Hi, thank you again for your help with this. It seems the issue was that the wrong angle was defined in the macro for the Coupler unlock - so it was calling it and rotating it to the wrong spot. I did some adjustments to the unlock macro and it seems to now home to the right spot! Thanks again for your help, it is much appreciated. Best, Emma

Best posts made by eyperry

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

Latest posts made by eyperry

-

RE: Toolhead Calibration Values Changingposted in My Duet controlled machine

@phaedrux Hi, I was wondering if you have had a chance to look at the files I have shared below? I would be really grateful for your further help as I am still facing this problem. Thank you again for your further time and assistance. Best, Emma

-

RE: Toolhead Calibration Values Changingposted in My Duet controlled machine

@phaedrux

Hi thank you for getting back to me. When I run M98 P'config.g' it tells me there is no macro file even though there is one in the list of files. If i run M98 Pconfig.g it resets the wifi access point and the access point does not work anymore. So I have to roll back to older files.The result of M122 is:

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet WiFi 1.02 or later + DueX5

Board ID: 08DLM-996RU-N8PS4-6J9F4-3S86N-1AUZN

Used output buffers: 3 of 24 (17 max)

=== RTOS ===

Static ram: 23876

Dynamic ram: 77720 of which 0 recycled

Never used RAM 12820, free system stack 184 words

Tasks: NETWORK(ready,13.7%,237) HEAT(delaying,0.0%,330) Move(notifyWait,0.1%,319) DUEX(notifyWait,0.0%,24) MAIN(running,85.8%,395) IDLE(ready,0.4%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:01:44 ago, cause: power up

Last software reset details not available

Error status: 0x00

Step timer max interval 0

MCU temperature: min 32.2, current 33.1, max 33.7

Supply voltage: min 24.2, current 24.3, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 0, standstill, SG min/max not available

Driver 1: position 0, standstill, SG min/max not available

Driver 2: position 0, standstill, SG min/max not available

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0, standstill, SG min/max not available

Driver 6: position 0, standstill, SG min/max not available

Driver 7: position 0, standstill, SG min/max not available

Driver 8: position 0, standstill, SG min/max not available

Driver 9: position 0, standstill, SG min/max not available

Driver 10: position 0

Driver 11: position 0

Date/time: 2021-09-07 11:44:58

Cache data hit count 3837611636

Slowest loop: 20.74ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 3.8ms, write time 6.4ms, max retries 0

=== Move ===

DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== DueX ===

Read count 0, 0.00 reads/min

=== Network ===

Slowest loop: 201.72ms; fastest: 0.09ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8- WiFi -

Network state is active

WiFi module is providing access point

Failed messages: pending 0, notready 0, noresp 1

WiFi firmware version 1.23

WiFi MAC address f6:cf:a2:66:49:81

WiFi Vcc 3.42, reset reason Turned on by main processor

WiFi flash size 4194304, free heap 23264

WiFi IP address 10.22.99.163

Connected clients 1

Clock register ffffffff

Socket states: 4 0 0 0 0 0 0 0

My config file is:

; Configuration file for Duet WiFi / Ethernet running RRF3 on E3D Tool Changer

; executed by the firmware on start-up; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin; Network

M550 P"ToolChanger" ; Set machine name

;M587 S"ssid" P"password" ; WiFi Settings

;M552 S1 P"ssid" ; Enable WiFi Networking

M552 S1 ; Enable Networking

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable TelnetM667 S1 ; Select CoreXY mode

; Drive direction

M569 P0 S0 ; Drive 0 X

M569 P1 S0 ; Drive 1 Y

M569 P2 S1 ; Drive 2 Z

M569 P3 S0 ; Drive 3 E0

M569 P4 S0 ; Drive 4 E1

M569 P5 S1 ; Drive 5 E2

M569 P6 S1 ; Drive 6 E3

M569 P7 S0 ; Drive 7 COUPLER

M569 P8 S0 ; Drive 8 UNUSED

M569 P9 S0 ; Drive 9 UNUSEDM584 X0 Y1 Z2 C7 E3:4:5:6 ; Apply custom drive mapping

M208 X-35:328.5 Y-49:243 Z0:300 C0:500 ; Set axis maxima & minima

M92 X100 Y100 Z1600 C200 E834:834:834:834 ; Set steps per mm assuming x16 microstepping

M350 E16:16:16:16 I1 ; Configure microstepping with interpolation

M350 C16 I10 ; Configure microstepping without interpolation

M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation

M566 X400 Y400 Z8 C2 E2:2:2:2 ; Set maximum instantaneous speed changes (mm/min)

M203 X35000 Y35000 Z1200 C10000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X6000 Y6000 Z400 C500 E2500:2500:2500:2500 ; Set accelerations (mm/s^2)

M906 X1800 Y1800 Z1330 C400 I30 ; Idle motion motors to 30%

M906 E1000:1000:1000:1000 I10 ; Idle extruder motors to 10%; Endstops

M574 X1 Y1 S3 ; Set X / Y endstop stall detection

M574 Z0 ; No Z endstop

M574 C1 S3 ; Stall detect coupler at low end of its range; Z probe

M558 P8 C"zstop" H3 F360 I0 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height

M557 X10:290 Y20:180 S40 ; Define mesh grid;Stall Detection

M915 C S6 F0 H200 R4700 ; Coupler;Stall Detection

M915 X Y S3 F0 H400 R4700 ; X / Y Axes; Heaters

M308 S0 P"bedtemp" Y"thermistor" A"Bed" T100000 B4138 C0 ; Set thermistor

M950 H0 C"bedheat" T0 ; Bed heater

M143 H0 S225 ; Set temperature limit for heater 0 to 225C

M140 H0 ; Bed heater is heater 0M308 S1 P"e0temp" Y"thermistor" A"T0" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H1 C"e0heat" T1 ; Extruder 1 heater

M143 H1 S305 ; Set temperature limit for heater 1 to 300CM308 S2 P"e1temp" Y"thermistor" A"T1" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H2 C"e1heat" T2 ; Extruder 2 heater

M143 H2 S305 ; Set temperature limit for heater 2 to 300CM308 S3 P"e2temp" Y"thermistor" A"T2" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H3 C"duex.e2heat" T3 ; Extruder 3 heater

M143 H3 S305 ; Set temperature limit for heater 3 to 300C; M308 S4 P"e3temp" Y"thermistor" A"T3" T100000 B4725 C7.06e-8 ; Set thermistor

