@alankilian Yes Prusa Slic3er does offer that. Like I said I am printing some different tests with first player speed and first layer bed temp to find the point where it goes from failing to working and hopefully keep those settings for all future prints.

Best posts made by R3D8U1L

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

ok guys, I tested different settings and I am happy with my temperature settings at 65 for the first layer with a speed of 20mm/s. Yes it takes longer but its worth it. Happy printing everybody and thanks for the support.

And btw I used a photo lighting softbox from amazon as my "chamber" and a personal heater to get it up to temp. Works great for what I paid.

Latest posts made by R3D8U1L

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

ok guys, I tested different settings and I am happy with my temperature settings at 65 for the first layer with a speed of 20mm/s. Yes it takes longer but its worth it. Happy printing everybody and thanks for the support.

And btw I used a photo lighting softbox from amazon as my "chamber" and a personal heater to get it up to temp. Works great for what I paid.

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

@alankilian Yes Prusa Slic3er does offer that. Like I said I am printing some different tests with first player speed and first layer bed temp to find the point where it goes from failing to working and hopefully keep those settings for all future prints.

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

@alankilian Did run a test with 10mm/s instead of 30mm/s. It definitely helped. Have to find the sweet spot cause the print time on larger object will be significantly higher.

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

@Phaedrux I used a glue stick before, didn't like cleaning up after

I think the ambient temperature here is maybe causing another issue. its 18C roughly. At night even less. Ordered a chamber to help that. Will try lowering the speed and do a test print. -

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

It looks like we have a winner! Thank you so much Joerg55 and Phaedrux, I would never have thought about the glass bed changing with temperature, now it makes sense.

I got one small issue left, My filament starts to "roll" and sometimes stick to the nozzle and cause this:

is that a temperature issue?

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

@JoergS5 It's a glass bed. I think they are unlikely to bend?

Yes I heat it to regular PLA temp of 65C for first layer.

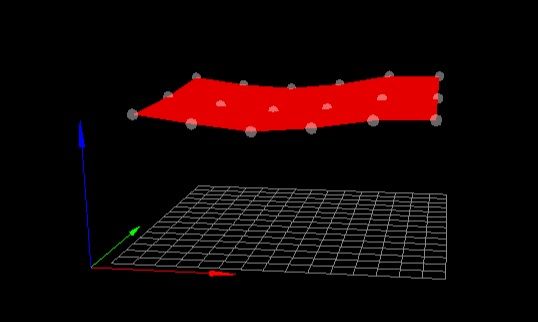

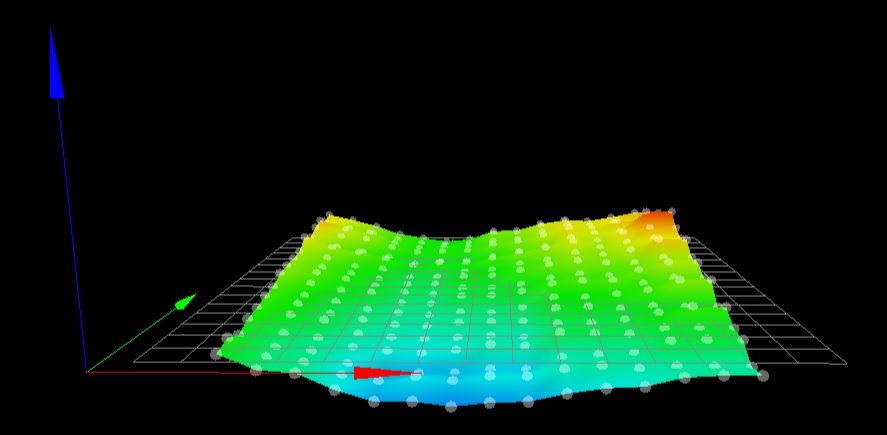

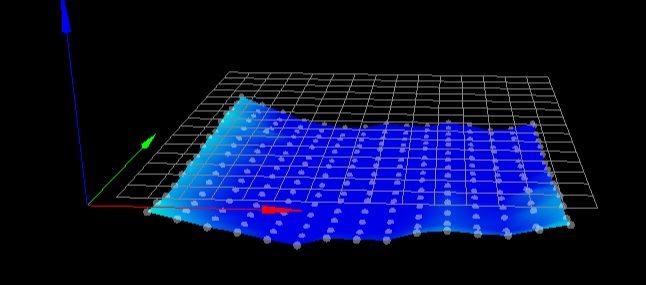

I just took all the gantry apart and assembled it with 90 degree on one site the other I could only manage 80.5.Here before and after mechanical changes:

before:

after:

I have noticed everything is "low" now.

As far as for the hotend, the bowden tube to me looks very free on the first layer printing. Can you describe this more in detail?

talking about the stiff screws, do you mean the adjuster knobs? Cause they are pretty stiffened up. Maybe loosen them all the way and just go back a bit to set in place?

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

@Phaedrux if it would bin in line on the Y and closer to the nozzle? SO offset would be x+- 10 and y also +-10?

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

This is what I am using so no modification possible I believe.

I need to be educated. If the probe does the mesh level, it is at the same position the nozzle will be later when printing. Why does the offset effect it so much?

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

in this case I would need a mount for a micro swiss direct drive extruder with the probe in line with the Y axis. Hope google can help me there.

-

RE: Mesh Compensation working only half of the built plateposted in Firmware installation

@Phaedrux said in Mesh Compensation working only half of the built plate:

Based on those numbers it does seem like you have a different trigger height from the left side to the right side.

3.495 vs 3.360

Try and get your printer squared up as much as possible. In a cartesian bed slider the bed (Y) and gantry (X) must be totally aligned. Mesh compensation can correct for a lot, but it assumes that the probe to nozzle offset is consistent regardless of XY position. There are certain mechanical situations such as skew of the X and Y axis that it can't really compensate for if the probe has an offset from the nozzle.

working on the tomorrow and keep you posted. It makes sense that its from hardware side since it has been consistent in any firmware.