Will do - thanks @dc42!

Mike

I couldn’t see anything either - glad I’m not going crazy! Ha.

It is 350mm using 26awg ribbon cable we buy from 3M. We make the cables in house.

I tried another (third) screen and that one worked too, just not sure why the first one won’t work with the PT100.

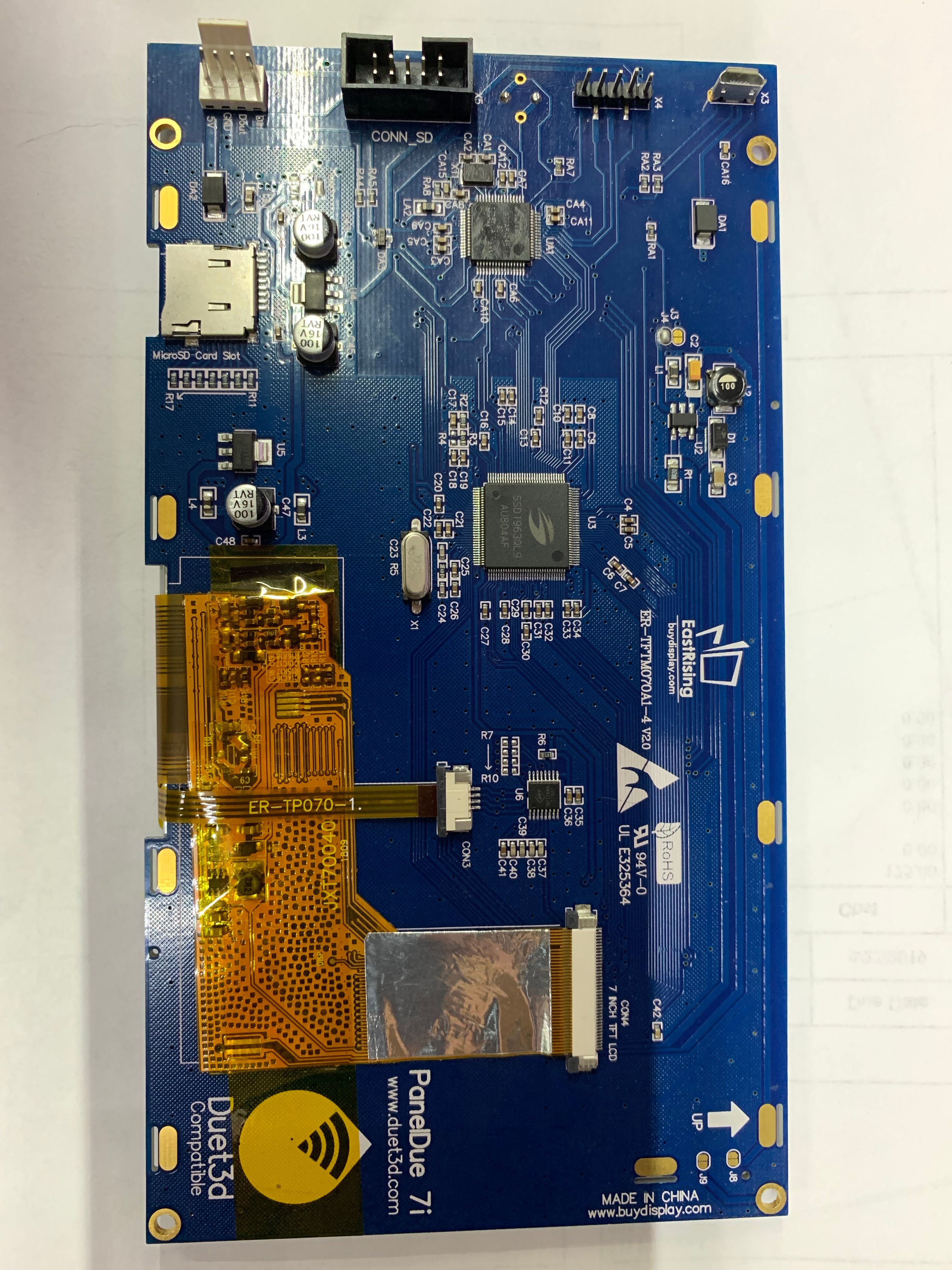

Apologize for the late reply here - but here are some pictures if you see anything I missed.

