Issues with print quality, wall surface rough.

-

Phaedrux is right that if changing the controller did not cause a change in the outcome it is most likely mechanical. I had hoped it would be noticeable from the video.

The only other thing is slicer. Have you tried any other ones or validated all the non-physics related settings are the same between the printer that doesn't do it and the Rat one?

-

@Baenwort Yeah I agree, I was really hoping it was the board, because I had already changed so much out. I have tried prusaslicer, cura, and idea maker. All the same. It has to be mechanical right?? I'm running about 1200mm/s^2 for acceleration, and 60mm/s print speed, 600 jerk per min, I forgot the units lol.

What do you think? Extruder? I really don't want to buy another one but if it fixes it, at this point, idgaf. I'm willing to try pretty much anything at this point.

-

Disassemble the Titan and check the bearings. See if they squeak or if they are leaking black lube. Usually pretty easy to tell if they have failed. It can happen pretty quickly if the spring tensioner is over tensioned.

-

Have you tried printing with the part fan off to see if it still looks the same ?

-

@Scachi yeah tried that too, no difference

-

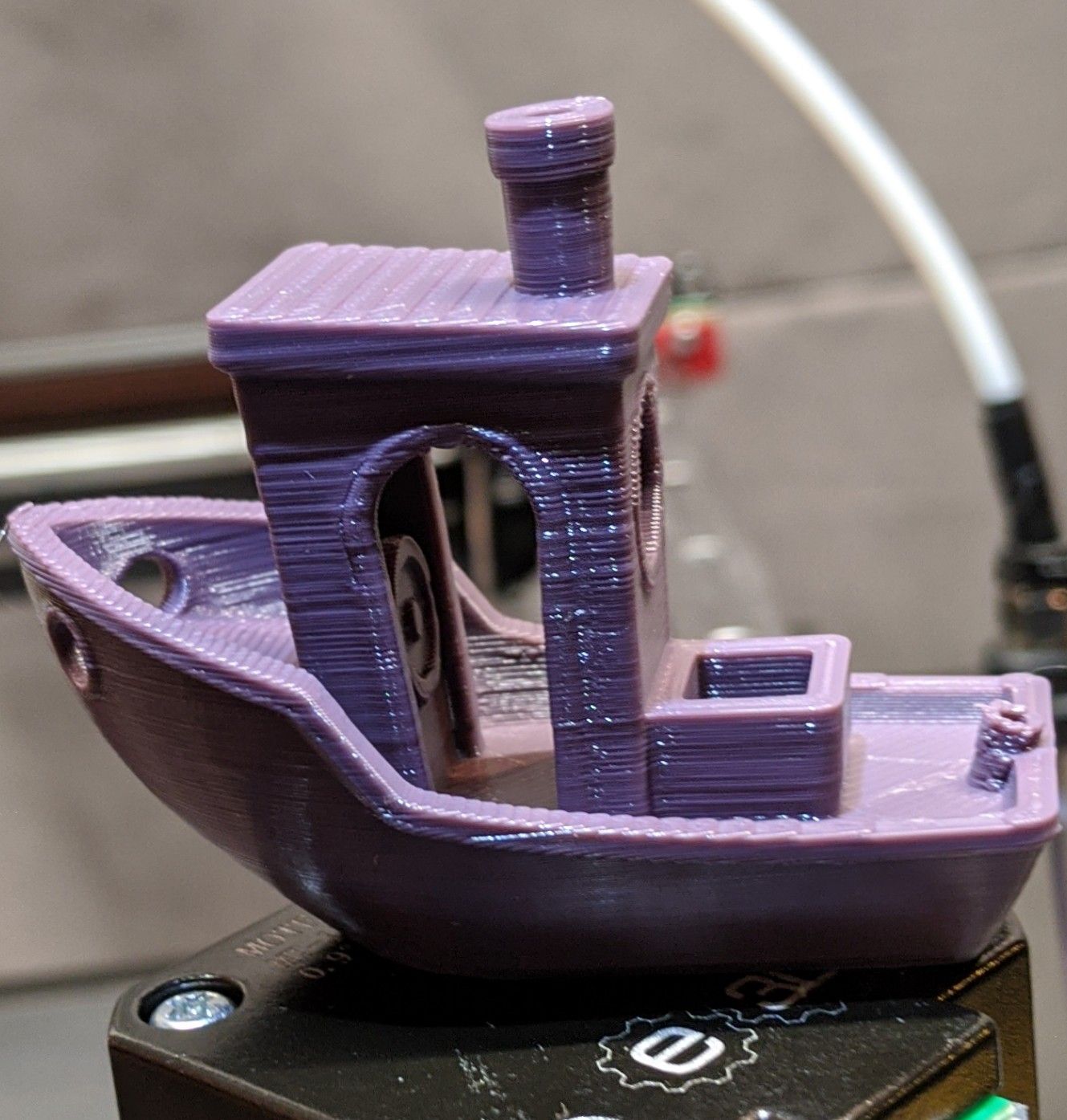

@Phaedrux Bearings all are good, no leaking or squeaking, turns smooth. He is a benchy, maybe you can see something in this.

-

I think you’re fighting a couple issues. Looks to me like over extrusion and also a possible issue with part cooling.

Having to run your extrusion multiplier at 93% is an indicator that your over extruding. Temp and or E-step could be too high and causing this.

220c for PLA is on the high side. Would recommend trying lowering it to 200 even 190 and trying.

Also recommend recalibration your esteps. I’ve found it best to calibrate the esteps with the nozzle removed and the hotend temp at 0. You will want to remove the nozzle, set the temp at 0, and enable cold extrusion. Mark the filament at 150mm and extrude 100mm at 1mm/sec. Doing it this way I can run my extrusion multiplier at 100%.