; M950 H4 C"duex.e3heat" T4 ; Extruder 4 heater

; M143 H4 S305 ; Set temperature limit for heater 4 to 300C; Tools

M563 P0 S"T0" D0 H1 F2 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets

G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0CM563 P1 S"T1" D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets

G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0CM563 P2 S"T2" D2 H3 F6 ; Define tool 2

G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets

G10 P2 R0 S0 ; Reset initial tool 2 active and standby temperatures to 0CM563 P3 S"T3" D3 H4 F8 ; Define tool 3

G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets

G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C; Fans

M950 F1 C"fan1"

M950 F2 C"fan2"

M950 F3 C"duex.fan3"

M950 F4 C"duex.fan4"

M950 F5 C"duex.fan5"

M950 F6 C"duex.fan6"

M950 F7 C"duex.fan7"

M950 F8 C"duex.fan8"M106 P1 S255 H1 T70 ; T0 HE

M106 P2 S0 ; T0 PCF

M106 P3 S255 H2 T70 ; T1 HE

M106 P4 S0 ; T1 PCF

M106 P5 S255 H3 T70 ; T2 HE

M106 P6 S0 ; T2 PCF

; M106 P7 S255 H4 T70 ; T3 HE

; M106 P8 S0 ; T3 PCFM593 F50 ; cancel ringing at 50Hz (https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/)

;M376 H15 ; bed compensation taper;tool offsets

; !ESTIMATED! offsets for:

; V6-tool: X-9 Y39 Z-5

; Volcano-tool: X-9 Y39 Z-13.5

; Hemera-tool: X-37.5 Y43.5 Z-6G10 P0 X-9 Y39 Z-5.062 ; T0

G10 P1 X-9 Y39 Z-5.039 ; T1

G10 P2 X-9 Y39 Z-13.5 ; T2

G10 P3 X-1.5 Y37.9 Z-38.21 ; T3

; ;;;;;;; Y40.4????;deselect tools

T-1;M572 D0 S0.2 ; pressure advance T0

;M572 D1 S0.2 ; pressure advance T1

;M572 D2 S0.2 ; pressure advance T2

;M572 D3 S0.2 ; pressure advance T3M501; load config-override.g

M98 P"/macros/define_glob.g"

; Added by Soph to create access point

M98 P"accesspoint.g"Example E0 toolchange file:

; tpre0.g

; called before tool 0 is selected;Unlock Coupler

M98 P"/macros/Coupler - Unlock";Move to location

G1 X-13.5 Y200 F50000;Move in

G1 X-13.5 Y220 F50000;Collect

G1 X-13.5 Y226.5 F2500;Close Coupler

M98 P"/macros/Coupler - Lock";WARNING! WARNING! WARNING! WARNING! WARNING! WARNING! WARNING! WARNING! WARNING! WARNING! WARNING! WARNING!

;if you are using non-standard length hotends ensure the bed is lowered enough BEFORE undocking the tool!

G91

G1 Z10 F1000

G90;Move Out

G1 X-13.5 Y150 F4000The homing files I have are the ones from the rrf3 - I modified the angle on in the lock and unlock Coupler macros to ensure that the toolchanger bar is horizontal and vertical for unlock and lock positions (as before they were slightly offset with the angles used inthe original macro).

I hope this clarifies and thank you again for taking a look at this!

Best,

Emma

- WiFi -

-

Toolhead Calibration Values Changingposted in My Duet controlled machine

Hi, I was wondering if I could get some help. I have been following the toolchange calibration process in this video: https://www.youtube.com/watch?v=37thDl6TVnw.

Once I completed the process and ran the toolchange_test.gcode. This worked the first time. I then ran it a second time and the toolhead moved backwards with the E3 extruder still attached.

