Greetings again!

I have set up my Prusa MK2.5S/Bear Extruder/Full Bear/Duet 2 WiFi upgrade combo and so far it seems to print at least.

I am facing weird looking extrusion artifacts I have never seen before though..

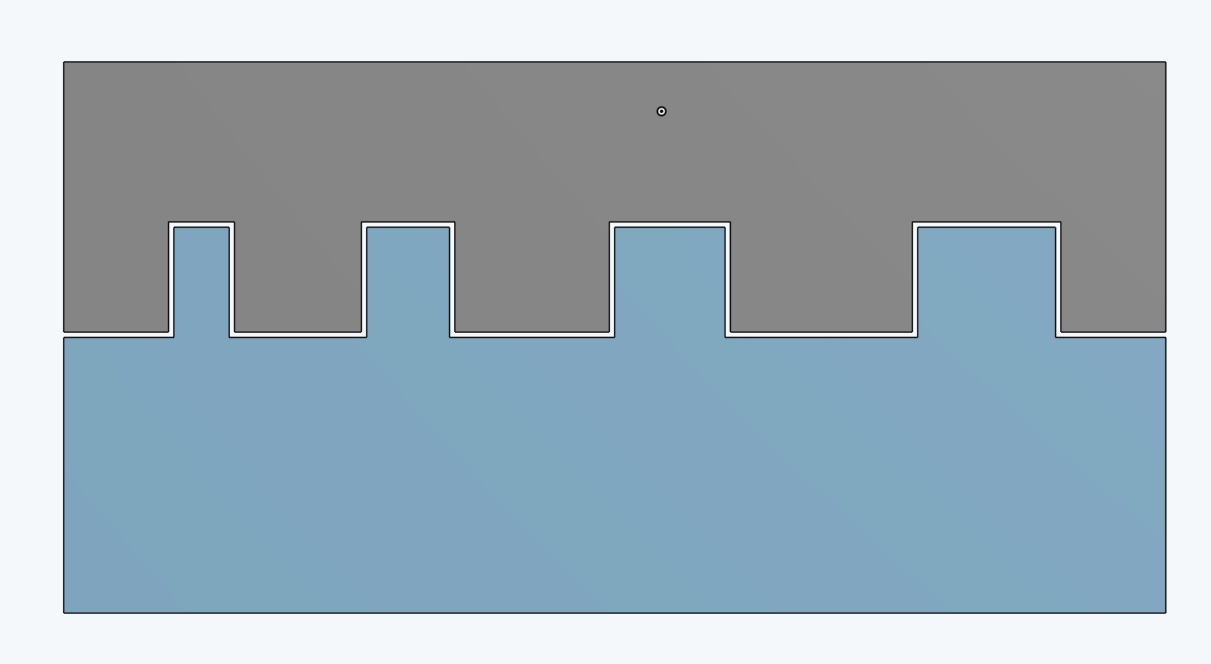

On one axis, I am getting intense vibrations, like, I can feel them with my nail:

The other axis side gets moire effect I have seen on Prusa github issues with MK3 owners..

My config is as follows:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.3 on Sat Nov 30 2019 21:16:45 GMT+0200 (Eastern European Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Prusa Bear MK2.5" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M671 X-36.0:290.0 Y110:110 S1 ; Set the Z motor relative locations correction 1mm

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E138 ; set steps per mm

M566 X600.00 Y600.00 Z12.00 E150.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z360.00 E7200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z200.00 E10000.00 ; set accelerations (mm/s^2)

M906 X600 Y600 Z600 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y-4 Z0 S1 ; set axis minima

M208 X250 Y210 Z210 S0 ; set axis maxima

; Endstops

M574 X1 Y1 S1 ; set active high endstops

M574 Z1 S2 ; set endstops controlled by probe

; Z-Probe

M558 P1 H0.85 F600 T12000 ;A3 S-0.03 ; set Z probe type to switch and the dive height + speeds

G31 P500 X23 Y5 Z0.625 ; set Z probe trigger value, offset(original 0.875) and trigger height

M557 X24:228 Y6:210 S50 ; define mesh grid

; Filament Sensor

M591 D0 P2 C3 S1

; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M305 P1 T100000 B4725 C7.060000e-8 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

T0 ; select first tool

;M572 D0 S0.104 ; pressure advance test

If anybody could see if anything is really wrong with my config, I would really appreciate this.

Right now the cube I have is perfectly 20x20x20mm and 0.45mm walled. So I would just love to get rid of these artifacts..