so if they are damaged is it means that my delta smart effector died?

Posts made by akrepsianka

-

RE: Delta smart effector sensitivity problemposted in Smart effector for delta printers

-

RE: Delta smart effector sensitivity problemposted in Smart effector for delta printers

Cables are ok. I have checked it. I change heater cable last week it connected directly to the board not through smart effector. Even so printer was working fine until last day. I suspect only one thing. I had clogged nozzle and i was changing it. While i was removing heatsink from pcb i damaged pcb around the nut that holding heatsink. I say damaged but lets say i scrathed a bit pcb

-

RE: Delta smart effector sensitivity problemposted in Smart effector for delta printers

What i mean is i cant do any probes. When i send g32 or g28 or g29 it gives error and says already triggered cant probe. i open the printer and it start to trigger. Nothing move no prints just switch on and it starts to trigger. I reduce sensitivity than it triggers (stop triggering on stand by) but also hits and bends pcb or some arms get loose from magnets. I havent change nothing in the firmware

-

Delta smart effector sensitivity problemposted in Smart effector for delta printers

Hello

I have Delta printer installed with delta smart effector and almost more than 1 year i am using it. some how it become more sensitive to vibrations. i set it up to M672 S105 155 since i use it. after a print i started a new print and i realize that green led is lightning almost all the time. i try to reduce sensitivity but than it hits to hard and bending pcb so i stop trying it. i dont know whats changed. printer works fine no extra viration more than usual. my steppers are working great. dont understand what happened?

155 since i use it. after a print i started a new print and i realize that green led is lightning almost all the time. i try to reduce sensitivity but than it hits to hard and bending pcb so i stop trying it. i dont know whats changed. printer works fine no extra viration more than usual. my steppers are working great. dont understand what happened? -

RE: Delta smart effector burnoutposted in General Discussion

i dont have multimeter but i will consider your suggestion and buy 30w of cartridge to be in safe area. i use silicone sock

-

RE: Delta smart effector burnoutposted in General Discussion

heater is 24v 40w powered. My machine runs on 24v. on the underside of pcb there is no trace of any burn or melted part.

below is my config

M305 P1 X200

M307 H1 A608.7 C274.3 D5.0 B0 S0.9i will connect directly cables to run the machine again.

i will reduce S0.9 to S0.6 to keep it low current -

Delta smart effector burnoutposted in General Discussion

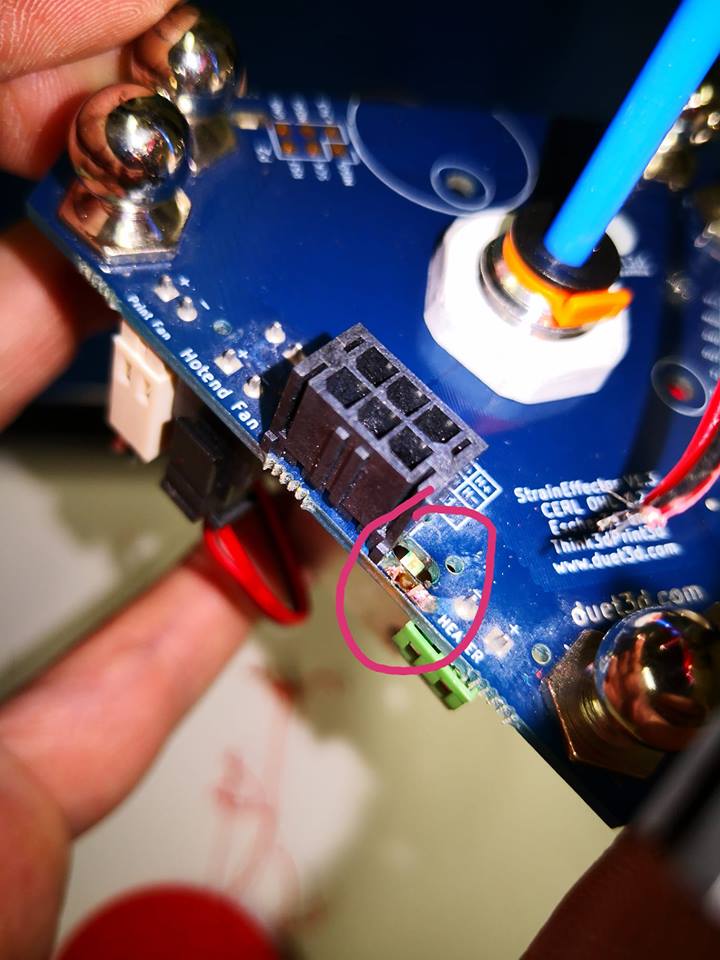

Started print and went home last night. When i came back to office printer was stopped. Than i see burnout of heater channel on the picture. İ checked the cables and didnt see any short circuit. İ was printing pla at 210 c degree. What should i do now?