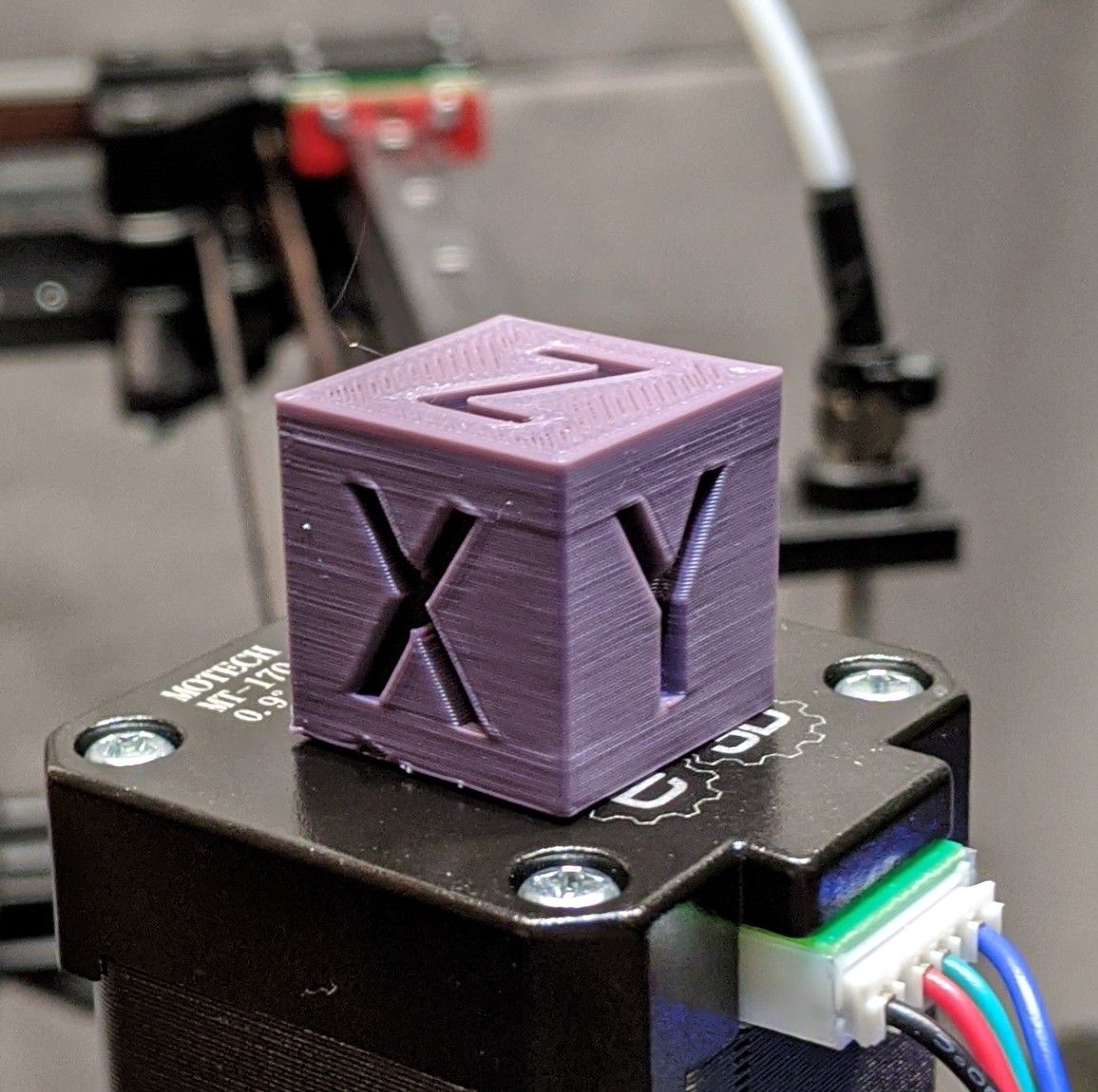

Is there a different cooling fan setup for that hotend that you can try? The ducts that come with the 4010 fans are not ideal and it looks like it’s blowing right on your hotend and the heater is having issues with keeping the temp consistent. This is evident at the tops and bottoms of the letters in the cube. Recommend finding a way to focus the airflow and direct it down a little so the air is not on the heat block. Having to print at 220 is also an indicator that you part cooling is actually cooling the heat block and you’re having to increase the temp to compensate.

Just a couple ideas of things to try. Hope it helps.

-

@mwolter I will try a lower temp right now, and I'll double check my esteps. That hot end is my personal hot mess lol, maybe I can design some fan ducts tho. No fan doesn't seem to help tho

-

@mwolter I checked my esteps without the nozzle, dead on. Here is a print at 195C:

-

Looks better, the layers are more consistent but would be good to do a temp tower test.

The issues at the top and bottom of the letters are still present. Have a feeling this due to the fan ducts. Seems like the cooling for the plastic isn't enough but it's also affecting the heat block temp. Printing a four-wall cube (no top or bottom) in vase mode that has no letters and solid walls would help to isolate the cooling issue.

Would also be good to tune Pressure Advance once the other issues are resolved.

-

@mwolter I'll try a temp tower, Ill have to look up how to do that in idea maker. Yeah I'll have to do something with the fans. That might take me awhile lol. I tried printing a cube at 220 and 107% flow, just to show I guess? Anyway:

-

To me, the 220 107% print is bulging and looks melted. Like a marshmallow.

-

I had a similar issue on a machine that showed vertical walls like in your picture. In my case, my extruder current was my issue. I increased my current from 600mA to 800mA in config.g and that took care of the weird striping issues. I'm assuming the backpressure inside the nozzle caused it to over/under extrude on a regular basis creating the bulging.

It's an easy test to increase your extruder motor current and then print again. Just something I've experienced with similar results as in your picture.

-

Have you PID tuned the bed and hot end heaters?

-

@PDBeal I will try that when I get home!

-

@Phaedrux Yep, temp is very stable, about +/-0.6c

-

@mwolter not as tasty tho haha, I'm probably printing too hot then. I'll go down to 205? 195 felt a bit weak to me.

-

I might try swapping out the backlash nuts for regular nuts and seeing if it's a binding issue.

-

@Phaedrux Can I just back off the backlash adjustors? They are this style nut :

https://openbuildspartstore.com/anti-backlash-nut-block-for-8mm-metric-acme-lead-screw/ -

Well here is 950mA on the extruder, temp 205. Really starting to think it's an extruder problem again: