Slicing G-Code curves from solid (not mesh) geometry.

-

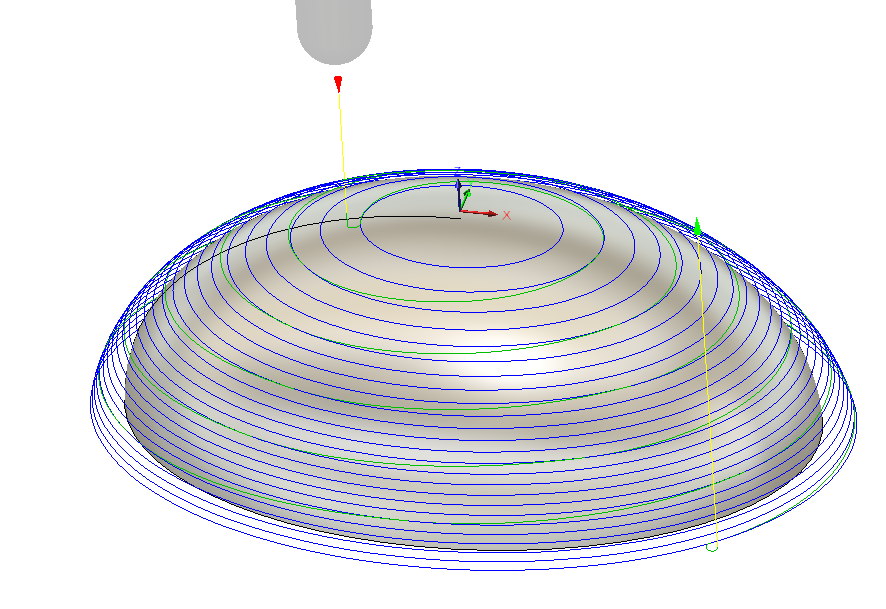

@bot: A very simple example of curves and CNC: half of an ellipse.

I did use 3D machining, because that is the most close match to 3D printing.The shape with a contour machining operation on it, sort of vase mode, but dumber.

The code, well, part of it:

(8MM BALLNOSE HSS) N30 S5500 M3 N35 G54 N40 M7 N45 G0 X-11.941 Y-2.03 N50 G43 Z15. H55 N55 G0 Z-0.239 N60 G1 Z-2. F1200. N65 G3 X-10.745 Y-1.161 I0.418 J0.682 N70 G1 X-10.75 Y-1.14 N75 G2 X-9.389 Y3.788 I5.511 J1.129 N80 X-5.224 Y6.596 I7.157 J-6.122 N85 X3.136 Y7.212 I5.216 J-13.752 N90 X8.884 Y4.382 I-2.11 J-11.539 N95 X10.838 Y0.763 I-4.762 J-4.907 N100 X9.022 Y-4.194 I-5.888 J-0.655 N105 X4.654 Y-6.798 I-7.136 J7.003 N110 X-6.811 Y-5.906 I-4.67 J14.086 N115 X-10.089 Y-2.86 I4.467 J8.094 N120 X-10.751 Y-1.162 I6.671 J3.579 N125 G1 X-10.782 Y-0.985 N130 X-10.815 Y-0.8 N135 X-10.839 Y-0.64 Z-2.001 N140 X-10.862 Y-0.449 N145 X-10.876 Y-0.298 Z-2.002 N150 X-10.891 Y-0.096 Z-2.003 N155 X-10.897 Y0.105 Z-2.004 N160 X-10.895 Y0.234 Z-2.005 N165 X-10.892 Y0.395 Z-2.006 N170 X-10.885 Y0.546 Z-2.008 N175 X-10.872 Y0.731 Z-2.009 N180 X-10.853 Y0.909 Z-2.011 N185 X-10.828 Y1.096 Z-2.013 N190 X-10.796 Y1.292 Z-2.015 N195 X-10.755 Y1.498 Z-2.018 N200 X-10.704 Y1.711 Z-2.021 N205 X-10.651 Y1.912 Z-2.024 N210 X-10.588 Y2.116 Z-2.028 N215 X-10.516 Y2.328 Z-2.031 N220 X-10.404 Y2.615 Z-2.036 N225 X-10.303 Y2.844 Z-2.041 N230 X-10.212 Y3.039 Z-2.045 N235 X-10.066 Y3.318 Z-2.052 N240 X-9.938 Y3.542 Z-2.057 .. .. N645 X14.98 Y1.695 Z-2.983 N650 X15.075 Y1.31 Z-2.988 N655 X15.149 Y0.92 Z-2.991 N660 X15.199 Y0.526 Z-2.995 N665 X15.226 Y0.129 Z-2.997 N670 X15.228 Y-0.269 Z-2.999 N675 X15.206 Y-0.667 Z-3. N680 X15.163 Y-0.997 N685 G2 X12.255 Y-6.262 I-8.719 J1.381 N690 X6.936 Y-9.396 I-9.608 J10.227 N695 X-4.087 Y-10.177 I-6.934 J19.678 N700 X-11.708 Y-6.796 I2.938 J16.904 N705 X-14.829 Y-2.476 I6.747 J8.161 N710 X-13.393 Y5.01 I7.445 J2.453 N715 X-9.026 Y8.501 I9.438 J-7.331 N720 X-0.475 Y10.551 I8.587 J-16.962 N725 X10.016 Y7.994 I0.754 J-19.714 N730 X14.009 Y4.188 I-6.515 J-10.83 N735 X15.175 Y-0.999 I-6.878 J-4.271It uses G2 arcs as much as it can. But circles can only be done in the XY/XZ/YZ plane, and that is why you see a whole stretch of G1 short segment code where the cutter ramps down in an arc (most of the 'green lines' between the 'blue lines')

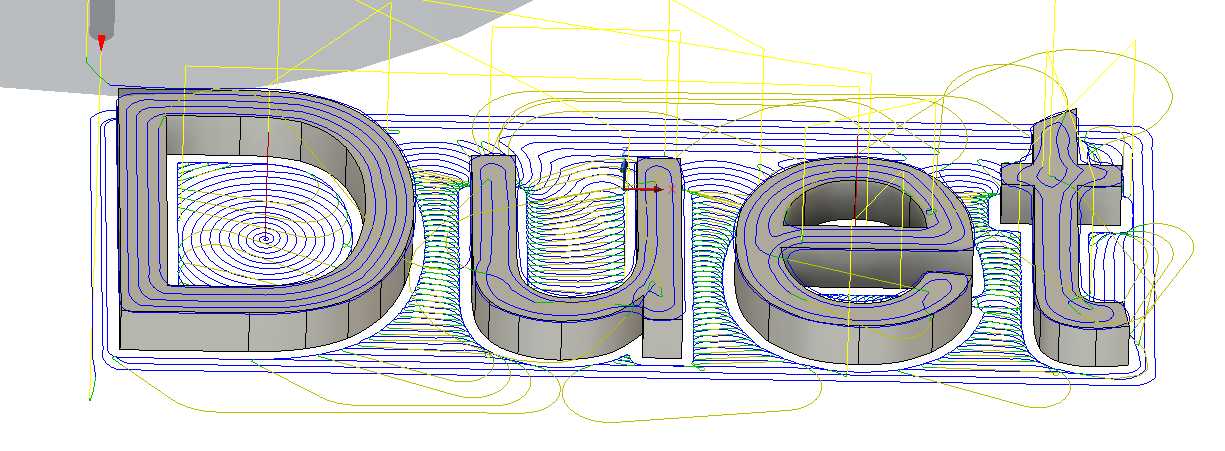

Thus, we won't get rid of the short segment code for these shapes.Another one: text, once again an automatic 3D machining operation (adaptive clearing):

Once again a piece of code:

... ... N270 G2 X-20.43 Y-7.523 I0.241 J0.81 N275 X-20.779 Y-7.028 I0.175 J0.494 N280 G1 X-20.778 Y-6.626 N285 Y7.108 N290 G2 X-20.024 Y7.76 I0.559 J0.115 N295 X-13.908 Y7.733 I2.674 J-84.969 N300 G3 X-11.691 Y7.553 I2.199 J13.356 N305 G1 X-7.796 Y7.555 N310 X19.822 N315 G2 X20.523 Y6.333 I-0.201 J-0.927 N320 G1 X20.559 Y5.969 N325 X20.561 Y5.615 N330 X20.562 Y4.199 N335 Y-5.651 N340 G2 X20.768 Y-7.149 I-4.593 J-1.394 N345 X20.022 Y-7.562 I-0.63 J0.256 N350 X17.278 Y-7.517 I-1.247 J7.555 N355 X11.16 Y-7.55 I-4.248 J216.39 N360 X7.583 Y-7.534 I-1.755 J7.226 N365 G1 X7.222 Y-7.551 N370 X6.868 Y-7.549 N375 X5.452 Y-7.547 N380 X-1.184 Y-7.543 N385 G2 X-4.139 Y-7.538 I-1.469 J4.827 ... ...As you can see: when it fits the capabilities of the machine a lot of arcs are emitted, allowing the curves to be actually round instead of a faceted approximation. Nothing wrong with a faceted approximation; in the end it all ends up as 'facets' the size of a motor step or encoder count. But at least it reduces G-code size tenfold, and it allows the controller to spend way more CPU cycles on creating nice curves instead of figuring out how to connect the thousand dots that form an arc.

Oh, and BTW, this resembles in no way decent CAM-code. Just synthetic, quick & dirty to give you an idea.

-

@DaBit Duuuude. Thanks for those g-code examples. This is interesting. I was already wondering how some of the crazy splines could be generated -- they can't!

How can a spline be defined, anyway? Would it be nonsensical to attempt to create a g-code spline specification?

-

I must be clairvoyant or something -- Fusion just dropped the update with FFF toolpath creation. See y'all in a few weeks... I've got some exploring to do.

-

I just pulled it down as well. Looks promising at first glance. Now if I could figure out how to generate gcode instead of a 3mf file...

-

How are you guys getting this into your fusion install ?

-

@gtj0 lol... I just generated some toolpaths and they certainly do NOT look promising.

I see no settings for "meshing" or smoothing/tolerance, and the supports are generated based on settings and it seems you can't edit them.

We shall see how they improve it...

-

@jens55 I had to close down fusion, restart it -- then when I restarted it started downloading the update, then when its done you click retsrat fusion 360 (it's in the clock icon at the top right)...

Then it's in the additive pane of the manufacture workspace.

-

Tried that initially but it didn't do an upgrade. Trying again ....

-

Ahh, this time it updated ... maybe I wasn't patient enough. Thanks !

-

I rest my case re my previous opinion about their ability to come up with anything that competes with the current slicers. They have a LONG way to go !

-

@jens55 I'm actually very upset right now how right you were. Damn.

-

Have you guys actually generated a gcode file? If so, how?

-

@gtj0 I did not generate a gcode file. A post-processing script would be required or something..

However, you can "simulate" the toolpath and see the preview of the toolpaths... they use the lowest resolution imagineable in generating the toolpaths. Not even close to approximating curves...

-

@gtj0 said in Slicing G-Code curves from solid (not mesh) geometry.:

Have you guys actually generated a gcode file? If so, how?

Tried but wasn't able to ... thought it was just me but glad to hear that it isn't just old age creeping up on me

-

@bot said in Slicing G-Code curves from solid (not mesh) geometry.:

@gtj0 I did not generate a gcode file. A post-processing script would be required or something..

However, you can "simulate" the toolpath and see the preview of the toolpaths... they use the lowest resolution imagineable in generating the toolpaths. Not even close to approximating curves...

Tried to simulate but no dice on that either

-

So they didn't include a post processor capable of outputting gcode to print on the machines they even have profiles for?

I was able to slice a model for the Ender3Pro and simulate it, but... what post processor are you supposed to choose? The default gives an .NC files...

A .3MF isn't much use?

It doesn't seem too bad for a first release. It's definitely very FUSION360 like, if you know what I mean.

-

@Phaedrux said in Slicing G-Code curves from solid (not mesh) geometry.:

It's definitely very FUSION360 like, if you know what I mean.

Con-fusion ....

-

This post is deleted! -

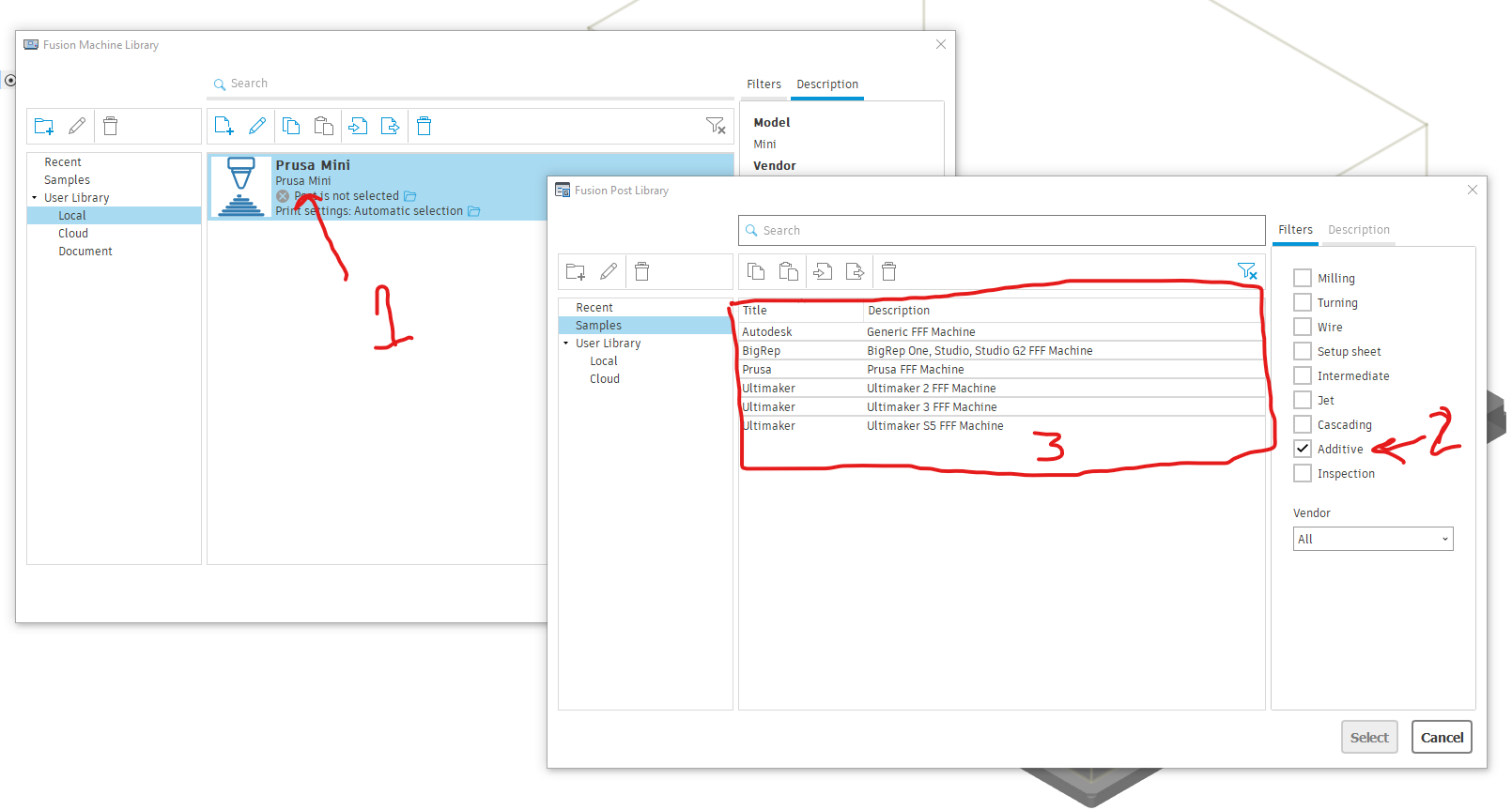

Try this. Open the Machine Configs from the additive toolbar.

In the samples find a test machine, and drag it to your local folder so you can modify it.

Next, select the local folder, pick the machine and choose the post (1).This brings up the post library. Filter to Additive (2).

Then select one of the sample posts to use (3).

-

@Phaedrux said in Slicing G-Code curves from solid (not mesh) geometry.:

The default gives an .NC files...

thats fusions default extension for g-code btw; but weather or not compatible with RRF is another story.