Having problems with Anycubic Kossel Linear Plus calibration

-

Unless you've posted newer files that I missed...

Your config-override contains:

M665 L271.500 R135.224 H287.541 B115.0 X0.505 Y-0.998 Z0.000

@snakesp said in Having problems with Anycubic Kossel Linear Plus calibration:

@danal In fact Marlin never gave really accurate dimensions. Y and Z were fine (less than 0.1 mm deviations), but X was always 1% more than it should be. This was with 267mm rod length. I assume that was due to inaccurate printer build. That's why a have rebuilt whole frame from scratch. And at the same time changed MB to Duet to move to 32 bit and 24 V for faster printing.

Now the X and Y dimesions errors are close, so looks like this can be compensated with M579.Got it. Sounds good.

As for Haydn's rods: too expensive right now for me. But i'm working on selfmade magball arms to test (with cylinder magnets in rod and steel balls on effector and carriages).

Cool! Magnetic joints really do help this printer. Of course, measure them as best you can after you build them (maybe even take them to a local school, or maker space, or...).

-

@danal

config-override.g now has the following:

M665 L266.500:266.500:266.500 R133.832 H287.529 B115.0 X0.460 Y-0.913 Z0.000

M666 X-0.711 Y1.035 Z-0.324 A-0.03 B-0.20The main thing for rods is to build them at the same jig, so they are totally egual in length. But yes, length measures are important too.

-

@snakesp said in Having problems with Anycubic Kossel Linear Plus calibration:

because i haven't found PT1000 in 3 mm

-

@veti Thanks

-

-

Got PT100 sensor. So now i'm almost sure the nozzle temperature is shown correctly.

However i'm still not even near to solving the first layer problem...

Started from scratch and removed everything to defaults. Meazured Z probe trigger height. Strangely enough now it is 15.845 mm (but measurements are consistent at x0y0). But it is different at other points. So changed bed.g to reflect those differences.

Autocalibration showed:

Calibrated 6 factors using 16 points, deviation before 0.007 after 0.006

and was consistent after several attempts.

So i conclude that printer is now calibrated.

Out of PLA so moved to PETG at 60x240 for first layer and 60x220 at subsequent layers.

But when i try to print i get first layer smashed into the bed just as before. After 2-3 layers it delaminates from table.

Tried using babystep +0.05 - no changes except that first layer is not smashed into table that hard as before.

With babystep up to +0.15 got something looking like normal extrusion but it delaminated from bed also.

Really out of ideas once again... -

Given the babystep, it sounds like you are close.

Try:

G28

G0 Z5

G1 Z0 F800And see if the nozzle is JUST touching the bed. Paper should drag but not get stuck. If this is off, change the probe height and recalibrate. Keep doing this until paper just drags after the above three commands.

If this works, as a double check, starting from the Z0 above, enter more commands, to check at a different spot on the bed:

G0 Z5

G0 Y50

G1 Z0Still "just touching?"

Let us know.

-

With babystep up to +0.15 got something looking like normal extrusion but it delaminated from bed also.

It’s a good approach to play with babystepping until you get a proper first layer. @Danal is right, you are close. And don’t be shy to go even higher: sometimes it is better to lay the filament smoothly onto the surface instead of pressing it into the bed.

Then, as @Veti posted (on 1st of September), „if i need to adjust it with microstepping to get a good first layer i update the offset with the microstepping used“. Good advice.

Delamination on subsequent layers is a different story: One reason may be the specific filament you use. More often, the upper layers cool down too quickly, so try to set your temperature to 240 deg. for all layers. Next, turn down the part cooling fan and see what happens then. Finally, you can try to close the sides of your printer, PETG doesn’t like fresh air.

-

@Danal

Got these results (with bed at 60C):

x0y0 - a bit too high

x-50y0 - ok

x-50y-50 - too low

x-50y50 - a bit too high

x0y50 - ok

x50y50 - ok

x50y0 - ok

x50y-50 - a bit too lowSo looks like the bed is slightly tilted? Tried recalibrating with S8 and got this:

M665 L266.500:266.500:266.500 R133.769 H287.544 B115.0 X0.385 Y-1.246 Z0.000

M666 X-1.295 Y1.179 Z0.116 A0.34 B0.21

But the check results are exactly the same.@infiniteloop Looks like just babystepping won't be enough here as there is a problem with probing results described above.

-

OK, you can try to physically level the bed a little.

Whether you do or not, do this:

-

Get the Z-Probe offset as correct as possible at X0Y0

-

Run a calibration. Maybe several.

-

Run a mesh bed probe. Be sure and put the G-Code to activate bed mesh in your slicer start script (I don't remember the exact code and don't have a printer near at this moment).

Also, if you test by hand again, like above, be sure mesh is active when you test.

You may have to repeat these steps a couple of times. But it all starts with correct probe offset (at X0Y0).

