Pressure Advance seems to not be working.

-

@Phaedrux - What printer would be a good test here, would just a simple cube be enough to test if its working or not, not looking to test how good its working, just that it is working...

-

@Samuel235 A cube would probably be alright. A benchy makes for a good test since it has a range of move types and areas to highlight flaws.

Since the issue we are trying to highlight is likely involving retraction and pressure advance, a simple XYZ cube scaled up a bit would be a good choice. Slightly more complex than a 4 sided cube but not as complex as a benchy and still fast to print.

-

@Phaedrux - Thank you for including the .stl for me. I will get to that tonight or tomorrow morning (UK Based).

-

Morning all,

I can confirm that PA now seems to be working after a change of extruder motor current, I assume it was skipping steps due to this. I'm going to continue further today to calibrate PA but I have just ran a XYZ Cube at 150% size and got awesome results from it, with a PA value of 0.22. I have included the information below that I said I would gather.

I do see some hiccups @Phaedrux, but I have done a quick research through this forum and can see that its not really an issue unless you are seeing around 50 per 200mm, is that correct?

- M572 before PA enabled:

M572 Extruder pressure advance 0.000 - M122 before PA enabled:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03 running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-956GU-DJMSN-6J1F4-3SJ6N-1BNBF Used output buffers: 5 of 24 (20 max) === RTOS === Static ram: 25680 Dynamic ram: 94256 of which 308 recycled Exception stack ram used: 596 Never used ram: 10232 Tasks: NETWORK(ready,524) HEAT(blocked,1236) DUEX(suspended,156) MAIN(running,1668) IDLE(ready,160) Owned mutexes: === Platform === Last reset 22:11:00 ago, cause: power up Last software reset at 2019-12-23 18:30, reason: User, spinning module GCodes, available RAM 10304 bytes (slot 1) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 16 Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 0.0ms, max retries 0 MCU temperature: min 48.9, current 52.3, max 55.6 Supply voltage: min 24.0, current 24.3, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max 0/1023 Driver 1: standstill, SG min/max 0/1023 Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max 0/1023 Driver 4: standstill, SG min/max not available Driver 5: standstill, SG min/max 8/252 Driver 6: standstill, SG min/max 34/260 Driver 7: standstill, SG min/max 31/250 Driver 8: standstill, SG min/max 0/266 Driver 9: standstill, SG min/max not available Date/time: 2019-12-31 18:36:04 Cache data hit count 4294967295 Slowest loop: 113.77ms; fastest: 0.08ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 0, FreeDm: 169, MinFreeDm: 146, MaxWait: 0ms Bed compensation in use: mesh, comp offset 0.000 === DDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.5 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 0 Stack records: 4 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is idle in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 200.53ms; fastest: 0.08ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 1 WiFi firmware version 1.23 WiFi MAC address XXXXXXXX WiFi Vcc 3.32, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24400 WiFi IP address XXXXXXXX WiFi signal strength -55dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0 - M572 after PA enabled, value of 0.22:

M572 Extruder pressure advance: 0.220 - M122 after PA enabled, value of 0.22:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03 running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-956GU-DJMSN-6J1F4-3SJ6N-1BNBF Used output buffers: 5 of 24 (20 max) === RTOS === Static ram: 25680 Dynamic ram: 94256 of which 308 recycled Exception stack ram used: 492 Never used ram: 10336 Tasks: NETWORK(ready,524) HEAT(blocked,1236) DUEX(suspended,156) MAIN(running,1668) IDLE(ready,160) Owned mutexes: === Platform === Last reset 06:31:07 ago, cause: software Last software reset at 2019-12-31 18:44, reason: User, spinning module GCodes, available RAM 10232 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 16 Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 0.0ms, max retries 0 MCU temperature: min 40.9, current 41.0, max 57.7 Supply voltage: min 23.9, current 24.5, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max 0/1023 Driver 1: standstill, SG min/max 0/1023 Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max 0/1023 Driver 4: standstill, SG min/max not available Driver 5: standstill, SG min/max 0/253 Driver 6: standstill, SG min/max 15/257 Driver 7: standstill, SG min/max 0/252 Driver 8: standstill, SG min/max 0/261 Driver 9: standstill, SG min/max not available Date/time: 1970-01-01 00:00:00 Cache data hit count 4294967295 Slowest loop: 101.62ms; fastest: 0.08ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 129, FreeDm: 169, MinFreeDm: 146, MaxWait: 0ms Bed compensation in use: mesh, comp offset 0.000 === DDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.6 === GCodes === Segments left: 0 Stack records: 4 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is idle in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 200.37ms; fastest: 0.08ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 7 WiFi firmware version 1.23 WiFi MAC address XXXXXXXX WiFi Vcc 3.33, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24400 WiFi IP address XXXXXXXX WiFi signal strength -55dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0 Thanks,

