Hi,

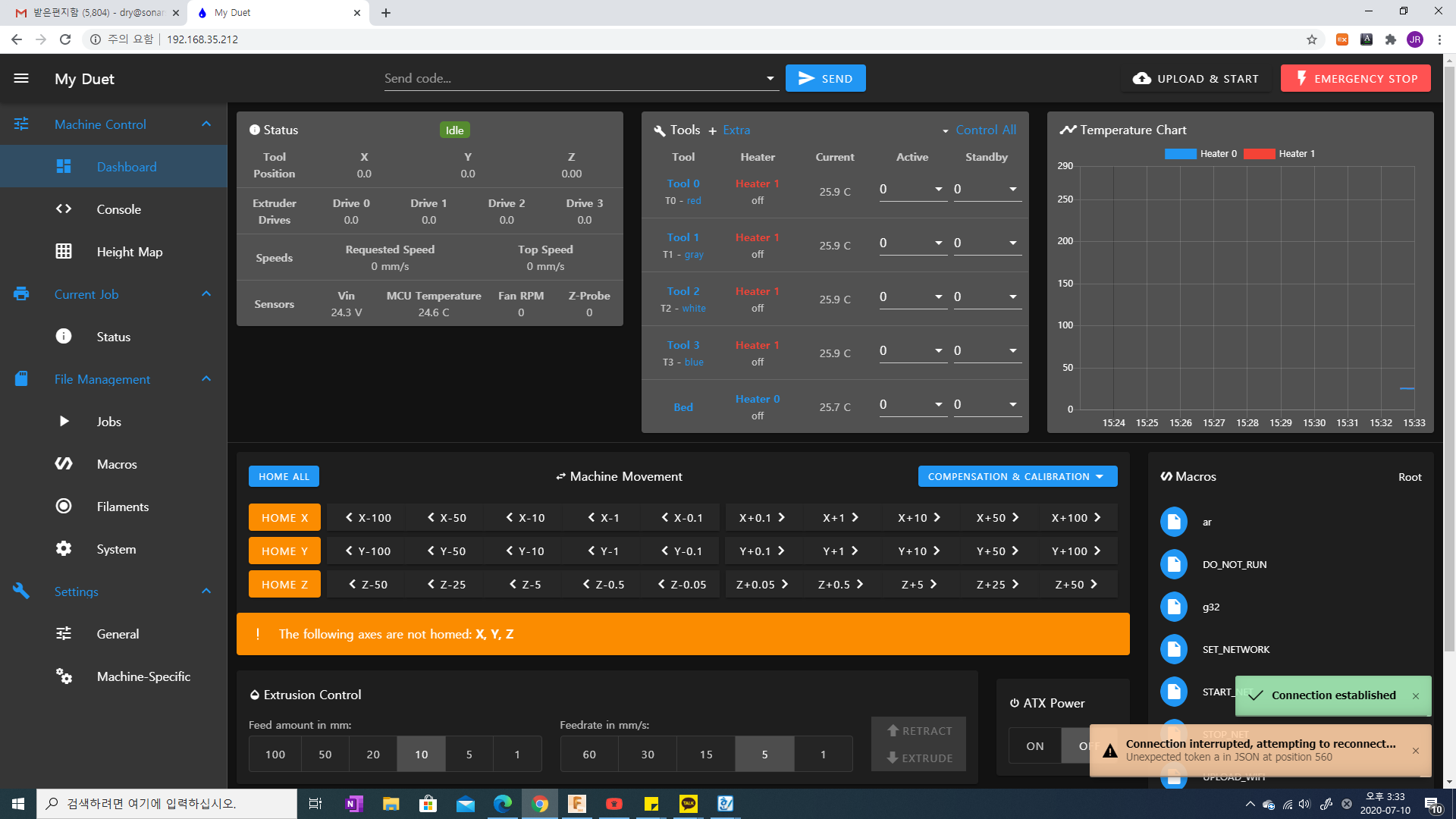

DWC shows below alert blinking every around 0.1seconds and then becomes uncontrollable status though it's connected(buttons are working but refreshing every 0.1seconds due to reconnection). It happened after I restarted the system after changing config.g file. Tried to use various method to fix but still not working.

alert : connection lost. attempting reconnect.

Console : Connection interrupted, attempting to reconnect... Unexpected token a in JSON at posion 560

Could anyone help to solve this problem?

I'm using DUET2WIFI with DUEX5 for 4 extruders for 4color mixed nozzle and I just found there is some error on M567 according to M588(diagnose) but I don't know what's error.

Configuration is as follows.

; Configuration file for Duet WiFi (firmware version 2.03)

; General preferences

G90 ; send absolute coordinates...

M83

; Network

M552 S1

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; ...but relative extruder moves

; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 4 goes forwards

M569 P5 S1 ; physical drive 5 goes forwards

M569 P6 S1 ; physical drive 6 goes forwards

M569 P7 S1 ; physical drive 7 goes forwards

M569 P8 S1 ; physical drive 8 goes forwards

M569 P9 S0 ; physical drive 9 goes forwards

M584 X9 Y2 Z0:1:3:4 E5:6:7:8 ; set drive mapping

M350 X16 Y16 Z16 E8:8:8:8 I1 ; configure microstepping with interpolation

M92 X106.67 Y106.67 Z800.00 E984.00:984.00:984.00:984.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z100.00 E3600.00:3600.00:E3600.00:3600.00 ; set maximum instantaneous speed changes (mm/min) jerk

M203 X36000.00 Y36000.00 Z2400.00 E3600.00:3600.00:3600.00:3600.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z200.00 E3600.00:3600.00:3600.00:3600.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z1500 E450:450:450:450 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X450 Y450 Z650 S0 ; set axis maxima

; Endstops

M574 X1 Y1 S1 ; set active high endstops

; Z-Probe

M574 Z1 S2 ; set endstops controlled by probe

M307 H7 A-1 C-1 D-1 ; disable heater on PWM channel for BLTouch

;M558 P9 F100 H5 R0.2 T6000 A2 B1 ; set Z probe type to bltouch and the dive height + speeds

M558 P9 X0 Y0 Z1 F300 T6000 H5

G31 P25 X16 Y10 Z3.95 ; set Z probe trigger value, offset and trigger height

M557 X50:400 Y50:400 S50 ; define mesh grid

M280 P7 S160

M669 K0 ; CARTESIAN

M671 X-70:545:545:-70 Y-80:-80:615:615 S10

; Heaters

M305 P0 T100000 B3950 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B3950 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

;Sensor

;M591 D0 P2 C3 S1

;M591 D1 P2 C4 S1

;M591 D2 P2 C5 S1

;M591 D3 P2 C6 S1

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M568 P0 S1

M567 P0 E0.94:0.02:0.02:0.02

M563 P1 D1 H1 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M568 P1 S1

M567 P1 E0.02:0.94:0.02:0.02

M563 P2 D2 H1 F0 ; define tool 0

G10 P2 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P2 R0 S0

M568 P2 S1

M567 P2 E0.02:0.02:0.94:0.02 ; set initial tool 0 active and standby temperatures to 0C

M563 P3 D3 H1 F0 ; define tool 1

G10 P3 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P3 R0 S0

M568 P3 S1

M567 P3 E0.02:0.02:0.02:0.94

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss