CR-10S5 Firmware

-

Lol, I've still had no luck. I feel as if I'm braking my printer, RIP.

-

Please post your config.g

-

What specifically are you stuck on? The CR10S and Ender3 are very very similar. The guides that Paul linked cover a lot of the basics.

-

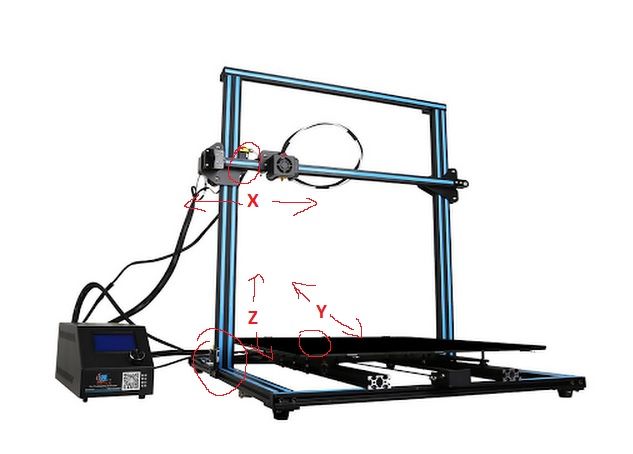

In the image shows the end stop locations however Y end stop is next to the motor (opposite side to where it is drawn)

.

.Z: I'm having trouble syncing my z axis, they will not move and x moves instead going left then right.

Y: Will move X to the right and move Z backwards away from the endstop.

X: Will move away from the end end stop and back.

Note: NONE of the end stops are working.

Attached is my config and each axis home:config.g homez.g homey.g homex.g homeall.g

-

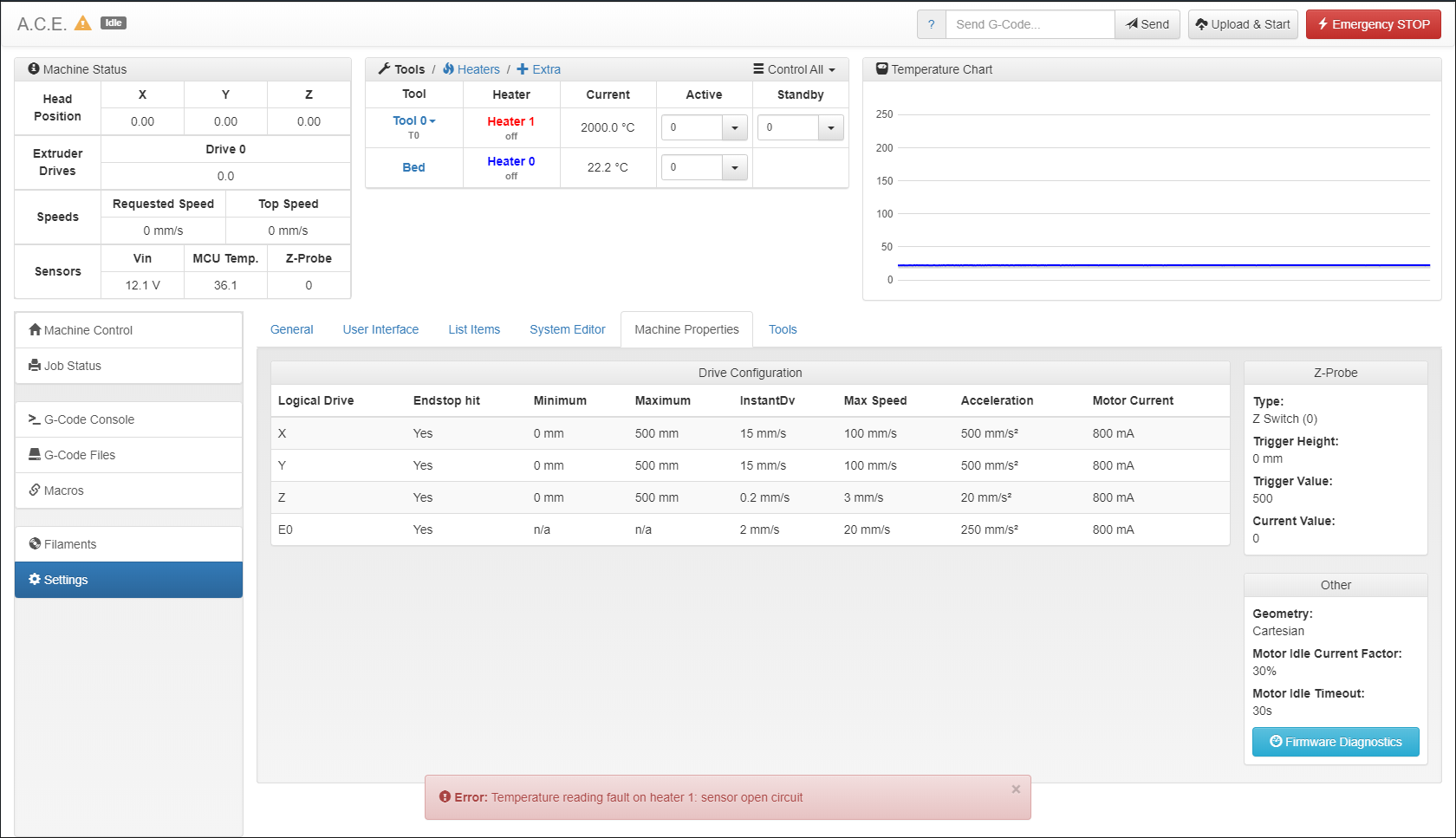

Also I can get my bed to heat up, but my hotend dosenot display.

-

In addition to all of those other problem, I can't get my hotend fan to spin up.

-

There's a few problems in this section of your config.g

M584 X0 Y1 ZA2:ZB2 ; two Z motors connected to driver outputs Z and E1 M671 X-20:220 Y0:0 S0.5 ; leadscrews at left (connected to Z) and right (connected to E1) of X axisFirst, the M584 command must come earlier. You already have one up earlier in your config, so you can modify that one. https://duet3d.dozuki.com/Wiki/Gcode#Section_M584_Set_drive_mapping

Order dependence

M584 must come earlier in config.g than any M350 and M906 commands. If it creates new axes, it must also be earlier than any M92, M201, M203, M208, M350, M566, M574 , M667 and M669 commands.

But the command you have

M584 X0 Y1 ZA2:ZB2isn't quite right either. ZA2:ZB2 isn't right. Are you trying to drive each Z axis independently for leveling? It doesn't look like you have a Z probe at the moment, so that could actually prove a little difficult.For the time being it might be easier to just have the Z axis motors connect to the 2 z axis ports and get the machine running first. You can then add in X axis leveling when you have a Z probe. https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

The next is the bed size commands. You've got two of them. I believe the CR10S is 500x500 so the second set of commands should be right? If so, delete the first one.

M208 X-5:205 Y0:200 ; X carriage moves from -5 to 205, Y bed goes from 0 to 200 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z500 S0 ; set axis maximaI suggest you follow these commissioning steps to test your motors and endstops.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+3:+Commissioning/39

-

No disrespect @Phaedrux, because he is using S0 and S1with his M208, it is correct....but...

A neater way of setting your maxima and minima is like this

M208 X0:500 Y0:500 Z0:500

It makes it easier to read and diagnose.

Also your M667 I think is incorrect. Your printer is a Cartesian, not Core XY

Remove M667, Use M669 K0, if you are using RRF2.03 or later, this is the new command and K0 defines your printer as a Cartesian.Also, you say that your 'Hotend' does not display. Are you talking about the cooling fan?

Also as mentioned you need a Z Probe like a BL Touch to do levelling.

If you buy a BL Touch, get an original not a clone, tooo many problems with clones.As we have both mentioned, read the Ender3 documentation, it will help get the base correct. It is not easy upgrading to a new board and it is a steep learning curve, but a fun one.

HTH. Paul.

-

If I was you I would also move one z axis motor cables to the spare extruder output and map that to the second z axis motor which would allow you to sync the z axis motors and this would allow you better control of getting the bed perpendicular to the nozzle. (if you have an "auto-level" sensor of course)

-

@PaulHew said in CR-10S5 Firmware:

No disrespect @Phaedrux, because he is using S0 and S1with his M208, it is correct....but..

I didn't mean the format was wrong. I was referring to the fact that he's using both formats with different size values. Just saying it should be verified and cleaned up.

