@Phaedrux

During the initial test I was still wondering what the folowing terms meant: Whether trigger occurs on an inactive to active edge of that input (S1,default.... Does it mean that I0x.in will trigger when there is a connection between 3.3v and the I0x.in or the power is applied and connection broken. With the actual configuration I was able to have an external response only when the power was cut of from Iox.in. then the message in the Dwc was stating that an external trigger was active.... this is my first Duet board and modifying an ender 3 pro to print in 4 colors one nozzle... would really like to be able to get the trigger to work for the next steep of filament detection... E-stop first! thank you for your help with the request.

Regards

Thal.

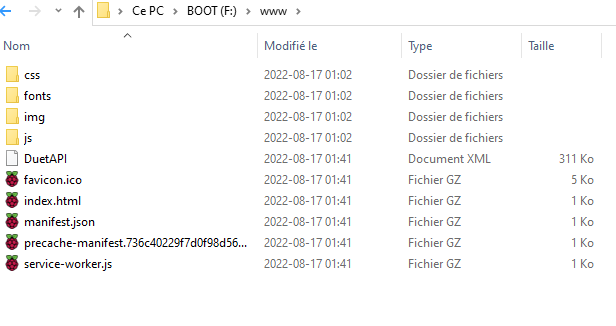

Here is the config.g files.

Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.13 on Sat Oct 15 2022 22:10:49 GMT-0400 (Eastern Daylight Saving Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Ender3Pro4ET" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S0 ; physical drive 0.3 goes backwards

M569 P0.4 S1 ; physical drive 0.4 goes forwards

M569 P0.5 S1 ; physical drive 0.5 goes forwards

M569 P0.6 S1 ; physical drive 0.6 goes forwards

M584 X0.0 Y0.1 Z0.2 E0.3:0.4:0.5:0.6 ; set drive mapping

M350 X16 Y16 Z16 E16:16:16:16 I1 ; configure microstepping with interpolation

M92 X79.46 Y79.36 Z401.00 E95.99:96.30:96.00:96.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00:120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00:1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00:250.00:250.00 ; set accelerations (mm/s^2)

M906 X900 Y900 Z900 E850:850:850:850 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; external trigger E_stop

M950 J1 C"io6.in" ; Create J1 external trigger on io6.in

;M581 P1 T0 S1 R0 ; Trigger Pn trigger J1 to execute T0 to reset motherboard T1 to put in pause with S1 positive to negative reading R0 for all the time R1 for printing from sd.

M581 P1 T1 S1 R0 ; Trigger to execute pause with S1

M82 T1 S0

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X235 Y235 Z215 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in

M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

; Z-Probe

M950 S0 C"io3.out" ; create servo pin 0 for BLTouch

M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-45 Y-15 Z3.718 ; set Z probe trigger value, offset and trigger height (3.63+.15)=3.718

M557 X10:235 Y10:235 S30 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 1 to 285C

; Fans

M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 S"Spool_1" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Spool_2" D1 H1 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"Spool_3" D2 H1 F0 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C

M563 P3 S"Spool_4" D3 H1 F0 ; define tool 3

G10 P3 X0 Y0 Z0 ; set tool 3 axis offsets

G10 P3 R0 S0 ; set initial tool 3 active and standby temperatures to 0C

; Custom settings are not defined

M501 ; Load non volatile parameters

M911 S21.0 R23.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Save position when power goes under 21 volts

; Emergency stop of the duet board

;M950 J1 C"io6.in" ; Create J1 external trigger on io6.in

;M581 P1 T0 S1 R0 ; Trigger Pn trigger J1 to execute T0; to reset motherboard T1 to put in pause with S1 positive to negative reading R0 for all the time R1 for printing from sd.

;M581 P1 T1 S1 R0 ; M581 with T1 for a pause.

;M582 T1

T0