Hi guys,

I'm trying to iron out some issues from my end gcode in Cura. I run RRF 2.05.1 and I do have the gcode flavour set to RRF.

At the end of a print I want to retract, move Z up 5mm from the relative position, move X and Y to min and Z to max, turn the extruder to 0C (so I don't cook the filament in the nozzle even if I'm not there immediately), and get a message that asks me if I want to cool down the printer. If yes, I want to turn the part-cooling fan on so the hotend can cool down faster, and if no, (for example if I'm going to start another print job and there is no point in cooling the hotend down) I want nothing to happen.

The current gcode is as follows:

G1 E-2 F1800; retract

G91; relative positioning

G1 Z5 F1800 ; lift Z relative to current position

G90; absolute positioning

G1 X5 F6000; move to X min

G1 Y5 F6000; move to Y min

G1 Z150 F1800; move to Z max

G10 R0 S0; turn extruder heater off

M291 P"Do you want to cool down the printer?" S3

G10 R50 S50; set extruder temp to 50C

M106 S255; turn part-cooling fan on

M116; wait

G10 R0 S0; turn extruder heater off

M106 S0; turn part-cooling fan off

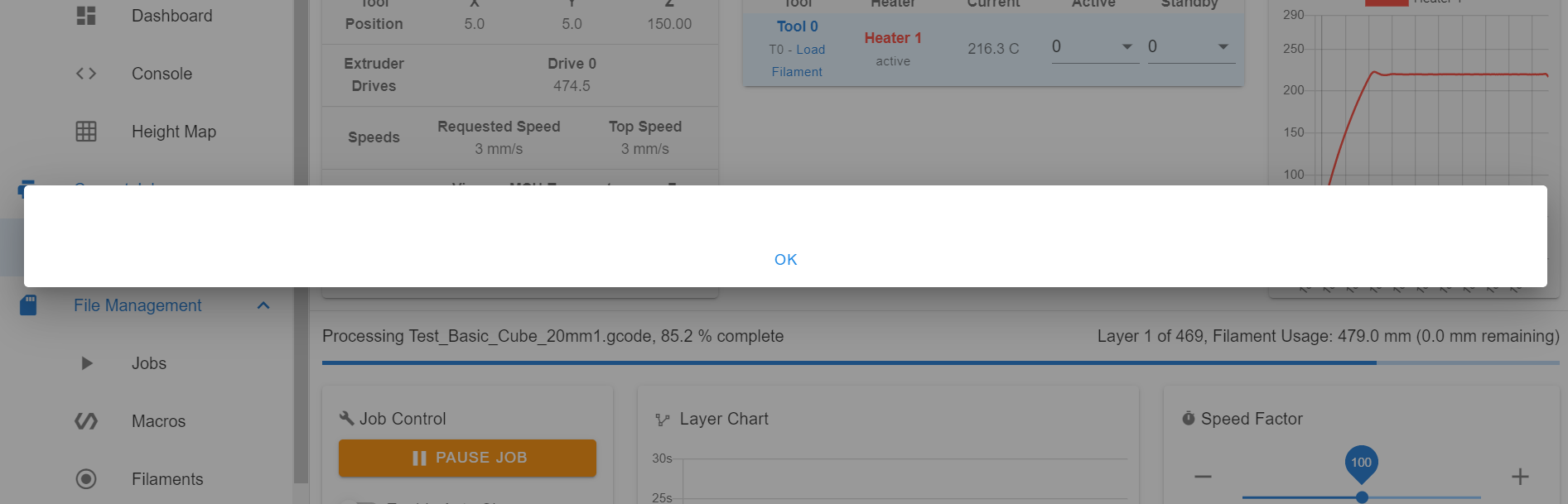

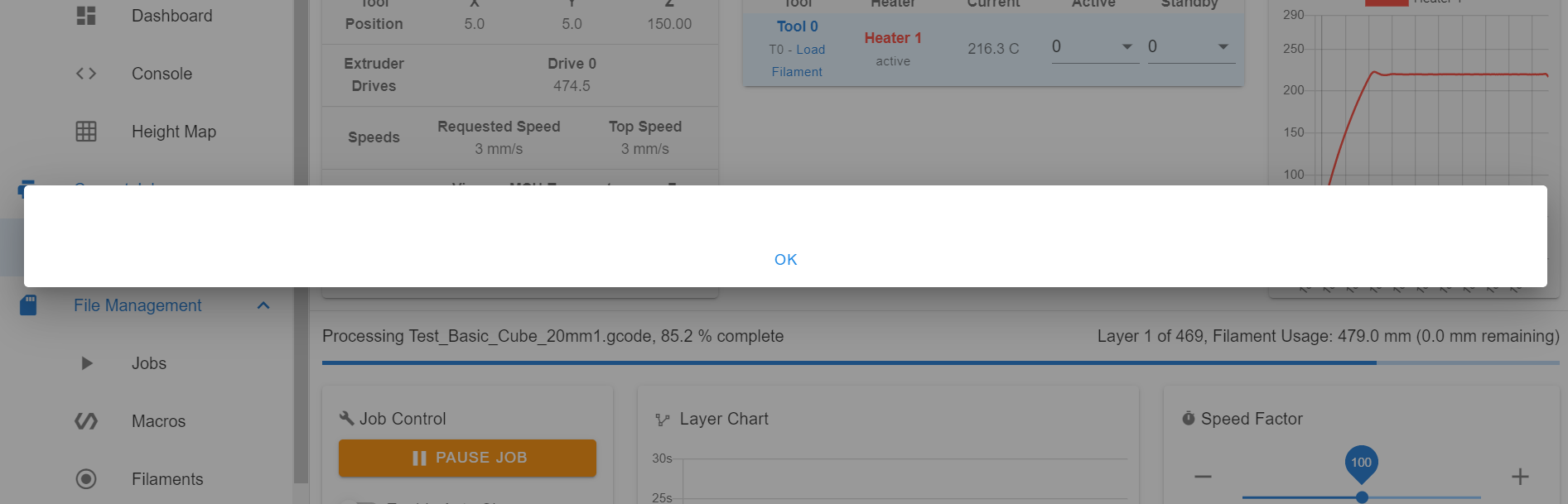

The first issue is that I dont get the "OK" and "Cancel" options on the pop-up message to cool down the printer as M291 S3 would suggest.

Pic:

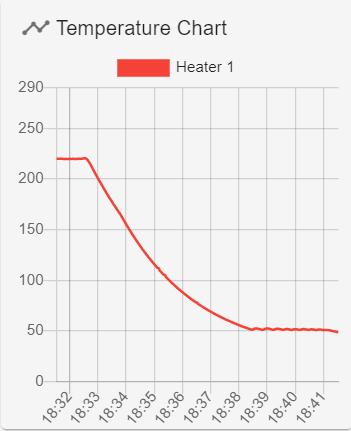

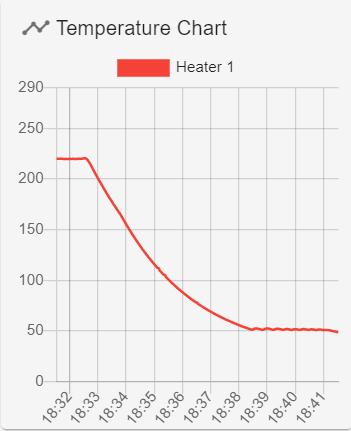

The second issue is that when I do decide to cool down the printer, the hotend goes down to about 51-52C and heats up to about 53-54C and starts to bounce up and down at about that temp for about 5 min. I have an original E3D v6, that has been PID tuned at 220C in addition to using the correct E3D settings in config.g

Pic:

Thanks to all who try and help!

Best!