@jay_s_uk worked an absolute CHARM!! now just need to get the depth within tolerance in thank you!

Posts made by magdi

-

RE: tool offsetsposted in General Discussion

-

RE: tool offsetsposted in General Discussion

@jay_s_uk this sounds like quite an elegant solution. I have probably a dumb question but how will all of the G10's interact with eachother? I have a G10 in the config.g and then two extra now... does each G10 command superseed the other? I will have a stab anyway hopefully it will work!

-

RE: tool offsetsposted in General Discussion

@jay_s_uk

Hi Jay, its one big job, I was hoping it would just work but guess not yet. I have tried with 2 jobs but then the tool just doesnt play well at all and decides to run off the bed...I have a servo which rotates the blade using M280

-

tool offsetsposted in General Discussion

Good evening,

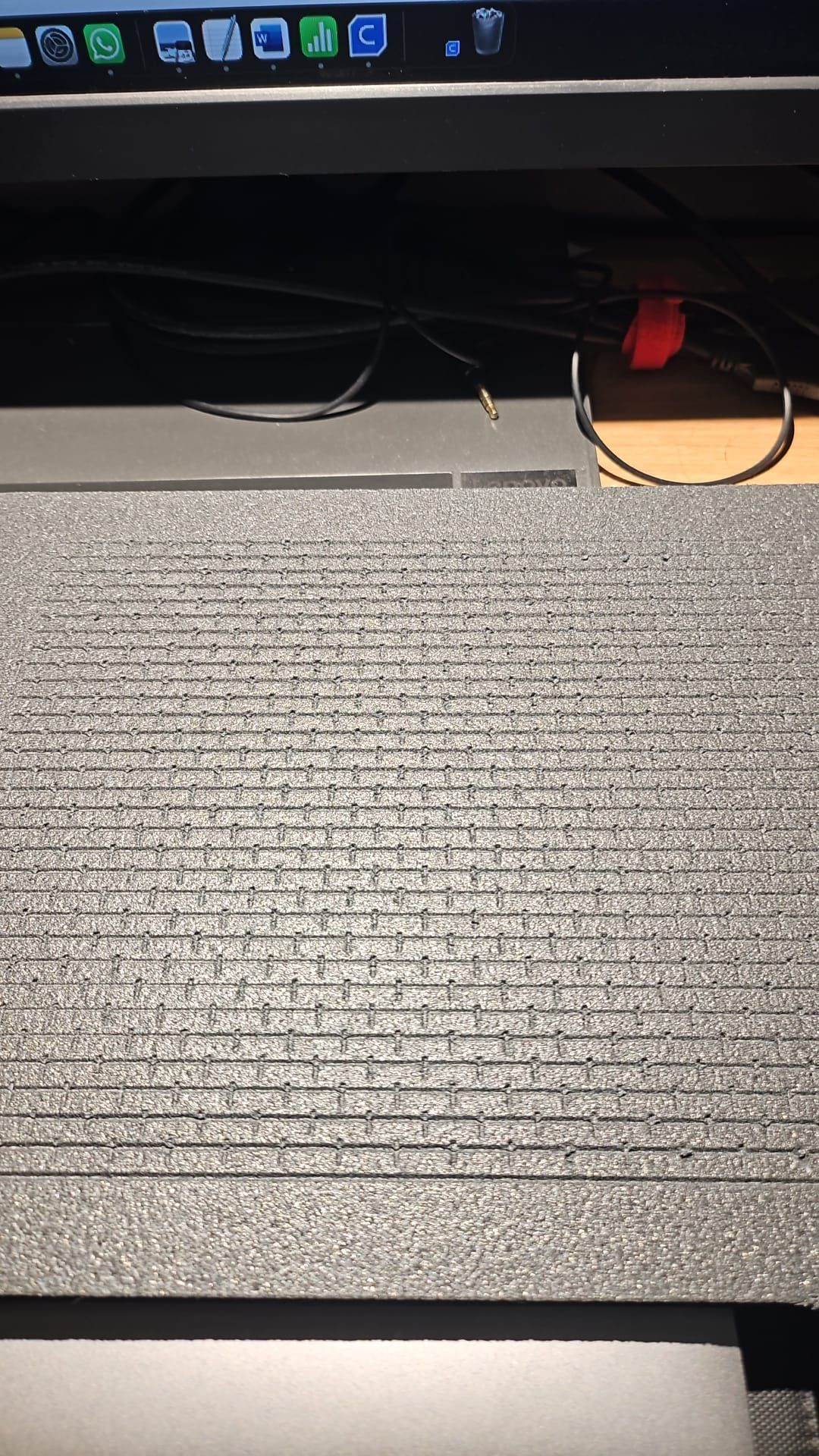

I have been scratching my head on this all day and cant seem to get it to work.Ive built a custom tool for my tool changer which I want to use to ‘engrave’ foam and make a wall of bricks for model making. The tool is a knife shape and can rotate from horizontal to vertical.

I have made the gcode work and the machine carves in the horizontal directions (imagine lines in a note pad) but when i go to vertical mode, the tool does not go in between the lines - this is because the blade is not in the centre of the tool, but offset. Please see picture attached which might help?

So the question is can i create a custom bit of gcode that works like it should in the x and y coordinate when cutting horizontal AND also then provides an offset when it is in the vertical? I thought a G52 offset would save me but this is not compatible with my duet. Can someone please guide me in the right direction!!

-

RE: Shipping damage duet 2 wifi and duex boardsposted in Order discussion

@Veti just going through the motion i guess... i just want to get make some suff now! haha

-

Shipping damage duet 2 wifi and duex boardsposted in Order discussion

I have recently purchased an E3D tool-changer directly from E3D and had it shipped within the UK. The box came damaged to my house, however being an old bigbox owner i believed the packaging would be more than adequate - it unfortunately wasn't as i received a few damaged items. This included a duet 2 board that had the E0 heater connector snapped off as well as a faulty E1 heater. I did try the E2 heater on the duex board which was working on and off sometimes the heater heated up, others it didn't (this might be a faulty heater cartridge i am yet to test this). Furthermore, both boards were giving me many issues with the drivers.

Error short to ground on drivers 1-2-3-4-5-6-7-8-9 came up a numerous times.

Followed by a constant

Error short to ground on drivers 5-6-7-8-9 error meaning i am unable to use any of the duex motor drivers, as well as the E0 and E1 heaters on the duet board.

In light of this, i contacted E3D and they suggested i should post here and hopefully we can get the issue sorted.

-

RE: Duet 2 wifi controlling brushless drone motorsposted in Duet Hardware and wiring

Understood, would this code be put in the config.g file or is there a better place to put it?

-

Duet 2 wifi controlling brushless drone motorsposted in Duet Hardware and wiring

Hi all, hope you're all taking care in these terbulant times.

I am in the process of building a shuttle feeder to help aid in my badminton training once we're allowed back to sports centres - this is the 'cockrocket MK3' so I'm slowly getting to a more defined design. I started with using servos but they keep burning out tragically.

I'm currently using an arduino with stepper drivers, but I'm have a spare duet board from an older project and I'm wondering if I can use a duet instead.

The movement is two parts:

Part 1 is done by 3 stepper motors that would rotate about 45 degrees clockwise and anti clockwise to turn an iris to feed the shuttles down and out towards two wheels. This process happens on repeat for 24 rounds as a round holds 24 shuttlecocks (was originally a servo but they're burning out on me)

Part 2 is done by two drone motors that spin and fling the shuttle away to the other side of the court. These motors have to be armed to fire and it's done via the servo library in arduino.

I was wondering how I would attack this with the duet, I dont know if this is the best use case for it either. Hopefully that all makes sense, will happily send across some pictures if they're needed!

-

RE: homing issuesposted in Duet Hardware and wiring

@phaedrux have just calibrated the steps per mm so hopefully it'll all work out now just doing a test print now will see how it goes.

thanks for the help as always guys! -

RE: homing issuesposted in Duet Hardware and wiring

update:

printer is homing wooo bed levelling is also working ay BUT now next problemo, just never end do they. when i start to print, the nozzle keeps laying down filament nice strand on the bottom layer and then just takes it out on the next pass (not nice). then it just starts to peel itself of so that is not ideal any idea how to sort out that conundrum?

or is it just bed adhesion problem (just have a glass bed atm) -

RE: homing issuesposted in Duet Hardware and wiring

oops totally forgot about that!

i typically just home all.

i see the 1000 on x and y on head positionM208

Axis limits X-55.0:300.0, Y-20.0:200.0, Z0.0:200.0

Axis limits X-55.0:300.0, Y-20.0:200.0, Z0.0:200.0the home code is:

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2 on Thu Mar 07 2019 19:22:18 GMT+0000 (Greenwich Mean Time)

G91 ; relative positioning

G1 Z0.5 F6000 S2 ; lift Z relative to current position

G1 S1 X-325 Y-230 F1800 ; move quickly to X and Y axis endstops and stop there (first pass)

G1 X5 Y5 F6000 ; go back a few mm

G1 S1 X-305 Y-205 F360 ; move slowly to X and Y axis endstops once more (second pass)

G90 ; absolute positioning

G1 X0 Y0 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 S2 Z0.5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

homing issuesposted in Duet Hardware and wiring

hi again guys, so ive got a few more problems involving homing now. The print head doesnt seem to go where i want it to! im not sure how to fix it.

my print size is 220x200x300 but when looking on my x y on the web interface i get like 1000 for both. any idea how to fix this?