-

RE: Need a decent power supplyposted in General Discussion

Look for omron 24v 500w psu. Omron is good brand

-

12v fan on 24v duetposted in General Discussion

Hello

My duet is powered 24v and i want to use 12v fan. İs it enough to use with resistor an will it damage the fan after some period of time? Or the board? İ will uei on allways on fans slot -

RE: PT100 + Themocouple configposted in General Discussion

is this correct?

M143 S260 ; Set maximum heater temperature to 260C

M143 H0 S110

M305 P0 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M305 P1 X200

M307 H0 A357.9 C296.8 D2.6 B0 S0.8

M307 H1 A730.8 C243.5 D6.2 B0 S0.8 -

PT100 + Themocouple configposted in General Discussion

Hello

After having problem with termistor i bought PT100 sensor and Thermocouple for pt100.

its arriving tomorrow and i want to know how should be my config for pt100 sensorBelow is my current config for heater section

M143 S260 ; Set maximum heater temperature to 260C

M143 H0 S110

M305 P0 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M305 P1 T100000 B3950 C0 R4700 ; Set thermistor + ADC parameters for heater 1

M307 H0 A357.9 C296.8 D2.6 B0 S0.8

M307 H1 A730.8 C243.5 D6.2 B0 S0.8What i have to change to adapt pt100 sensor?

-

RE: Termocouple board necessary??posted in General Discussion

where i can find pt1000 sensors??? look better and cheaper solution.

-

RE: Termocouple board necessary??posted in General Discussion

if i get pt100 sensor ca i attached directly to the duet wifi board. or need to buy thermocouple board?

and what should be my config if i have pt100 sensor? -

RE: Termocouple board necessary??posted in General Discussion

Here is my config for termistor. i copied it from my other printer because they use absolutly same termistor.

M305 P1 T100000 B3950 R4700 ; Set thermistor + ADC parameters for heater 1Here is termistor parameters

Thermistor:100K NTC B 3950 ±1% ,1m long,2 pin connect -

Termocouple board necessary??posted in General Discussion

I just finish my new 3d printer setup. i have strange problem with termistor. I heated up to 210 C degree hearter block and i try to extrude pla filament. (my other 2 printer extrude at 210 C without any problem) it wasnt extruding properly. so i heated up to 235 C degree and start to extrude properly. My question is:

My termistor cable is around 2.5m long and i guess because its too long it dosent read properly. so in this case will thermocouple board solve my problem?? -

RE: Cooling fan behaviourposted in General Discussion

i have 3 printer with duet. so the best solution is to connect fan 0 connector all cooling fans. looks more easy and rigit solution

-

Cooling fan behaviourposted in General Discussion

Hello

I have problem with cooling fan. I am using simplyfi3d for slicing models and i adjust cooling fan to start at %65 percent from 4th layer and each layer incresing more fan speed untill 100%. Problem is that it never start the fan on the 4th layer. İn the slicer gcode i chekced that at the begining of 4th layer gcode send M106 S165 code but fan dosent start.

When i enter duet interface and send M106 S165 or S255 fan also doesnt start. so to Start i have to send M106 P2 S165 code and it starts to run

Here is my config file for fans

; Fans

M106 P2 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S255 I0 F500 H1 T50 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned onSo where is my problem? İn the slicer program or somewhere else?

-

RE: Z step motor connection problemposted in General Discussion

i swap as you suggested and now x is not working. so z output is the problem. what should i do now?

-

RE: Z step motor connection problemposted in General Discussion

i have another printer which is working without any problem so i copy the firmware to my new printer. both has exactly same leadscrew so option 1 cant be the problem. tomorrow i will try option 2 and see the result. swapping x and z motor and still have problem on z output what its gonna be than?