@t3p3tony

I appreciate this link!

Posts made by printernoodle

-

RE: What does M913 Znnn change in the object modelposted in Gcode meta commands

-

RE: What does M913 Znnn change in the object modelposted in Gcode meta commands

@dc42

Thank you very much indeed. -

What does M913 Znnn change in the object modelposted in Gcode meta commands

I cant find where this gcode changes anything in the object model:

M913 Z50Where should I be looking?

-

RE: Trouble Declaring Global Varposted in Gcode meta commands

going to the release version of 3.3 seems to have fixed it.

Thank you very much indeed!! -

RE: Trouble Declaring Global Varposted in Gcode meta commands

@fcwilt

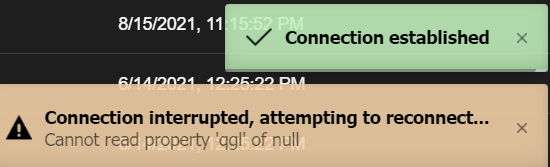

yes I've tried "global derack" "global magprobe_status" "global qgl"

all start some weird connection loop on the DWC -

RE: Trouble Declaring Global Varposted in Gcode meta commands

@fcwilt

sorry it's 3.3 rc2

duet 2 wifi -

Trouble Declaring Global Varposted in Gcode meta commands

How do you define a global variable?

I have tried enteringglobal status=truein the console

And then the web interface just goes into a non stop connect disconnect loop.

Tried the same withglobal status=1even tried putting this declaration right into gonfig.g

That just put the entire system into the same connection connect disconnect loop regardless of reboot.I've been struggling with this for a bit now....

cant get a global variable created...

What am I not doing here? -

RE: Here's a strange filament change behavior!posted in Using Duet Controllers

Oh god...never friggin mind....

I had inserted a 16mm compensation in tpost1.g this morning at 4am which I forgot about....All better now close post.....mark as solved.....revoke my 3dP license..

-

RE: Here's a strange filament change behavior!posted in Using Duet Controllers

@fcwilt

So I'm observing the change over on T1 and there's two moves on re-priming one short and then one the normal length...this cant be the slicer at this point in the code as the printer has full control...unless it's a buffered move? I just don't get it...how could the slicer be affecting things at this point. -

RE: Here's a strange filament change behavior!posted in Using Duet Controllers

G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"GEMLIN" ; set printer name M669 K1 ; select CoreXY mode ; Network M551 P"**************************" M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M569 P4 S1 ; physical drive 4 goes forwards M584 X3 Y4 Z0 E2:1 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E406.00:406.00 ; set steps per mm M566 X200.00 Y200.00 Z600.00 E600.00:600.00 ; set maximum instantaneous speed changes (mm/min) M203 X65000.00 Y65000.00 Z10000.00 E6000.00:6000.00 ; set maximum speeds (mm/min) M201 X6000.00 Y6000.00 Z500.00 E300.00:300.00 ; set accelerations (mm/s^2) M906 X2000 Y2000 Z750 E600:600 I75 ; set motor currents (mA) and motor idle factor in per centI30 M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X152 Y160 Z145 S0 ; set axis maxima ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin !xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin !ystop M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin !zstop ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:135 Y15:135 S15 ; define mesh grid ; Heaters M308 S3 Y"mcu-temp" A"CPU" ; Board thermal sensor M912 P0 S-8 ; MCU tempurature sensor correction (subtract 8°c) ;Bed heater dual thermistor setup M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 A"Bed Pad" ; configure sensor 0 as thermistor on pin bedtemp M308 S2 P"e0temp" Y"thermistor" T100000 B3950 A"Bed Plate" M950 H0 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2 M307 H0 B0 R0.135 C1478.8 D30.02 S1.00 V23.8 ; disable bang-bang mode for the bed heater and set PWM limit M307 H0 B0 R0.135 C1478.8 D30.02 S1.00 V23.8 M140 H0 ; map heated bed to heater 0 M143 H0 P1 T0 A2 S130 C0 ; Regulate (A2) bed heater (H0) to have pad sensor (T0) below 110°C. Use Heater monitor 1 for it M143 H0 P2 T0 A1 S145 C0 ; Shut off (A1) bed heater (H0) if pad sensor (T0) exceeds 120°C. Use Heater monitor 2 for it M143 H0 S110 ; set temperature limit for heater 0 to 120C ;hot end M308 S1 P"e1temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 R3.366 C143.3 D8.26 S1.00 V23.8 ; disable bang-bang mode for heater and set PWM limit H1 B0 R3.366 C143.3 D8.26 S1.00 V23.8 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q120 ; part cooler, set to 20Hz PWM M106 P0 S0 H-1 C"TOOL FAN" L0.25 B0.1 ; Name it "PartCooler" ;Hot End M950 F1 C"fan1" Q120 ; create fan 1 on pin fan1 and set its frequency M106 P1 H1 T45:270 C"HotEndFan" L0.25 B0.1 ; set fan 1 value. Thermostatic control is turned on ; controller / electronics fan M950 F2 C"fan2" Q120 ; create fan 2 on pin fan2 and set its frequency M106 P2 H3 T20:35 C"ElectronicsFan" L0.40 B0.1 ; fan is activated when MCU reports 35°C; runs on full speed from 50°C on H100:101:102 M950 F3 C"e1heat" Q120 ; create fan 2 on pin fan2 and set its frequency M106 P3 H1 T45:190 C"Lights" L0.0 B0.0 ; fan is activated when MCU reports 35°C; runs on full speed from 50°C on H100:101:102 ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H1 F0 ; define tool 1 G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss ;T0 ; select first tool M302 S160 R20 M572 D0:1 S0.2 ; pressure advance -

RE: Here's a strange filament change behavior!posted in Using Duet Controllers

Must be slicer because when I manually switch the tools back and forth there's no problem....I wonder what I'm missing in Cura for this strangeness to be happening..

-

RE: Here's a strange filament change behavior!posted in Using Duet Controllers

Actually I take it back....trying now with settings adjusted and Cura is still over extruding on tool change to T1.

-

RE: What would you build if you were starting again now?posted in General Discussion

Tiny-m - It's like a voron v.0.1 but 2020 extrusions and a bit bigger!

Very fast and precise...shown here in dual material configuration.

-

RE: Here's a strange filament change behavior!posted in Using Duet Controllers

you're on the right track....it was a slicer setting

all aspects of each material profile are the same for both tools in this case....I missed one called "nozzle switch retraction distance" under dual extrusion in Cura....I had it set to 16mm so there's the issue....over retraction and then sudden over extrusion because of the extra 16. -

Here's a strange filament change behavior!posted in Using Duet Controllers

So I have two tools set up on a duet 2 wifi.

When Cura switches between them the strangest thing seems to happen. Here's the setup...When Cura calls "tool 0" or "tool 1" the printer executes "tfree1.g" or "tfree0.g" which both contain:

M302 P1 ; allow cold fusion M98 P"/macros/moveto/filchange.g" M98 P"/macros/loadunload/unload.g" M302 P0 ; prevent cold fusionfilchange.g contains:

G91 ; rel moves G1 z.5 F99999 ; zhop G90 ; abs moves G1 x2 y140 F99999 ; move to purge spotunload.g contains:

G1 E-8 F1000 ; initial retract G4 S10 ; dwell to cool filament G1 E-90 F99999 ; fully retract filamentThen the machine calls "tpre0.g" which contains nothing at he moment.

And then "tpost0.g" or "tpost1.g" is called which contains:

M98 P"/macros/loadunload/load.g"load.g contains:

M302 P1 ; allow cold fusion G1 E99 F3600 ; quickly load back +1 G1 E10 F150 ; slowly purge 10mm M302 P0 ; prevent cold fusionSo what I'm observing is this

on changing over to "tool1" there seems to be a strange pause after

G1 E99 F3600 of load.g

then the slow purge which follows it...well it happens really rapidly instead of following the F150 speed....This only happens on changing over to T1

going from T1 back to T0 the slow purge works fine...THOUGHTS?

-

RE: Cant seem to set chamber temp via M141posted in Duet Hardware and wiring

Never mind I see it:

M141 P2 H2 should be M141 P0 H2 -

Cant seem to set chamber temp via M141posted in Duet Hardware and wiring

I can't set the chamber temp via Gcode terminal?

This is in my config.g:

;CHAMBER heater dual thermistor setup M308 S9 P"duex.e2temp" Y"thermistor" T100000 B4725 A"Chamber HEATER" ; configure sensor 9 as thermistor on pin temp1 (CHAMBER HEATER) C7.060000e-8 M308 S7 P"spi.cs6" Y"dht22" A"Chamber Temp" ; define DHT22 CHAMBER ACTUAL temperature sensor (CHAMBER TEMP) M308 S8 P"S7.1" Y"dhthumidity" A"Chamber Hum[%]" ; Attach DHT22 humidity sensor to secondary output of temperature sensor M950 H2 C"duex.e3heat" T7 Q60 ; create bed heater output on duex e3heat and map it to sensor 7 (CHAMBER TEMP). Set PWM frequency to 60Hz M141 P2 H2 ; Mark heater H2 as CHAMBER heater (for DWC) M143 H2 P1 T9 A2 S100 C0 ; Regulate (A2) CHAMBER HEATER (H2) to keep thermister (T9) below 200°C. Use Heater monitor 1 for it M143 H2 P2 T9 A1 S200 C0 ; Shut off (A1) bed heater (H2) if pad sensor (T9) exceeds 120°C. Use Heater monitor 2 for it M143 H2 S70 ; Set chamber heat max temperature to 56°C, use monitor 2 which is configured M307 H2 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit B0 R0.168 C1269.4 D15.79 S1.00 V24.0entering M141 S30

Returns:M141 S30

Error: M141: No chamber heater has been configured for slot 0What!?

-

Conditional setting of G31 based on thermistor inputposted in Gcode meta commands

Is there a conditional way to configure (G31 P1000 X0 Y0 Z-0.3) Z offset based on a dedicated thermistor?

Called in G30 (bed.g) or G29 (mesh.g)?

RRF 3.3 rc2 DuetWifi2