@deckingman Bud, you're not wrong. I know what you're talking about from using my old bedslingers.

But at the sametime, I think having missing values on an extruder I have zero experience with is a symptom for my problems. And that Bondtech guide while it is in english, is difficult for me to confirm if I can apply it to Duet.

Like I can't be sure LONG_MOVE_SPEED (UM2 firmware value) is the same as Max Speed (Duet firmware). Something could be lost in translation of different styles of text for what may or may not be the same values.

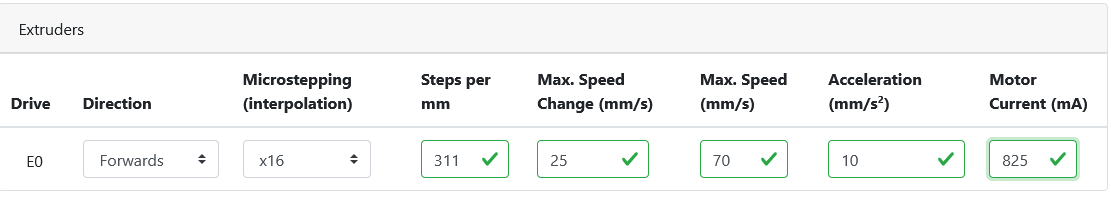

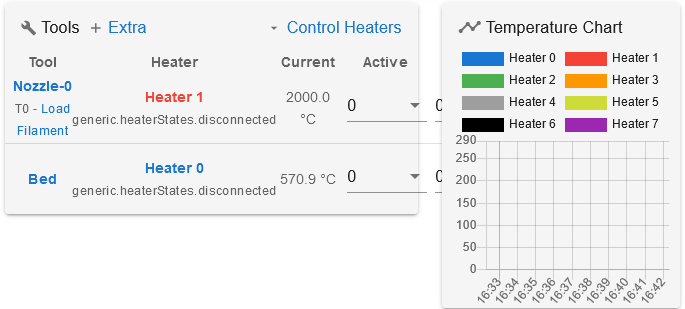

Which is why I keep surfing google for DDG values and bombarding different forums that I think might be able to answer this question: what am I missing for Max. Speed Change (mm/s), Max Speed (mm/s), Acceleration (mm/s2), and Motor Current (mA)?

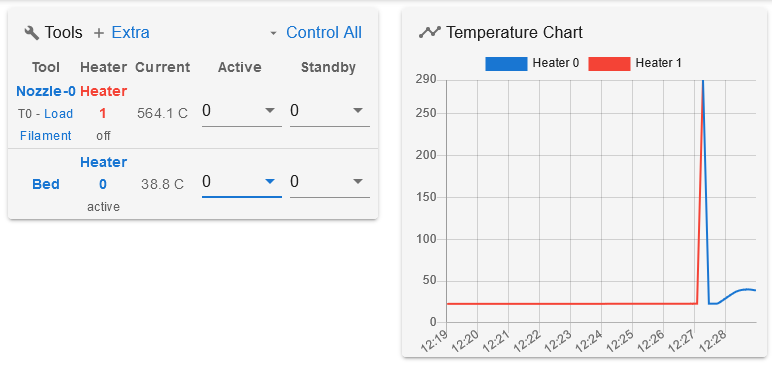

I need a baseline. With those values, I could then approach it different. If it's printing with the right numbers and it's still making noise, I can then ask new questions. I could watch it print and if it does so without issue (aside from sometimes clicking), I'd have a baseline where it's like "ok, so this is what it sounds like normally when it prints." I don't have that.

And Bondtech makes it a point in their guide that certain values need to be changed (not just e-steps).

Still, I welcome all advice. So thank you. This long rant was more for...well hope against hope some random Duet user who also has a DDG or a Bondtech dev that has a Duet board in his UM2 stumbles on this thread. To give some insight on this. I guess I could try Bondtech support next.

And maybe going to youtube is an option to listen to someone's DDG on a regular Ultimaker for me to calibrate my inner baseline to how the extruder should sound for my machine. But right now I feel defeated. I haven't had much success with my experiments.

I'll dig back into this on Monday.