@Phaedrux

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.3 (2021-06-15 21:44:54) running on Duet Ethernet 1.02 or later

Board ID: 08DDM-9FAM2-LW4SD-6J9F4-3SN6M-92ZVY

Used output buffers: 3 of 24 (12 max)

=== RTOS ===

Static ram: 23876

Dynamic ram: 70408 of which 0 recycled

Never used RAM 20132, free system stack 122 words

Tasks: NETWORK(ready,28.0%,237) HEAT(delaying,0.0%,330) Move(notifyWait,0.1%,311) MAIN(running,71.7%,445) IDLE(ready,0.1%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:09:47 ago, cause: power up

Last software reset at 2023-02-13 14:38, reason: User, GCodes spinning, available RAM 20132, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 0

MCU temperature: min 17.4, current 27.9, max 28.3

Supply voltage: min 24.0, current 24.3, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Driver 0: position 132587, standstill, SG min/max 0/289

Driver 1: position 132587, standstill, SG min/max 0/291

Driver 2: position 132587, standstill, SG min/max 0/282

Driver 3: position 0, standstill, SG min/max not available

Driver 4: position 0, standstill, SG min/max not available

Driver 5: position 0

Driver 6: position 0

Driver 7: position 0

Driver 8: position 0

Driver 9: position 0

Driver 10: position 0

Driver 11: position 0

Date/time: 2023-02-13 18:05:45

Cache data hit count 4294967295

Slowest loop: 6.22ms; fastest: 0.17ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 2.8ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 410ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 11, completed moves 11, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 8.25ms; fastest: 0.02ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

Interface state active, link 100Mbps full duplex

OK, I answered to oliof just before that the network problem dissolved.... wrong. After issuing the response for M122 the network disconnect popped up on the right lower screen, it seems to be faster reconnected on a newer computer though...

DWC files... i did not intentionally, so how do I do it. yesterday I downgraded to 3.3.

Paneldue ... no since it says it only has about 29kb memory and as far as I read it, it is impossible to run

a newer firmware as 1.22 on it anyways...Am I wrong?

Config.g comes here....

; Configuration file for testing Duet Ethernet and Wifi

M575 P1 S1 B57600 ; enable support for PanelDue

M550 P"Monstaprint" ; Machine name and Netbios name (can be anything you like)

; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 R80 ; enable HTTP on Port80

; General preferences

;M665 L397.190:397.190:397.190 R175.000 H537.500

M665 R170 L397.19 B155 H525 ; set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here

; Drives

M569 P0 S1 ; Drive 0 (X) goes forwards

M569 P1 S1 ; Drive 1 (Y) goes forwards

M569 P2 S1 ; Drive 2 (Z) goes forwards

M569 P3 S1 ; Drive 3 (E0) goes forwards

M584 X0 Y1 Z2 E3 ; X on motor0, Y on motor1, Z on motor2, E0 on motor4

M350 E128 I0 ; Configure microstepping without interpolation

M350 X64 Y64 Z64 I1 ; Configure microstepping with interpolation

M92 X320 Y320 Z320 E1100 ; Set steps per mm

M566 X1200 Y1200 Z1200 E2500 ; Set maximum instantaneous speed changes (mm/min)

M203 X10000 Y10000 Z10000 E3000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1000 ; Set accelerations (mm/s^2)

M906 X1600 Y1600 Z1600 E1250 I50 ; Set motor currents (mA) and motor idle factor in per cent

; Endstops

M574 X1 S1 P"xstop" ; X min active high endstop switch

M574 Y1 S1 P"ystop" ; Y min active high endstop switch

M574 Z1 S1 P"zstop" ; Z min active high endstop switch

; Z-Probe - BLTouch

M950 H7 C"nil" ; Disable heaters h7 to free up pins

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 K0 F1500:150 T5000 ; set Z probe type to bltouch and the dive height + speeds

G31 X0 Y20 Z2.70 P50 K0; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

; Z-Probe - Nozzle

M558 P5 C"!e1stop" H10 K1 F1000:100 T2500 ; set Z probe type to bltouch and the dive height + speeds

G31 X0 Y0 Z0.1 P50 K1 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

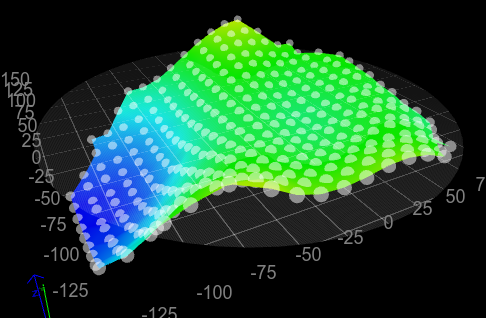

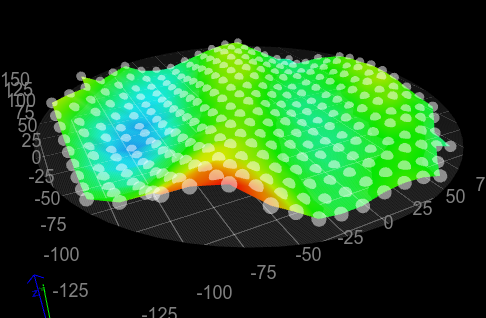

M557 R150 S15 ; Define mesh grid ;

; Bedheater

M301 H0 S1.00 P10 I0.1 D200 T0.4 W180 B30 ; Use PID on bed heater (may require further tuning) - old allowed to stay

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; sensor 0 ### R4700

M950 H0 C"bedheat" T0 ; create bed heater and map sensor 0

M140 H0 ; the bed heater is heater 0

M140 S65 R0 ; set bed temperature to 65C and bed standby temperature to 20C

M144 S0 ; activate standby temperature

;Hotend

M308 S1 P"e0temp" Y"thermistor" T100000 B4607 C8.950070e-8 R4700 ; sensor 1

M950 H1 C"e0heat" T1 ; create heater and map sensor 1; Tools

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 P0 S280 A2 ; switch off heater 1 temporarily if it exceeds 280°C

M143 H1 P1 S290 A0 ; raise a heater fault if it exceeds 290°C

; Fan Modes

M950 F0 C"fan0" ; Fan 0 definition

M950 F1 C"fan1" ; Fan 1 definition

M106 P0 T40 H1 ; Turn on Fan0 if Heater Temperature is above 40°C

M106 P1 S0 H-1 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned off

; Tools

M563 P0 D0 H1 F0 S"Extruder" ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R120 S0 ; set initial tool 0 active and standby temperatures to 120C

M501

M280 P0 S160 I1 ; Alarm Release and Push-Pin UP

G28

My M501 seems to work now... why don't know.

I tried to setup a second probe since the offset was to high and I can not make it work with BLTouch, since it is 20mm from the nozzle so I tried to go with some supermicro aliexpress tactile switch which I have to stick on the tip of the nozzle...

Bad thing about it ... can't get it configured as Probe ONE, always reads zero. I connected it to E1Stop and GND on DUET2... G31 K1 always reads 0, as K0 BLTOUCH reads 1000 when I activate it....

Is there something else to do?

Thank you so much for engagement, I feel now I'm not alone anymore.

BTW I figured out a Workaround for my Homeing Zero Problem.

- After Homing... all Axes did not Zero so I put a M92 X0Y0 and magically it zeroed....

- Relative move down to test BED with BLTOUCH.

- BLTOUCH updated correct 0(at least in the middle) so I do not crush the BED anymore..

Don't know how you do it but my homeing looks like that:

; Use relative positioning

G91

; Move all towers to the high end stopping at the endstops (first pass)

G1 H1 X750 Y750 Z750 F3500

; Go down a few mm

G1 H2 X-5 Y-5 Z-5 F2500

; Move all towers up once more (second pass)

G1 H1 X50 Y50 Z50 F500

; Go down a few mm

G1 H2 X-2.5 Y-2.5 Z-2.5 F2500

; Move all towers up once more (third pass)

G1 H1 X50 Y50 Z50 F100

G92 X0Y0

; Move down a few mm so that the nozzle can be centred

;G1 X-25 Y-25 Z-25 F5000 H2

;G1 X50 Y50 Z50 F1000 H3

; Reset BL-Touch

M280 P0 S160 I1 ; Clear any Alarms of BLTOUCH

M280 P0 S90 I1 ; Pen up

G1 X0 Y-20 Z-500 F10000

; Switch back to absolute positioning and go to the centre

G90

Over and out ... waiting for feedback