@dc42

I set the value for M566 up to 9000 but it didn't help.

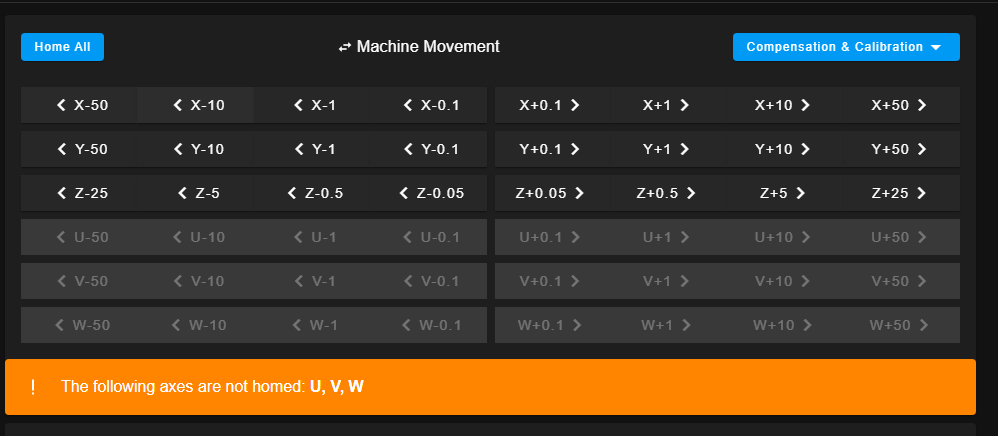

So if I move with coupled axes

M584 X0.4:0.5 Y0.2:0.3 Z0.0:0.1 E1.0

everything works fine with a value of M566 1200.

As soon as I decouple the motors like this , the movement jerks a lot.

M584 X0.4 Y0.5 Z0.0 U0.1 V0.2 W0.3 P6 ; Motoren entkoppeln

M350 X16 U16 Y16 V16 Z16 W16 E16 I1 ; configure microstepping with interpolation (*)

M92 X160.00 U160.00 Y160.00 V160.00 Z160.00 W160.00 E690.00 ; set steps per mm (*)

M566 X1200.00 U1200.00 Y1200.00 V1200.00 Z1200.00 W1200.00 E300.00 ; set maximum instantaneous speed changes (mm/min) (*)

M203 X18000.00 U18000.00 Y18000.00 V18000.00 Z18000.00 W18000.00 E7200.00 ; set maximum speeds (mm/min) (*)

M201 X1000.00 U1000.00 Y1000.00 V1000.00 Z1000.00 W1000.00 E3000.00 ; set accelerations (mm/s^2) (*)

M906 X1600 U1600 Y1600 V1600 Z1600 W1600 E1200 I80 ; current (A)

G92 X0 Y0 Z0 U0 V0 W0

G91

M83 ; use absolute distances for extrusion

This is the config. file:

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes forwards (y1)

M569 P0.1 S1 ; physical drive 0.1 goes forwards (y2)

M569 P0.2 S0 ; physical drive 0.2 goes forwards (x1)

M569 P0.3 S1 ; physical drive 0.3 goes forwards (x2)

M569 P0.4 S0 ; physical drive 0.4 goes forwards (z1)

M569 P0.5 S0 ; physical drive 0.5 goes forwards (z2)

M569 P1.0 S0 ; physical drive 1.0 goes forwards (Extruder 1)

M584 X0.4:0.5 Y0.2:0.3 Z0.0:0.1 E1.0

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation FUNKTIONIERT!

M92 X160.00 Y160.00 Z160.00 E690.00 ; set steps per mm FUNKTIONIERT!

M566 X1200.00 Y1200.00 Z1200.00 E600.00 ; set maximum instantaneous speed changes (mm/min) FUNKTIONIERT!

M203 X18000.00 Y18000.00 Z18000.00 E7200.00 ; set maximum speeds (mm/min) FUNKTIONIERT!

M201 X1000.00 Y1000.00 Z1000.00 E3000.00 ; set accelerations (mm/s^2) FUNKTIONIERT!

M906 X1600 Y1600 Z1600 E1200 I80 ; set motor currents (mA) and motor idle factor in per cent FUNKTIONIERT!

M84 S30

M208 Z0 S1

M574 X2 S1 P"io5.in+io6.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin 1.io1.in

M574 Y2 S1 P"io3.in+io4.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin 1.io2.in

M574 Z2 S1 P"io1.in+io2.in"

M558 P8 R0.4 H10 C"io8.in+io8.out" F1200

G31 P100 X0 Y0 Z-0.1 ; set Z probe trigger value, offset and trigger height

M557 R85 S20

M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"1.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp3

M950 H1 C"1.out0" T1 ; create nozzle heater output on 1.out0 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M950 F0 C"1.out7" Q500 ; create fan 0 on pin 1.out7 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"1.out6" Q500 ; create fan 1 on pin 1.out6 and set its frequency

M106 P1 S1 H1 T45

M563 P0 S"SIX" D0 H1 F1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0