@phaedrux oh that's funny. I'm going to try that.

Posts made by sg2020

-

RE: bed thermistor problemposted in General Discussion

-

bed thermistor problemposted in General Discussion

Duet Wifi

RRF 3.2.2

AC silicone heater w/SSR, ThermistorThe heated bed was working on RRF2.1. Since upgrading it has not worked.

When I turned on my heated bed I received "Error: Heater 0 fault: temperature rising much more slowly than the expected 1.1°C/sec"

Spurious heater faults and how to avoid them recommended running a PID tune.I tried to run M303 T0 S60 and that turned on my extruder

M303 T1 S60 gave me an error saying "Error: M303: tool 1 not found"If I understand the gcode correctly, T0 should be the bed heater and T1 should be the extruder.

I should also add that my heater settings in RRF 2.1 was

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120Why isn't my bed heating up? what am I doing wrong?

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:52 GMT-0700 (Pacific Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode M564 S0 H0 ; allow movement outside of boundry, before homing ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X32 Y32 I0 ; configure microstepping without interpolation M350 Z16 E16 I1 ; configure microstepping with interpolation M350 X32 Y32 Z16 E16 I1 ; Configure microstepping with interpolation M92 X160.00 Y160.00 Z3230.00 E820.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X550 Y330 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"^zprobe.in" H2 F500 T8000 A1 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch G31 P500 X-6.5 Y-27 Z1.88 ; set Z probe trigger value, offset and trigger height 1.88 M557 X15:570 Y15:315 S71 ; define mesh grid M280 P0 S10 ; send control signal to BLTouch through servo/gpio 0 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue -

RE: Thermistor at 2000cposted in Firmware installation

@phaedrux I was also trying to get my E3D PT100 sensor to work and your code helped. Could you explain why this works? Why does it need p"spi.cs1"? why is it configuring the sensor 1 as a thermocouple?

-

RE: crashes when I run mesh bed compensationposted in General Discussion

@phaedrux

Changing the X2 Y2 to X1 Y1 seems to have done the trick.I setup the grid from fcwilt's advice.

Thanks everybody. I really appreciate it. For some reason going to RRF 2.1 to RRF 3.2.2 really confused me so thank you all for helping me get back up and running.

-

RE: crashes when I run mesh bed compensationposted in General Discussion

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; Lift z relative to current position G1 H1 X-555 F3000 ; home X axis G1 X15 F3000 G1 H1 X-30 F3000 G1 X15 F3000 G1 H1 Y-335 ; home Y axis G1 Y15 F3000 G1 H1 Y-30 F3000 G1 Y15 F3000 ;G90 ; absolute positioning is BAD REALLY REALLY BAD IT WILL CRASH!!! G1 X290 Y160 F3000 ; go to center of bed, probe point and home Z G30 ; home Z by probing the bed ; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-555 F600 ; move quickly to X axis endstop and stop there (first pass) G1 X15 F600 ; go back a few mm G1 H1 X-30 F600 ; move slowly to X axis endstop once more (second pass) G1 X15 F600 ; go back a few mm G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning ; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-335 F600 ; move quickly to Y axis endstop and stop there (first pass) G1 Y15 F600 ; go back a few mm G1 H1 Y-30 F600 ; move slowly to Y axis endstop once more (second pass) G1 Y15 F600 ; go back a few mm G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning ; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position ;G90 ; absolute positioning G1 X15 Y15 F600 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 H2 Z5 F100 ; lift Z relative to current position G90 ; absolute positioning -

RE: crashes when I run mesh bed compensationposted in General Discussion

Hmm, my endstops are physically located in the front left corner. That is my 0,0 point.

-X moves left, +X moves right

-Y moves to the front, +Y moves to the backMy homing sequence is working for x,y and z.

Are endstops supposed to be active low? should I invert it like is shows in the M574 Gcode dictonary?

"Endstop type S0 (active low switch) is no longer supported in M574 commands. Instead, use type S1 and invert the input by prefixing the pin name with '!'. Ex: M574 X1 S1 P"!xstop". Invert the input when using an NPN output inductive or capacitive sensor, or using a NO switch (not recommended, use a NC switch instead)."

-

RE: crashes when I run mesh bed compensationposted in General Discussion

@phaedrux the extruder carriage moves towards the origin and physically crashes. It ignores the end stops. I was really close to the origin and wasn't expecting that to happen when I first ran the mesh bed compensation macro, which is G29, and it actually split my 9mm wide gt2 timing belt when it crashed. It was absolutely terrifying and awesome to see the belt split like that.

-

crashes when I run mesh bed compensationposted in General Discussion

I can now home all of the axis. Thank you guys for helping with that. The next problem is, when I run Mesh bed compensation it will move to the origin and crash.

refference

Re: looking for an example of rrf3.2.2 corexy with bltouch config; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:52 GMT-0700 (Pacific Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode M564 S0 H0 ; allow movement outside of boundry, before homing ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes backwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X32 Y32 I0 ; configure microstepping without interpolation M350 Z16 E16 I1 ; configure microstepping with interpolation M350 X32 Y32 Z16 E16 I1 ; Configure microstepping with interpolation M92 X160.00 Y160.00 Z3230.00 E820.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X550 Y330 Z400 S0 ; set axis maxima ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"^zprobe.in" H2 F500 T8000 A1 ; set Z probe type to bltouch and the dive height + speeds M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch G31 P500 X-6.5 Y-27 Z1.88 ; set Z probe trigger value, offset and trigger height 1.88 M557 X15:500 Y15:330 S50 ; define mesh grid M280 P0 S10 ; send control signal to BLTouch through servo/gpio 0 ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue ; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; Lift z relative to current position G1 H1 X-555 F3000 ; home X axis G1 X15 F3000 G1 H1 X-30 F3000 G1 X15 F3000 G1 H1 Y-335 ; home Y axis G1 Y15 F3000 G1 H1 Y-30 F3000 G1 Y15 F3000 ;G90 ; absolute positioning is BAD REALLY REALLY BAD IT WILL CRASH!!! G1 X290 Y160 F3000 ; go to center of bed, probe point and home Z G30 ; home Z by probing the bed ; homex.g ; called to home the X axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 X-555 F600 ; move quickly to X axis endstop and stop there (first pass) G1 X15 F600 ; go back a few mm G1 H1 X-30 F600 ; move slowly to X axis endstop once more (second pass) G1 X15 F600 ; go back a few mm G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning ; homey.g ; called to home the Y axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G1 H1 Y-335 F600 ; move quickly to Y axis endstop and stop there (first pass) G1 Y15 F600 ; go back a few mm G1 H1 Y-30 F600 ; move slowly to Y axis endstop once more (second pass) G1 Y15 F600 ; go back a few mm G1 H2 Z-5 F6000 ; lower Z again G90 ; absolute positioning ; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position ;G90 ; absolute positioning G1 X15 Y15 F600 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 H2 Z5 F100 ; lift Z relative to current position G90 ; absolute positioningMy Mesh Grid macro is simply G29 S0

-

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

I got closer with homez. Thanks Nuramori your code helped a lot.

the code below works but moves the nozzle an extra 15mm in x and y.

Question, I commented out the relative positioning and only had it as absolute positioning. I already ran homex and homey then why is it moving towards x0,y0 and crash?

code_text ```; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time) G91 ; relative positioning G1 H2 Z5 F6000 ; lift Z relative to current position G90 ; absolute positioning G1 X15 Y15 F6000 ; go to first probe point G30 ; home Z by probing the bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 H2 Z5 F100 ; lift Z relative to current position G90 ; absolute positioningcode_text

-

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

Its wired exactly like the Duet 2 WiFi/Ethernet without expansion board picture from https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe#Section_BLTouch

-

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

M401 and M402 do not work.

That makes sense to move G29 S1 to the end of the config.g file. Done.

m115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.2.2 ELECTRONICS: Duet WiFi 1.0 or 1.01 FIRMWARE_DATE: 2021-02-11M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled -

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

@phaedrux ```

code_textPin Down M280 P7 S10 I1 ; Send PWM channel 7 the s10 (angle) command Pin Up M280 P7 S90 I1 ; Send PWM channel 7 the S90 (angle) command -

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

How did you guys post your config files earlier? Its a much cleaner way of sharing it.

-

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

here is my config.g

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:52 GMT-0700 (Pacific Daylight Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

M669 K1 ; select CoreXY mode

M564 S0 H0 ; allow movement outside of boundry, before homing; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X32 Y32 I0 ; configure microstepping without interpolation

M350 Z16 E16 I1 ; configure microstepping with interpolation

M350 X32 Y32 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X160.00 Y160.00 Z3230.00 E820.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X1600 Y1600 Z1500 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X550 Y330 Z400 S0 ; set axis maxima; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Z-Probe

M558 P9 C"^zprobe.in" H2 F100 T8000 A5 ; set Z probe type to bltouch and the dive height + speeds

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

G31 P500 X-6.5 Y-27 Z1.88 ; set Z probe trigger value, offset and trigger height 1.88

M557 X15:500 Y15:330 S50 ; define mesh grid

M280 P0 S10 ; send control signal to BLTouch through servo/gpio 0; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-555 F6000 ; move quickly to X axis endstop and stop there (first pass)

G1 X15 F6000 ; go back a few mm

G1 H1 X-30 F600 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Y-335 F6000 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y15 F6000 ; go back a few mm

G1 H1 Y-30 F600 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time)

;G91 ; relative positioning

;G1 H2 Z5 F600 ; lift Z relative to current position

;G90 ; absolute positioning

;G1 X15 Y15 F600 ; go to first probe point

;G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioningG91 ; relative positioning

G29 S1 ; use stored heightmap

G1 Z5 F6000 ; move down 30mm

G30 ; Do a single probe to home our Z axis

G1 Z5 F6000 ; Rapidly move the Z axis to Z=30G90 ; absolute mode

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Sun Jun 06 2021 18:17:53 GMT-0700 (Pacific Daylight Time)

G91 ; relative positioning

;G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X555 Y335 F6000 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X555 ; home X axis

G1 H1 Y335 ; home Y axis

G1 X-5 Y-5 F6000 ; go back a few mm

G1 H1 X555 F600 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y335 ; then move slowly to Y axis endstop

G90 ; absolute positioning

;G1 X290 Y160 F6000 ; go to center of bed, probe point and home Z

;G30 ; home Z by probing the bed; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning -

RE: looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

thank you everyone for the replies because I've been stuck.

Corexy

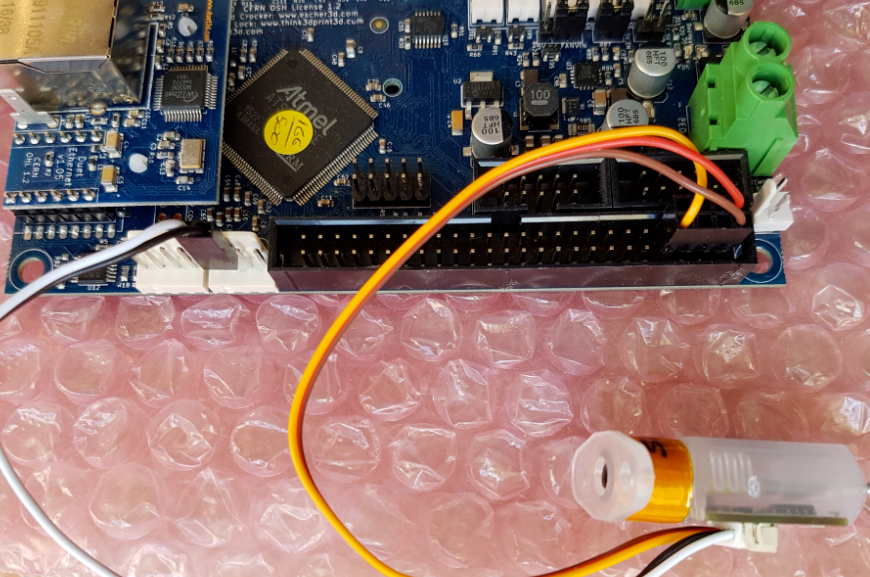

duet 2 wifi 2 board. a very early version, one of the early bird boards.

hooked up my bltouch according to without expansion board https://duet3d.dozuki.com/Wiki/Connecting_a_Z_probe#Section_BLTouchIt was working great on RRF 2.1 but stopped working when I upgraded to 3.2.2

What works:

web control

Home X and Home Y works

bltouch lights up and deploys/retracts during startup

sending deployprobe.g ( M280 P0 S10 ) and retractprobe.g ( M280 P0 S90 )what doesn't work:

z home

height map

deploy/retract macros

I haven't done anything with the heater, fans or tools sections yet. -

looking for an example of rrf3.2.2 corexy with bltouch configposted in General Discussion

I have a custom corexy that was running great on rrf 2.1 (duet wifi board) until I bought a new router. It wouldn't connect to the Wifi. I did some research and found how to update the SSID and password. Then I had the stupid idea of why don't I upgrade the firmware while I'm at it. That's where the problems started. I have most of my config file working but I can't figure out the Bltouch for the life of me. Does anyone have a good config.g file of a corexy with a bltouch I can see as an example?