Thank you!

@dc42 said in PT100 Reads 2000C With PanelDue7 Plugged In Via 10 Pin Cable:

PanelDue

Thanks for the reply @dc42 and @Phaedrux .

Looks like the problem is solved - must be a short on the PanelDue7i screen. I took another one from inventory and swapped them out - everything is working fine. Thank you both for your suggestions!

@dc42 - Is there anything we can do to fix the one screen we have? Or do we need to write it off?

Thanks!

Mike

@Phaedrux - we did follow that page for setup, but I did not see the two to four wire conversion for the daughter board. I’ll try that tomorrow and report back. Thanks for the tip!

Mike

@Phaedrux Appreciate the info. We are open to ideas. We need to be able to give our customers a way to print offline - so I’m open to trying any ideas you or @dc42 may have.

Thanks!

Mike

Thanks for the reply @Phaedrux .

It is a 2 wire PT100 using the Duet Daughter board.

Hello Everyone,

We are upgrading our BFP-ICARUS units to PT100 sensors on the Dyze Pro hotends, and we noticed, upon installing the PT100 with the appropriate adapter board, the temperature will read 2000C with the PanelDue7 plugged in with the 10 pin ribbon cable. When the cable is unplugged, the PT100 works great and has an accurate reading. We used the four pin cable in the mean time to be able to use the touchscreen with the unit, but is there something we can do to be able to use the PT100 sensor and the PanelDue7 screen with the 10 pin ribbon cable? Somehow using the 10 pin ribbon cable is causing interference with the PT100 sensor and we are not sure how to troubleshoot this further. Some of our customers do not have Wifi and rely on offline printing via the MicroSD card on the touchscreen.

Thanks!

Mike

@dc42 Thank you so much sir! That is exactly what we needed to here. I wanted to be sure, spec wise, we were shipping our units within reasonable tolerances. Thanks to @Phaedrux who helped us out a few months ago with getting our bed leveling just right, this was a final question we had. As always, great product and keep up the good work! We are very impressed with the QC standards you have and are proud to be shipping our BFP-ICARUS units with your hardware.

Mike

Just seeing if anyone has any suggestions on this - thanks!

Mike

Hi All,

I apologize if this has been answered - but I looked all over and couldn't find any answers for it. For Mesh Bed Compensation, is there a suggested or acceptable level of deviation (max to min) to ensure Mesh Bed Compensation is working as intended? Just curious as to what the Duet Wifi can handle from a max/min deviation perspective. Our print area on our machines tend to be within 0.300mm (max/min deviation) over a 475mm (X) and 410mm (Y) span.

Thanks!

Mike

Wanted to share this with you.

By making:

Look at the heigh map we have now: Link

This is night and day compared to what we had before, by doing nothing but software adjustments. I will keep you in the loop on how we progress. We truly appreciation your support from all of us here at FI.

Mike

Thanks for the help! We will be trying this either today or tomorrow and will report back what we find. We have some prints for some customers wrapping up and I will test this ASAP.

Mike

Absolutely. Thank you again for your help.

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Sun Nov 04 2018 16:39:54 GMT-0500 (Eastern Standard Time)

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Network

M550 PBFP-ICARUS-X DEMO UNIT ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S0 ; Drive 4 goes backwards (second Z motor)

M584 X0 Y1 Z2:4 E3 U4 P3 ; Driver 0 For X, 1 for Y, Z=2:4 U=4, Extruder Motor 3

M671 X-140:710 Y207.5:207.5 S20 ; leadscrews at middle left and right

M350 X128 Y128 Z128:128 E128 U128 I0 ; Configure microstepping without interpolation

M92 X355.556 Y355.556 Z6400:6400 U6400 E4624 ; Set steps per mm

M566 X600 Y600 Z300:300 U300 E600 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z180:180 U180 E2000 ; Set maximum speeds (mm/min)

M201 X2000 Y2000 Z250:250 U250 E250 ; Set accelerations (mm/s^2)

M906 X1600 Y1600 Z1600:1600 U1600 E900 I30 ; Set motor currents (mA) and motor idle factor in per cent below

M84 S30 ; idle timeout in seconds

; Axis Limits

M208 X0 Y0 Z-5 S1 ; Set axis minima

M208 X475 Y410 Z915 S0 ; Set axis maxima

; Endstops

M574 X2 Y1 S1 ; Set active high endstops

M591 D0 P1 C3 S1 ; filament sensing for Dyze Sentinel

; Z-Probe

M574 Z1 S2 ; Set endstops controlled by probe

M558 P5 I1 F120 T12000 ; Set Z probe type NPN and dive height and speeds

G31 P25 X50 Y50 Z0.9 ; Set Z probe trigger value, offset and trigger height

M557 X50:475 Y50:410 S60 ; Define mesh grid

; Heaters

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S110 ; Set temperature limit for heater 0 to 110C

M305 P1 T4606017 B5848 C5.548428e-8 R4700 S0.5 H0 L0 ; Set thermistor + ADC parameters for heater 1

M143 H1 S410 ; Set temperature limit for heater 1 to 410C

; Fans

M106 P0 S1 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P2 S1 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off

; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss

; Custom settings are not configured

M501

For Z axis speed, max speed is 3mm/s

First layer print speed is normally about 25mm/s

Increasing the probing matrix can be done, we can try that. That is one of the few things we haven't tried. From what I can see, everything we have done is reasonable in terms of speed and such, please let us know your opinion.

Hi Phaedrux,

Thanks for the reply. I'll answer best we can.

Here is a link to the picture of the heightmap. Granted it isn't the most level as this plate didn't meet tolerances, but it is a great example to see how mesh bed level can compensate. From the human eye, the plate looks flat as ever - that is why I like Duet Web Control to be able to get a good visual.

For grid spacing we are at 60mm with 52 probe points.

We have ran G29 by both running the command and storing the info in the printer to be recalled at a later time, and both right at the end of the starting gcocde so it is the last thing the printer does before a print, and we get the same results.

The Duet system is definitely in mesh bed leveling mode and applying the mesh from the probing, but it doesn't seem to be compensating to create a level print, if that makes sense.

Thanks!

Mike

Hello Everyone,

We are getting ready to ship our first few BFP-ICARUS units with the Duet 2 Wifi board, and first and foremost, we are very impressed by the Duet 2 Wifi board. Thank you to everyone who helped to make it a reality and such a great board.

We have an 18"x16" print area that we use 5mm Carbon Fiber plates for, on top of that, is a magnetic sheet and a GECKO flex plate. I grabbed one of our Carbon Fiber plates that wasn't quite in spec to be sure mesh bed leveling is indeed working to ensure everything is good with the system. What I am seeing is, Mesh Bed Leveling is active by checking with the M122 command, and the Z motors are turning for compensation, but we don't see any compensation actually happening when you look at what is being printed. If the bed has a low point, then the filament is too high, is the bed has a high point, then the filament is squished into the bed, per what we can visually see via the height-map. We can feel the Z motors turning and they are turning in the correct direction as G32 works fine for tilt compensation and levels the bed accordingly, but it seems like the mesh compensation values aren't being applied?

We have one unit here with an NPN sensor that we are testing this on and the readings are consistent.

Here is some information that may be useful:

Starting gCode in S3D:

G32 ; home and check bed tilt

G29 S1 ; load prior mesh map

Clear Bed Map data M and G commands have been researched and are not present in bed.g and any home files

Z probe offsets are correct in the config.g file

M122 verifies Mesh Bed Leveling is in use

The systems are generating height maps via the G29 command.

To sum it up, we can see and feel mesh bed leveling in the Z motors, we just don't see the "compensation" actually happening on the printer. It sounds like there is no height map being applied. but we checked bed.g, all homing files, and the start gcode, and there is nothing to wipe it out. Plus M122 confirms it is working, but there is no "compensation" in the print.

Any ideas? All help is appreciated. Thanks!

Mike