The object is in the center of the slicer table, but when I export the g-code and upload and print the object prints of-center by about 80mm. I tried more than one slicer with the same result.

Latest posts made by Jddt

-

Print offset From Slicer to Printerposted in Tuning and tweaking

-

RE: Calibrating steps/mmposted in Tuning and tweaking

The motors started to work properly with a value of T5

-

RE: Calibrating steps/mmposted in Tuning and tweaking

What is the max T values you suggest to be safe?

-

RE: Calibrating steps/mmposted in Tuning and tweaking

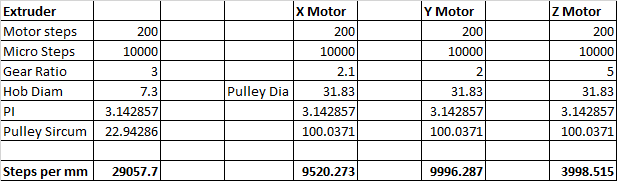

Thanks for noticing the error in my calculation. I am using external drivers and are not using the M350 command.

-

RE: Calibrating steps/mmposted in Tuning and tweaking

Settings I am using now. Can the T setting influence the accuracy of my steps?

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P5 S1 R1 T2.5:2.5:5:2.5

M569 P6 S1 R1 T2.5:2.5:5:2.5

M569 P7 S0 R1 T2.5:2.5:5:2.5

M569 P8 S0 R1 T2.5:2.5:5:2.5

M584 X5 Y6 Z7 E8 -

RE: Calibrating steps/mmposted in Tuning and tweaking

I am using external drivers. All my final drive pulleys are HTD5 20 tooth. I do not get any consistency with the distance the axis move.

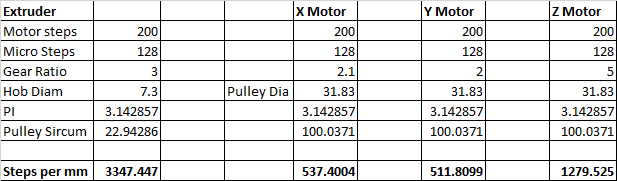

See calculations below.

-

Calibrating steps/mmposted in Tuning and tweaking

When I completed the steps/mm calibration and I run code, like the homing code, then the distance is completely wrong.

Any advice.

Thanks -

Set external motor amps.posted in Tuning and tweaking

Does the M906 command to set the motor current work for external motors as well?