-

-

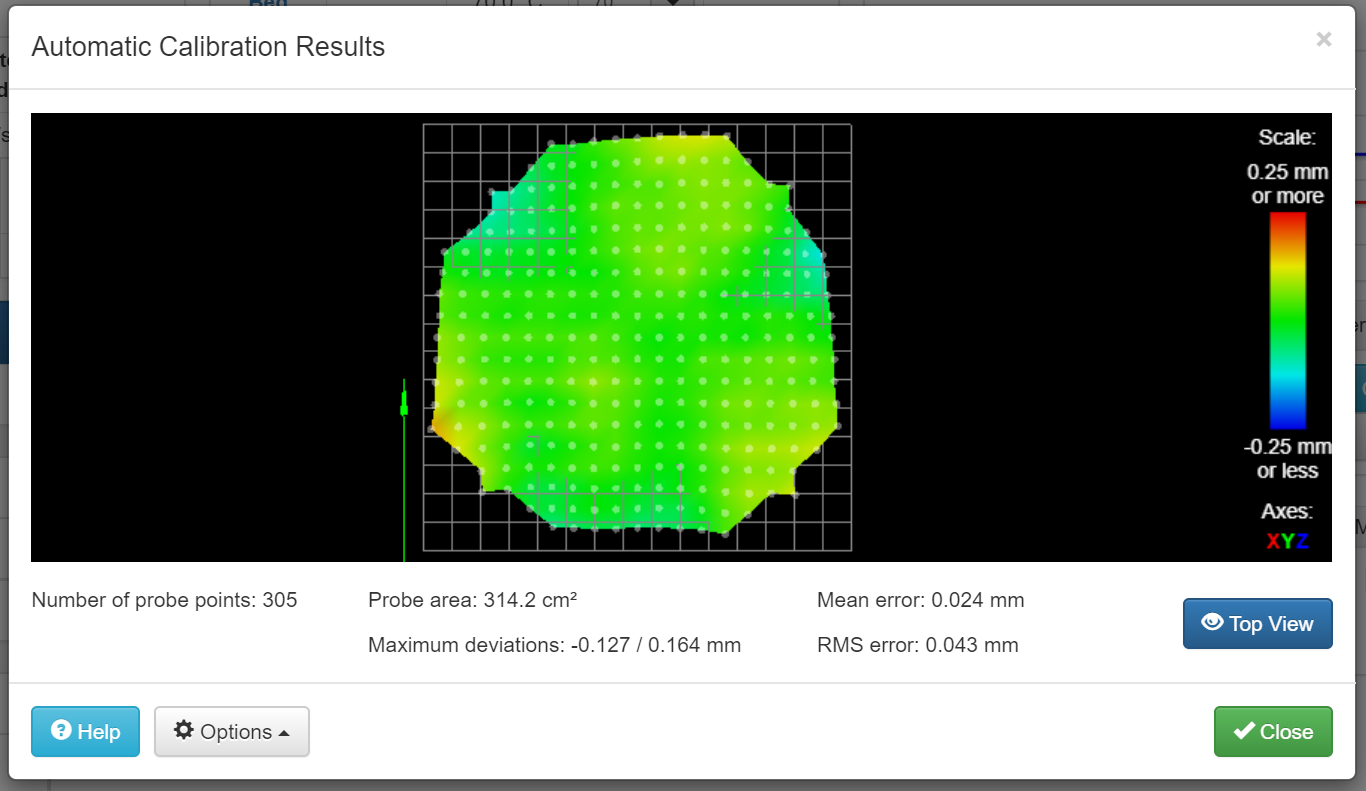

can you post the picture of a bed mesh level? G29

-

@Veti said in Having problems with Anycubic Kossel Linear Plus calibration:

can you post the picture of a bed mesh level? G29

YES!! @SnakeSP Please post.

-

-

that bed would account for the slight irregularities that you are seeing. so you will need to print with mesh bed levelling enabled.

check with M122 that the bed was actually loaded and is active.

-

@Veti

M122:

=== Move ===

Hiccups: 0, FreeDm: 169, MinFreeDm: 163, MaxWait: 26536ms

Bed compensation in use: mesh, comp offset 0.000so mesh is enabled. Then why the nozzle height is good at center but too low at x-50 y-50 for example? I thought with mesh enabled nozzle height should be more accurate at all points.

One more thing, on loading bed mesh (G29 S1) i get this:

Warning: the height map was loaded when the current Z=0 datum was not determined probing. This may result in a height offset.

What am i missing? -

just checking, but you did generate a new heightmap when i asked you to run the G29?

-

@Veti

Yes, this is a new map. I run S8 autocalibration when adjusted Z probe height. Rebooted printer. Checked that with z0 paper can be just dragged under the nozzle in bed center after that.

After that i run G28 and G29 S0 P"heightmap.csv"

When finished i check that the map is generated (can be viewed in DWC).

Rebooted printer again. Run G28 and G29 S1. Check that z0 is good at bed center. Move to x-50 y-50 and check z0 again - it occurs too low (paper is stuck under the nozzle).

M122 shows that mesh is active at that moment. -

@SnakeSP said in Having problems with Anycubic Kossel Linear Plus calibration:

x-50y0 - ok

x-50y-50 - too low

x-50y50 - a bit too highhmm. i am thinking there might be a slight effector tilt that shows up due to the distance from the probing point to the nozzle.

if you are willing to invest an euro this is what i have swapped to as a probe on my kossel linear plus.

https://de.aliexpress.com/item/32838312776.html

its cheap and has nearly no offset. -

@Veti

Yes, thought of that thing, possibly will do.

I'm using stock Anycubic probe right now and have a BL Touch clone, but cannot try it with stock effector. Need to print a custom effector to try BL Touch.

So yes, this thing is worth trying except for wait time till it gets to me from China. -

the bltouch mounts will have a significant offset in the x and y direction. if there is effector tilt, then that will also cause problems.