Indirect (bearing) laser filament monitor concept

-

@JADoglio my understanding is that with S1, the monitor pauses the print if the extrusion falls outside the specified range. So it will pause on blockages if the extrusion is sufficiently affected. I didn't think you got a pause with S0, even with runout - not sure if this applies with a microswitch added. I have only used A1 so far - will investigate A0 sometime. You do get a pause with S0 if you have a wiring fault - I had some irritating pauses until I fixed a dodgy crimp.

-

@Adrian52 Thanks. You are right even on run out when S is set to 0 it will not stop the extruder. I did that experiment a few days ago and just forgot about it.

-

@Adrian52 what does the A parameter do? I don't see that defined on the reprap g-code wiki site.

-

@mitch see https://duet3d.dozuki.com/Wiki/Gcode#Section_M591_Configure_filament_sensing

An (firmware 2.03 and later) 1 = check All extruder motion, 0 (default) = only check extruder motion of printing moves (moves with both movement and forward extrusion)

Ian

-

@droftarts Thanks

-

I'm waking up this topic, ( deleted mine also ).

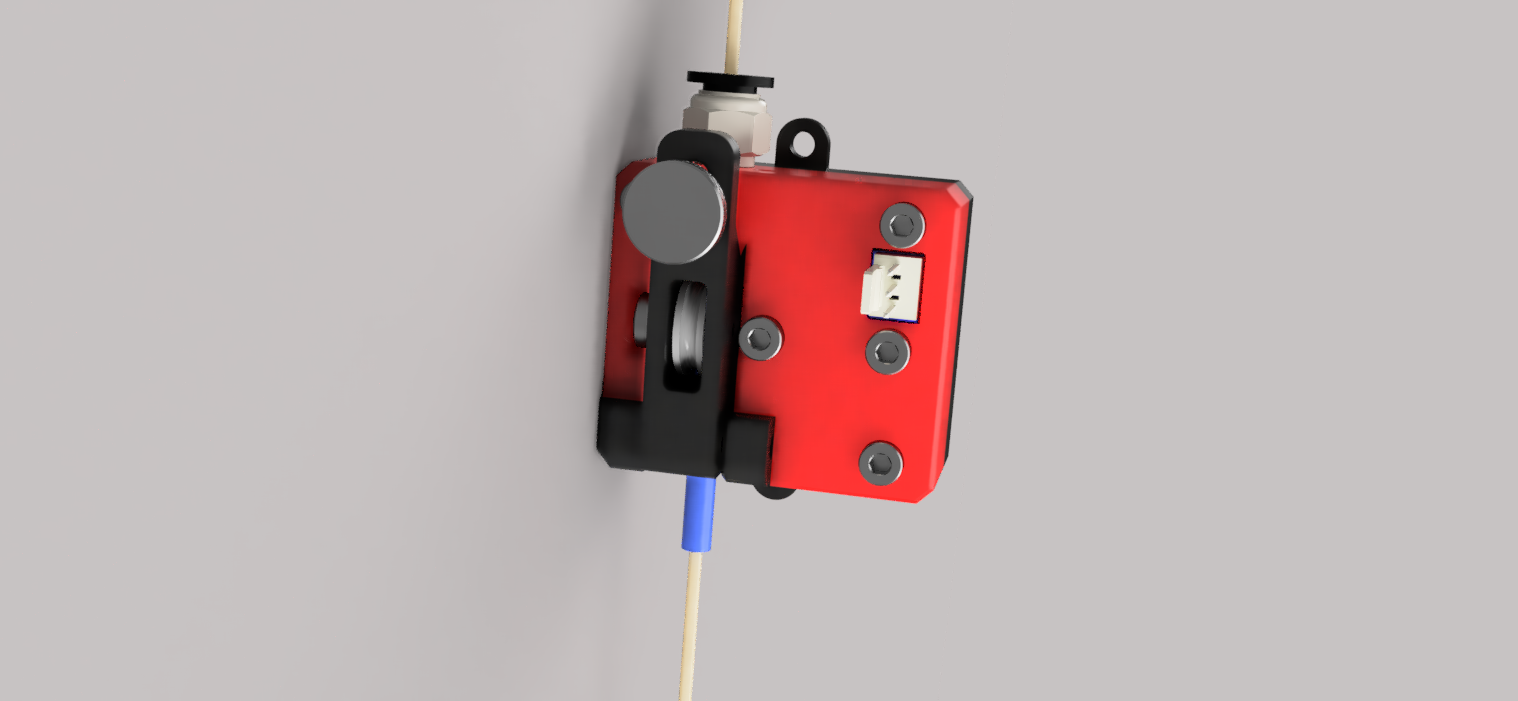

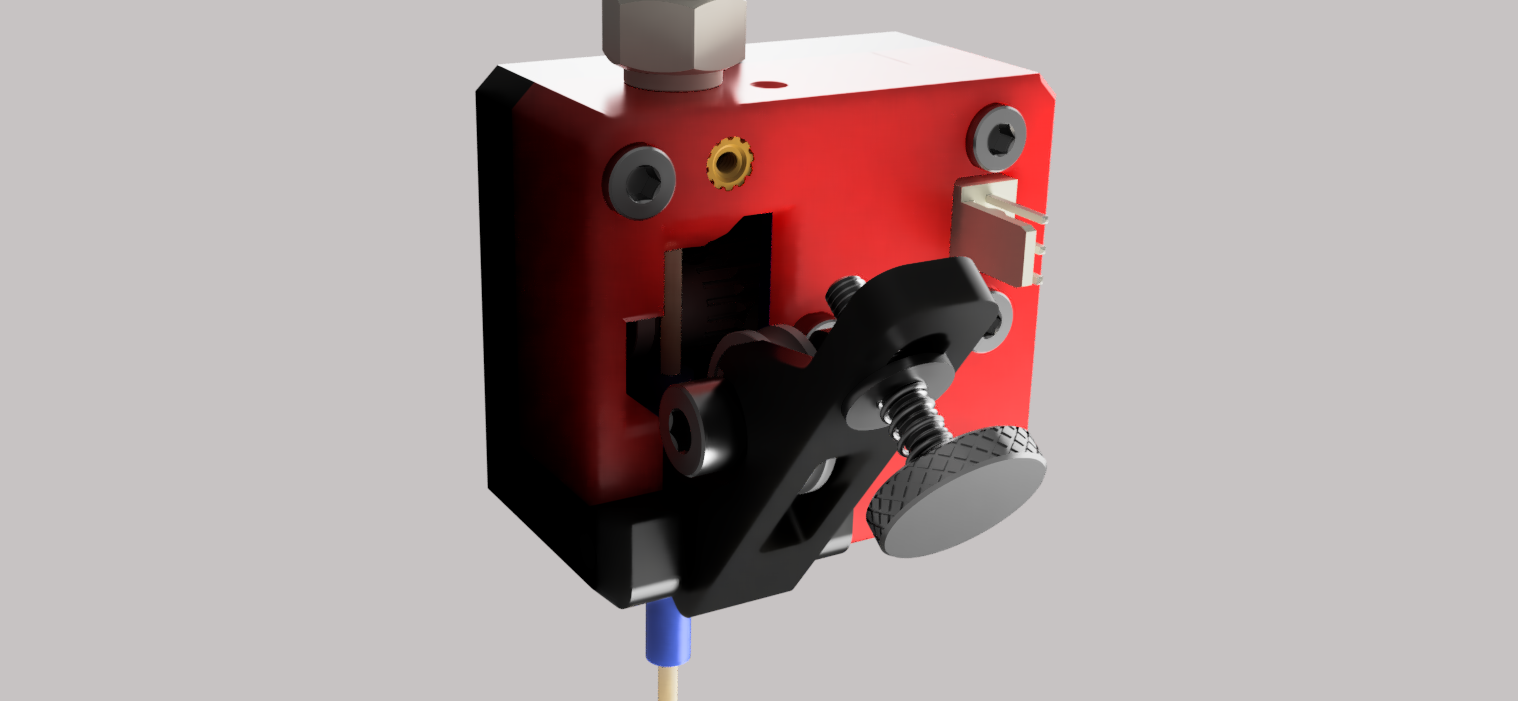

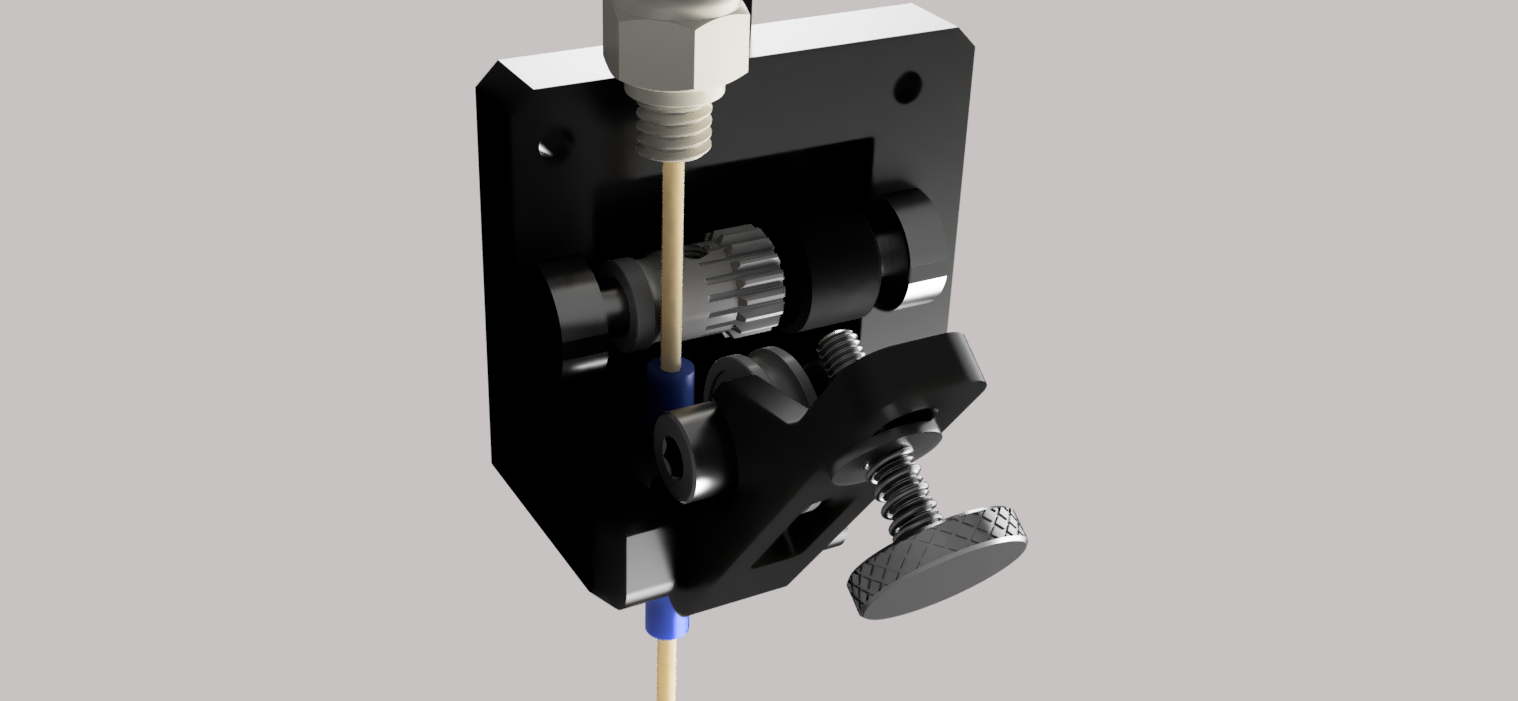

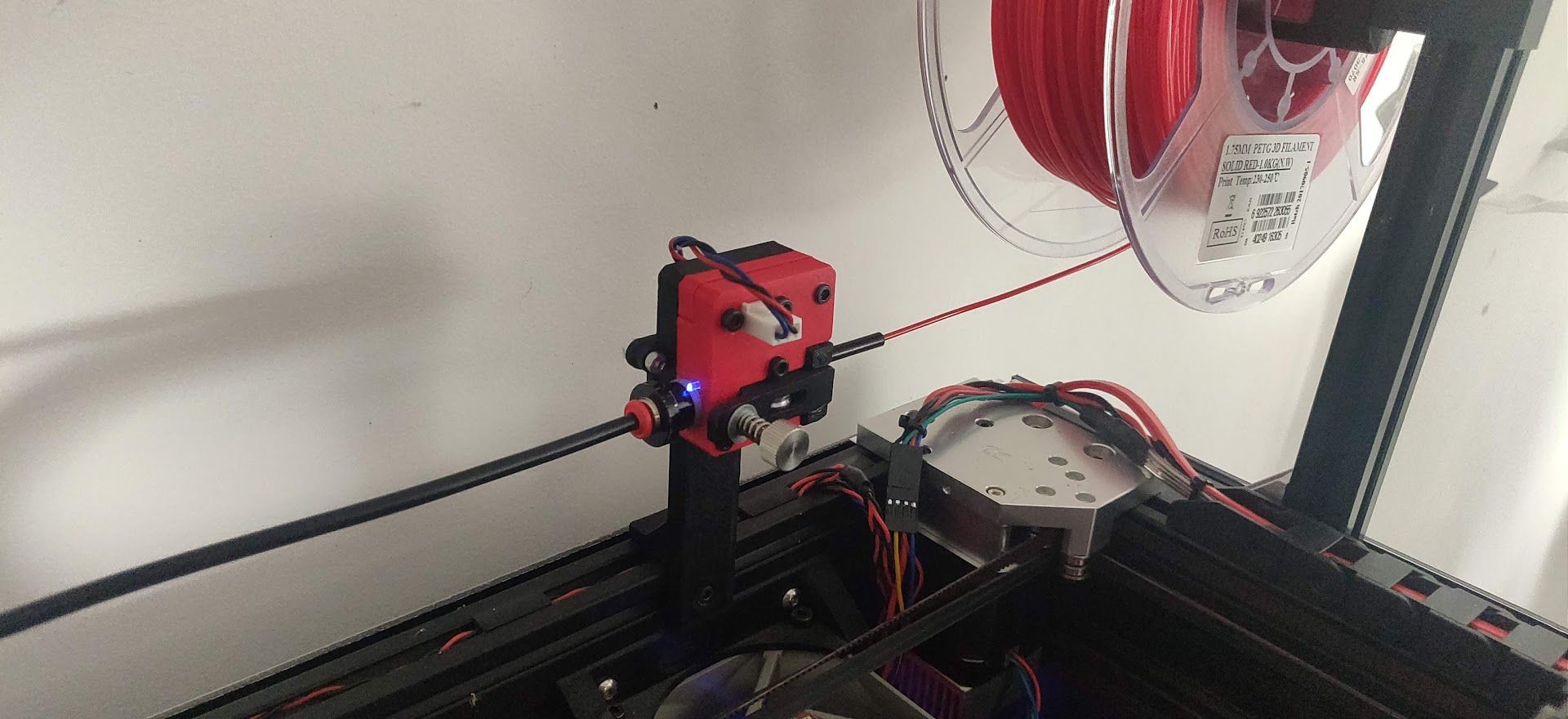

Here is my version of indirect filament reading, inspired by your ideas here.

It uses an 5mm shaft hobbed gear from Bondtech and U shape bearing on the latch.

Tensionning can be adjusted from the latch.I use it outside of my DD carriage, don't have any problem with retractions ( considering I have 0.6mm retracts this prollyt explains why ).

https://www.thingiverse.com/thing:4882602

I get readings from 188% to 266% , average 230%. Is it acceptable or should I try to read around the 100% ? I think I can tweak it by adjusting the printed wheel diameter.

-

@kipk you can adjust the calibration factor in RRF 3.2 and later using the M591 L parameter. See https://duet3d.dozuki.com/Wiki/Gcode#Section_M591_RepRapFirmware_Num_3.

-

@dc42 ho that's just perfect then.

-

@brunofporto just use a bondtech hobbed gear - that's what I use and it always engages with the filament to register movement.

-

That's what I use here, bondtech hobbed gear.

So after using the calibration factor + few change on the indirect casing, I now have this reported values :

measured min 93% avg 101% max 107% over 12365.3mm

Looks far better than what I ever achieved with direct reading.

I still have some false trigger because of the PTFE tube moving too fast with high acceleration, I will restrain it before the filament reader. -

undefined droftarts referenced this topic

undefined droftarts referenced this topic