If I wanted to tilt the bed on a tool change with a chimera to give one side some extra room would I need to disable the mesh bed and re enable it after the bed movement or is there anything else. (Dual independent Z). So in tpre I want to lower one side and then in tfree I want to bring it back to normal. Just to experiment. Im on RRF 3.1.1.

Posts made by Ozzzzzzy

-

Chimera bed tiltposted in Tuning and tweaking

-

RE: Tool Changer con. g codeposted in General Discussion

Will this work

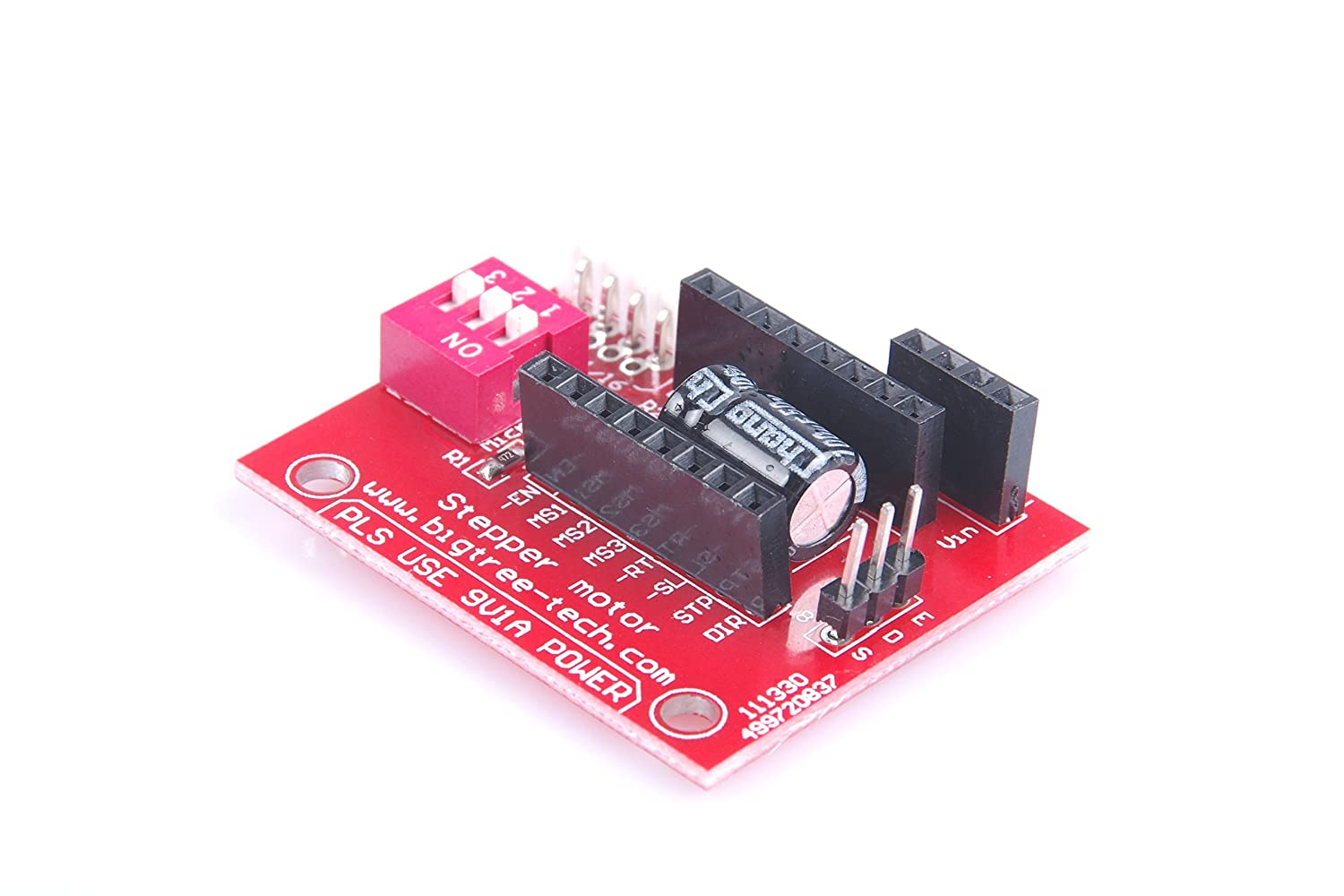

https://images-na.ssl-images-amazon.com/images/I/71LSxfU8%2BFL.AC_SL1000.jpg

https://images-na.ssl-images-amazon.com/images/I/71LSxfU8%2BFL.AC_SL1000.jpgI got this

https://images-na.ssl-images-amazon.com/images/I/81YyEdQAhCL.SL1500.jpg but it looks like it does not work with the 2208. it says it works with A4988 DRV8825

https://images-na.ssl-images-amazon.com/images/I/81YyEdQAhCL.SL1500.jpg but it looks like it does not work with the 2208. it says it works with A4988 DRV8825I want to add a volcano also witch will make 7 tools.

-

RE: Tool Changer con. g codeposted in General Discussion

Am I getting close on trying to not tool change with a chimera?

tfree0.gif state.nextTool = T1 break else G91 G1 Z4 F1000 G90 ;mesh levelling off G29 S2 ;Purge nozzle ;M98 Ppurge.g ;Move In G53 G1 X-9 Y150 F50000 G53 G1 X-9 Y300 F50000 G53 G1 X-9 Y310 F50000 G53 G1 X-9 Y317 F5000 ;Open Coupler M98 P/macros/Coupler - Unlock ;fan off M106 P2 S0 ;Move Out G53 G1 X-9 Y100 F50000 -

RE: C coupler direction.posted in General Discussion

I got .001 on one set of leads and .003 on the other. I had it set to ohms where it beeps. i got a beep on both leads. thats at the end of the extension wire threw the connector.

I have the M906 set to 400 now cause i didnt know the best way to reduce it before i ran the homec. I know it reduces after an unlock or lock. do i put an M913 after the M906 in the config.

Is there another way to reverse the motor.

-

RE: C coupler direction.posted in General Discussion

I dont know how to link a thread but i tried this allready.

dc42

If your C motor will only go one way, it could be that one of the phases is disconnected, because of a burned out motor winding, bad crimp connection, or faulty driver on the Duet. Try the following:

Use G92 followed by G1 H2 Cxx moves to test the motor and driver, with both positive and negative C values

Measure the resistance of the motor phases between the pins of the Duet motor connector (with power off of course).

If they look correct then try swapping the motor output with anther one, using M584 in config,g to swap them in firmware too (don't forget to swap the values in the two M569 commands too).except the resistance. Do I just check to see if the have the same resistance.

I order a new motor. wont hurt to have a spare if its not it.

also when i had it at 60% it only turned 1 direction but when i went to 70% it went both ways but still backwards.

-

RE: C coupler direction.posted in General Discussion

Im all over the place. I changed to 8 to see if it was the driver, just said it wrong. is that supposed to change the direction? Im rustry i first built my printer over a year ago.

-

RE: Independent Dual Z axis auto level.posted in Duet Hardware and wiring

I would try adding .05 or subtracting to one of youre leadscrew distances (M671 X-116.05:322 Y100:100 S4 ) and then see if you get a better score. or maybe .5

Might be you're probe. I use an original bl touch.

-

RE: C coupler direction.posted in General Discussion

; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin M667 S1 ; select CoreXY mode ;M550 ATronXY ; Set machine name M552 S1 ; Enable network M587 S"" P"" ; Configure access point. You can delete this line once connected M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M569 P5 S0 ; physical drive 5 goes backwards M569 P6 S0 ; physical drive 6 goes backwards M569 P7 S0 ; physical drive 7 goes backwards M569 P8 S0 M584 X0 Y1 Z2:5 C8 E3:4:6 ; set drive mapping M208 X-36.0:300 Y-4.0:317 Z0:400 C0:500 ; Set axis maxima & minima M350 X32 Y32 Z16:16 E16:16:16:16:16 I0 ; configure microstepping without interpolation M350 C8 I0 M92 X160.00 Y160.00 Z3200.00:3200.00 C100 E440.00:440.00:3200.00:3200.00:3200.00 ; set steps per mm M566 X3000.00 Y3000.00 Z12.00:12.00 C2 E120.00:120.00:12.00:12.00:12.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z200.00:200.00 C5000 E1200.00:1200.00:900.00:900.00:900.00 ; set maximum speeds (mm/min) M201 X300.00 Y300.00 Z200.00:200.00 C400 E300.00:300.00:1500.00:1500.00:1500.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200:1200.00 C400 E800:800:1200:800:800 I15 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Endstops M574 X1 S1 P"xstop" ; X min active high endstop switch M574 Y1 S1 P"ystop" ; Y min active high endstop switch ;M574 Z1 S1 P"zstop" ; Z min active high endstop switch M574 C1 S3 ; Stall detection for the couple ; Z probe ;M558 P7 H2 F360 I0 T35000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds M558 P8 C"zstop" H3 F360 I0 T35000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height M557 X20:260 Y20:240 S20.0 ; Define mesh grid M671 X-102.00:408.00 Y150.0:150.0 S8 ;Stall Detection MM915 C S6 F0 H200 R4700 ; Coupler ;Stall Detection M915 X Y S5 F0 H400 R4700 ; X / Y Axes ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 C0 ; Set thermistor M950 H0 C"bedheat" T0 ; Bed heater M143 H0 S225 ; Set temperature limit for heater 0 to 225C ;tool 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S270 ; set temperature limit for heater 1 to 270C ;tool 1 M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M143 H2 S270 ; set temperature limit for heater 2 to 270C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1:2 T20 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan1 and set its frequency M106 P2 S1 H-1 ; set fan 2 value. Thermostatic control is turned off ; Tools M563 P0 S"T0" D0 H1 F2 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"T1" D1 H2 F4 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M563 P2 S"T2" D2 H3 F6 ; define tool 2 G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C M563 P3 S"T3" D3 H4 F8 ; define tool 3 G10 P3 X0 Y0 Z0 ; set tool 3 axis offsets G10 P3 R0 S0 ; set initial tool 3 active and standby temperatures to 0C G10 P0 X-9 Y40 Z-4.9575 ; T0 - V6 G10 P1 X-8.55 Y39.7 Z-5.0125 ; T1 - V6 G10 P2 X-8.85 Y39.625 Z-5.0125 ; T2 - V6 G10 P3 X20.05 Y45.19 Z-5.7 ; T3 - Hemera ;deselect tools T-1 M501; homec.g ; called to home the C axis (coupler) G91 M400 ;M913 C70 ; XY MOTORS TO 60% CURRENT ;G1 H2 C30 F5000 ;M400 M913 C70 ; XY MOTORS TO 60% CURRENT G1 H2 C-1000 F10000 G92 C-125 G90 M913 C100 ; XY MOTORS TO 100% CURRENT G1 C0 F10000 ;Open Coupler M98 P"/macros/Coupler - Unlock"M400 M913 C100 G1 C33 F50000 M400 M913 C50M400 M913 C100 G1 C129 F50000 M400 M913 C50 -

C coupler direction.posted in General Discussion

What are all the ways I can try to change the motor direction. I tried changing the wiring and changed the M569 P7 S0 to S1 and tried changing my endstop from high to low with.

I am having trouble homing my c coupler. I think im over heating it. sometimes i can trick it and make it unlock and lock but after 2 or 3 it starts acting like an extruder and only goes one directionBoard: Duet WiFi 1.02 or later + DueX5

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.01-RC11 (2020-04-30b3)

Duet WiFi Server Version: 1.23 -

RE: Independent Dual Z axis auto level.posted in Duet Hardware and wiring

I can get down to .o3 . You can make a macro with you're bed.g.

dc42 said this in another thread.Copy your bed.g file to another macro file; then change the S parameter on the final G30 command to S-1 to get a report only when you run that macro.

-

RE: Independent Dual Z axis auto level.posted in Duet Hardware and wiring

I had that problem at first and it was I had both my z motors connected to the same z driver. I needed to switch one to a separate driver. I use driver 2 and 5 Z2:5 depending on youre firmware you might need a u axis.

-

RE: Tool Changer con. g codeposted in General Discussion

Yes that was me.This is awesome thank you. I do have the duex 5 and WiFi but I am going to get a duet 3. I have 2 printers I am converting. Im struggling with the C coupler. I posted on the e3d forum,

I cant get my C motor to go the right direction. I tried doing a G92 C123 and doing a C33 but the motor always goes the wrong way.I changed the wires on the stepper and changed the M569 P7 S1 and S0 but it always go the same direction. I tried homing C (stall) and M92. What is the best way to do the M92-- should i start it at 0 or go to unlock at 123 or go to 33 lock?

; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M569 P5 S0 ; physical drive 5 goes backwards M569 P6 S0 ; physical drive 6 goes backwards M569 P7 S0 ; physical drive 7 goes backwards M584 X0 Y1 Z2:5 C7 E3:4:6 ; set drive mapping M208 X-36.0:300 Y-4.0:317 Z0:400 C-500:500 ; Set axis maxima & minima M350 X32 Y32 Z16:16 E16:16:16:16:16 I0 ; configure microstepping without interpolation M350 C8 I0 M92 X160.00 Y160.00 Z3200.00:3200.00 C100 E440.00:440.00:3200.00:3200.00:3200.00 ; set steps per mm M566 X3000.00 Y3000.00 Z12.00:12.00 C2 E120.00:120.00:12.00:12.00:12.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z200.00:200.00 C5000 E1200.00:1200.00:900.00:900.00:900.00 ; set maximum speeds (mm/min) M201 X300.00 Y300.00 Z200.00:200.00 C500 E300.00:300.00:1500.00:1500.00:1500.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200:1200.00 C500 E800:800:1200:800:800 I15 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Endstops M574 X1 S1 P"xstop" ; X min active high endstop switch M574 Y1 S1 P"ystop" ; Y min active high endstop switch ;M574 Z1 S1 P"zstop" ; Z min active high endstop switch M574 C1 S2 ; Stall detection for the couple ; Z probe ;M558 P7 H2 F360 I0 T35000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds M558 P8 C"zstop" H3 F360 I0 T35000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height M557 X20:260 Y20:240 S20.0 ; Define mesh grid M671 X-102.00:408.00 Y150.0:150.0 S8 ;Stall Detection MM915 C S6 F0 H200 R4700 ; Coupler ;Stall Detection M915 X Y S5 F0 H400 R4700 ; X / Y Axes ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 C0 ; Set thermistor M950 H0 C"bedheat" T0 ; Bed heater M143 H0 S225 ; Set temperature limit for heater 0 to 225C; homec.g ; called to home the C axis (coupler) G91 M400 ;M913 C60 ; XY MOTORS TO 60% CURRENT ;G1 H2 C30 F5000 ;M400 M913 C60 ; XY MOTORS TO 60% CURRENT G1 H2 C-1000 F10000 G92 C-125 G90 M913 C100 ; XY MOTORS TO 100% CURRENT G1 C0 F10000 ;Open Coupler M98 P"/macros/Coupler - Unlock"G1 C33 F50000 M400G1 C123 F50000

M400 -

Tool Changer con. g codeposted in General Discussion

what external steppers should I use? extruder . I am not good with a soldering iron.

If its easy can someone get me started on the conditional G-code to not pick up or dock a tool with a chimera?

-

RE: Leadscrew G32 distance.posted in General Discussion

I have it working really good. I just know that my distances to the lead screws are just a close reference and I think that's where the small error comes in when doing a G32. I think there is a formula that will figure out what the true distance is, It might only have to run g32 once. Maybe save the new distances in the pid folder(M501) I love the way it is now. It might be easier to set one lead screw as a pivot point (dual independent) instead of X0 or Y0 if a formula would work.

-

Leadscrew G32 distance.posted in General Discussion

I think I can only get so close with my distances to the lead screws for the g32 level.(dual independent) I think I saw a thread were dc42 might have been talking about it but he used words I didn't know. There should be a way to run the g32 then it adjust the lead screw distances to get closer and repeats till its perfect. I was thinking i could do it with conditional gcode but now i think it has to be in the firmware.

-

RE: Bed levelling with 3 pointsposted in Tuning and tweaking

@dc42 I am running a chimera and I think my main concern is having the x axis the closest. I set my nozzle heights after I get dialed in. Its been working really good. It also seems like if I had a single nozzle it would be better if I could get it super close in 1 axes and close in the other. Rather then really close in all axes.