambiguity and use the (over-constrained) I/J parameters instead. Perhaps there should be another parameter which specifies which of the two arcs to traverse? Or perhaps just use the shorter of the two arcs?

The Marlin firmware doesn't define the behavior either, but their example has an arc of 90 degrees. I don't have a printer with Marlin on it anymore to test.

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2020-05-19b2