-

@PaulHew thanks for the help. However the Y motor seems to be fighting against itself (it vibrates/slightly turns in one direction then reverses). As for Z moving slightly will allow the axis to move together, however when Y+10 the motors stair step (Only one axis moves upwards while the other stays in place then they reverse direction).

-

Also none of the endstops are working.

-

Current config.g please

Lets see if we can assist further to get the endstops working.

Its nearly midnight here in the UK! -

@Gost101 said in CR-10S5 Firmware:

@PaulHew thanks for the help. However the Y motor seems to be fighting against itself (it vibrates/slightly turns in one direction then reverses). As for Z moving slightly will allow the axis to move together, however when Y+10 the motors stair step (Only one axis moves upwards while the other stays in place then they reverse direction).

If the Y axis motor is doing that, it's more than likely that it is not wired up properly, you need to find the base pairs for coil A and B to find the base pair unplug the connector and you can probe the connector using a multimeter set to continuity probe two wires when you get a beep you have found one pair, the other two wires are the second pair, if i was you I would find the base pairs on all the motors to be on the safe side.

-

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.0.3 on Wed Sep 11 2019 20:24:24 GMT-0600 (Mountain Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"A.C.E." ; set printer name M669 K0 ; select Cartesian mode ; Network M551 P"12345" ; set password M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; X physical drive 0 goes forwards M569 P1 S1 ; Y physical drive 1 goes forwards M569 P2 S0 ; Z physical drive 2 goes backwards M569 P3 S1 ; E physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z4000.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z12.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X0:500 Y0:500 Z0:500 ; set axis maxima ; Endstops M574 X1 Y1 Z1 S0 ; set active low and disabled endstops ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M106 P0 S0 I0 F500 H-1 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off M106 P1 S1 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined -

@Gost101 said in CR-10S5 Firmware:

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X0:500 Y0:500 Z0:500 ; set axis maximaYou've still got two competing formats here for the minima and maxima. Just delete the first line with the S1 since the second line includes both the minima and maxima range in one line.

You can use this procedure to determine the phases of the motor wiring. https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Identifying_the_stepper_motor_phases

-

Still having trouble getting the Y motor to work. Its wired just as all the other motors. In addition could someone send me to the appropriate link for endstop switch gcode. Acording to this guide: https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+3:+Commissioning/39 "If the values for X, Y, and Z show "Yes" by default, and "No" when triggered, you chose the wrong switch type in the configurator." I'm doing it wrong.

-

I also cannot get my hot end to heat up, or the fan to turn on.

I also cannot get my hot end to heat up, or the fan to turn on. -

Endstops.

If your bed is all the way to the back, the hot end all the way to the left and fully down, then they will show yes yes yes.

Power down and slowy move the hotend to the centre of X axis, move the bed central, and wind the Z zxis up about 10mm

Power up, look at that screen again and it should of changed to no no no. Press the individual switches to confirm that its status changes from no to yes. If that works then...press the individual homing buttons, X Y then Z

If they are still not working do the below.- Please make sure you are using the 2 outer pins on each endstop connector.

- Use a multimeter to confirm that the endstop switchs are working. You can insert a paper clip into the connector on each side of the new plug you have crimped to your multimeter and press each switch.

Make sure it is on short or beep test. if your probes are thin enough you might get them to touch the contacts from where your wire goes into the connector. Make sure you are not plugged into the board. - double and double check your crimps on those terminals, gently pull the wire to see if it comes comes away.

I have had issue where I did not crimp them properly and the wire fell out or the connector had not clipped in properly or I had crimped the insulator!

Hotend.

The hotend will not heatup whilst it is reading 2000 degrees!

Again check your wiring and crimps. You can also use your multimeter to see if you can get a resistance from the thermistor.Finally as mentioned before, you need a Z probe. especially with 2 Z axis motors.

I suggest you get the Creality BL Touch kit as it comes with the bracket and long cables for connecting to the Duet and also comes with a proper BL Touch.HTH. Paul

-

Struggled to find a spec for the motors are they all creality 42-40? If so do they match the resistance of the following link?

If so your current settings are low. 80% of a 1.68A motor is 1.344A, not 0.8. Not likely to make the motion juttery unless the acis is stiff.

Please make sure the motor pairs are wired right to the board (different manufacturers change the cable orders) before upping the current. You may be getting away woth it at low current but you may fry your board if you up the current with the motors wired wrong.