Noob building a HEVO in need of help.

-

@Veti said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

I haven't changed much in the config, i don't know how many steps it is. How do i know? How do i set the probe to actice? What is wrong about the M574 line?

it depends on your stepper motor 0.9 degree or 1.8 degree and your lead screw pitch.

normal values are 400 or 1600.Ok. The motors are 1.8 degrees, but the threads on the screw has some wierd info, it says "TR8x8 (P2)" The other ones for sale is 8x2. I assume 8mm x 2mm pitch. What does "lead" mean?

@zapta said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

No, i did not use the online configurator, because i don't know what values to use. But its maybe better to use that

The online configurators has a sequence for web forms where you enter the data and then it generates the config file for you. I would recommend going through it and if you have questions about specific fields ask here. This will give you a good baseline that you can tweak.

Even if you already have a manual config file, you can generate one from the configurator and compare.

As for the G1 codes in my post, they are for testing through the console, not for the config file. Enter them via the console and watch the direction of the motors.

Also, here are a few things I learned over time from my HEVO build

- Direct extruder (BMG, Hemera, etc) give much better results than bowden.

- Stall detection works great instead of X/Y endstops.

- Bltouch or similar good prod works great as Z endstop and for bed leveling/compensation.

- 0.9 deg X/Y steppers and 16T pulleys everywhere provide more accusation positioning.

- Dampers on the X/Y steppers makes the movements significantly quieter.

- Being proficient with Fusion 360 and being able to modify parts is very useful (I used Fusion for this purpose).

- Bearings and rods from reputable vendors such as Misumi are better than cheap chinese stuff (though the Chinese stuff does work and is getting better and better)

- It takes a lot of work and patient to tweak a printer but it's also fun.

YMMV.

I am going to use the configurator now, i have to figure things out first. Thanks for the upgrade advice. I am going to upgrade the printer when i can afford it. The first on the list is a direct extruder. I am drawing alot of car parts in Fusion. I just made some tweakes on reinforced brackets and printing them on the Prusa now.

@Veti said in Noob building a HEVO in need of help.:

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

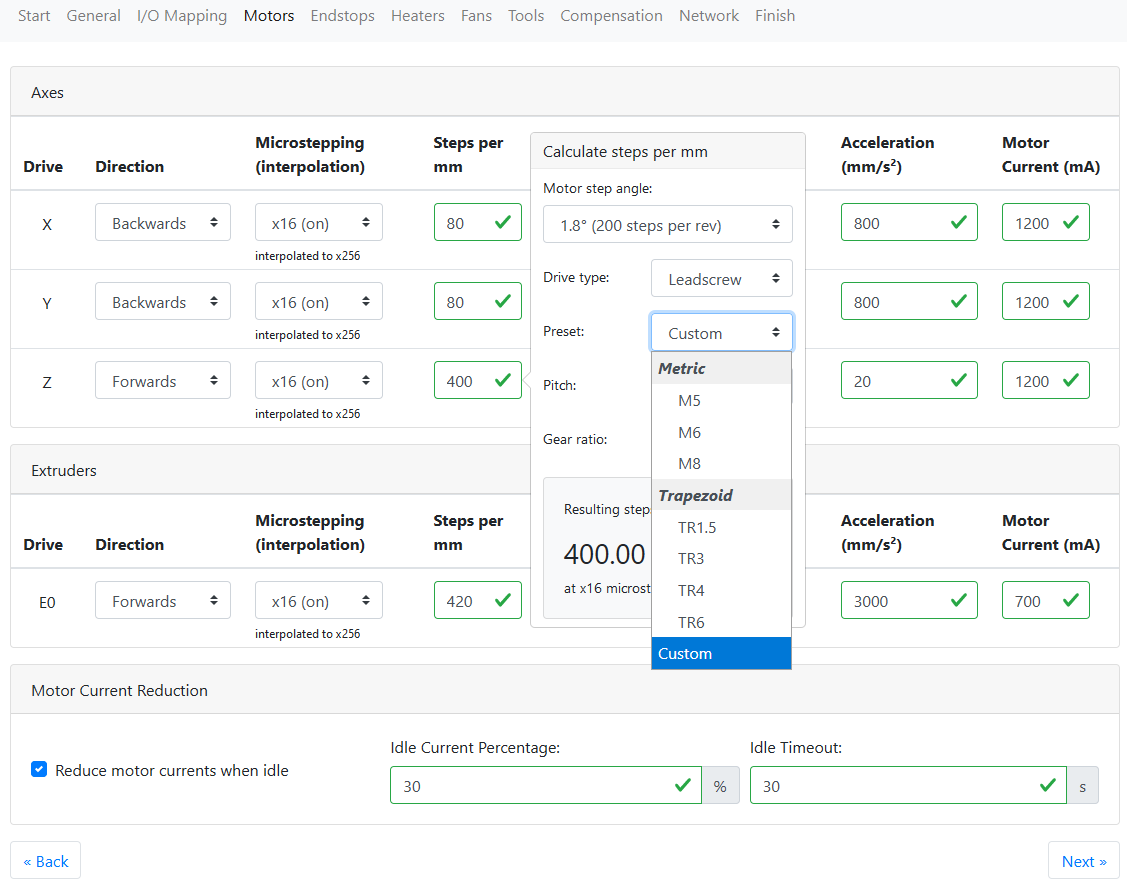

Maybe the best way to calculate the steps is to use the online calculator

thats included in the configurator. just click on the steps per mm field. it opens up a calculator.

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

No, i did not use the online configurator, because i don't know what values to use.

I have prepared a json file, witch you can load into the configurator.

You have to adept steps and the dimension for the Z-axis.

Also the typ of extruder (geared or direct). And typ of end stops.

Then you are able to generate all required sys files.We have to adepted the config.g later on, as some parts of configuration aren't saved propper in the json file, eg. network settings or should be tweaked a little bit....

Edit: I have change the json, as there was a mistake in probe configuration

Thank you. I have loaded in the file in the configurator but i need help to understand a few things first.

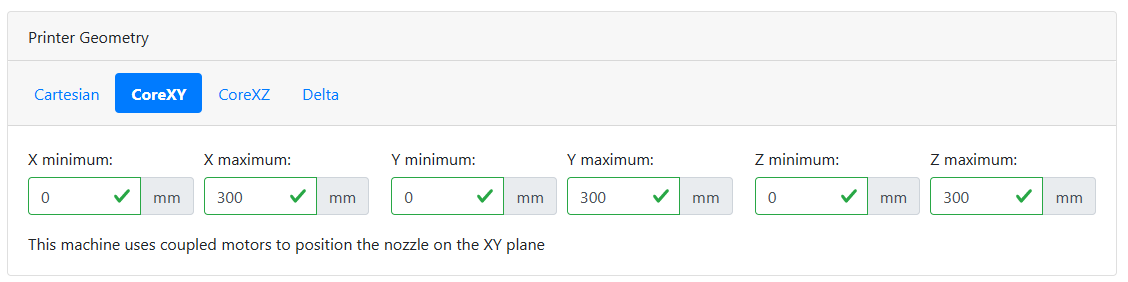

Do i measure "Z maximum" when the bed is on the bottom and up to the nozzle?Do I have to change the X and Y minimum and maximum if I want to skip the "end stops" and use sensorless? The Y and X axis must be a little bit shorter i think, because both axis is longer then the glass plate on the bed. When I move the Y axis to the back (minimum?) it is aligned to the edge of the glass plate where the extruder stops, but the other way the extrudes goes further then the edge of the plate.

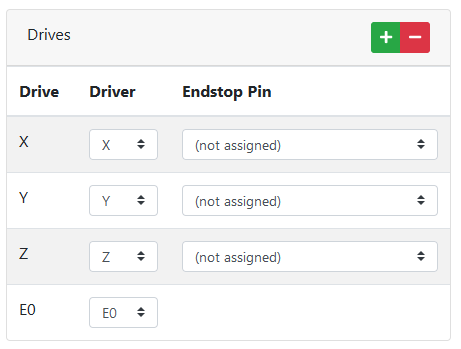

Do I select not assigned here if i want to use sensorless?

I changed the motor current to 1.2A, The Z-motor is probably 1.67A, does it matter only for the sensorless homing?

The Z-motor specs is still confusing, there is no TR 8 in the list, should i use M8x2?

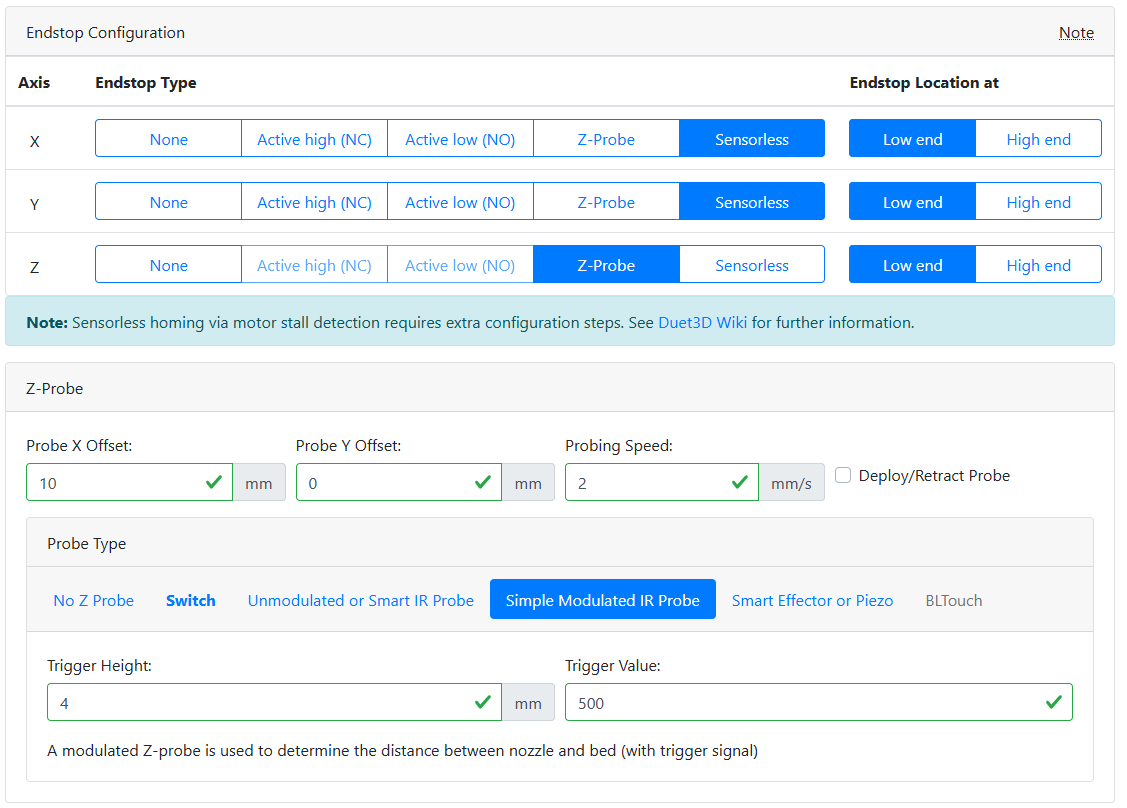

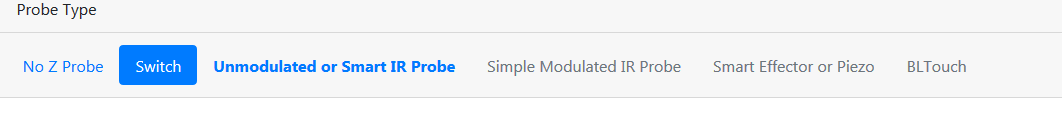

Do i select sensorless on X and Y? What kind of Z-probe is NPN? "Simple modulated IR probe?"

Does it matter if I use the "standard values" for resistance? I have measured them to be around 113k with a multimeter.

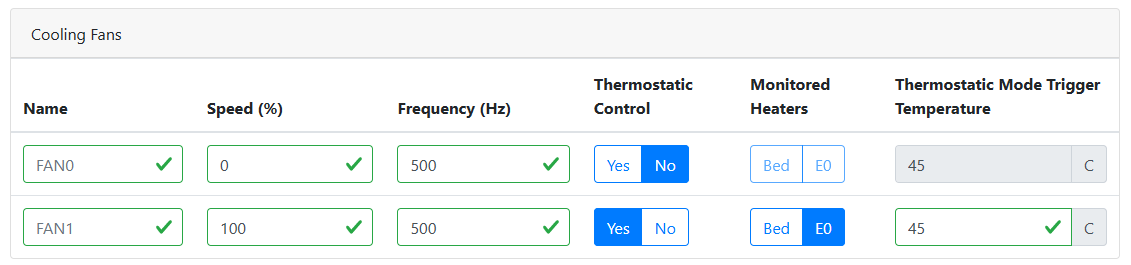

Should i change this if I am going to use a fan for part cooling and one fan for the extruder heat sink?

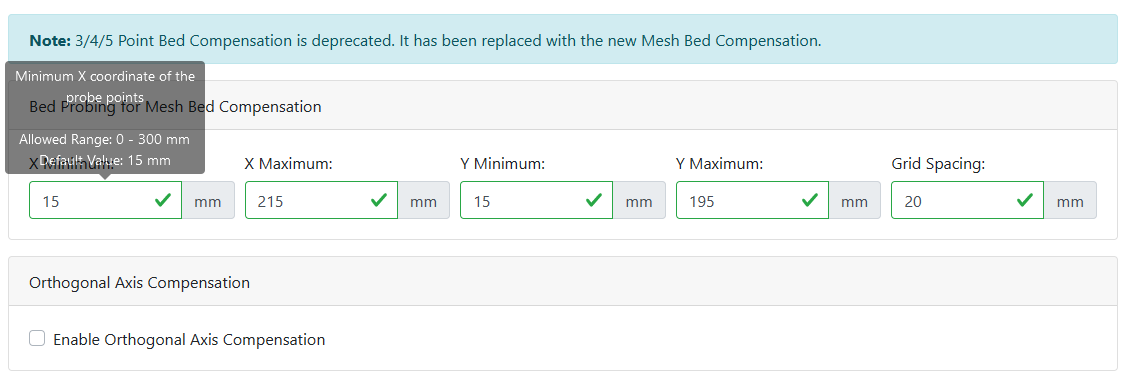

Should the maximum values be changed to 300 - 15mm offset on both X and Y axis? This seems to only measure some of the bed.Thank you all for helping me!

-

@Quattro said in Noob building a HEVO in need of help.:

TR8x8

that means 8mm diameter. lifting 8mm per revolution.

with that you have 400steps/mm using a 1.8 degree motor at x16 interpolation. -

@Quattro said in Noob building a HEVO in need of help.:

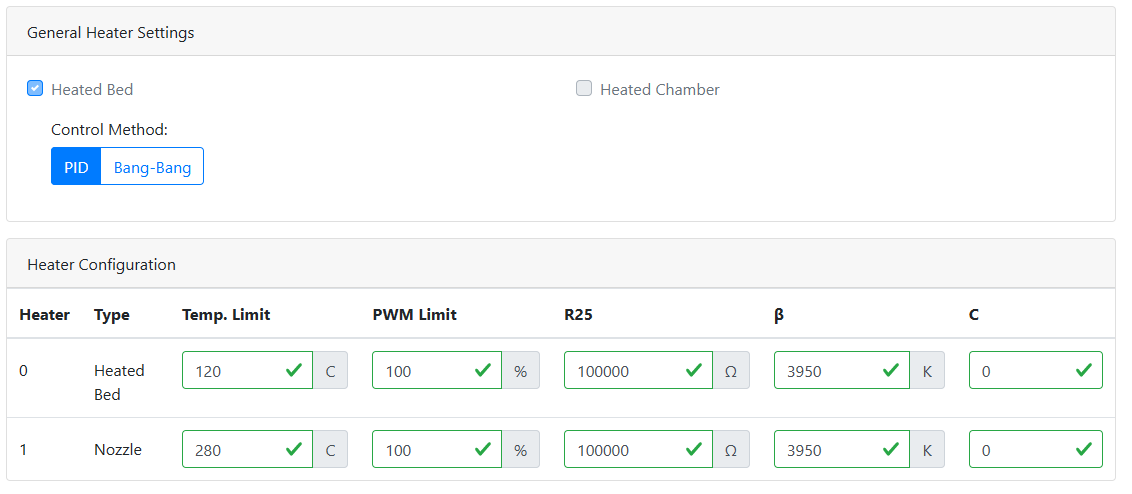

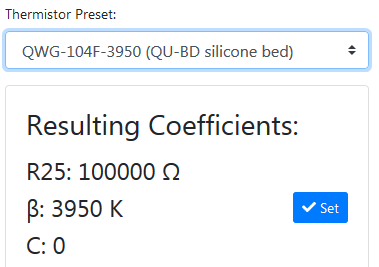

Does it matter if I use the "standard values" for resistance? I have measured them to be around 113k with a multimeter.

If you click into a value field a menu pops up where you can select the sensor typ

For the bed I think this one

For the heater you can select the E3D if it is a genuine. -

@Quattro said in Noob building a HEVO in need of help.:

Do i measure "Z maximum" when the bed is on the bottom and up to the nozzle?

-

@Quattro said in Noob building a HEVO in need of help.:

Do I have to change the X and Y minimum and maximum if I want to skip the "end stops" and use sensorless?

The homing procedure will do that for you. The file is generated by the tool.

In the homing sequence the axis are allowed to move outside the print aera. (Till they hit the end stop or sensorless homing takes in place) -

@Quattro said in Noob building a HEVO in need of help.:

Do I select not assigned here if i want to use sensorless?

For me it seams to be right. But I have never set up a system with sensorless homing.

So you better should read her

https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homing -

@Quattro said in Noob building a HEVO in need of help.:

Should i change this if I am going to use a fan for part cooling and one fan for the extruder heat sink?

That is set as standard. FAN0 is for part cooling

FAN1 is for the hotend. Configured like that the fan will start to rotate when then hotend reaches 45 °C -

@Quattro said in Noob building a HEVO in need of help.:

Should the maximum values be changed to 300 - 15mm offset on both X and Y axis? This seems to only measure some of the bed.

That is depending where you will mount the probe.

Normaly the probe sits on the side or behind of the hotend.

So if the aera is set to big it could go beside the bed.

I would keep the sandard values and adept them when the printer is set up. -

@Quattro said in Noob building a HEVO in need of help.:

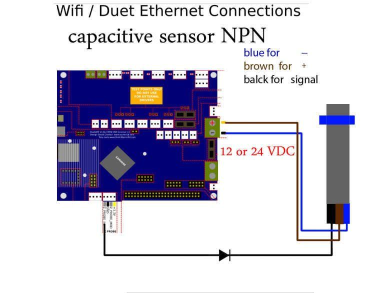

Do i select sensorless on X and Y? What kind of Z-probe is NPN? "Simple modulated IR probe?"

I think switch will generate the proper value for M558 (should be P5)To invert the signal in config.g, you have to do that by hand..

For RRF3 the code should look like this

M558 P5 C"^zprobe.in" H5 F120 T6000

(^ inverts the signal)For a detailed description how this kind of probe is working, read her

https://forum.duet3d.com/topic/2133/connecting-the-z-probe/6 -

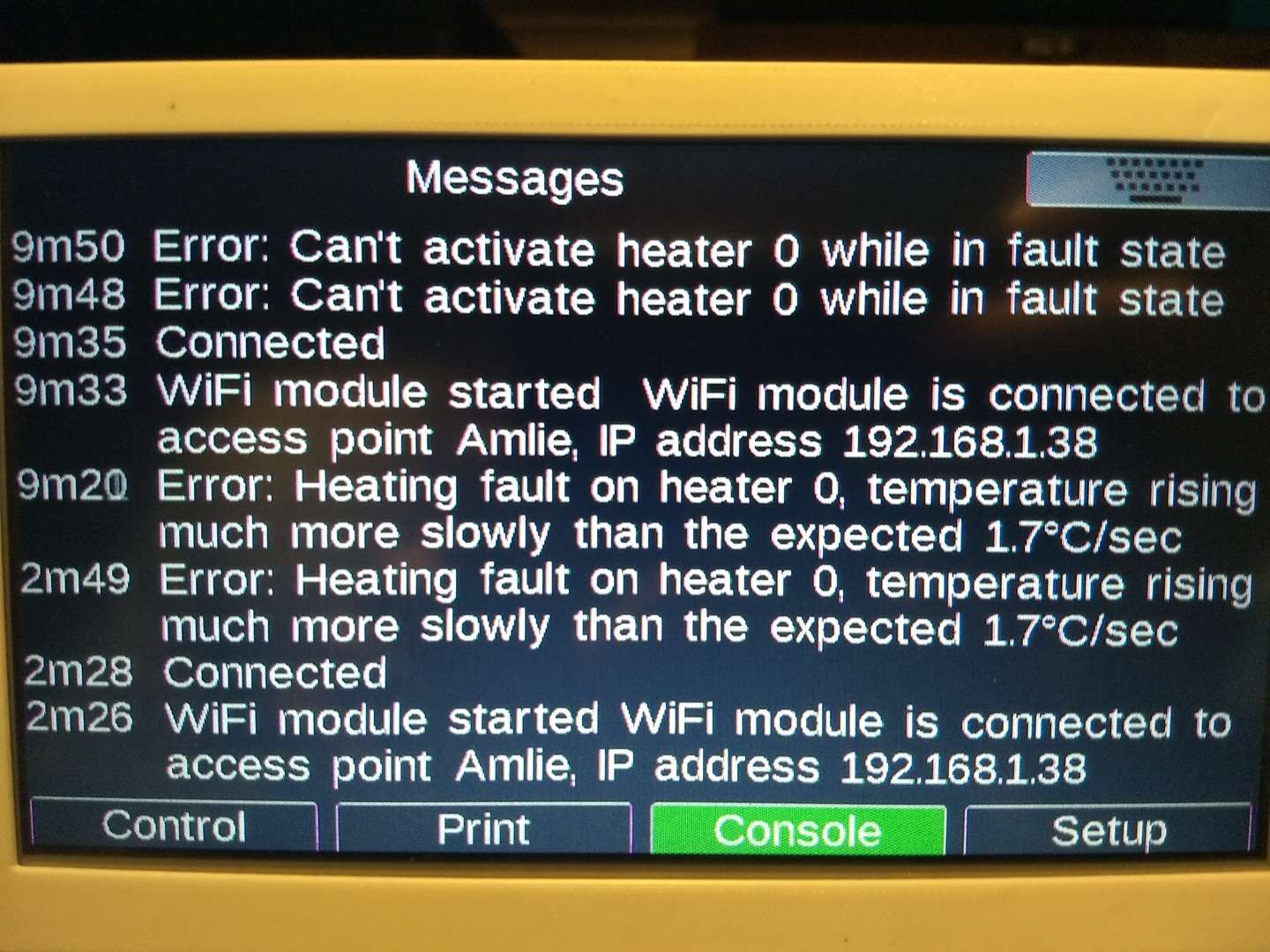

I got new problems with the new config.

1: The bed gets a heat error. It does heat some seconds, and then stops. This did work with the old config.

It is heating up if i remove "M307 H0 B0 S1.00 ; disable bang-bang mode for the nozzle heater and set PWM limit"

Should i remove it or change som parameters?

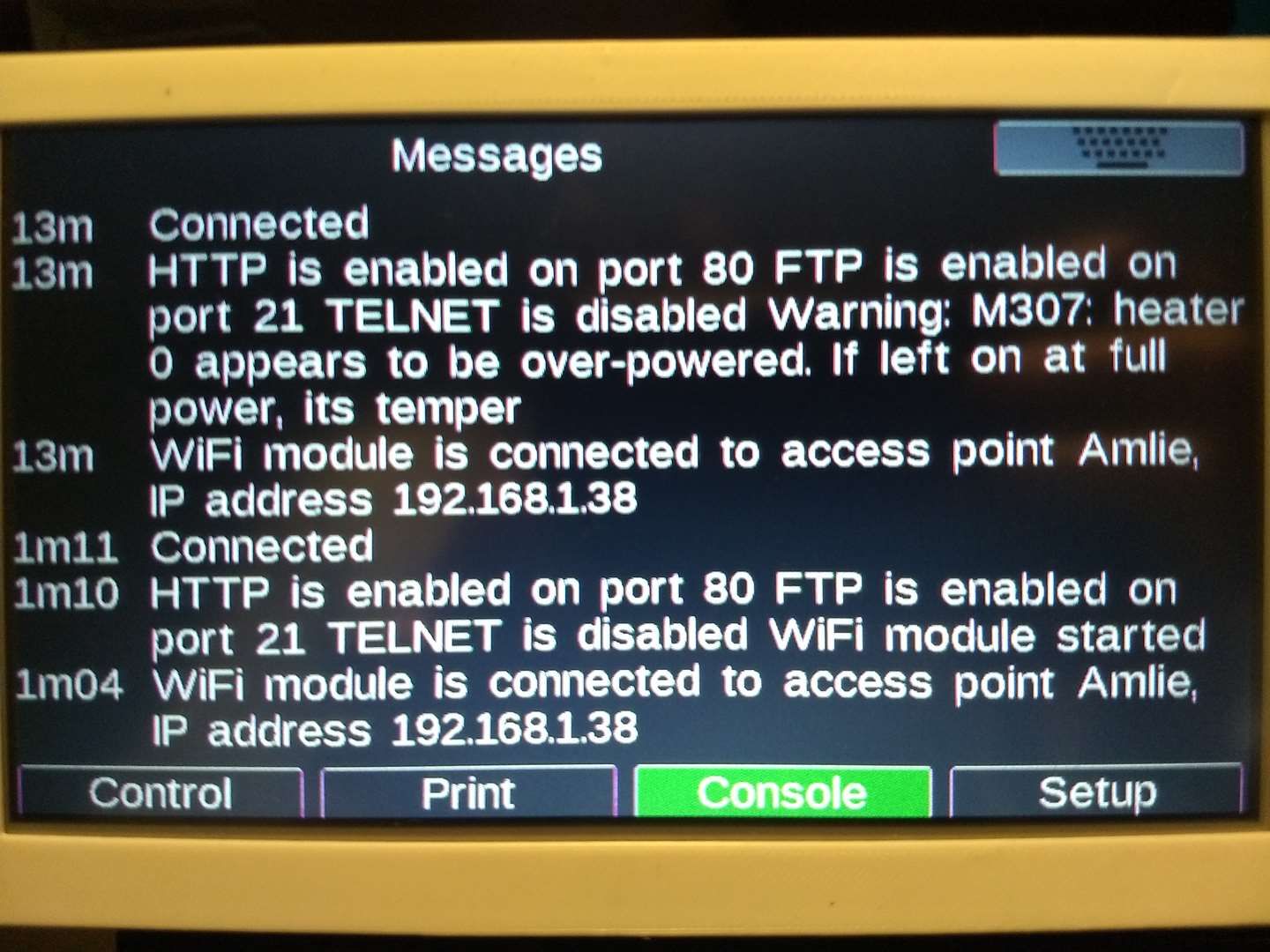

I also get a warning for "over-powered."

2: How to i test the probe? The distance is "0" when i run G31. Even with a object placed under the probe.3: Can I use this for sensorless homing? Or does it need a update for firmware v3? It is from my friends HEVO with firmware V2. Should this be placed in the config.g or one of the other files?

; Endstop configuration -----------------------------------

M574 Z1 S2 ; Set endstops controlled by probe

M915 Y S1.5 R0 F1 ; Higher S = less sens

M915 X S1.5 R0 F1The Z-axis seems to move the right amount now.

