Hi,

are there plans to implement input shapers for CAN extensions, such as 1HCL, in the future?

Thanks.

Latest posts made by ErlerPrint3D

-

input shaper for Expansion 1HCLposted in Firmware wishlist

-

RE: Data Collection and Reporting for DWCposted in Duet Web Control

@T3P3Tony

Thank you for your quick reply. I find the visualization of the data very exciting, but I have no idea how to implement it. Can you please send me the link to the blog post.Has anyone from the community already implemented this?

-

Closed loop tuning with multi-driver axisposted in Firmware wishlist

Hi,

I am currently building a large 3D printer with an axis system like the one used in the Annex-Engineering K3 (https://www.youtube.com/watch?v=75OxlE8eso8&ab_channel=AnnexEngineering). This means 2 axes for X and Y. The axes should run with quadrature encoders in closed loop mode (Duet 3 Expansion 1HCL). As I currently have to calibrate each motor individually and my system is relatively stiff, so I get backlash values of 0.25-0.35 (firmeware limited is 0.22) for the calibration movement (M569.6 P50.0 V1). Depending on where the machining head is positioned, the resistance for the motor is lower and I was also able to achieve values of 0.2. But I can't do that for every motor. I also use the maximum current for the motors and have also tried to calibrate a motor when all others are currentless to exclude the counter forces but without success.Does anyone have any experience with this or any ideas what else I could try?

@dc42: Will it be possible in the future to calibrate axes with 2 motors at the same time?

-

Data Collection and Reporting for DWCposted in Duet Web Control

Hello everyone,

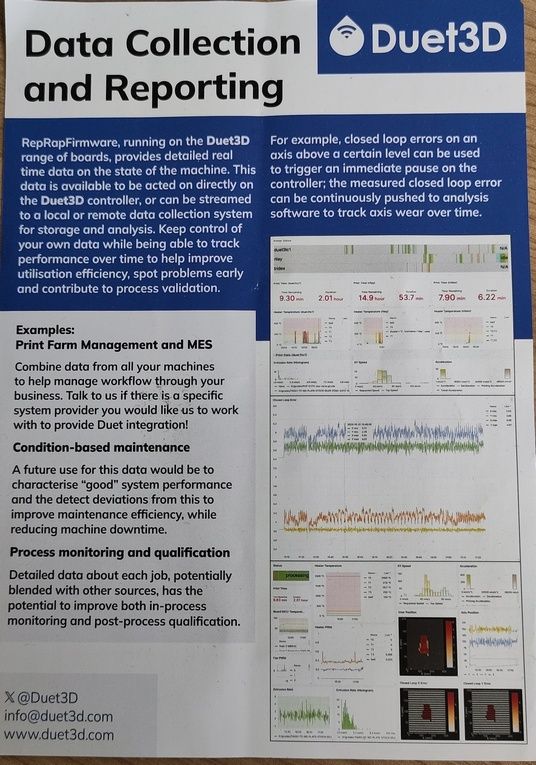

I was at Formnext 2023 in November and took the flyer for data collection and reporting from the Duet3D stand (see the image below). I am currently building an axis system with a measuring system (Duet 3 Expansion 1HCL) and would like to use the visualization of the encoder data, but I can't find anything about it anywhere.

Has anyone already used this or will it only be available in the future?

-

RE: Read Voltage from Heatbed Power INposted in General Discussion

@bricor Thanks for your answer. As I said, I have tested it with M308 and it would be a solution, but I ask myself if there is another way. For example via the free Power IN. In addition, all inputs (I0_0 to IO_8) are used for endstops. Therefore I am looking for another input.

-

RE: Read Voltage from Heatbed Power INposted in General Discussion

@ErlerPrint3D

I have already tested:M308 S18 P "io3.in" Y "linear-analog" A "MySensor" F0

It works well but you have to convert the voltage from 0-10V to 0-3.3V. And I would like to avoid that.

-

Read Voltage from Heatbed Power INposted in General Discussion

Hello everyone,

I am looking for a way to read in an analog signal of 0-10V from a distance sensor and display it. I use the Duet 3 Mainboard 6HC and build a laser powder 3d printer. I don't need a heating bed for this and my idea is to use the free OUT 0 POWER IN for the analog signal. Is there any way to read out the voltage value. I have not found anything in the documentation.

Thanks -

RE: Short circuit on TMC stepper driverposted in Duet Hardware and wiring

I removed the stepper driver from board (but I used a small side cutter) und the Wifi is now stable.

With M569 P3 R-1 i disabled the driver and now i get no more error message.

Thanks for your help -

RE: Short circuit on TMC stepper driverposted in Duet Hardware and wiring

yes, i get also that error message when the E0 motor is disconnected. Do you think that after the removing of the stepper driver the wifi works correctly again?