The quick gist of what i am doing and why:

I am developing an open source hotend for semisolid metal direct write and direct ceramic 3D printing.

my hot end consists of a glow plug like the one I have modeled at this link, with a 0.5mm ID straight center bore(60mm deep)hole EDM drilled through it lengthwise. These glowplugs are capable of long term stable operation in air at up to about ~1500 C, and are essentially nonwetting and nonreactive to most nonferrous molten metals at temperatures below 1300 C. they are made of Si3N4-MoSi2 ceramic, which is an electrically semiconducting ceramic matrix composite, and they only heat at the tiny region at the tip, about 2.8mm OD, and ~2 mm long.

Shameless plug

i have a youtube video showing the hotend mounted and working on and ender 3 when we were clearing some bronze that got jammed inside it when I stupidly overheated the bronze and simultaneously pulled the feedstock wire out of the hotend, leaving behind a blob of oxide rich slag which had to be remelted and wicked out with a more refractory wire of silicon carbide.

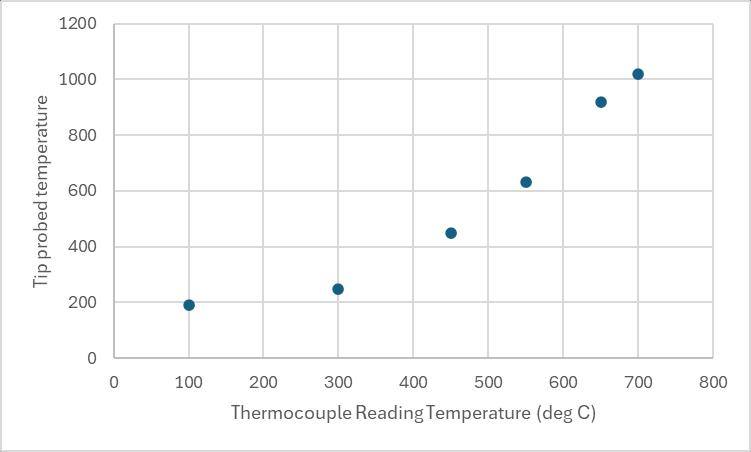

We use the EDM drilled ceramic glow plug as a combined heated nozzle +hotend+temperature sensor that is extremely fast, and has surface power density comparable to a torch flame(between 1 and 15 watt/mm^2 typical depending on what we are printing) to be able to rapidly heat and cool a a 24 AWG (0.522mm OD, 510 phosphor bronze) metal wire (with no nozzle constriction) to maintain the temperature between the solidus and liquidus for the wire, at the deposition region where the wire touches the build plate. Maintaining such temperature control requires extremely fast temperature cycling up and down(up to about 1000 degrees C/second) (more typical 350 degrees C /second) , and requires very sensitive temperature measurement(+- 1 degree C at a minimum..) to be able to respond to changes in flow conditions in time to maintain stable deposition.

a little bit about what we are printing with:

it helps to have metals that have a wide window between solidus and liquidus. 510 phosphor Bronze is one of the few easily available alloys that has a wide window. between 930 and 1060 C, about 130 degrees C.

so we have opted to start by trying to print bronze from 24AWG (0.52mm) 510 phosphor bronze wire available on mcmaster.

small wire diameter also helps because it reduces total mass flow requirements and reduces dead metal and risks for granular jamming in the hotend. small hole diameter in the hotend enables the high temperature of the heater to exclude air from the bore, and this provides a relatively anoxic environment inside the hotend which protects the metal from oxidation. the small mass of metal being deposited means that rapid quenching occurs on the build plate, and this means there is little time for oxidation, and for grain growth... because the metal is semisolid as printed, it develops about 3 orders of magnitude less internal stress than in approaches like WAAM.

this all means that a single rather challenging machining operation was requried to make the ceramic glowplugs into suitable hotends, that is, EDM drilling a centerbored a 60mm X 0.5mm diameter through hole in the Si3N4 MoSi2 ceramic body of the glowplug.

we have managed to obtain reliable operations for doing the manufacturing.

we now just need to get control of the system which may require a few minimal firmware alterations...

we have been aiming for a drop in mod for the ender 3 being the first thing we make and offer for a wider audience, if it works.

The crux of the problem

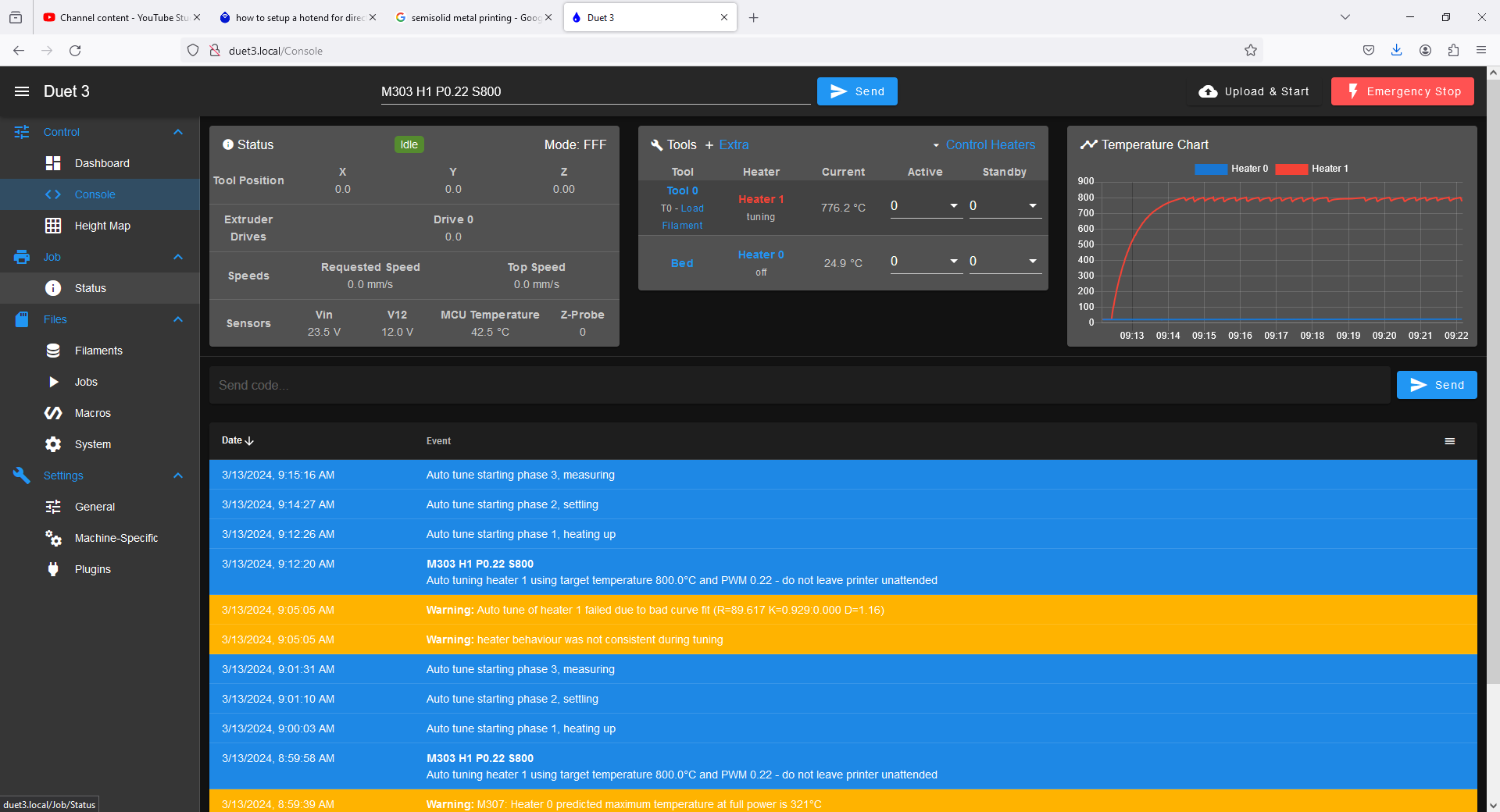

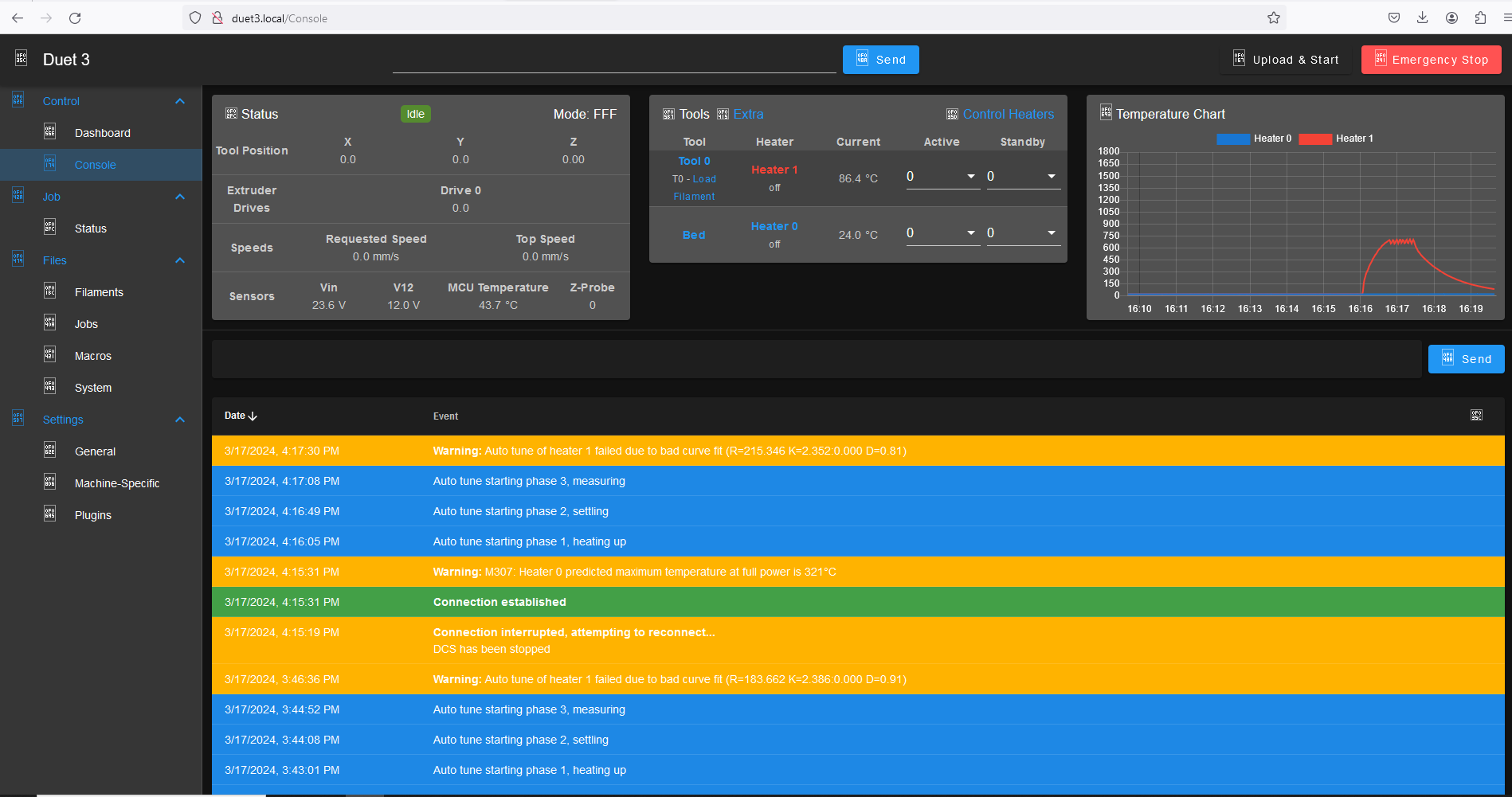

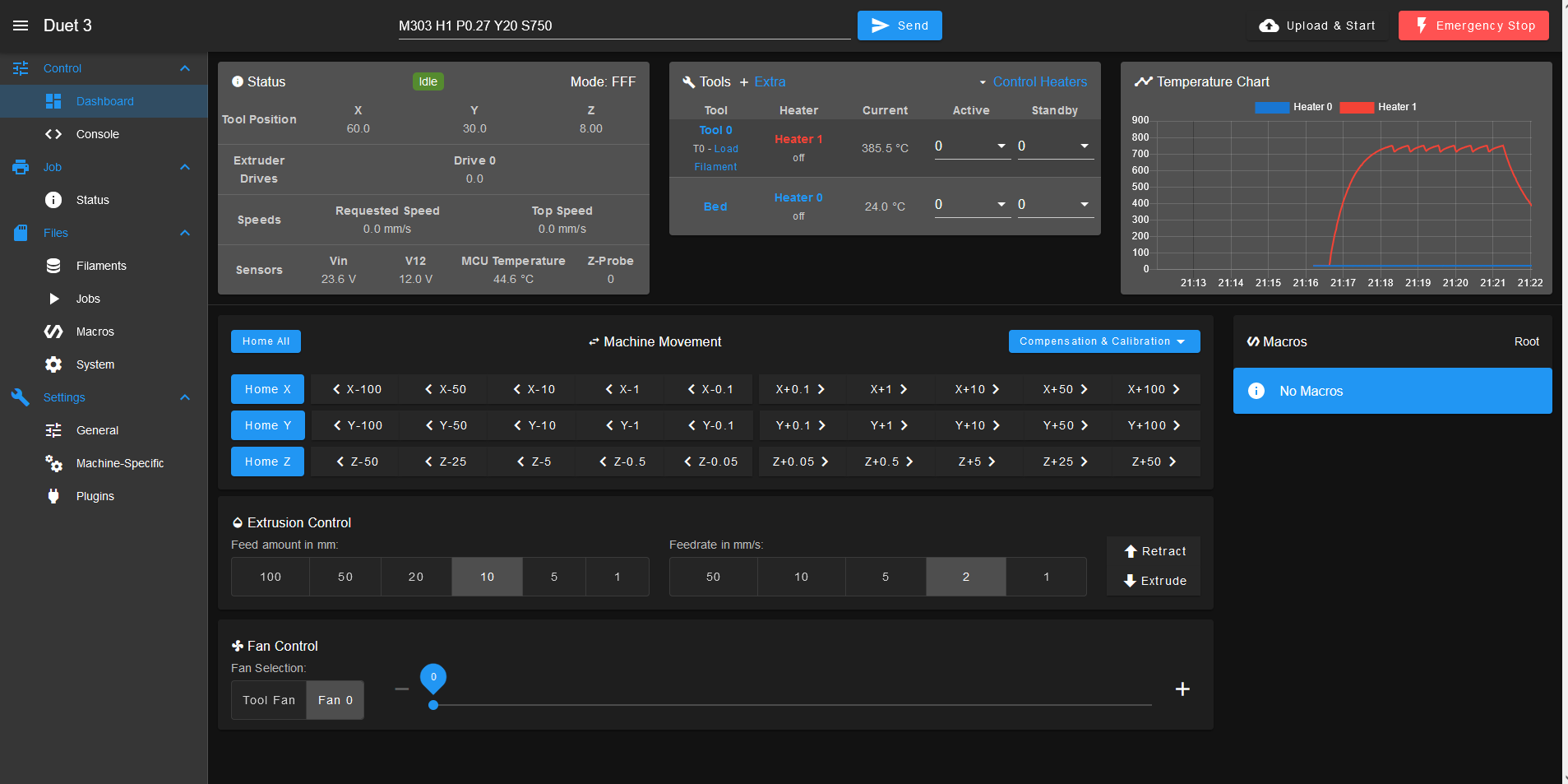

I am having a lot of trouble getting the duet to cooperate and control these extremely high performing heaters. the PID tuning algorithm seems to be too slow to respond to them, and this trip heater faults.

I am also doing temperature sensing of the heaters by wrapping a type K thermocouple around the ceramic tip and slathering it in refractory cement. this appears to cause some amount of signal cross talk with the thermocouple amplifier MAX 31856 duet daughterboard. or something... I keep getting the error "fault on heater 1:sensor short to other wiring"

but if I leave the printer to sit after clearing the fault, for perhaps 10-20 minutes, the thermocouple reads temperatures on the hotend heaters of ~30-45C. I can then attempt a PID tun or to enable the heaters, but the tune fails consistently when the overshoot is much larger than anticipated or for some other reason I have not identified.

## Basically I need help controlling the temperature of these heaters and making the necessary firmware adjustments to make their control reliable.

I am not a firmware or software developer, please keep responses at the level of a 5 year old if at all possible...

Any assistance is greatly appreciated.