@dc42 Can't you adjust the speed somehow in g-code or in the macro?

Posts made by axiom

-

RE: speed of bed levelingposted in Using Duet Controllers

-

speed of bed levelingposted in Using Duet Controllers

How can I increase the speed of my bed leveling (G29).

-

optical light barrier as filament sensor invertposted in Filament Monitor

I built an optical light barrier as a filament sensor (see screenshot). The filament sensor also reacts when I put the filament in. But I want the error message with pause when the filament is missing, so the barrier is not interrupted. Nothing has changed about S1 and S2...is there another option?

-

RE: controller for flowposted in Using Duet Controllers

@cosmowave and what do I have to write into the g-code so that it appears in the DWC and I can regulate it?

-

RE: controller for flowposted in Using Duet Controllers

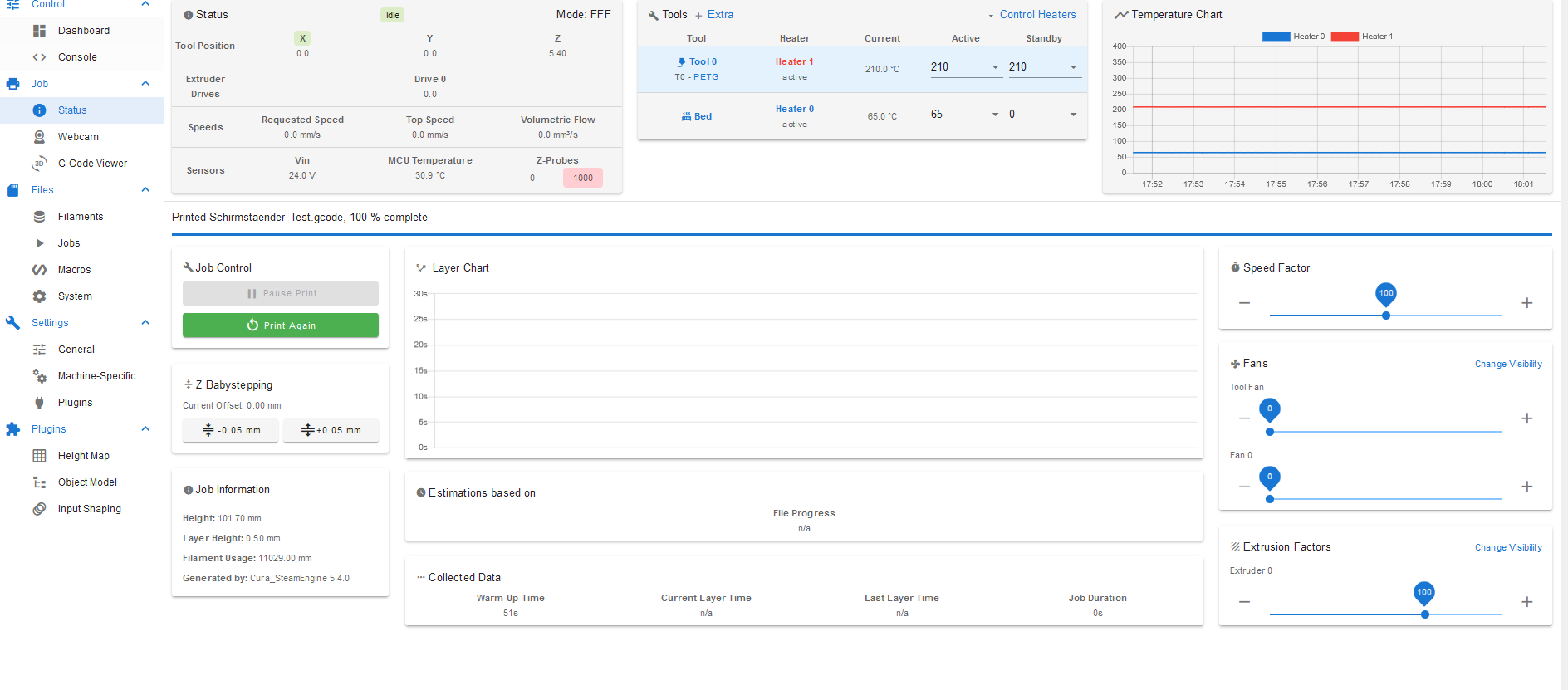

@dc42 I would like to be able to "play" with the flow (see cura screenshot) during the printing process