The head goes off the print bed to hit the limit switches (it should do that) but i still cant get it to both go to the middle of the bed and auto level the whole be.movement code looks something like

; Drives

M569 P0 S1

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forward

M584 X0 Y1 Z3 D4:2 ; Apply custom drive mapping

M906 X800 Y600 Z800 E1000 ; Set motor currents (mA)

M201 X800 Y800 Z15 E1000 ; Accelerations (mm/s^2)

M203 X15000 Y15000 Z100 E3600 ; Maximum speeds (mm/min)

M566 X600 Y600 Z30 E20 ; Minimum speeds mm/minute

M208 X300 Y200 Z200 ; set axis maxima (adjust to suit your machine)

M208 X0 Y0 Z-0.2 S1 ; set axis minimum (adjust to make X=0 and Y=0 the edge of the bed)

M92 X160 Y360 Z1600 ; Set axis steps/mm

M92 E304:304 ; Set extruder steps per mm

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M350 X16 Y16 E16 I1 ; Set 16x microstepping with interpolation; Axis Limits

M208 X-30 Y-20 Z0 S1 ; Set axis minima

M208 X220 Y200 Z300 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S1 ; Set active high endstops; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P1 H5 F120 T6000 ; Set Z probe type to unmodulated and the dive height + speeds

G31 P500 X150 Y100 Z-0.25 ; Set Z probe trigger value, offset and trigger height

M557 X10:220 Y100:200 S40 ; Define a 6x4 point grid for measuring the bed -

RE: big box madnessposted in Duet Hardware and wiring

Yes they are correctly working in another driver currently in E1 abd working fine

-

RE: big box madnessposted in Duet Hardware and wiring

@phaedrux have tried that too but there was the same phasing error

-

RE: big box madnessposted in Duet Hardware and wiring

ok whilst im waiting for the thermistors ive hit a new problemo, the z axis motors are not working.

currently i have two z axis motors and they're in parallel so two wires are connected to make one pin point (have tried singular connections too) .

have had them in driver 0 but they're not working.

have then re-pinned it to the E1 driver and managed to get the z to work so now i have all of the axis working yay. BUT driver 0 is still playing up. currently i have my other extruder there but its also not working. i keep getting a phase error as before for the Y driver. so the error, and no movement but every other driver works fine,have done everything as advised earlier in the thread so im no sure what else to do in relation to this driver.

-

RE: big box madnessposted in Duet Hardware and wiring

@veti im with you now!

thanks so much

will feedback once i get the new thermistors -

RE: big box madnessposted in Duet Hardware and wiring

@Veti it has been done before

https://forum.e3d-online.com/threads/bigbox-duetwifi-controller.1766/

so im confused now haha!

the dude got it to work with

;*** If you have a Duet board with 1K thermistor series resistors, change R4700 to R1000 to the following M305 commands

M305 P0 T100000 B4388 R4700 H30 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 T100000 B4388 R4700 H30 L0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M305 P2 R4700 H0 L0 ; Put your own H and/or L values here to set the second nozzle thermistor ADC correction

M301 H1 P10 I0.10 D100 T0.50 S1.0 ; PID settings for extruder 0

M301 H2 P10 I0.10 D100 T0.50 S1.0 ; PID settings for extruder 1

M570 S120 ; Increase to allow extra heating time if needed

M106 F10 ; Fix for Bigbox Blower -

RE: big box madnessposted in Duet Hardware and wiring

@phaedrux yes used the ones as advised on the wiki

-

RE: big box madnessposted in Duet Hardware and wiring

@phaedrux thanks for the help as always. have just done it. temps are now ~280 so we we need another 90%hit! print head is stone cold.

M305 P0 R4700 T100000 B3950 (for the bed WORKS!)

M305 P1 R4700 T100000 B4725 C0.0000000706 (HOT END NOT WORKS) -

RE: big box madnessposted in Duet Hardware and wiring

@phaedrux i have a separate thermistor sorry i should of said that, the thermistor fist into the pt100 but i dont understand why i cant just put it in the motherboard. temps are still wrong when i do that