Sam. -

@Samuel235 said in Pressure Advance seems to not be working.:

got awesome results from it, with a PA value of 0.22

Is this a direct extruder or bowden?

-

@zapta Its bowden, around 650mm bowden length.

-

@Samuel235 said in Pressure Advance seems to not be working.:

Hiccups: 129

I wouldn't be too concerned by this over the course of a print.

Do you happen to have Z hop on retract enabled?

You can do more fine grained testing to try and pin down when the hiccups are occuring. Every time you send M122 it resets the counter, so you can send it at the start, send it after homing, send it after the first layer, etc. and eventually you'll get an idea of where and when they are occuring.

-

@Phaedrux - I was doing this while it was printing also, it seems to be consistent on most layers if i remember correctly. I'm not currently running Z Hop, no.

-

@Samuel235 said in Pressure Advance seems to not be working.:

@zapta Its bowden, around 650mm bowden length.

0.22 for a 650mm bowden is very low, good for you. I got > 1.0 with 600mm 1.9mm capricon bowden and lowered it to 0.15 when switched to direct drive.

-

I'm currently running some tests to attempt to calibrate it. I'm currently using CURA so I'm unable to force a seam to be in the middle of a flat face, so i'm using a cone print to put a seam on the face and to change PA as the print goes and then to find the best section. I'd be interested to know the calibration method you all face, do you all go for the python script that is floating around?

-

@Samuel235 said in Pressure Advance seems to not be working.:

I'm currently using CURA so I'm unable to force a seam to be in the middle of a flat face

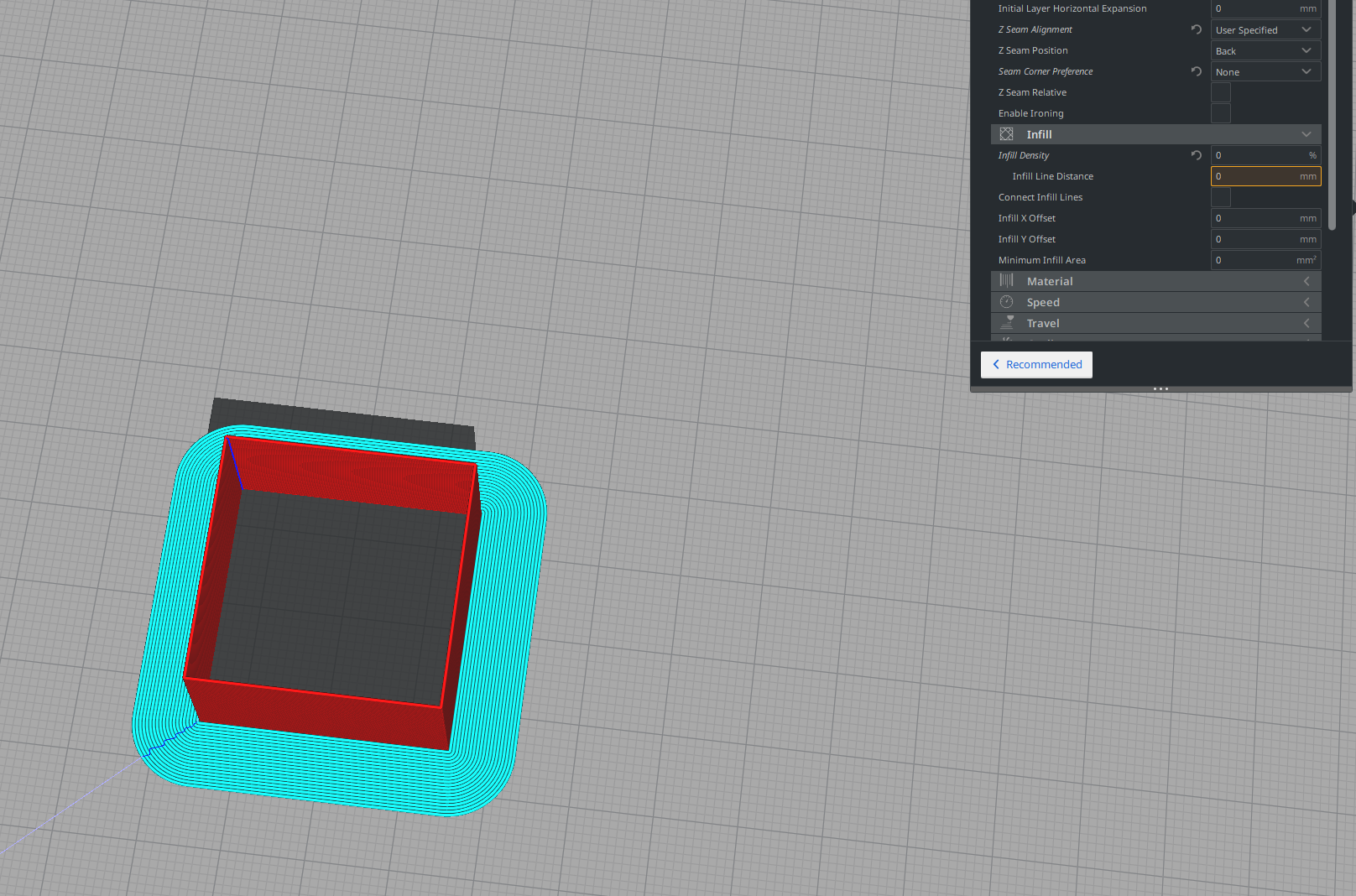

It can be done in Cura.

https://ultimaker.com/en/resources/52343-shellThe options may be hidden by default. Use the gear icon on the shell heading to see any hidden options.

Z seam alignment - User specified

Z seam position - back

Seam corner preference - noneProduces the desired result. That's in 4.4.1. In older versions there was an X and Y position you could specify. The setting is still there in the settings visibility filter, but it's not being shown and I'm not sure what's blocking it. Regardless, setting it to back, front, left, or right works to align it to a face.

-

@Phaedrux - Im on 4.2.1 and the XY position will not put it in the middle of a flat face for me and a few others I chat to. I will try their update shortly to see if that new option works for me.

-

@Samuel235 The corner preference must be none as well.

