@moth4017

this is my config and it works nice

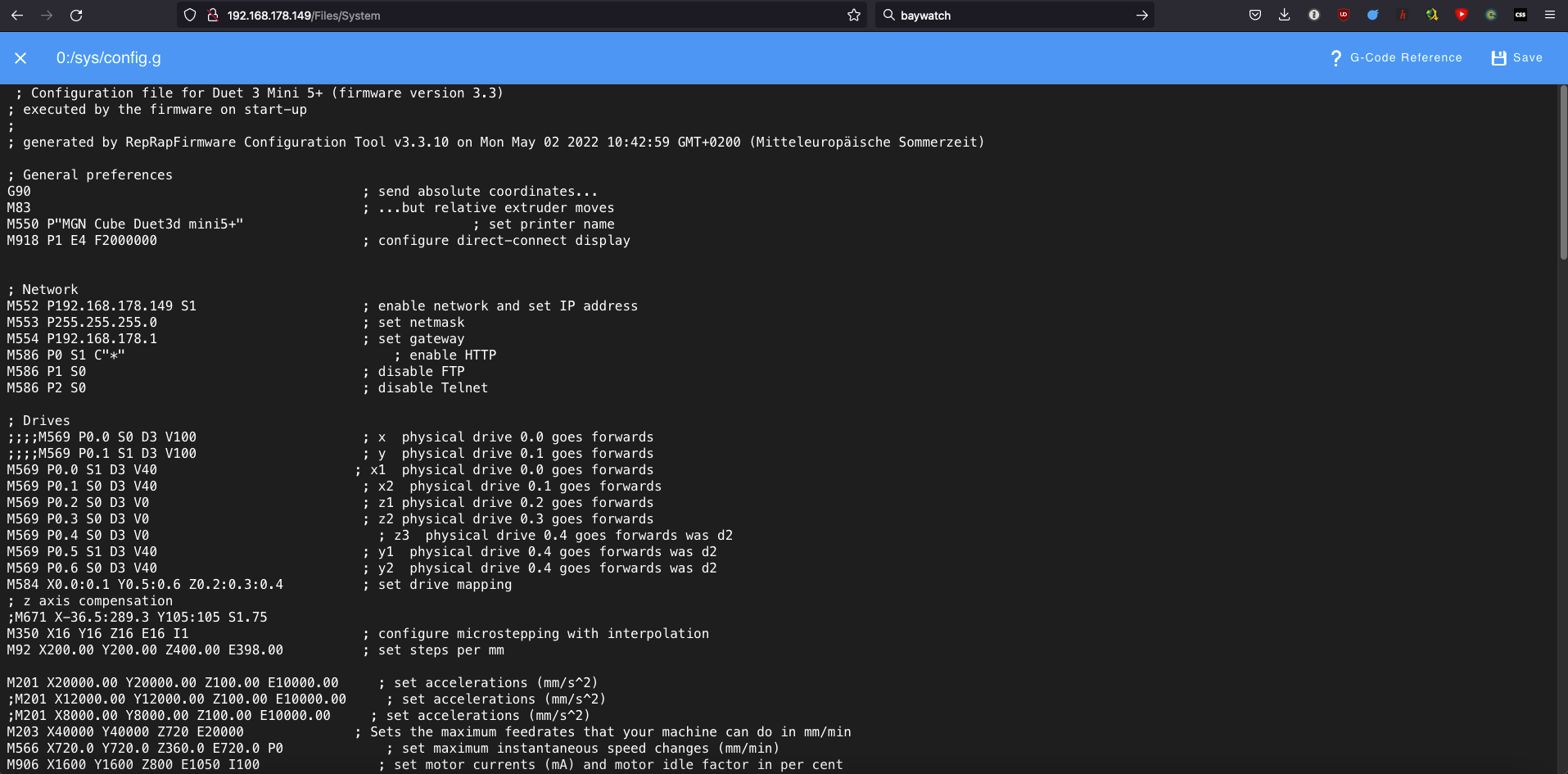

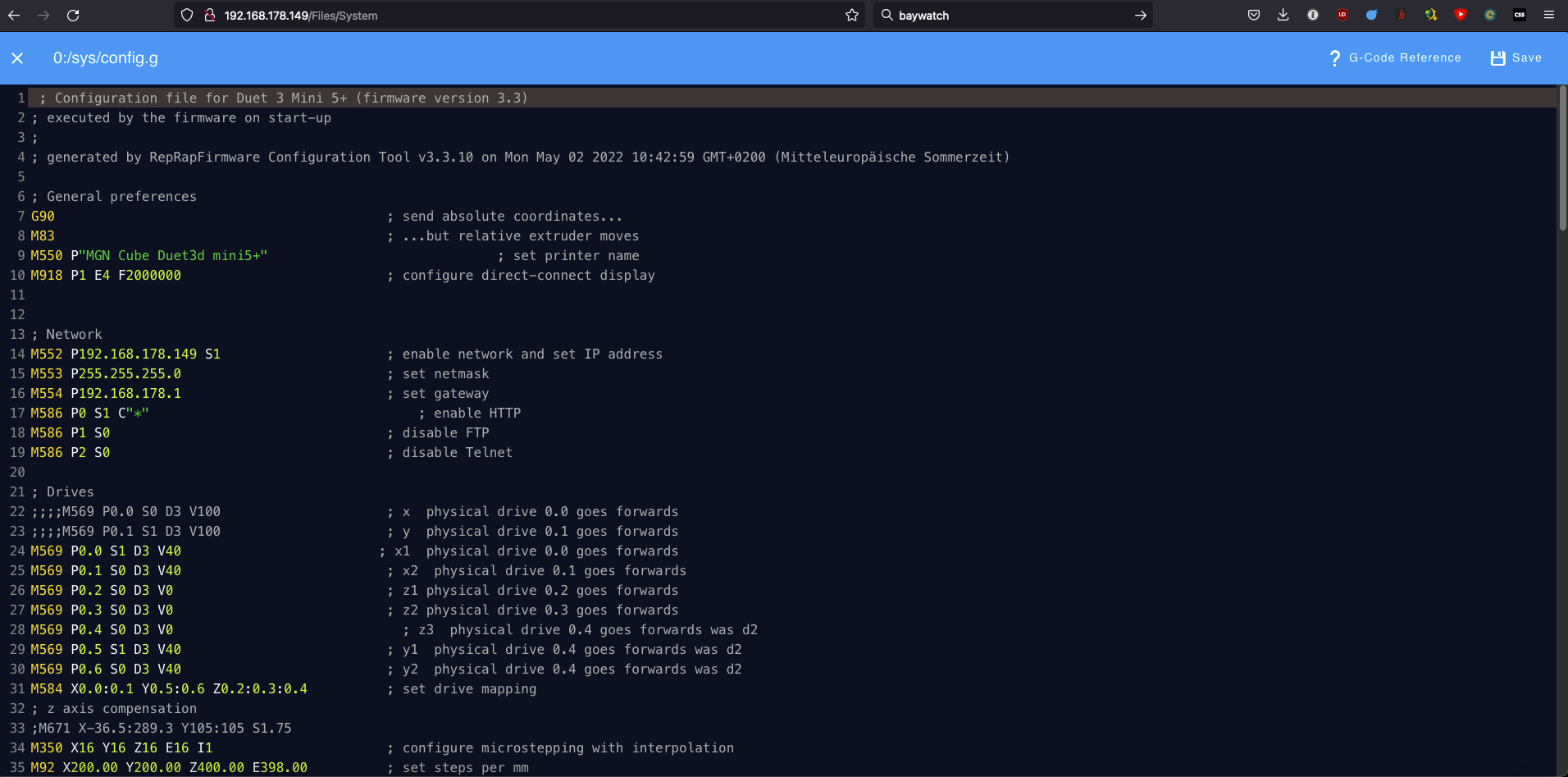

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon May 02 2022 10:42:59 GMT+0200 (Mitteleuropäische Sommerzeit)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Bear 2.1 Duet3d mini5+" ; set printer name

M918 P1 E4 F2000000 ; configure direct-connect display

; Network

M552 P192.168.178.148 S1 ; enable network and set IP address

M553 P255.255.255.0 ; set netmask

M554 P192.168.178.1 ; set gateway

M586 P0 S1 C"*" ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 D3 V100 ; x physical drive 0.0 goes forwards

M569 P0.1 S1 D3 V100 ; y physical drive 0.1 goes forwards

;M569 P0.0 S0 D3 V40 ; x physical drive 0.0 goes forwards

;M569 P0.1 S1 D3 V40 ; y physical drive 0.1 goes forwards

M569 P0.2 S0 D3 V0 ; z1 physical drive 0.2 goes forwards

M569 P0.3 S0 D3 V0 ; z2 physical drive 0.3 goes forwards

M569 P0.4 S1 D3 ; e physical drive 0.4 goes forwards was d2

M584 X0.0 Y0.1 Z0.2:0.3 E0.4 ; set drive mapping

; z axis compensation

M671 X-36.5:289.3 Y105:105 S1.75

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E398.00 ; set steps per mm

;M566 X360.0 Y360.0 Z360.0 E360.0 ; set maximum instantaneous speed changes (mm/min) Worked with vibrations

;M566 X360.0 Y360.0 Z360.0 E360.0 ; set maximum instantaneous speed changes (mm/min)

M566 X900.0 Y900.0 Z60.0 E3000.0 P1 ; set maximum instantaneous speed changes (mm/min)

;M566 X900 Y900 Z60 E3000 P1

M203 X9000.00 Y9000.00 Z1800.00 E4800.00 ; set maximum speeds (mm/min)

;M203 X15000.00 Y15000.00 Z1800.00 E4800.00 ; set maximum speeds (mm/min)

M201 X2500.00 Y2500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

;M201 X8000.00 Y8000.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

M203 X9000 Y9000 Z600 E20000 ; Sets the maximum feedrates that your machine can do in mm/min

;M203 X15000 Y15000 Z600 E20000 ; Sets the maximum feedrates that your machine can do in mm/min

;M566 X360.0 Y360.0 Z360.0 E360.0 ; set maximum instantaneous speed changes (mm/min)

;M566 X520.0 Y520.0 Z360.0 E360.0 ; set maximum instantaneous speed changes (mm/min)

;M203 X12000.00 Y12000.00 Z1800.00 E4800.00 ; set maximum speeds (mm/min)

;M201 X2500.00 Y2500.00 Z100.00 E10000.00 ; set accelerations (mm/s^2)

;M201 X3500.00 Y3500.00 Z250.00 E10000.00

;M201 X4500.00 Y4500.00 Z250.00 E10000.00

;M906 X920 Y990 Z800 E1050 I100 ; set motor currents (mA) and motor idle factor in per cent

M906 X920 Y1050 Z800 E1050 I100 ; set motor currents (mA) and motor idle factor in per cent

M564 H0 ; allow unhomed movement

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y-4 Z0 S1 ; set axis minima

M208 X250 Y210 Z200 S0 ; set axis maxima

; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y1 S3 ; configure sensorless endstop for low end on Y

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M915 X S30 H150 R0

;M915 Y S30 H150 R0

M915 Y S65 H150 R0

; Z-Probe

;M558 P1 C"io3.in+io3.out" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

;G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

;M557 X15:215 Y11:195 S20 ; define mesh grid

; Z-Probe PINDA

M574 Z1 S2 ; Above at EndstopsSet endstops controlled by probe

;M558 P5 C"io3.in" I1 H0.7 F1000 T6000 A20 S0.005 ; PINDA

M558 P5 C"io3.in" I1 H1.0 F1000 T8000 A20 S0.005 ; PINDA H dive height old

M558 P5 C"io3.in" I1 H1.4 F1000 T8000 A20 S0.005 ; PINDA H dive height

;M558 P5 C"io3.in" I1 H1 F1000 T6000 A20 ; PINDA

;M558 P5 C"io3.in" I1 H1.5 F600 T8000 A20 S0.03 ; PINDA

M308 S2 P"temp2" A"PINDA" Y"thermistor" T100000 B3950

;G31 P1000 X23 Y5 Z0.837 ; PEI Sheet Offset C0.0010 S20 H2 original

;G31 P1000 X23 Y5 Z0.870 ; PEI Sheet Offset C0.0010 S20 H2

;G31 P1000 X23 Y5 Z0.855 ; PEI Sheet Offset C0.0010 S20 H2

;G31 P1000 X23 Y5 Z1.315 ; Textured Sheet Offset

;G31 P500 X23 Y5 Z0.630 ;trigger height Octoprint sheet

;G31 P1000 X23 Y12 Z1.130 ;trigger height Octoprint sheet

;G31 P1000 X23 Y5 Z0.738 S21 H2 T0.02 ; Nozzle offset - Powder Coated Sheet with temperature compensation (0.02mm/°C)

;G31 P1000 X23 Y5 Z1.130 S21 H2 T0.02 ; Nozzle offset - Zirflex. Powder Coated Sheet with temperature compensation (0.02mm/°C)

;G31 P1000 X23 Y5 Z1.06 S21 H2 T0.02 ; Nozzle offset - Satin Powder Coated Sheet with temperature compensation (0.02mm/°C)

;M557 X24:221 Y10:195 P3 ; Define mesh grid

M557 X36:244 Y14:208 P5 ; Define mesh grid

;M557 X12:220 Y5:197 P3 ; Define mesh grid

; ##### Z-Probe Settings for PINDA 2

;M558 P5 C"io2.in" I1 H1 F1000 T6000 A3 ; Prusa PindaV2 Endstop

;M308 S2 P"temp2" A"Pinda V2" Y"thermistor" T100000 B3950 ; Prusa PindaV2 Thermistor

M376 H5 ; Fade height 5mm

; Heaters

M308 S0 P"temp0" A"MK52" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 R0.22 ; disable bang-bang mode for the bed heater and set PWM limit 21s for 5 degrees

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" A"Volcano" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out2" T1 ; create nozzle heater output on out2 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F0 C"out5" Q100 ; create fan 0 on pin out3 and set its frequency

M106 P0 C"Part Cooling" S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out6" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P1 C"Revo Fan" S255 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

M556 S100 X0,586

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

T0 ; select first tool

; Default config.g template for DuetPi

; Replace this with a proper configuration file (e.g from https://configtool.reprapfirmware.org)

; Display initial welcome message

;M291 P"Please go to <a href=""https://www.duet3d.com/StartHere"" target=""_blank"">this</a> page for further instructions on how to set it up." R"Welcome to your new Duet 3!" S1 T0

M98 P"mksmini12864.g"

M98 P"/sys/surface.g"

;G4 S30

;M999