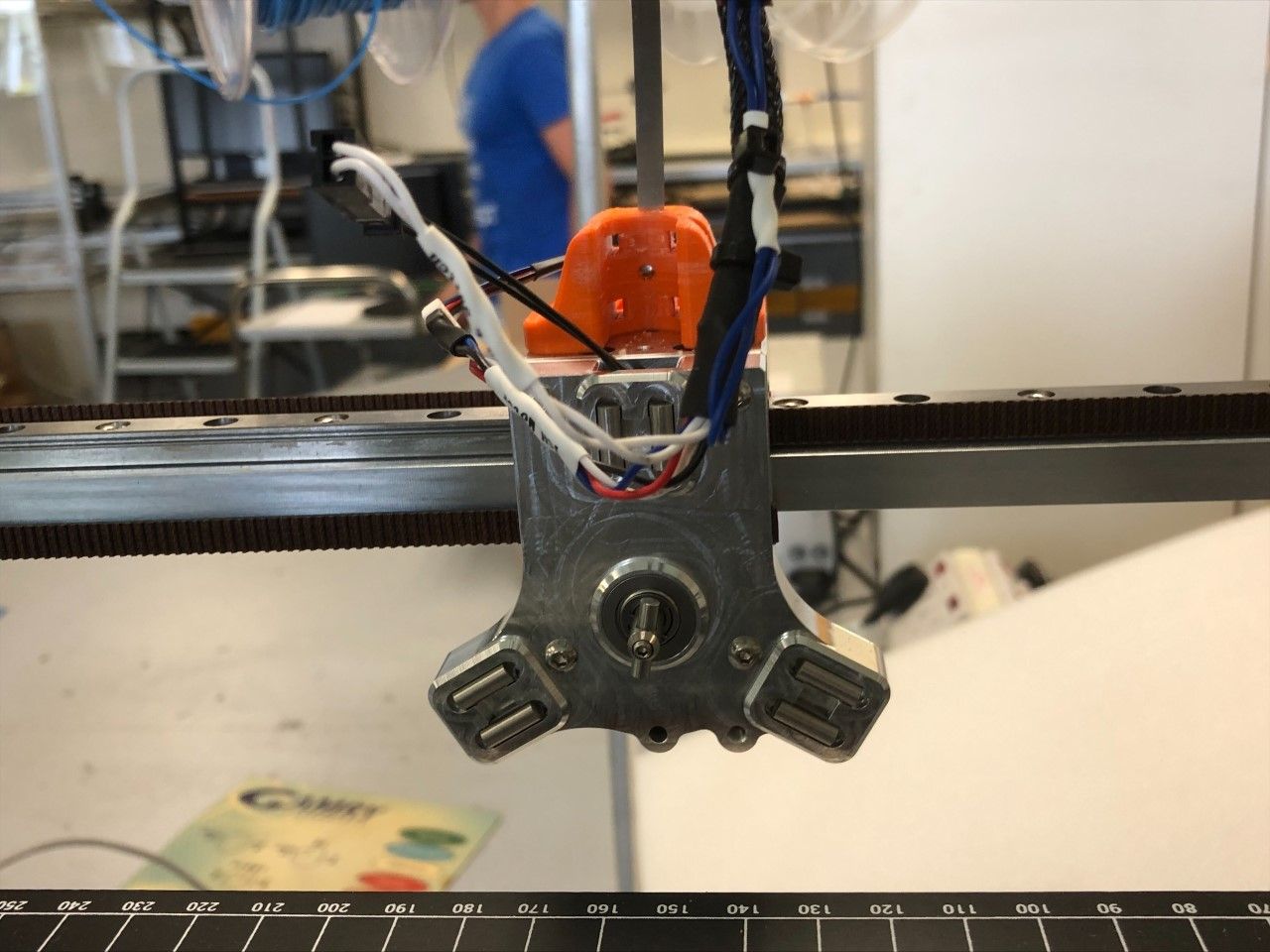

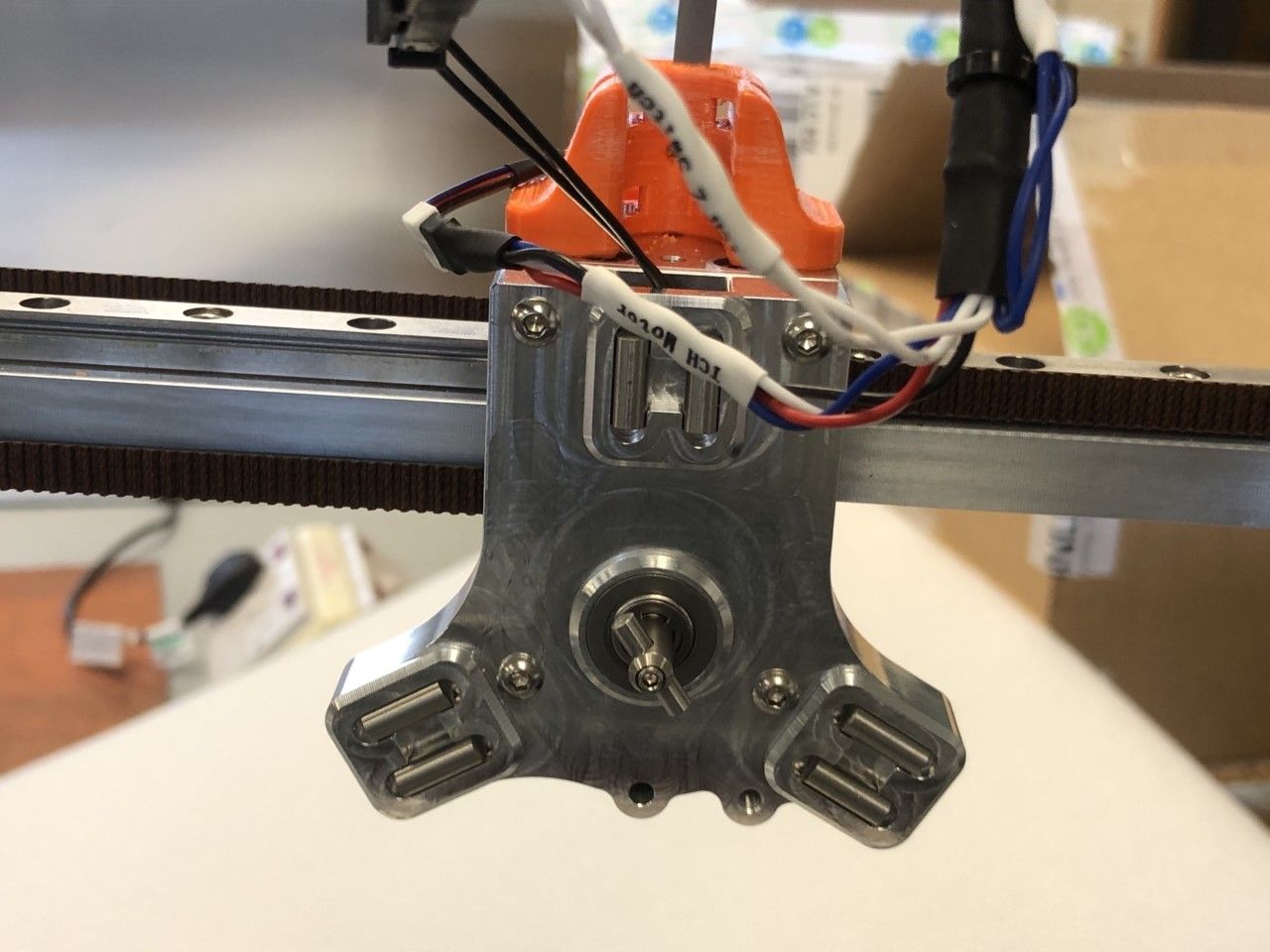

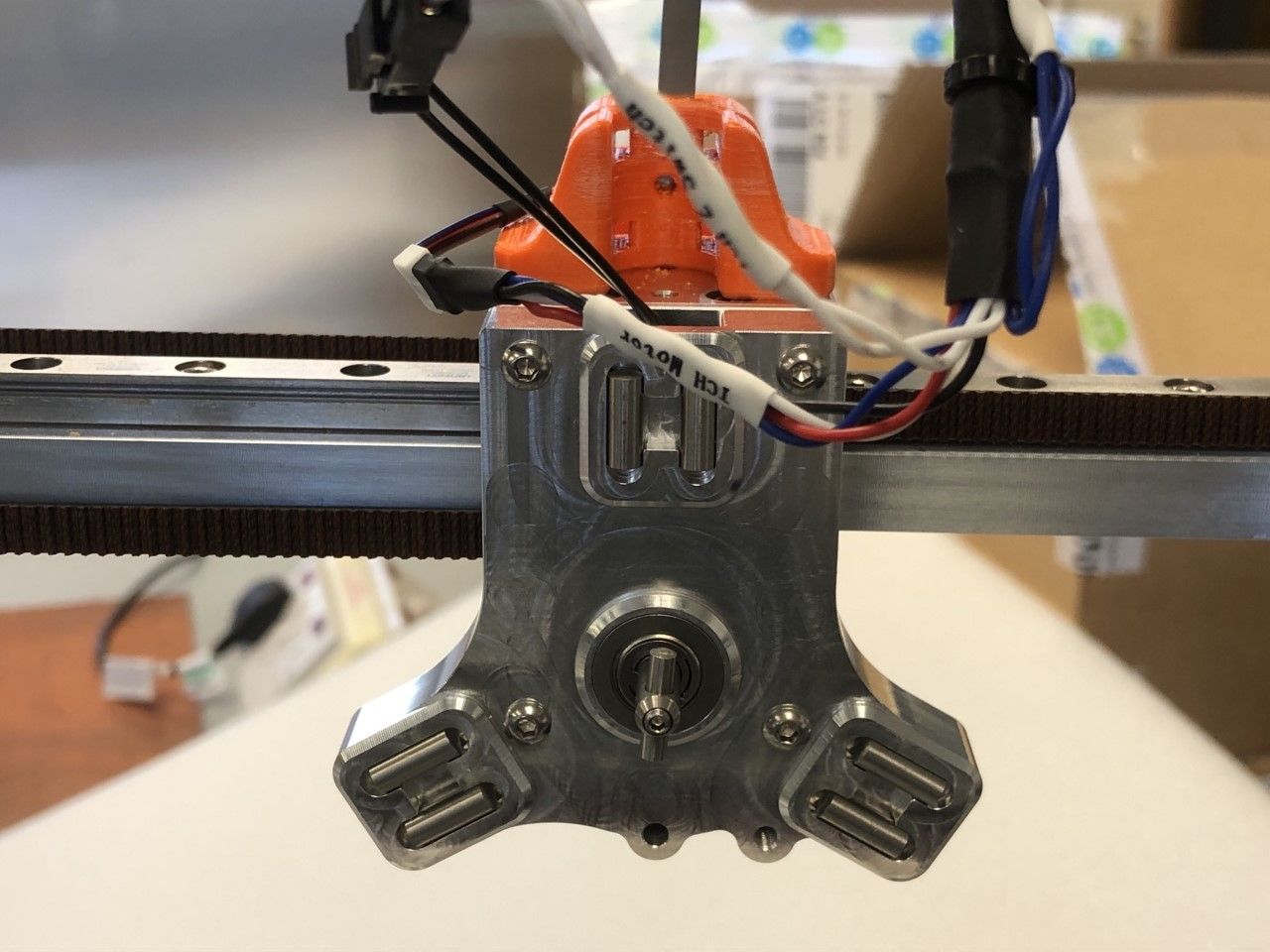

I noticed that the coupler was no longer horizontal, and no longer vertical.

I homed the machine again and then modified the C values for the angle of the coupler for unlock and lock in the Coupler-lock and Coupler-unlock macros. I homed the machine again and I get a nice horizontal homed position.

I repeated the process for my E0 extruder and I am finding the same problem - the unlock is no longer horizontal and the toolhead removes the E0 extruder with it.

I was wondering if I could get some help? I am not sure if maybe I have done something wrong, and after repeating the process a few times now I am at a loss.

Thanks in advance for your help.

Best,