-

-

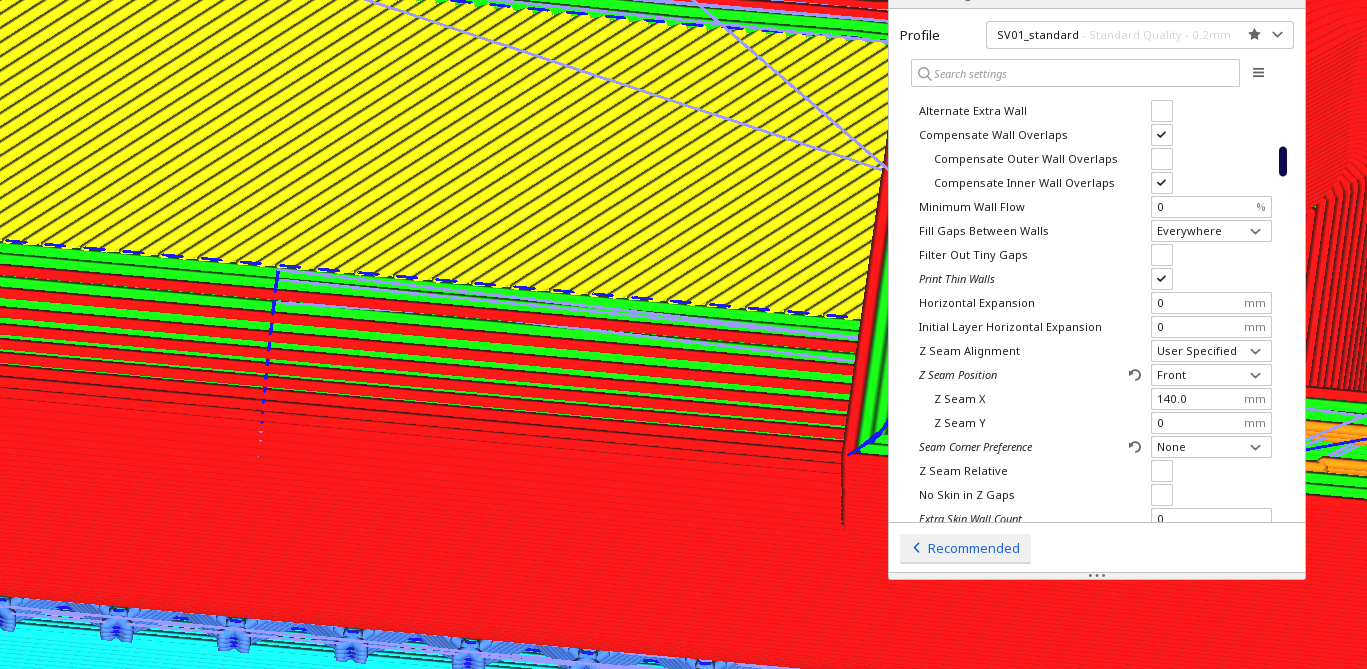

Re getting the z-seam in the middle of a flat face using Cura. Well, it can't be done using the UM releases but my Cura builds do now provide that capability. Setting the z-seam to user-defined and seam corner preference to none will enable this feature. You can find my releases at https://www.dropbox.com/sh/s43vqzmi4d2bqe2/AAADdYdSu9iwcKa0Knqgurm4a?dl=0. Please read the README.md file there for more info.

Here's an example, you can see the travel moves associated with the z-seam to the left of the middle of the flat area at the botttom of the image.

-

@burtoogle said in Pressure Advance seems to not be working.:

Well, it can't be done using the UM releases but my Cura builds do now provide that capability.

Just one more reason to use your builds.

@Samuel235 I was going by memory on the settings and didn't realize that the stock Cura does not allow this.

-

@Samuel235 For what it's worth, setting the seam to a corner of the cube is also usable, it just makes finding the smoothest transition a little harder. You can also use a cylinder, but then you miss out on the corner bulge tuning.

-

Oh awesome, thank you for including your build @burtoogle!

@Phaedrux - I have been using a cone, I imagine this to be the same as a cylinder for the sake of this test, just the layers would get quicker as they go up, and I ranged from 0.1 to 0.9 PA, I didn't get any change in apperance of the seam at all across the range of PA values unfortunately. I will try with a cube tomorrow to test.

-

A cone might be ok. I think the fact the size is changing as it goes up would make it harder to see the difference in the seam since the layer time is a confounding factor.

The cube is probably the best option for this because you get up to speed over the 100mm length and the corners show the bulge and the seam on the face is clearly visible.

-

Currently printing a 100mm cube with a single skin, no infil. Seam is in the middle of the face at the back with the build of Cura linked above (Thanks @burtoogle). I have PA changing its value from 0.05 to 0.9 in 0.05 increments every 25 layers. Will see how this turns out.