I use some thermal pads under the glass when I need it. It sticks well to the magnetic surface.

Best posts made by KipK

-

RE: Sticking magnetic surface to Borosilicate glass?posted in 3D Printing General Chat

-

RE: G1 H3 and M500 P31 to save multiple endstop on combined Z axisposted in Firmware wishlist

Found it.

Seems I have to set also U and V to 0 reference after a Z probe.

Now it works.

macro calibrate Z max for each axis:

M208 S1 Z-3; Allow z to be negative G90; G1 X0 Y0 F10000; go to the center G1 Z30 F1000; G30 ; probe bed and set z=0 G32 ; start 3 point bed leveling G1 X0 Y0 F10000; G30 ; Probe for Z=0 G1 Z10 F800 ; raise nozzle M584 Z6 U8 V7 P5 ; split z axis G92 U10 V10; set U V axis to 10 as Z G91 ; relative mode G1 H3 Z370 U370 V370 F1000; move Z, U, V down until endstops trigger and get new z limits M500 P31 ; save new z height M584 Z6:8:7 P3 ; unsplit z axis G90Have to say, object models and conditionnal gcode is a killer feature.

-

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

I'm waking up this topic, ( deleted mine also ).

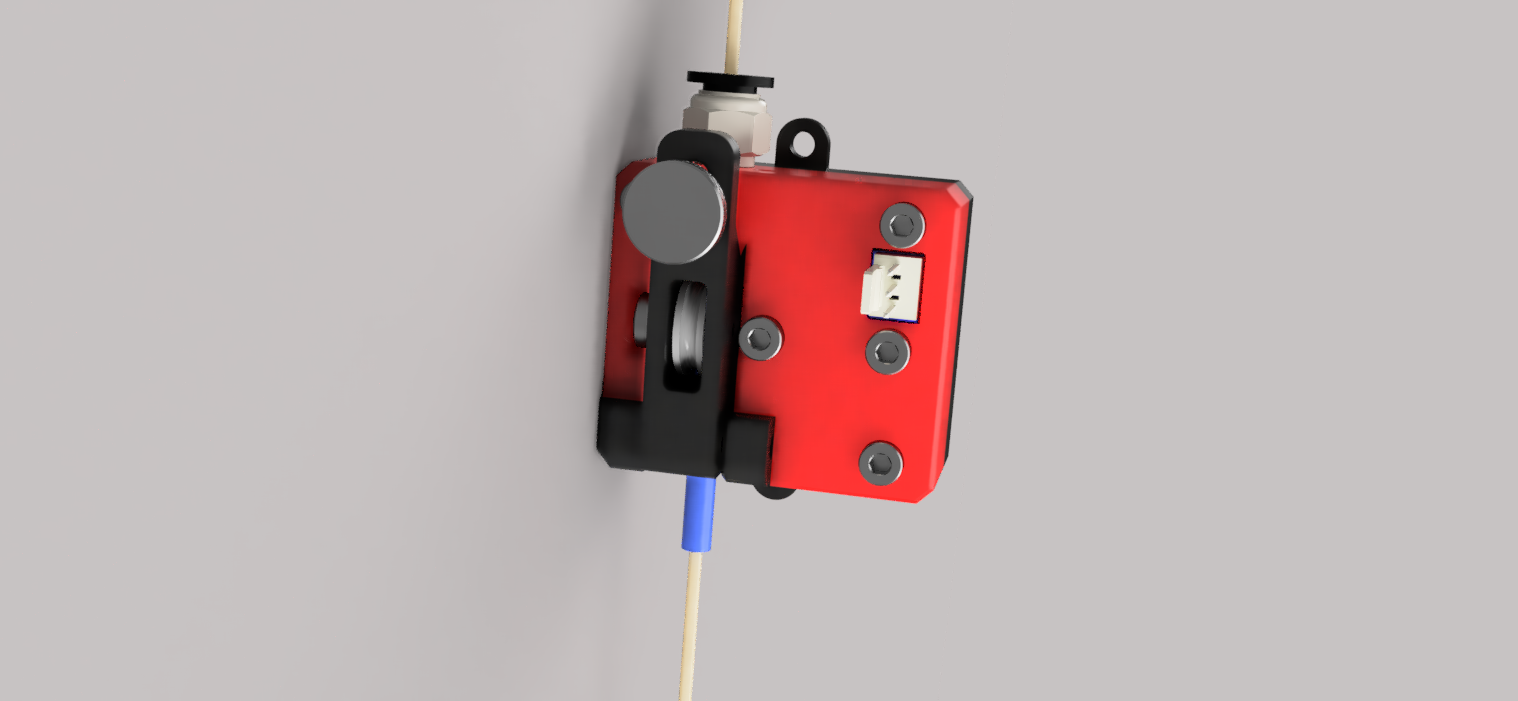

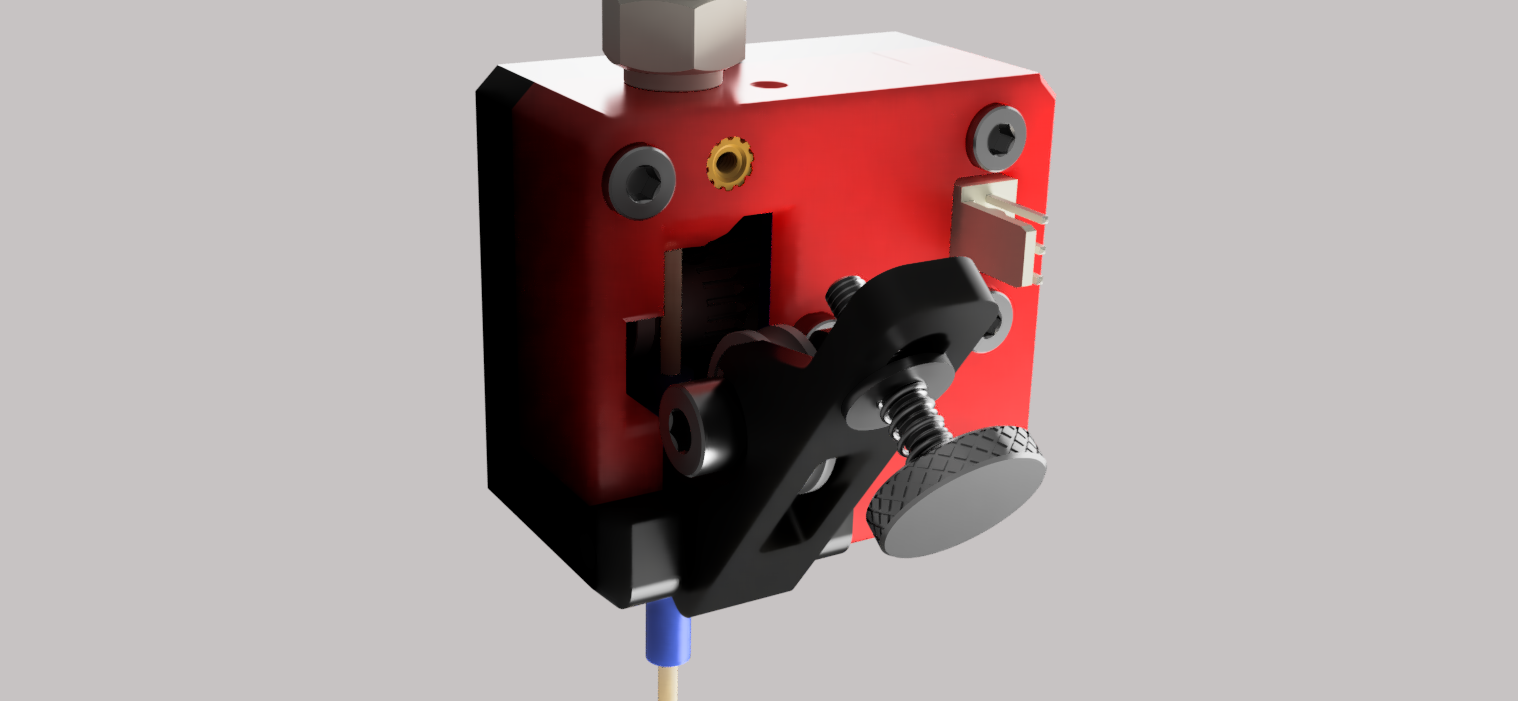

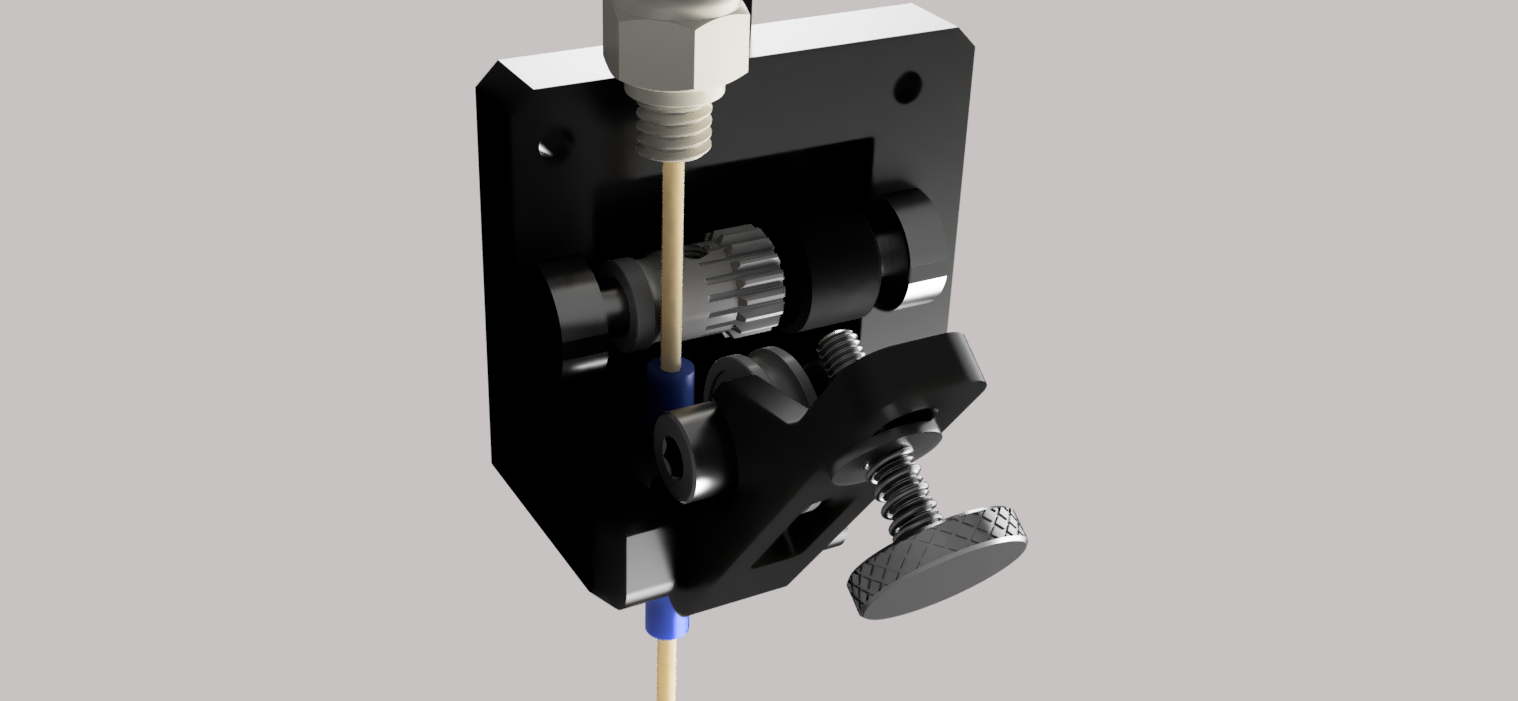

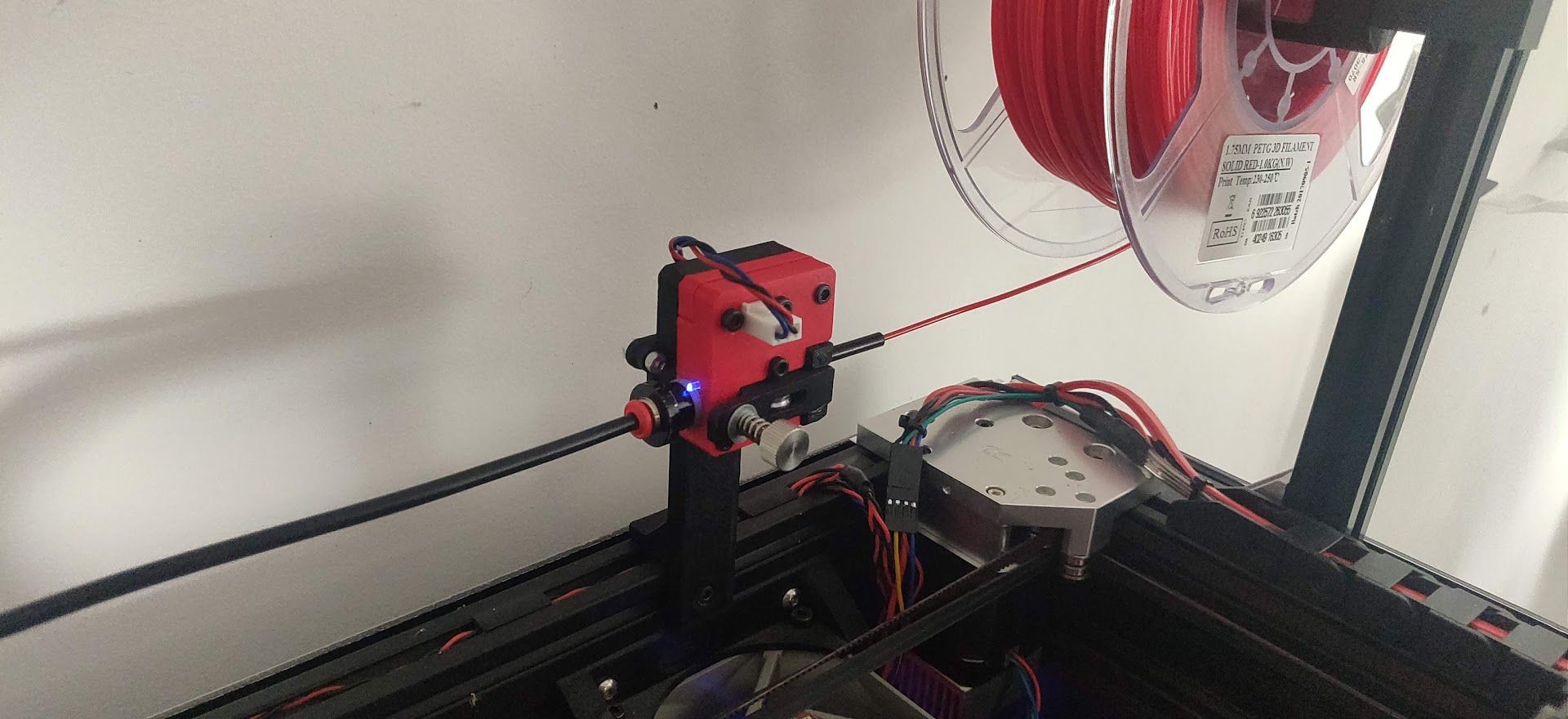

Here is my version of indirect filament reading, inspired by your ideas here.

It uses an 5mm shaft hobbed gear from Bondtech and U shape bearing on the latch.

Tensionning can be adjusted from the latch.I use it outside of my DD carriage, don't have any problem with retractions ( considering I have 0.6mm retracts this prollyt explains why ).

https://www.thingiverse.com/thing:4882602

I get readings from 188% to 266% , average 230%. Is it acceptable or should I try to read around the 100% ? I think I can tweak it by adjusting the printed wheel diameter.

-

RE: Independent Z Axis - One Endstop Not Workingposted in General Discussion

Don't forget that if your bed is not perfectly flat, bed leveling will try to align 2 points that are not necessarily aligned on the bed plane resulting in tilted bed.

Then you'll also need mesh compensation. -

RE: Indirect (bearing) laser filament monitor conceptposted in Filament Monitor

That's what I use here, bondtech hobbed gear.

So after using the calibration factor + few change on the indirect casing, I now have this reported values :

measured min 93% avg 101% max 107% over 12365.3mm

Looks far better than what I ever achieved with direct reading.

I still have some false trigger because of the PTFE tube moving too fast with high acceleration, I will restrain it before the filament reader.