I extensively use self adhesive foiled rubber foam. Its the stuff that comes sometimes with heated beds for insulation. Its actually manufactured as automotive engine bay sound and heat insulation. In my opinion this knocks the socks off all other options. Easy to install, cheap and very effective. My enclosures are all passively heated and achieve 74degrees consistently. Heres the aliexpress link. https://www.aliexpress.com/item/1005001475455913.html?spm=a2g0o.order_list.0.0.21ef1802dXxfYm

Best posts made by bubblevisor

-

RE: What Insulation do you use?posted in General Discussion

-

RE: Random additional steps - interference?posted in Tuning and tweaking

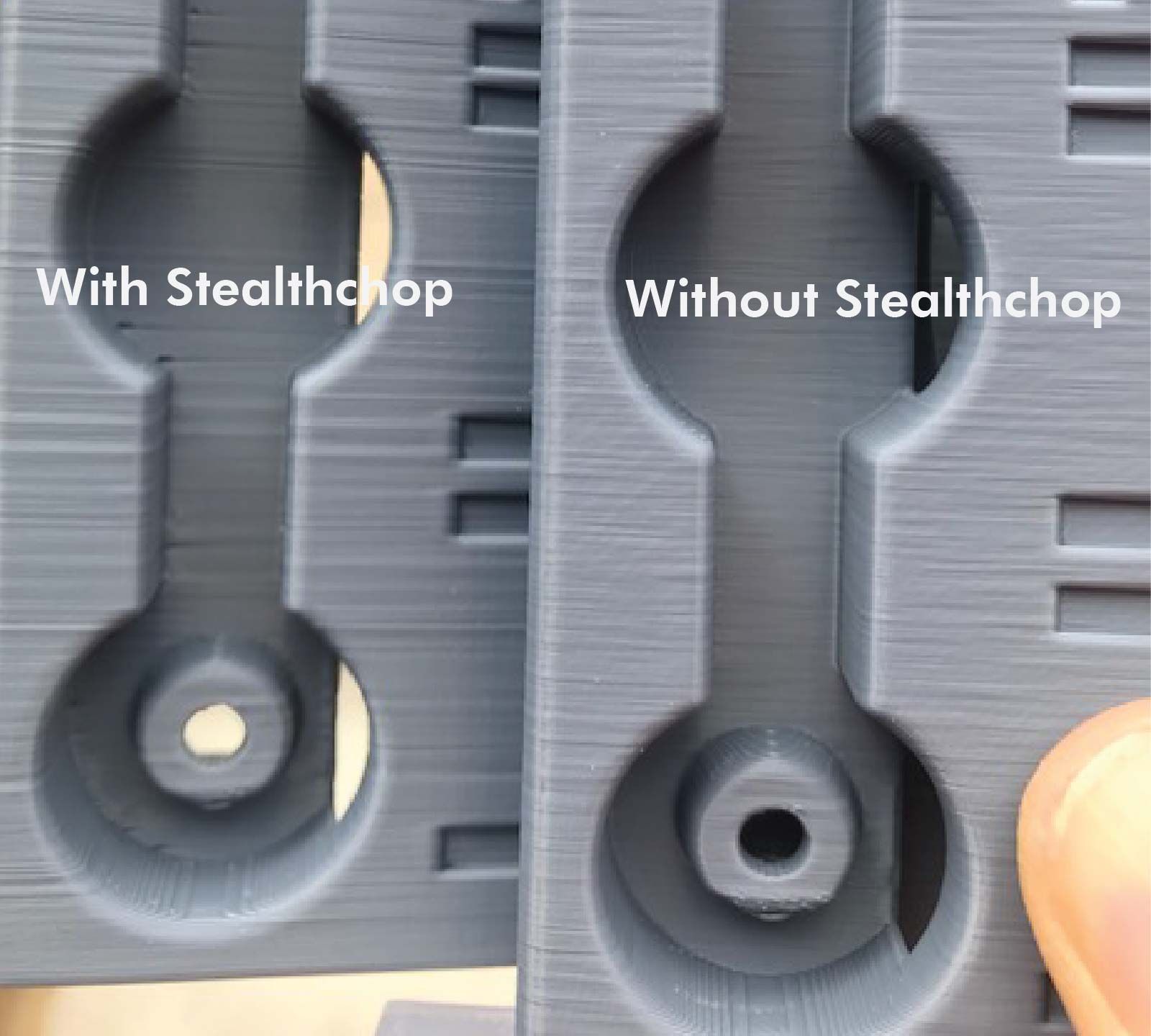

@phaedrux The stealth chop point seems potentially likely as the good printer is running RRF3.3 on Duet 2 spreadcycle and bad printer is 3.4 on big dipper TMC2209 defaulting to stealthchop with a weird speed threshold that switches to spreadcycle. This sounds like it can give rise to inconsistencies.

I'll change the M569 to enforce spreadcycle and report back. Fingers crossed.

-

RE: Tool Length Switchposted in General Discussion

@phaedrux said in Tool Length Switch:

ou should be using the probe to set the Z position

I'm a little confused. I am trying to achieve a setup that ignores the induction probe z offset entirely and relies only on the tool length switch. Indeed the voron guys don't even bother accurately setting the induction probe trigger height in the config as they don't use it. The probe is just used to create the contour (delta z) map and the switch to set the global height. My goal is to avoid the heat drift problem with probes.

-

RE: Random additional steps - interference?posted in Tuning and tweaking

BINGO! I turned off the default stealthchop and enabled spreadcycle via M569. Completeley solved the problem.

Default Stealthchop switches back and forth between spreadcycle and stealthchop when the speed is low. This seems to create a print blemish when this happens. My advice is STICK TO SPREADCYCLE!

-

RE: Glass 3D printing featuring RRFposted in General Discussion

@oliof That's incredible. I'm more thinking of the engineering applications more than art though!