-

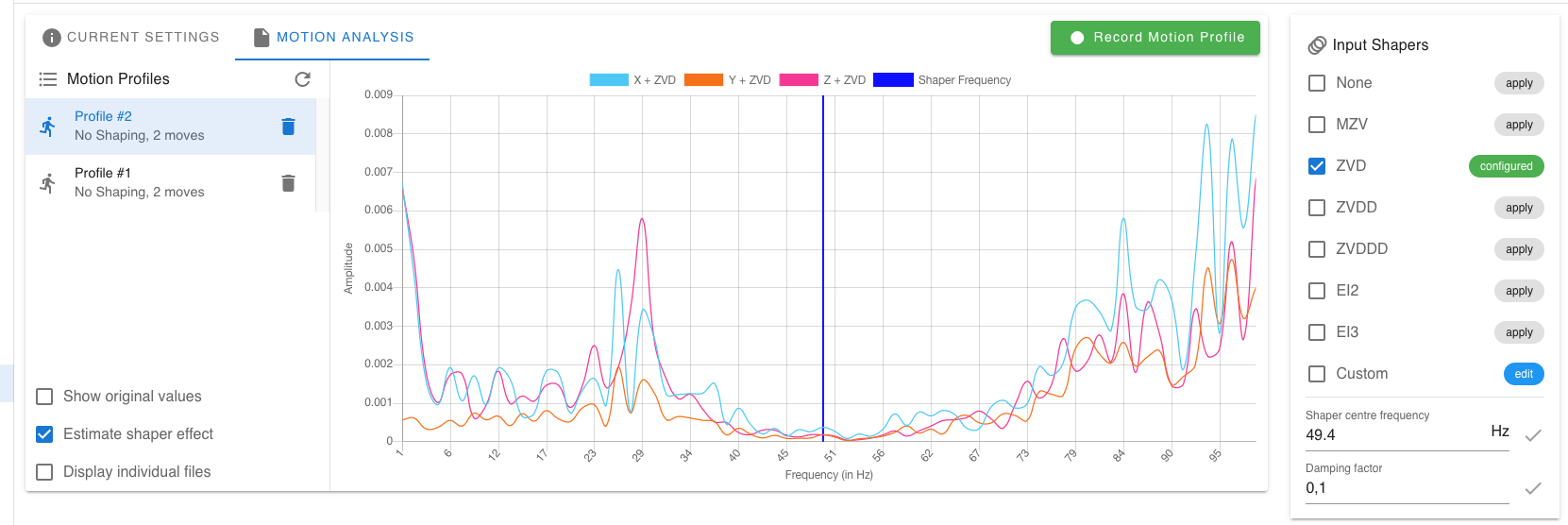

RE: videostream without duet framework?posted in Using Duet Controllers

@stuartofmt Thank you for the answers, everything actually works if I simply copy the IP address from Motion....sadly my new raspberry 5 said goodbye after 1 hour...despite the expensive original fan and expensive power supply

-

controller for flowposted in Using Duet Controllers

Is there a way to call up a flow controller in the DWC to make corrections while driving (like speed)?

-

RE: Trying to force install pluginposted in Plugins for DWC and DSF

@Notepad Thank you very much, unfortunately I only have the option to install the plugin...perhaps the other options are no longer available in version 3.5.4?

-

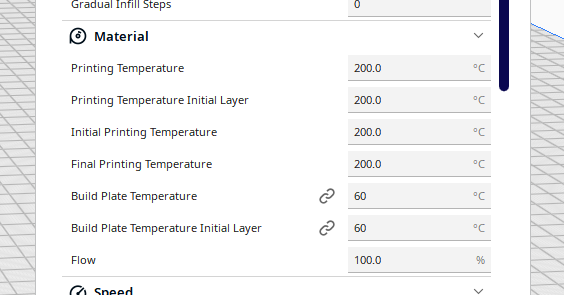

videostream without duet framework?posted in Using Duet Controllers

I would like to use the motionwebcamplugin for the video transmission. But when I try to install it, I get a message saying that the Duet software framework is missing (see photo).

But since I don't want to switch everything to the framework (because I don't understand it), I wanted to find out if there is an easier way to integrate the video stream from motioneye into the DWC? -

RE: optimize input shaping in the other directionposted in Using Duet Controllers

@engikeneer thank you very much, then I will just print a few tests

-

RE: optimize input shaping in the other directionposted in Using Duet Controllers

@engikeneer Thank you very much, but how do I enter the second frequency?

-

RE: optimize input shaping in the other directionposted in Using Duet Controllers

@dc42 That's interesting, and how can I write that into the config?

-

solution for dwc with camera for rapi 5?posted in Using Duet Controllers

Is there now a solution to control the surface and a camera via a raspberry pi 5. Unfortunately there is no octoprint for the raspi 5 and I can't find a solution?