Emma

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

Hi, thank you again for your help with this. It seems the issue was that the wrong angle was defined in the macro for the Coupler unlock - so it was calling it and rotating it to the wrong spot. I did some adjustments to the unlock macro and it seems to now home to the right spot! Thanks again for your help, it is much appreciated. Best, Emma

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

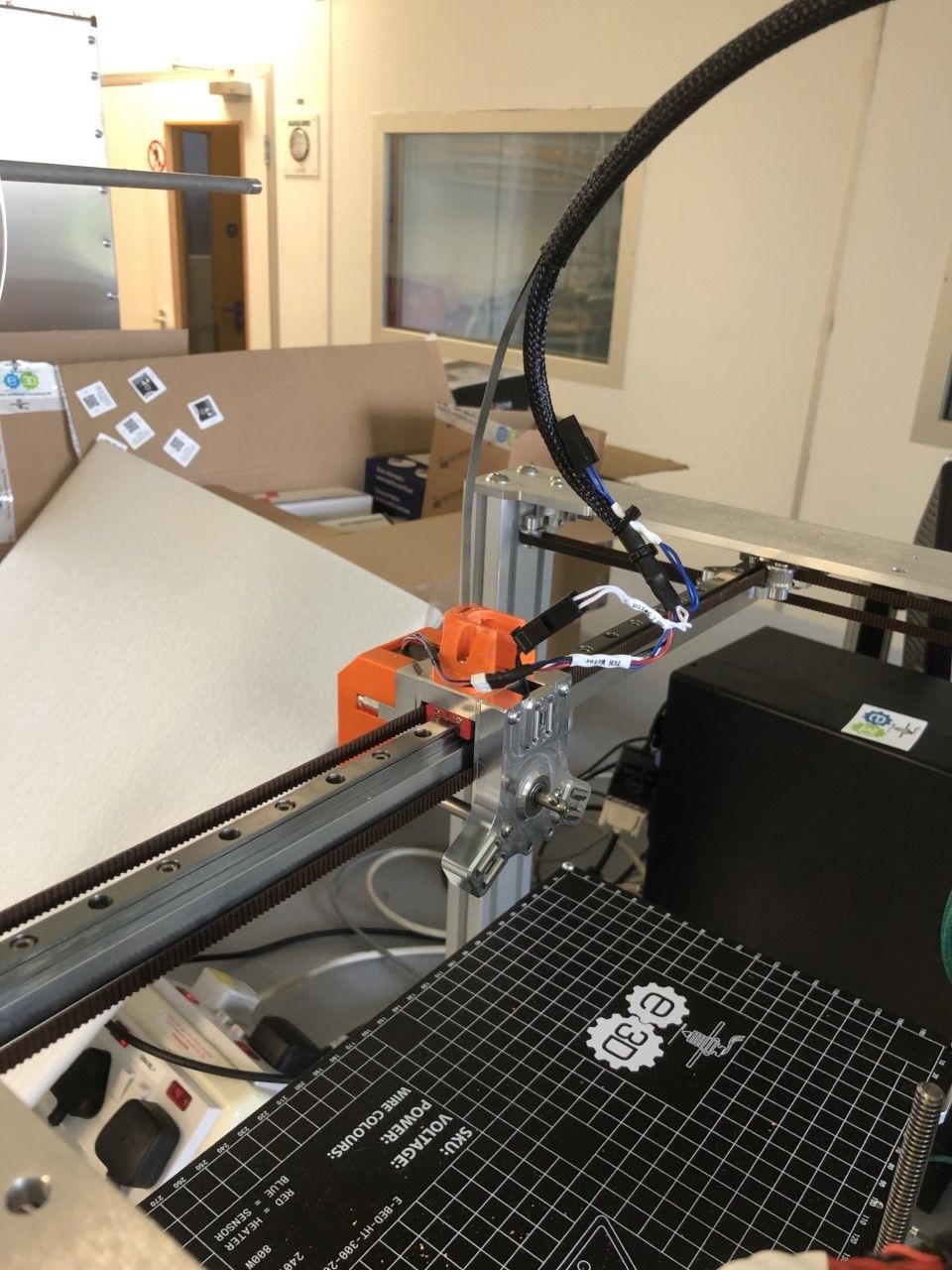

@eyperry Further to my previous message I note I was using the rrf3.x files. I tried also just now to use the rrf2.x files and I got a better result but the coupler unlock and lock positions are still slightly off centre (albeit better than before). I have attached photos of this below.

