Having a couple extra Duet 3 Mainboards sounds like a fun problem to have

Best posts made by raykholo

-

RE: Option to use Duet 3 MB6HC as Expansion boardposted in General Discussion

-

RE: Laser/ CNC Support in RRF - gCode Semanticsposted in Laser Cutters

Smoothieware gives the cleanest corners when cutting we have seen. To the best of my knowledge it is handling the calculations for acceleration, deceleration, speed, and respective laser power pwm on each step generated.

The PWM rate is proportional to the speed, so the power to the tube is, but the CO2 tube doesn't respond in a linear way, so it's not perfect.

-

RE: Duet 3 with E3D Toolchanger setup - small Stepper Motor questionposted in Duet Hardware and wiring

David,

It sounds like OP wants to use the 6 high power stepper drivers on the Duet 3 for other purposes, and is essentially asking whether he can tap a stepstick into some IO pins directly on the Duet 3 Mainboard.

You are saying that this is not possible, and that you have to use the 6 onboard drivers and that a 3HC (or 1LC) expansion board is the only way to do more stepper drivers - is my understanding correct?

Latest posts made by raykholo

-

Control PanelDue through gCode commands?posted in PanelDue

I would like to make a minor usability improvement for myself, which is that when a print finishes, I would like the PanelDue to go from the print "Status" tab over to the "Control" tab so that I can interact with the machine. I was wondering if there was a gCode command that would tell the PanelDue to do this, or perhaps there is some other method or a setting to achieve this result?

It also made me wonder if there are other gCode commands that can tell the PanelDue things like "do this" or "show this". -

RE: Binary GCode Support (.BGCODE)posted in Firmware wishlist

@deckingman been a long time, hope you are doing well. Watched a lot of your more recent videos last week to get caught up on "fun crazy machines".

Thanks for that link. My search didn't find it, likely because they didn't say "binary" in the title.

-

Binary GCode Support (.BGCODE)posted in Firmware wishlist

Hi folks,

In the latest Prusa blog update, they mention that PrusaSlicer 2.7 will have support for a more efficient binary GCode file format.

You can read about it here:

https://blog.prusa3d.com/update-original-prusa-xl-input-shaper_83744/

by going to the section titledSlicer packed with tons of new features – introducing .BGCODE, SVG supportThe library is available here: https://github.com/prusa3d/libbgcode

I am wondering if this is something that the Duets could be made to handle. The appeal would be faster upload speeds of large files.

I am currently getting sub 1-meg speeds uploading files to my Duet 2 Ethernet. I'm going to check the suggestions in this thread after my long print finishes. https://forum.duet3d.com/topic/29825/slow-project-upload-speeds-using-dwc

It's not horrible, I just have the bed pre-heating while the file uploads, but for large prints we might be looking at up to a few minutes of upload time.

The Duet 3 with SBC, even on WiFi, has substantially faster upload speeds, but:

a) it is not economically feasible to upgrade all of my Duet2 machines to a Duet 3 + Pi, and

b) I am hoping that all my Duet 2 Wifi/ Ethernet based boards/ machines have a lot of life left in them. -

RE: Option to use Duet 3 MB6HC as Expansion boardposted in General Discussion

Having a couple extra Duet 3 Mainboards sounds like a fun problem to have

-

RE: Danal's passingposted in Off Topic

Just seeing this now. Couldn't have said it better than @poofjunior did. He helped me with a whole bunch of seemingly random parts of bigger projects since 2+ years ago, great guy, I don't have the words.

-

RE: Duet 3 with E3D Toolchanger setup - small Stepper Motor questionposted in Duet Hardware and wiring

David,

It sounds like OP wants to use the 6 high power stepper drivers on the Duet 3 for other purposes, and is essentially asking whether he can tap a stepstick into some IO pins directly on the Duet 3 Mainboard.

You are saying that this is not possible, and that you have to use the 6 onboard drivers and that a 3HC (or 1LC) expansion board is the only way to do more stepper drivers - is my understanding correct?