-

RE: optimize input shaping in the other directionposted in Using Duet Controllers

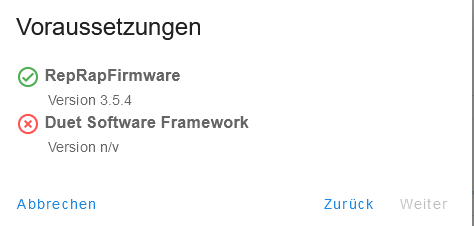

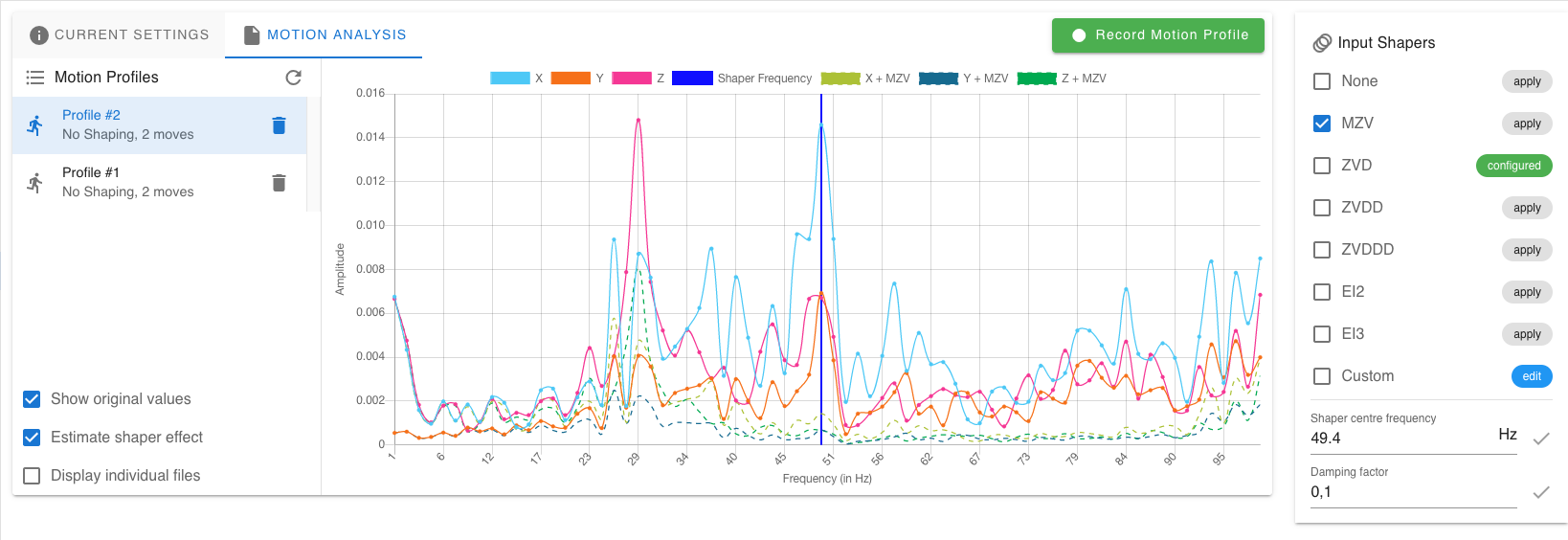

@axiom and here with shaper effect:

-

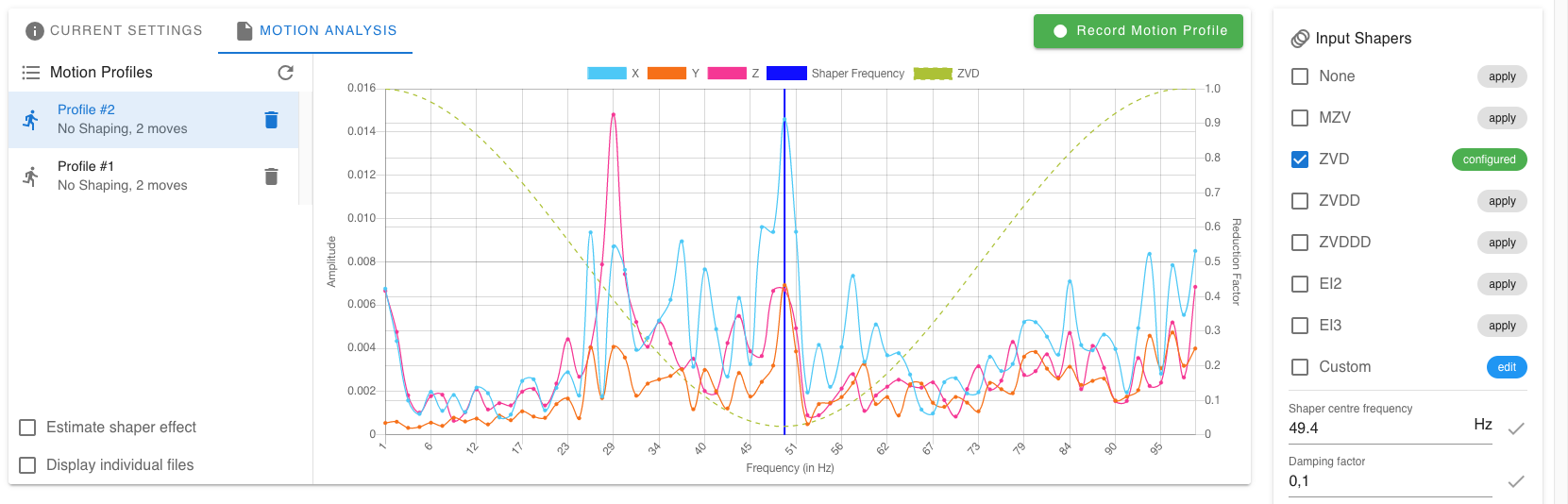

RE: optimize input shaping in the other directionposted in Using Duet Controllers

@jay_s_uk sorry, i ve postet the wrong screenshot, here ist the right one:

-

RE: optimize input shaping in the other directionposted in Using Duet Controllers

@jay_s_uk

It is the newest 3.5.4 on a duet 2 wifi board, the acelerator is a duet v 0.2 -

optimize input shaping in the other directionposted in Using Duet Controllers

I have now achieved my first success in input shaping. The ringing in one direction has been reduced enormously...in the other direction it is still very expandable. Are there ways to reduce this ringing?

can I add something else in the code?

here is the code:M593 P"zvd" F49.4

and here a screenshot of the current profile (previously measured with duet acelerator)

-

RE: Accelerometer not foundposted in Using Duet Controllers

@jay_s_uk

wow, thank you so much! That was the solution, now I just have to figure out the input shaping....have a nice Sunday, cheers, Don -

RE: Accelerometer not foundposted in Using Duet Controllers

@jay_s_uk

I'm happy, I took the code from the instructions...if the indicator light on the acelerator lights up green, couldn't it be the wiring?; Configuration file for Duet WiFi (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"DUKA1300" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S1 ; enable Telnet ; Drives ;M569 P4 R-1 ; Treiber 4 deaktivieren ;M569 P3 R-1 ; Treiber 4 deaktivieren M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S0 ; physical drive 3 goes forwards M569 P5 S1 ; physical drive 3 goes forwards Expansionboard M569 P6 S1 ; physical drive 3 goes forwards Expansionboard M569 P7 S1 ; physical drive 3 goes forwards Expansionboard M569 P8 S1 ; physical drive 3 goes forwards Expansionboard ;M584 X0 Z2 E1 ; set drive mapping ;M584 X0 Z2 E1 ; set drive mapping ;M584 X0:4 Y1 Z2 E3 ; set drive mapping M584 X0:4 Y1 Z5:6:7:8 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z640 E322.58 ; set steps per mm M566 X900.00 Y900.00 Z100.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z300.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z40.00 E250.00 ; set accelerations (mm/s^2) M906 X1800 Y1800 Z1800 E1700 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X750 Y643 Z1220 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop + e0stop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop M574 Z1 S2 ;S1 P"duex.e2stop+duex.e3stop+duex.e4stop+duex.e5stop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop ; Z-Probe M558 K0 P5 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds (Kapazitiver Sensor) M558 K1 P8 A2 S7 C"duex.e6stop" H5 F80 T3000 G31 P1000 K0 X0 Y-25 Z0.9 ; set Z probe trigger value, offset and trigger height (Kapazitiver Sensor) M557 X0:735 Y-25:573 S35 ; define mesh grid ; Heaters ; Bed M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S280 ; set temperature limit for heater 0 to 120C ;Hotend M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit M143 H1 S400 ; set temperature limit for heater 1 to 400C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F2 C"fan1" Q350 ; create fan 2 on pin fan2 and set its frequency M106 P2 S1 H1 T60 ; set fan 2 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 1 G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Filamentsensor M591 D0 P1 C"e1stop" S1 ;R40:120 E3.0 S1 Filament Sensor ;Inputshaper/Accelarator M955 P0 C"spi.cs1+spi.cs0" I10 ; configure accelerometer on mainboard using SPI pins and specify orientation ;Auto Z-Offset ; Custom settings are not defined M501