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

@dc42 Hi, thanks for getting back to me. When I press the Home C, it rotates clockwise to the same position as shown in your photograph, and then it rotates anticlockwise to the position in the first image I shared.

I only get the vertical position when I run the coupler lock macro. When I run the coupler unlock macro I get the same position as in the first image I shared again.

Thanks again for looking at this!

Best,

Emma

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

@eyperry Hi, thank you so much for your help with the firmware update - it is finally now updated and the Z stop is working. I have however now run into another issue - do I need to post this as a new post? My issue is that now when I home the coupler C, it does not go into a horizontal position. When I run the Coupler-Lock macro the coupler is vertical as expected, but when I run Coupler-Unlock macro it is not horizontal. Would you be able to help? Thanks again in advance. Best, Emma

I have attached images of the two positions below so you can see it is not horizontal.

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

Hi,

Thank you for getting back to me.

Yes the LED goes out when I press the z switch.

When I ran M98 P"config.g" on YAT it seems to remove the access point I had kell5568 and changes it to DuetSSID which I cannot access as I do not have the network access key, but I get the below after disabling and renabling the Wifi.

M552 S2

ok<LF>WiFi module is providing access point kell5568, IP address 10.22.99.163<LF>M98P"config.g"

Turn off the current WiFi mode before selecting a new one<LF>HTTP is enabled on port 80<LF>FTP is disabled<LF>TELNET is disabled<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>Warning: Macro file config-override.g not found.<LF>Warning: Macro file /macros/define_glob.g not found.<LF>WiFi module is idle<LF>ok<LF>WiFi module is providing access point DuetSSID, IP address 192.168.0.1<LF>M552 S0

ok<LF>WiFi module is idle<LF>M98P"config.g"

Error: Could not set WiFi hostname<LF>Failed to change WiFi mode (code -7)<LF>HTTP is enabled on port 80<LF>FTP is disabled<LF>TELNET is disabled<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>Warning: Macro file config-override.g not found.<LF>Warning: Macro file /macros/define_glob.g not found.<LF>M589: Failed to configure access point parameters<LF>Turn off the current WiFi mode before selecting a new one<LF>ok<LF>WiFi module started<LF>Error: Failed to initialise WiFi module, code -7<LF>M552 S2

ok<LF>WiFi module started<LF>WiFi module is providing access point DuetSSID, IP address 192.168.0.1<LF>M98 P"config.g"

Turn off the current WiFi mode before selecting a new one<LF>HTTP is enabled on port 80<LF>FTP is disabled<LF>TELNET is disabled<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M308 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>M950 command is not supported<LF>Warning: Macro file config-override.g not found.<LF>Warning: Macro file /macros/define_glob.g not found.<LF>WiFi module is idle<LF>ok<LF>WiFi module is providing access point DuetSSID, IP address 192.168.0.1<LF>When I send M558 i get:

M558

Z Probe type 8, input 0, invert no, dive height 3.0mm, probe speed 360mm/min, travel speed 20000mm/min, recovery time 0.00 sec, heaters normal, max taps 1, max diff 0.03<LF>ok<LF>Thanks again in advance for your help.

Best,

Emma

-

RE: Update firmware direct to SD card or using access point helpposted in Firmware installation

Thank you. The firmware version it is running is 2.05.1 and the electronics is Duet WiFi 1.02 or later + DueX5 Firmware date 2020-02-09b1 - is there something different I need to do to update these?

-

RE: Z-Probe sensor stuck at 1000posted in Duet Hardware and wiring

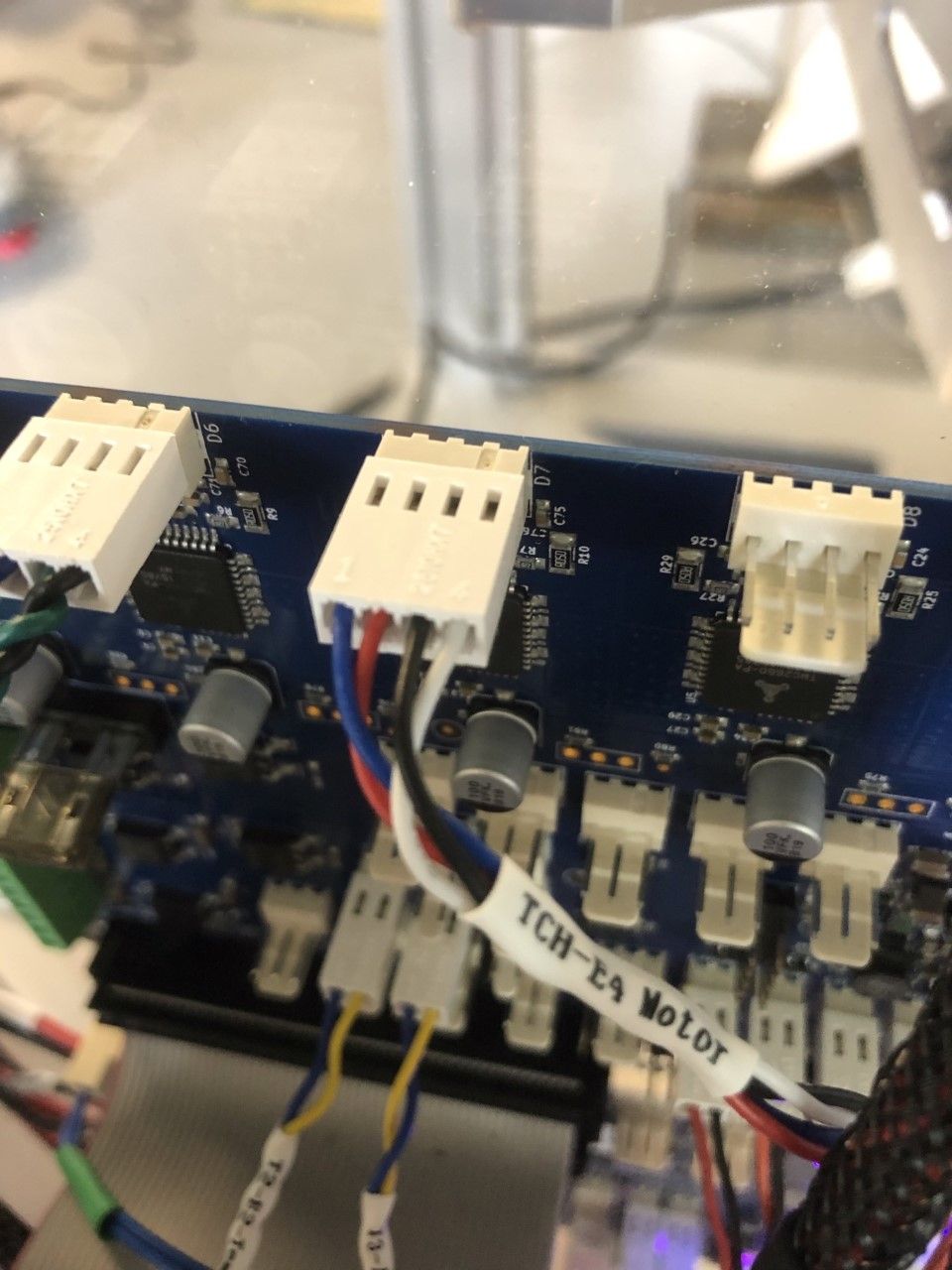

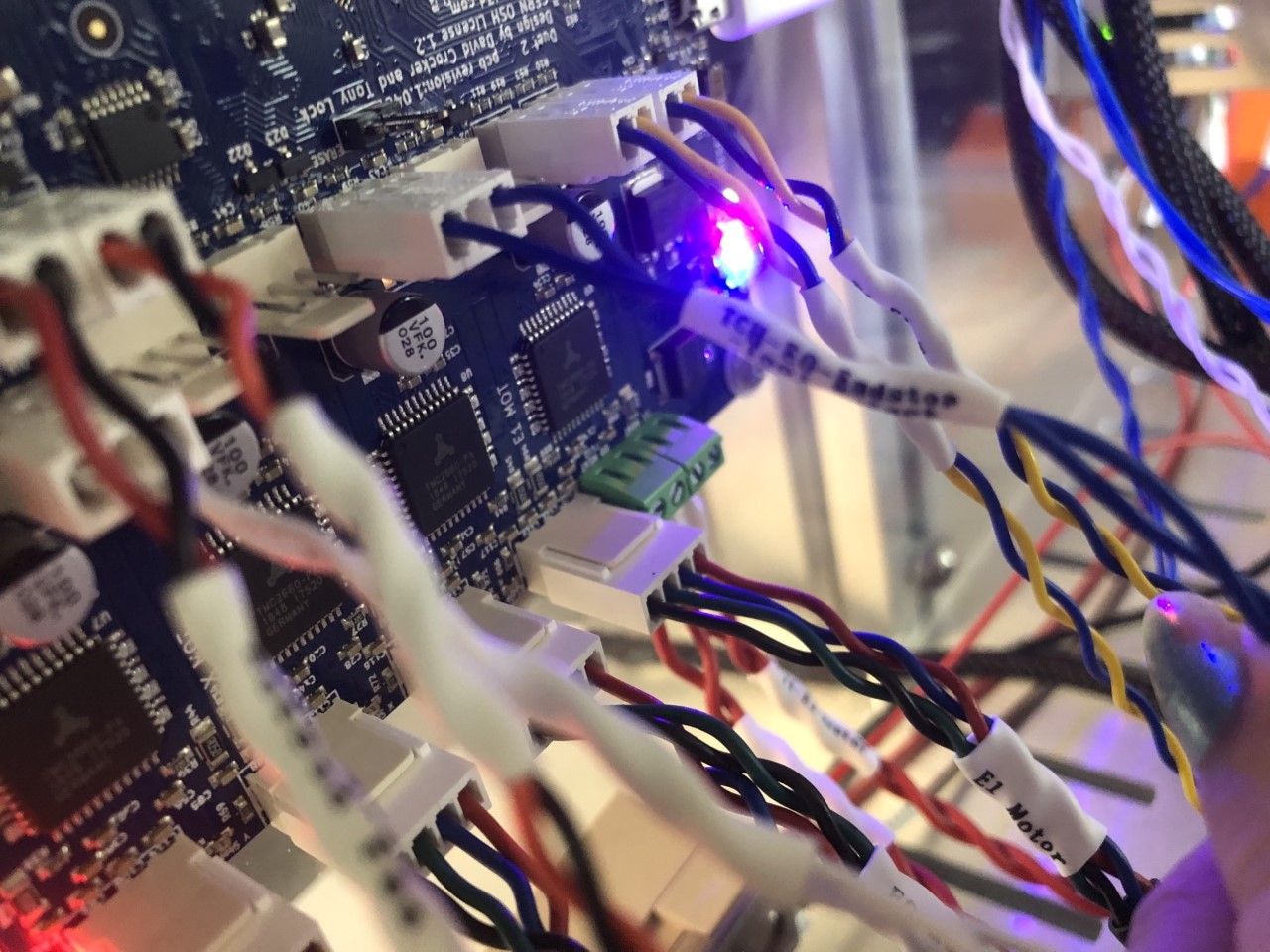

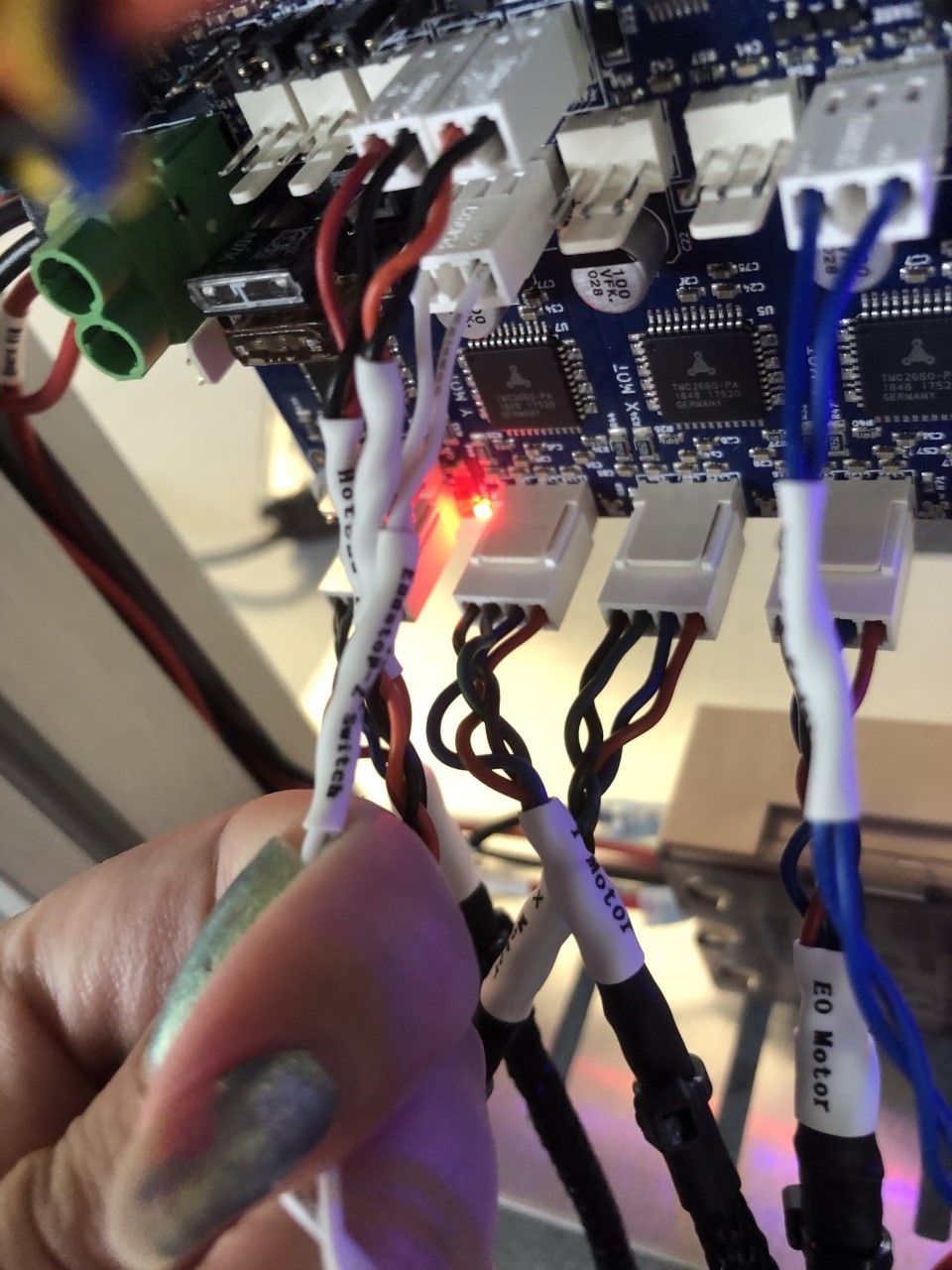

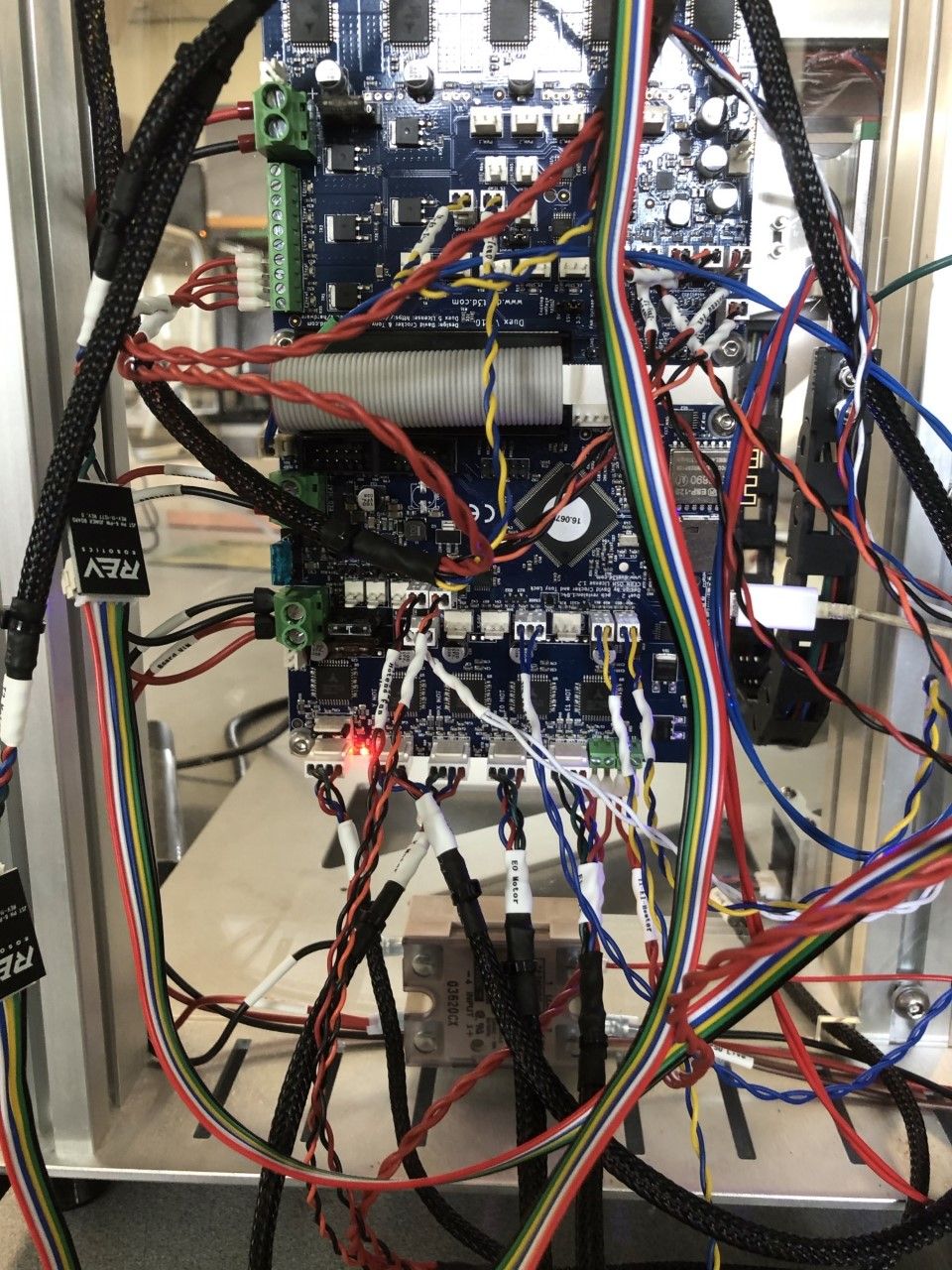

@kb58 Hi thank you for getting back to me. I have attached my config file below as well as photographs of the wiring of the toolchanger head. If you would be able to have a look and assist further it would be much appreciated. Thanks! Best, Emma

; Configuration file for Duet WiFi / Ethernet running RRF3 on E3D Tool Changer

; executed by the firmware on start-up; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin; Network

M550 P"ToolChanger" ; Set machine name

;M587 S"ssid" P"password" ; WiFi Settings

;M552 S1 P"ssid" ; Enable WiFi Networking

M552 S1 ; Enable Networking

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable TelnetM667 S1 ; Select CoreXY mode

; Drive direction

M569 P0 S0 ; Drive 0 X

M569 P1 S0 ; Drive 1 Y

M569 P2 S1 ; Drive 2 Z

M569 P3 S0 ; Drive 3 E0

M569 P4 S0 ; Drive 4 E1

M569 P5 S1 ; Drive 5 E2

M569 P6 S1 ; Drive 6 E3

M569 P7 S0 ; Drive 7 COUPLER

M569 P8 S0 ; Drive 8 UNUSED

M569 P9 S0 ; Drive 9 UNUSEDM584 X0 Y1 Z2 C7 E3:4:5:6 ; Apply custom drive mapping

M208 X-35:328.5 Y-49:243 Z0:300 C0:500 ; Set axis maxima & minima

M92 X100 Y100 Z1600 C200 E834:834:834:834 ; Set steps per mm assuming x16 microstepping

M350 E16:16:16:16 I1 ; Configure microstepping with interpolation

M350 C16 I10 ; Configure microstepping without interpolation

M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation

M566 X400 Y400 Z8 C2 E2:2:2:2 ; Set maximum instantaneous speed changes (mm/min)

M203 X35000 Y35000 Z1200 C10000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X6000 Y6000 Z400 C500 E2500:2500:2500:2500 ; Set accelerations (mm/s^2)

M906 X1800 Y1800 Z1330 C400 I30 ; Idle motion motors to 30%

M906 E1000:1000:1000:1000 I10 ; Idle extruder motors to 10%; Endstops

M574 X1 Y1 S3 ; Set X / Y endstop stall detection

M574 Z0 ; No Z endstop

M574 C1 S3 ; Stall detect coupler at low end of its range; Z probe

M558 P8 C"zstop" H3 F360 I0 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height

M557 X10:290 Y20:180 S40 ; Define mesh grid;Stall Detection

M915 C S6 F0 H200 R4700 ; Coupler;Stall Detection

M915 X Y S3 F0 H400 R4700 ; X / Y Axes; Heaters

M308 S0 P"bedtemp" Y"thermistor" A"Bed" T100000 B4138 C0 ; Set thermistor

M950 H0 C"bedheat" T0 ; Bed heater

M143 H0 S225 ; Set temperature limit for heater 0 to 225C

M140 H0 ; Bed heater is heater 0M308 S1 P"e0temp" Y"thermistor" A"T0" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H1 C"e0heat" T1 ; Extruder 1 heater

M143 H1 S305 ; Set temperature limit for heater 1 to 300CM308 S2 P"e1temp" Y"thermistor" A"T1" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H2 C"e1heat" T2 ; Extruder 2 heater

M143 H2 S305 ; Set temperature limit for heater 2 to 300CM308 S3 P"e2temp" Y"thermistor" A"T2" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H3 C"duex.e2heat" T3 ; Extruder 3 heater

M143 H3 S305 ; Set temperature limit for heater 3 to 300C; M308 S4 P"e3temp" Y"thermistor" A"T3" T100000 B4725 C7.06e-8 ; Set thermistor

; M950 H4 C"duex.e3heat" T4 ; Extruder 4 heater

; M143 H4 S305 ; Set temperature limit for heater 4 to 300C; Tools

M563 P0 S"T0" D0 H1 F2 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets

G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0CM563 P1 S"T1" D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets

G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0CM563 P2 S"T2" D2 H3 F6 ; Define tool 2

G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets

G10 P2 R0 S0 ; Reset initial tool 2 active and standby temperatures to 0CM563 P3 S"T3" D3 H4 F8 ; Define tool 3

G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets

G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C; Fans

M950 F1 C"fan1"

M950 F2 C"fan2"

M950 F3 C"duex.fan3"

M950 F4 C"duex.fan4"

M950 F5 C"duex.fan5"

M950 F6 C"duex.fan6"

M950 F7 C"duex.fan7"

M950 F8 C"duex.fan8"M106 P1 S255 H1 T70 ; T0 HE

M106 P2 S0 ; T0 PCF

M106 P3 S255 H2 T70 ; T1 HE

M106 P4 S0 ; T1 PCF

M106 P5 S255 H3 T70 ; T2 HE

M106 P6 S0 ; T2 PCF

; M106 P7 S255 H4 T70 ; T3 HE

; M106 P8 S0 ; T3 PCFM593 F50 ; cancel ringing at 50Hz (https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/)

;M376 H15 ; bed compensation taper;tool offsets

; !ESTIMATED! offsets for:

; V6-tool: X-9 Y39 Z-5

; Volcano-tool: X-9 Y39 Z-13.5

; Hemera-tool: X-37.5 Y43.5 Z-6G10 P0 X-9 Y39 Z-5.062 ; T0

G10 P1 X-9 Y39 Z-5.039 ; T1

G10 P2 X-9 Y39 Z-13.5 ; T2

G10 P3 X-1.5 Y37.9 Z-38.21 ; T3

; ;;;;;;; Y40.4????;deselect tools

T-1;M572 D0 S0.2 ; pressure advance T0

;M572 D1 S0.2 ; pressure advance T1

;M572 D2 S0.2 ; pressure advance T2

;M572 D3 S0.2 ; pressure advance T3M501; load config-override.g

M98 P"/macros/define_glob.g"

; Added by Soph to create access point

M98 P"accesspoint.g"