-

RE: CAN-FD commands ?posted in Firmware developers

This is also of interest to me.

@Danal the active development appears to be happening in branch

v3.01-dev, notdevwhere that file does not exist.I have started reading the contents of:

https://github.com/dc42/RepRapFirmware/tree/v3.01-dev/src/CAN

and:

-

RE: Quotient and Modulo Mathematical Operations Requestposted in General Discussion

I agree that having to use

a-b*floor(a/b)for remainder hurts readability, especially when inside complex expressions. Please please please have a dedicated mod operation. Either syntax ofmod(a,b)ora%bis completely fine.For the quotient, rounding is surely another option and

floor(a,b)would be fine for our purposes.Also, please note that I used syntax of

function (a,b)and notfunction (a/b)above. I have usually seen it as comma separated parameters and I am concerned that using/would confuse the system into thinking it is division inside the function.Thank you very much for the consideration.

-

Quotient and Modulo Mathematical Operations Requestposted in General Discussion

Hi David,

Would it be possible to have the mathematical operations of "Quotient" (divide without remainder) and Modulo (just the remainder)? I did not see any reference to these in the Meta Commands documentation.

I want to build a filament changer (MMU2 style to feed different filament types/ colors) on top of a tool changer (grab different nozzle sizes) so that any combination of filament/ color and nozzle size is possible.

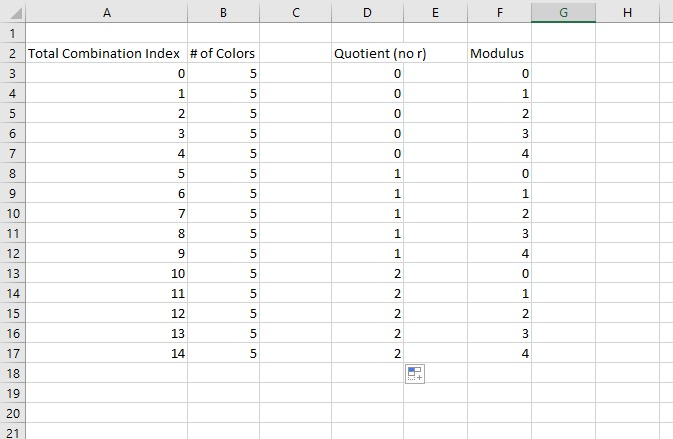

In an example of 3 tools (say a 0.25, 0.4, and 0.8 volcano nozzle sizes) and 5 filament colors, we have 15 combinations to resolve. I would use the existing T# functionality to handle tool changing, and would write a similar construct in Macros to handle the filament color changer.

I would use a Macro to resolve the 15 possible combinations into the existing T# commands to select tool, and Macros would handle the filament switching commands.

As you can see in the spreadsheet image here, we would need a Quotient and Modulo operation to do this. Quotient is Tool #, Modulo is Filament Color #.

Thanks!

-

RE: Advanced Functionality Questionsposted in General Discussion

Yes, I was using the button send as the simple example of "yes, this should be straightforward to replicate". I just checked how a defined macro button works, and it does indeed send an M98 command with its name "Test1" so that's fine.

rr_gcode?gcode=M98%20P%220%3A%2Fmacros%2FTest%201%22I was thinking about making other UI elements (dropdowns, sliders, etc...), where it would have to be written into HTML. So yeah, M98 seems to be the proper way to do this.

Perhaps... you are asking "Does the new conditional/variables stuff include having macros take arguments and return results?" I'm investigating that same question myself.

For getting data back, yes, I would like Macros to be able to return data that the DWC can use to update custom UI elements (show values in text field, change a slider position, all the things that already happen with temps and so on).

Right now, I only see an

echocommand that writes a message to console: https://duet3d.dozuki.com/Wiki/GCode_Meta_Commands#Section_Echo_commandI do not know that the webpage would be able to parse console messages to see if it finds data to update the UI. A real way to return data would be preferable.

I'm not sure if the data might need to persist somewhere for things to work well, which is why I brought up sticking it in the object model/ lastStatusResponse JSON object.