Thank you very much for your help. I changed the M84 in the config.g file to 20 and all is well. Please mark this resolved and again, a big thanks for the quick response.

Mark

Thank you very much for your help. I changed the M84 in the config.g file to 20 and all is well. Please mark this resolved and again, a big thanks for the quick response.

Mark

Sorry about the bad link. Here is the correct link for the video:

https://vimeo.com/456388566

config file:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X9000.00 Y9000.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z500.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X9000.00 Y9000.00 Z50.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X2200 Y2200 Z3200 E1800:1800 I0 ; set motor currents (mA) and motor idle factor in per cent

M84 S.5 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.59 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 170C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; set temperature limit for heater 1 to 450C

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S450 ; set temperature limit for heater 2 to 450C

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out9" T3 ; create bed heater output on out9 and map it to sensor 3

M141 H3 ; Define heater h3 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C

; Fans

;M950 F0 C"out8" ; create fan 0 on pin out8 and set its frequency

;M106 P0 C"fan + lights" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

;M563 P0 D0 H0 ; tool 0 uses extruder 0, heater 1 (and fan 0)

;M563 P1 D1 H1 ; tool 0 uses extruder 0, heater 1 (and fan 0)

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config override

M572 D0 S0.4 ; enable pressure advance

M572 D1 S0.4 ; enable pressure advance

Hello everyone,

I have been printing with my Duet 3 powered corexy for a couple of weeks and now I am having a "loop" where when I try to home, it resets to an unhomed state upon homing. If you do a single axis it does the same thing and flashes homed and then resets to unhomed. No errors on the console reported.

Short video of the homing issue:

https://vimeo.com/manage/456388566/general

Here is the M122:

9/9/2020, 6:07:29 PM m122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v0.6 or 1.0 (SBC mode)

Board ID: 08DJM-956L2-G43S4-6J9F2-3SJ6M-1A6UG

Used output buffers: 1 of 40 (13 max)

=== RTOS ===

Static ram: 154604

Dynamic ram: 163388 of which 20 recycled

Exception stack ram used: 528

Never used ram: 74676

Tasks: NETWORK(ready,1968) HEAT(blocked,1188) CanReceiv(suspended,3820) CanSender(suspended,1384) CanClock(blocked,1436) TMC(blocked,60) MAIN(running,4544) IDLE(ready,76)

Owned mutexes:

=== Platform ===

Last reset 00:42:06 ago, cause: software

Last software reset at 2020-09-10 01:25, reason: User, spinning module LinuxInterface, available RAM 74788 bytes (slot 2)

Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN

Error status: 0

MCU temperature: min 40.2, current 40.3, max 40.5

Supply voltage: min 23.8, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.1, max 12.1, under voltage events: 0

Driver 0: standstill, reads 40080, writes 4 timeouts 0, SG min/max 0/638

Driver 1: standstill, reads 40080, writes 4 timeouts 0, SG min/max 0/646

Driver 2: standstill, reads 40080, writes 4 timeouts 0, SG min/max 0/861

Driver 3: standstill, reads 40083, writes 0 timeouts 0, SG min/max not available

Driver 4: standstill, reads 40084, writes 0 timeouts 0, SG min/max not available

Driver 5: standstill, reads 40083, writes 0 timeouts 0, SG min/max not available

Date/time: 2020-09-10 02:07:26

Slowest loop: 5.28ms; fastest: 0.14ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 375, MinFreeDm: 373, MaxWait: 49201ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 90, completed moves: 90, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = 3 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is ready with "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 1.97ms; fastest: 0.01ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 0 of 8

Any suggestions would be appreciated.

Mark

I switched from out3 to out7 and mapped it per config file below and it works. I am not sure why but at least the chamber heater works now and I was able to tune it.

