Figured it out.

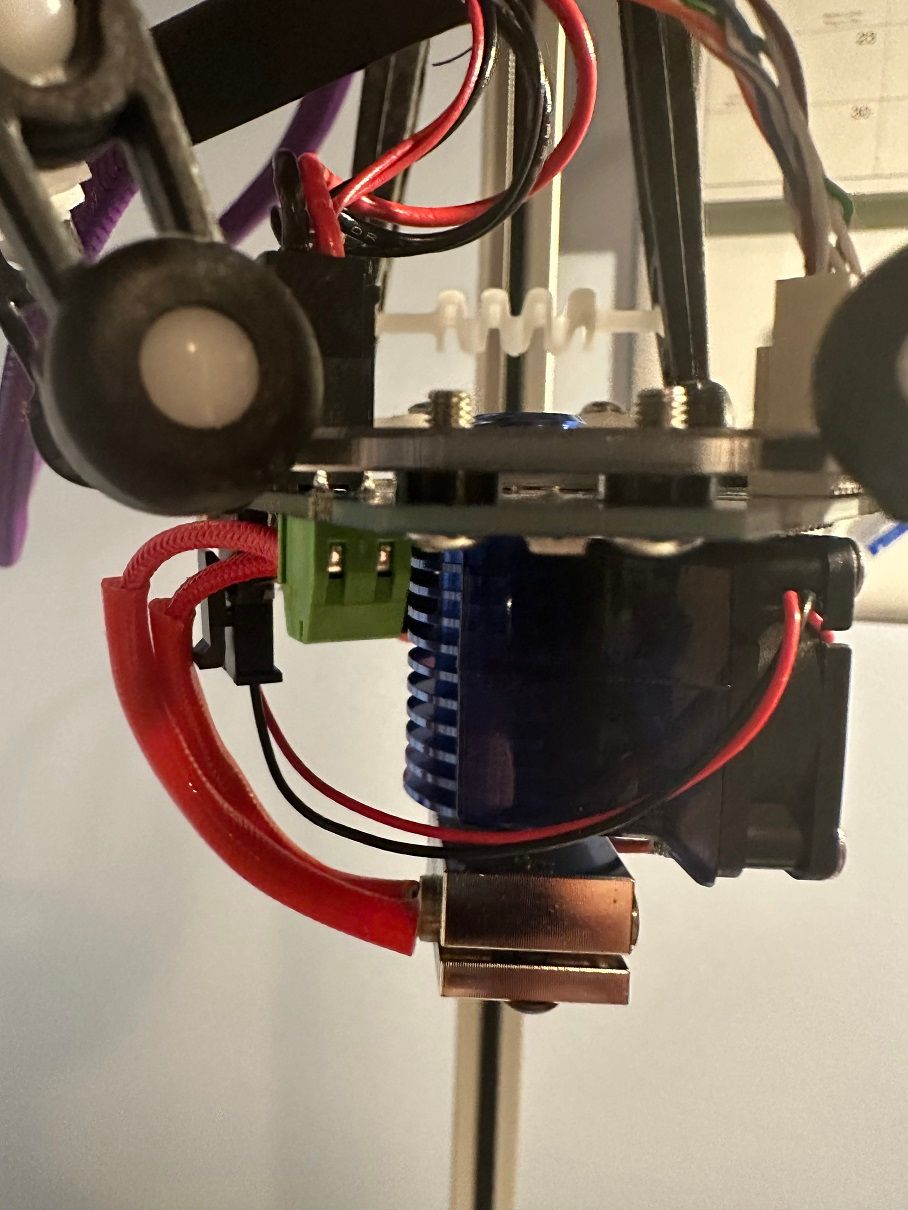

I believe the PT100 wire gauge was too small to make a good contact in the connector.

It was good enough for resistance reading but not when things were powered up.

I seperated out the PT100 wires out and used a smaller JST plug and it's all working now.

Thanks for the patience.

Thk

Thk