-

Please post the complete config.g

-

New config.g

I forgot and was about to post it. Here it is. -

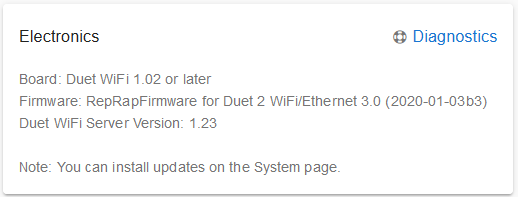

Your config is for RRF3

-

@DIY-O-Sphere

Isn't that right? -

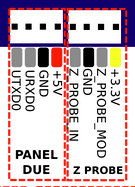

The config for the probe says "P5 (from RepRapFirmware 1.14) selects a switch by default (normally closed) for bed probing between the In and Gnd pins of the Z-probe connector (Duet 0.8.5 and Duet 2 WiFi)."

But I have it the + and GND connected to a fan output and the "Z Probe in". -

For the bed.

Looks to me like your bed heater needs to be tuned.

M303 H0 P1.0 Swhatever temperature you usually printThen take the values it returns and put it in the M307 in your config.g as the A, C, and D parameters.

-

Try this for the probe

; Z-Probe

M558 P5 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speedsWhy have you uncommented that ?

;M307 H0 B0 S1.00

Delete the ; -

@Quattro said in Noob building a HEVO in need of help.:

100 kohm NTC3950 thermistor

Check what thermistor is really used for the bed. I think it's not the correct one.

-

@Quattro said in Noob building a HEVO in need of help.:

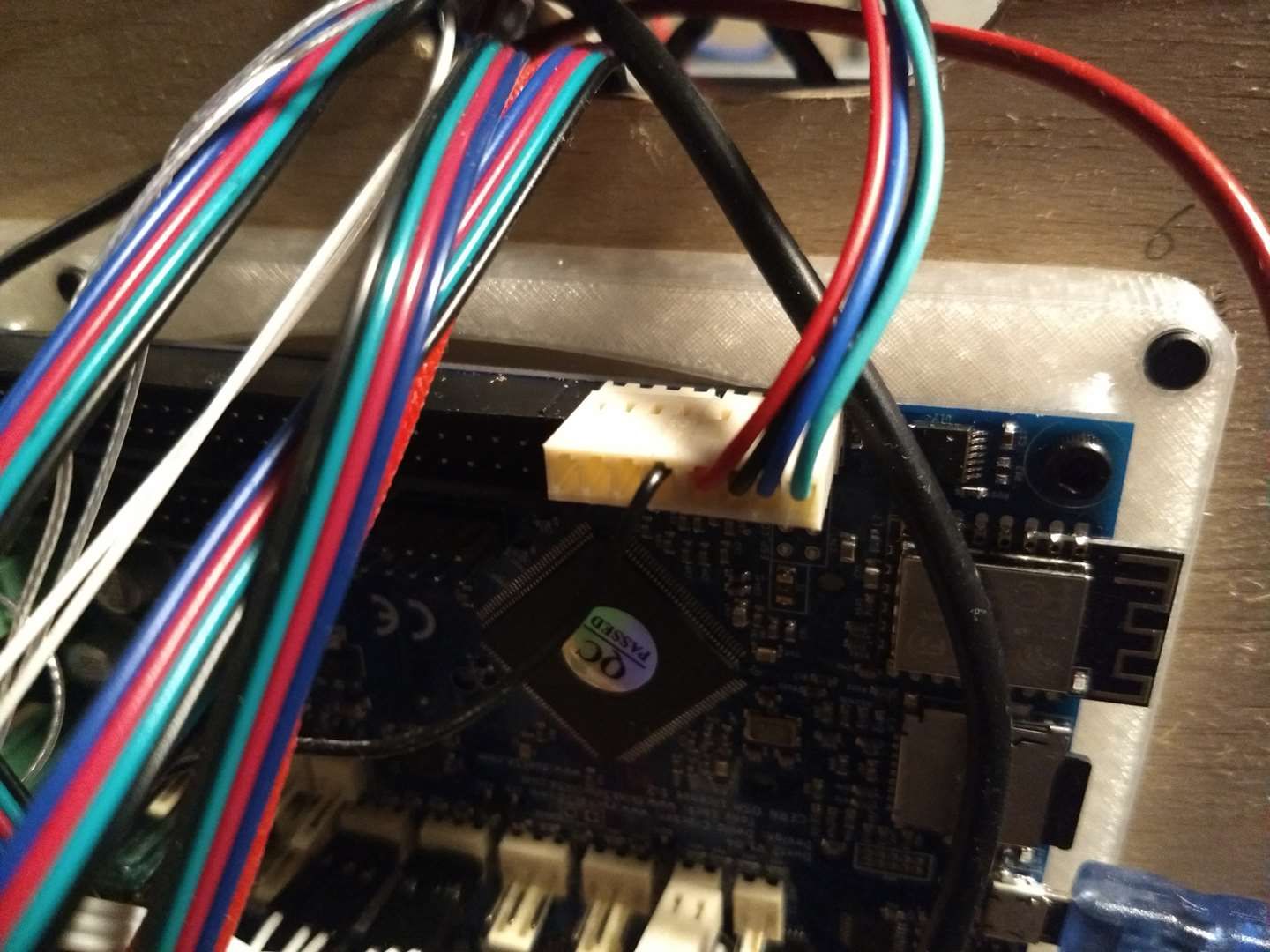

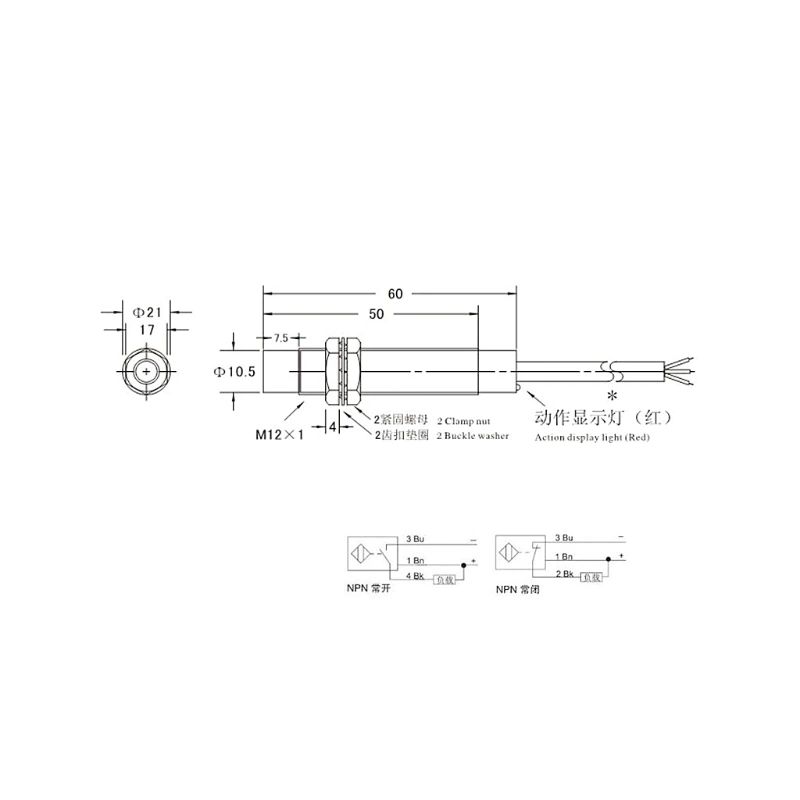

The sensor is connected like this, but the power goes to the 5V ext/fan output.

I'm not shure where you have puged power of the probe.

I would suggest to plug it in the +5V for PanelDue

And also check if the diode is in correct direction.

-

@blt3dp said in Noob building a HEVO in need of help.:

For the bed.

Looks to me like your bed heater needs to be tuned.

M303 H0 P1.0 Swhatever temperature you usually printThen take the values it returns and put it in the M307 in your config.g as the A, C, and D parameters.

Heater 0 model: gain 129.7, time constant 343.8, dead time 1.0, max PWM 1.00, calibration voltage 23.7, mode PID

Computed PID parameters for setpoint change: P463.5, I24.749, D331.1

Computed PID parameters for load change: P463.5, I93.008, D331.1Like this? M307 H0 A129.7 C343.8 D1.0 V23.7 B0

@DIY-O-Sphere said in Noob building a HEVO in need of help.:

Try this for the probe

; Z-Probe

M558 P5 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to switch and the dive height + speedsWhy have you uncommented that ?

;M307 H0 B0 S1.00

Delete the ;Because the bed heating did not work with this command.

(Black cable) Signal connected to "Z PROBE IN"

(Brown and blue) Power connected to fan output (always on fan, measured 4.86V)

The probe does read "Current reading 1000, threshold 500, trigger height 4.000, offsets X21.0 Y0.0" with G31 now.

It's a cheap Chinese probe, so it might be crap, but I expect it to work.@DIY-O-Sphere said in Noob building a HEVO in need of help.:

@Quattro said in Noob building a HEVO in need of help.:

100 kohm NTC3950 thermistor

Check what thermistor is used for the bed. I think it's not the correct one.

The bed is working after the PID adjustment.