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X600.00 Y600.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X120000.00 Y120000.00 Z1200.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X800.00 Y800.00 Z30.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z3200 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.722 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 170C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; set temperature limit for heater 1 to 450C

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S450 ; set temperature limit for heater 2 to 450C

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out7" T3 ; create bed heater output on out7 and map it to sensor 3

M141 H3 ; Define heater h7 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C

; Fans

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config override

M572 D0 S0.7 ; enable pressure advance

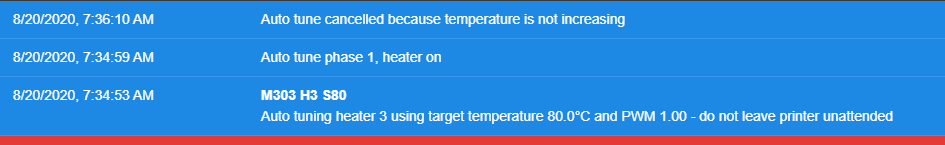

I tried to tune as you suggested:

The SSR has an LED that lights when it is activated and it didn't turn on during tuning. It will activate if I supply voltage to the terminals so I verified it works.

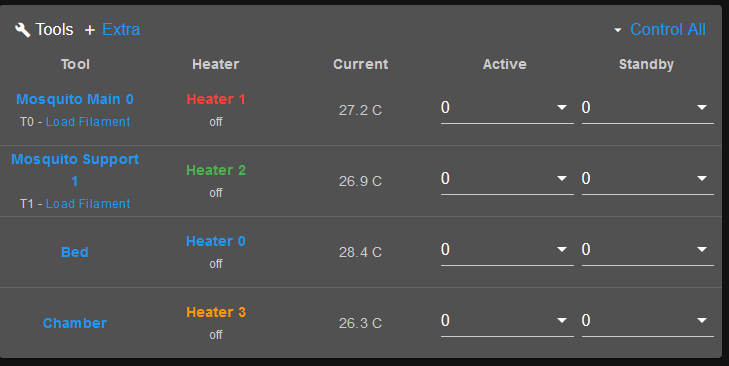

I am trying to get my chamber heater working on my Duet 3. I am using an SSR and if I provide the SSR with voltage it triggers and the heater works. When I try to activate it with DWC, it just faults because there is no change in temp and I get the rising too slowly error.

Here is the relevant section of my config file on the chamber heater:

M308 S3 P"temp3" Y"pt1000" R2200 ; configure sensor 3 as PT1000 on pin temp3

M950 H3 C"out3" T3 ; create bed heater output on out0 and map it to sensor 3

M141 H3 ; Define heater h3 as chamber heater

M301 H3 P-1 ; Disable PID settings to use bang-bang

M143 H3 S150 ; set temperature limit for heater 3 to 150C

I am using Duet Web Control 3.1.1. Note the temp is correct and reflects change if you manually cycle the ssr.

Any suggestions would be appreciated.

Thanks,

Mark

You nailed it. I had a change in my starting script for simplify that fixed it once removed.

Thanks for the help and mark this solved.

Mark

I cannot run any new files regardless of the name. Only files previously printed. If I attempt to print it just gives the same error. I have tried this multiple times.

The file is really named t.gcode.

It was just a test print file to see if the problem repeats. Every file try to print now fails to print with the same error.

Here is the file

It is duet 3 with sbc: FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet 3 MB6HC v0.6 or 1.0 FIRMWARE_DATE: 2020-05-19b2

Thanks,

Mark

Getting an error now whenever I upload a file to print. old prints previously loaded can run:

Here is the firmware:

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.1.1 ELECTRONICS: Duet 3 MB6HC v0.6 or 1.0 FIRMWARE_DATE: 2020-05-19b2

Error:

8/16/2020, 4:14:01 PM M32 "0:/gcodes/t.gcode"

Error: Failed to parse major T-code number (o)

8/16/2020, 4:14:01 PM Upload of t.gcode successful after 0s

config file:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Thu Aug 13 2020 09:44:43 GMT-0700 (Pacific Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.3 S1 ; physical drive 0.3 goes forwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z640.00 E822.67:822.67 ; set steps per mm

M566 X600.00 Y600.00 Z300.00 E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X120000.00 Y120000.00 Z1200.00 E4800.00:4800.00 ; set maximum speeds (mm/min)

M201 X800.00 Y800.00 Z30.00 E80.00:80.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z3200 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S20 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y280 Z320 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"io1.in" ; configure active-high endstop for high end on X via pin io1.in

M574 Y1 S1 P"!^io2.in" ; configure active-high endstop for low end on Y via pin !^io2.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M558 P5 C"^!io3.in" H2 F150 T1800 ; set Z probe type to switch and the dive height + speeds

M558 H2 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P1000 X0 Y0 Z0.722 ; set Z probe trigger value, offset and trigger height

M557 X0:450 Y20:280 S20 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"pt1000" R2200 ; configure sensor 0 as PT1000 on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S170 ; set temperature limit for heater 0 to 150C

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S450 ; max temp for extruder 450c

M308 S2 P"temp2" Y"pt1000" R2200 ; configure sensor 2 as PT1000 on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M308 S3 P"temp3" Y"pt1000" R2200 ; define bed temperature sensor

M950 H3 C"out3" T3 ; create bed heater output on out3 and map it to sensor 3

M141 H3 ; heater 3 is the chamber heater

; Fans

; Tools

M563 P0 S"Mosquito Main 0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Mosquito Support 1" D1 H2 F0 ; define tool 1

G10 P1 X16.150 Y2.15 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; enable config override

M572 D0 S0.7 ; enable pressure advance

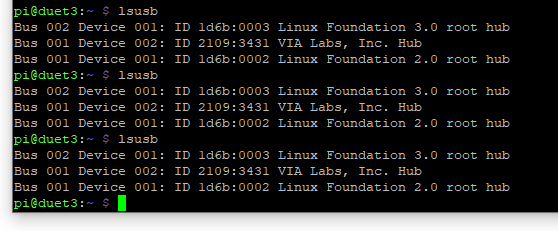

You are correct, when it worked before the ribbon was the only connection between the pi and the duet

Trying the erase jumper multiple times and no bossa port shows. Also hit the reset button - no change in the diag led. Turning on the Duet without any usb had no change. I only plugged in the usb to try to connect via serial for bossa. Before when it worked, the ribbon cable was connected to the Pi only. I checked the 26 pin cable but it was not unplugged from when it worked.

I got it from Filastruder, December of last year.

I do have a powered hub. I have tried plugging the usb to the duet from my desktop through the hub and the diag led is the same dim result

Thanks for the feedback. I tested the USB cables on other devices and they work.

I don't know where to go at this point. Any suggestions are appreciated.

Here are logs with 3 different micro usb cables:

Diag LED is dimly lit:

Here is the log from the pi:

no connection via serial port- I couldn't get windows to recognize the USB com. Same with bossa

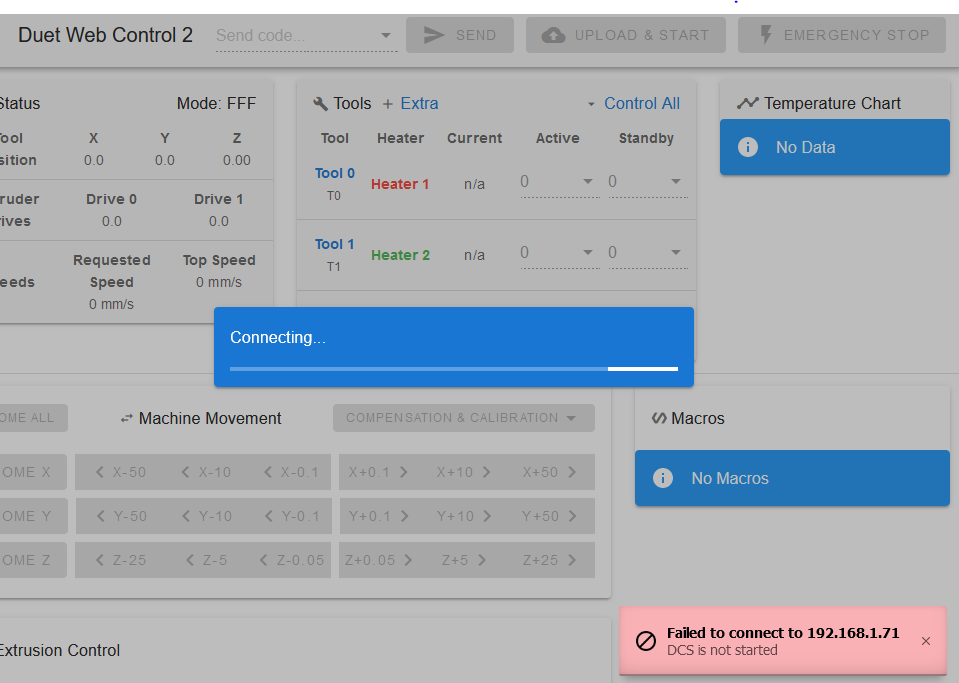

Hi:

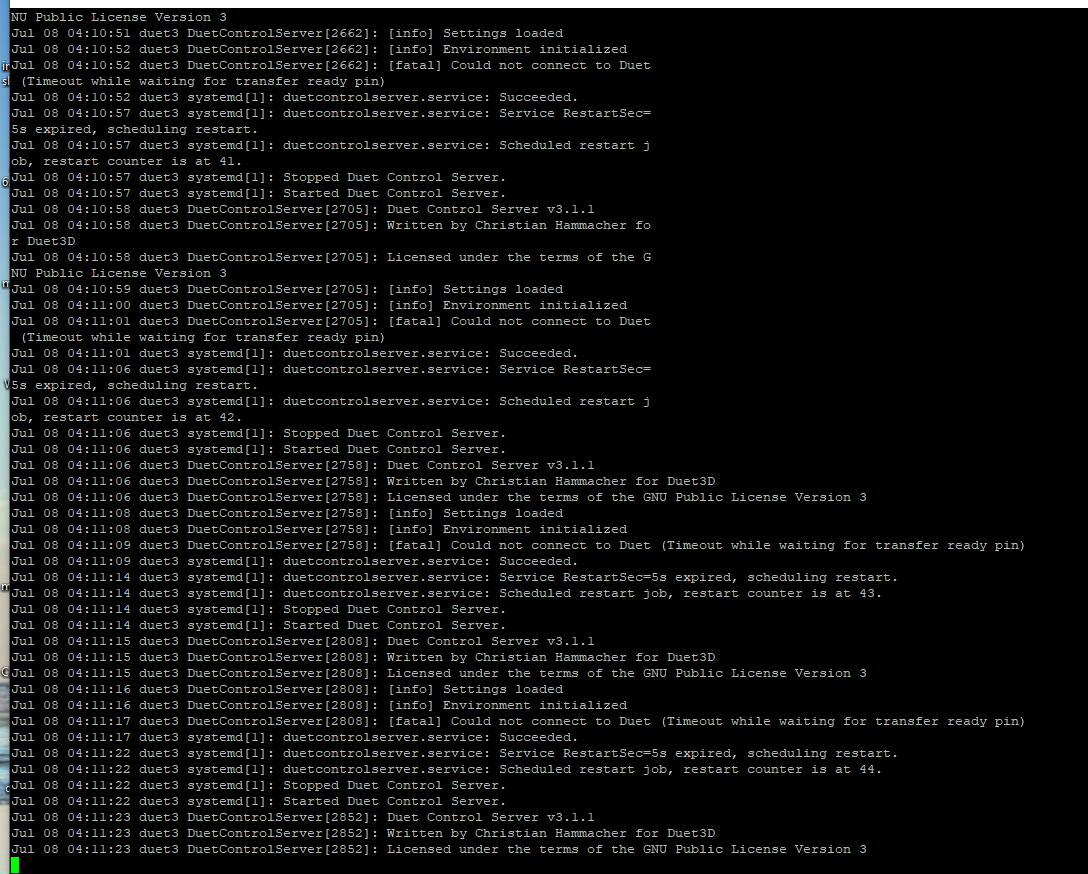

I have a duet 3 and pi. I updated the sd card on the Pi following instructions to format the card properly, balena to load the newest I am getting a DCS not working message when I try to connect.

Also note that the duet turns on, but I am not sure it is responsive. No blinking lights but it does power up

Thanks in advance for any help.

Mark

I unplugged the PI and no change on led's. You are correct that only the red and blue in the pic are lit. I have nothing else plugged into the PI and it is still a basic setup= extruder, xyz steppers, hot end heater. The two SSR's are for the mains voltage bed heater and chamber heater which I haven't connected yet.