Duet 3 StealthChop 2 Tuning for Nema23

-

@dc42 Yep I lowered the accel already down to 1000mm/s2; doesn't help

Increasing current doesn't either, tried up to 2.2amps out of rated 2.8; just more noisy.

Rotor inertia is specified to 305 g.cm2

-

Please see this post https://forum.duet3d.com/post/172593 and let me know if it helps.

-

@dc42 Ok thanks for the detailed instructions

I changed my config to

M569 P0 V50 H50 M915 P0 S3 F1 H153 T50 R0(and repeat for P1 ofc)

Which gives me the console returns:

8/13/2020, 11:12:24 PM M569 P0 Drive 0 runs forwards, active low enable, step timing fast, mode stealthChop, ccr 0x08053, toff 3, tblank 1, hstart/hend/hdec 5/0/0, pos 936, tpwmthrs 50 (93.8 mm/sec), thigh 50 (93.8 mm/sec) 8/13/2020, 11:12:04 PM M915 P0 Driver 0.0: stall threshold 3, filter on, steps/sec 153 (15.3 mm/sec), coolstep 0, action: noneResults are bad; the seizure happen at yet lower speed now; 60mm/s on diagonals

I tried increasing current up to 2.8amps; scary, no effect

-

@fractalengineer said in Duet 3 StealthChop 2 Tuning for Nema23:

@dc42 Ok thanks for the detailed instructions

I changed my config to

M569 P0 V50 H50 M915 P0 S3 F1 H153 T50 R0(and repeat for P1 ofc)

Which gives me the console returns:

8/13/2020, 11:12:24 PM M569 P0 Drive 0 runs forwards, active low enable, step timing fast, mode stealthChop, ccr 0x08053, toff 3, tblank 1, hstart/hend/hdec 5/0/0, pos 936, tpwmthrs 50 (93.8 mm/sec), thigh 50 (93.8 mm/sec) 8/13/2020, 11:12:04 PM M915 P0 Driver 0.0: stall threshold 3, filter on, steps/sec 153 (15.3 mm/sec), coolstep 0, action: noneResults are bad; the seizure happen at yet lower speed now; 60mm/s on diagonals

On a diagonal, the belt speed has to move the sum of the X and Y amounts, which is sqrt(2) times the diagonal amount. So 60mm/sec diagonal speed corresponds to 85mm/sec belt speed, which is fairly close to the 93.8mm/sec value returned by M569.

Try reducing all 3 values to 25.

-

@dc42 oh man this test is so painful to the ear but

Diagonal seizes from 73mm/s again

All axis from 100mm/s -

I will try the same settings. What is your steps/mm ?

-

@dc42 appreciate it; 160steps/mm

In fact here's my last workingish config.g

; General Setup - RailCore RRF on a SBC for Duet3 G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Debugging M111 S0 ; Debug (S0 is off; S1 is on) M929 P"eventlog.txt" S1 ; start logging to file eventlog.txt M915 X Y S10 F0 R1 ; log motor stalls (added 5/4/2019) ; Stepper configuration M569 P0 S1 D3 ; Drive 0 X / Rear M569 P1 S0 D3 ; Drive 1 Y / Front M569 P2 S1 D3 ; Drive 2 Z Front Left M569 P3 S1 D3 ; Drive 3 Z Rear Left M569 P4 S1 D3 ; Drive 4 Z Right M569 P5 S0 D3 ; Drive 5 Extruder ; Trinamic Drive Tuning ; Tune tpwmthrs (V) so stealthchop runs at appropriate speeds ; and tune thigh (H) to avoid shifting into fullstep mode M569 P0 V30 H23 ; X - Set tpwmthrs so StealthChop runs up to 70mm/sec (try V47) M569 P1 V30 H23 ; Y - Set tpwmthrs so StealthChop runs up to 70mm/sec M569 P2 V15 H5 ; Z Right - Set tpwmthrs so StealthChop runs up to 15.6mm/sec M569 P3 V15 H5 ; Z Left Rear - Set tpwmthrs so StealthChop runs up to 15.6mm/sec M569 P4 V15 H5 ; Z Left Front - Set tpwmthrs so StealthChop runs up to 15.6mm/sec M569 P5 V125 H5 ; E - Set tpwmthrs so StealthChop runs up to 7.2mm/sec ; Stealthchop parameters M915 P0 S3 F1 H153 T1 R0 M915 P1 S3 F1 H153 T1 R0 ; Axis configuration M669 K1 ; Corexy mode M584 X0 Y1 Z2:3:4 E5 ; Map X to drive 0 Y to drive 1, Z to drives 2, 3, 4, and E to drive 5 ; Leadscrew locations M671 X-10:-10:333 Y22.5:277.5:150 S7.5 ; Steppers Settings M350 X16 Y16 Z16 I1 ; Set 16x microstepping for axes with interpolation M350 Z16 I1 M350 E16 I0 ; Set 8x microstepping for Flex3Drive extruder interpolation OFF M906 X1820 Y1820 Z1008 E420 I35 ; Set motor currents (mA) and motor idle factor (%) // X/Y 65% of rated 2800mA M84 S30 ; Idle timeout 30s M201 X1600 Y1600 Z100 E120 ; Accelerations (mm/s^2) (Was 2500) M203 X24000 Y24000 Z900 E2400 ; Maximum speeds (mm/min) M566 X800 Y800 Z100 E6 ; Maximum jerk speeds mm/minute M208 X290 Y303 Z325 ; Set axis maxima and high homing switch positions (adjust to suit your machine) M208 X-27 Y0 Z0 S1 ; Set axis minima and low homing switch positions (adjust to make X=0 and Y=0 the edges of the bed) M92 X160 Y160 Z1600 E4130 ; Steps/mm ; End Stops M574 X1 S1 P"io0.in" ; Map the X endstop to io1.in M574 Y1 S1 P"io3.in" ; May the Y endstop to io2.in ; Define Bed M140 H0 M557 X5:290 Y30:300 P8:8 ; Probe from X=5 to 290, Y=30 to 300mm with 8x8 points ; Thermistors M308 S0 P"temp0" Y"thermistor" A"Keenovo" T100000 B4240 H0 L0 ; Bed thermistor - connected to temp0 M308 S1 P"temp1" Y"thermistor" A"Mosquito" T4606017 B5848 C5.548428e-8 H0 L0 ; Dyze 500c thermistor - connected to e0_heat ; Define Heaters M950 H0 C"out0" T0 ; Bed heater is on out0 M950 H1 C"out1" T1 ; Hotend heater is on out1 ; Heater model parameters M307 H0 A158.5 C366.7 D2.1 S1.0 V24.0 B0 ; Keenovo duet 3 configuration M307 H1 A324.0 C114.3 D4.4 S1.0 V23.9 B0 ; Heating process parameters for 24V a system ; Heater Fault Parameters M570 H1 P10 T15 S180 ; Hotend allows 10sec for anomaly, permits 15deg excursion, abandons print after 180s M143 S350 ; Set max hotend temperature ; Fans M950 F0 C"out5" ; Hotend fan on "out5" connector M106 P0 S1.0 H1 T75 ; Enable thermostatic mode for hotend fan (S225) M950 F1 C"out4" ; Layer fan on "out4" connector M106 P1 S0 ; Layer Fan ; Tool definitions M563 P0 D0 H1 F1 ; Define tool 0 G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ; BLTouch M558 P9 C"io7.in" H5 R1 F120 T6000 A5 S0.02 B1 ; Define the bltouch input on io7.in M950 S0 C"io7.out" ; Define the bltouch servo on io7.out G31 X Y25 Z1.95 P25 ; Set the offsets for the bltouch ; Duet3 Cooling M308 S2 Y"drivers" A"DRIVERS" ; Configure sensor 2 as temperature warning and overheat flags on the TMC2660 on Duet M308 S3 Y"mcu-temp" A"MCU" ; Configure sensor 3 as thermistor on pin e1temp for left stepper M950 F2 C"out6" Q100 ; Create fan 2 on pin fan2 and set its frequency M106 P2 C"ElectroBox" H1 L0.0 X1.0 B0.3 T70:160 ; Set fan 2 value ; Filament Sensor M591 D0 P7 C"io6.in" S0 E50 L1.25 R25:175 A1 T0 ; Select first hot end ; Mesh Bed Compensation G29 S1 ; Load height map from SD card M376 H3 ; Set taper height 3mm ; Dynamic Acceleration Adjustment M593 F52 ; Logging M929 P"eventlog.txt" S1 ; start logging to file eventlog.txtThanks David

-

@dc42 Ok a few more observations from today's experiments:

-

The motors don't seem to like hanging around the V setting speed; movements gets either in StealthC with hiccups, or in SpreadC with hiccups, or just stalls/seizes altogether.

-

Changing the V value doesn't fix this weird zone; it just moves it around

-

Turning M569 do D2 makes it smoother at those speeds; no more hiccup, just regular screamy Spreadcycle

-

Even then, In SpreadCycle mode they still stall at relatively low speed; 160mm/s even on X/Y moves

-

These stalls don't happen right upon movement start; it builds up over the length of the -long- move. That means, the speed of 160mm/s doesn't change over the duration of the movement, but it tracks well in the beginning, then stalls at the end

Hope that helps

-

-

Thanks for the extra info.

@fractalengineer said in Duet 3 StealthChop 2 Tuning for Nema23:

Even then, In SpreadCycle mode they still stall at relatively low speed; 160mm/s even on X/Y moves

These stalls don't happen right upon movement start; it builds up over the length of the -long- move. That means, the speed of 160mm/s doesn't change over the duration of the movement, but it tracks well in the beginning, then stalls at the end

Barring the TMC5160 drivers doing odd things, or air resistance increasing substantially at the end of the move, that suggests that the motors are not powerful to overcome frictional forces.

- Are you sure that the mechanism isn't tending to bind at high speeds?

- Does the same happen with both pure X and pure Y moves?

- What are the maximum speeds before reduction in torque predicted by the motor EMF calculator now?

- Does the torque/speed curve for the motors (if available) show anything odd at those speeds?

- Please confirm that in spreadCycle mode you have thigh set high enough so that coolStep won't be operating at those speeds.

-

-

Well again the steppers are running free; nothing connected to them

-

And yes all the observations were made with a manual gcode that goes from origin to top left corner to front right and back to origin

-

Maximum speed according to EMF Calc should be at least 220mm/s

@fractalengineer said in Duet 3 StealthChop 2 Tuning for Nema23:

@dc42 Thank you.

Okay well the EMF calc is giving yet a faster slipping speed in cartesian:

And the steppers are running free right now; zero friction as the belts are off

-

Thigh is set to 5 usually which makes 999mm/s

-

I'll see if I can get the curve

-

-

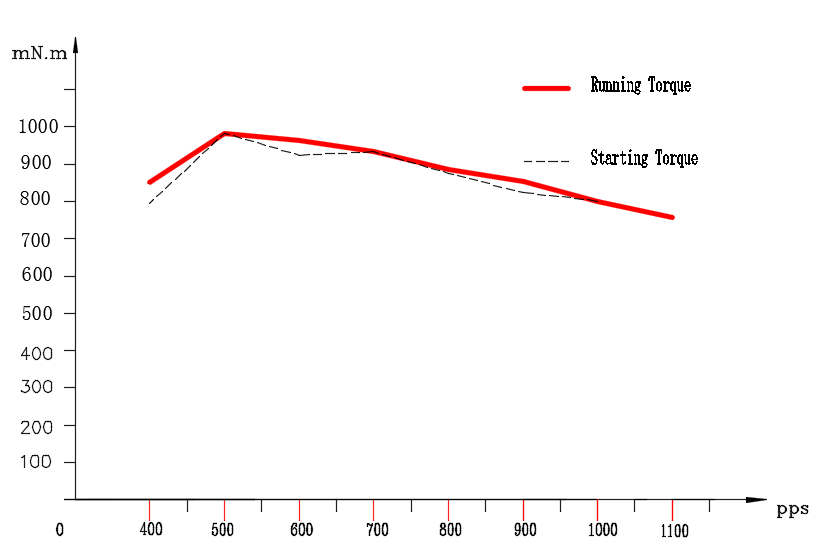

@dc42 that one is for the previous 8.5mH steppers that had the same issues but at sightly higher speed

-

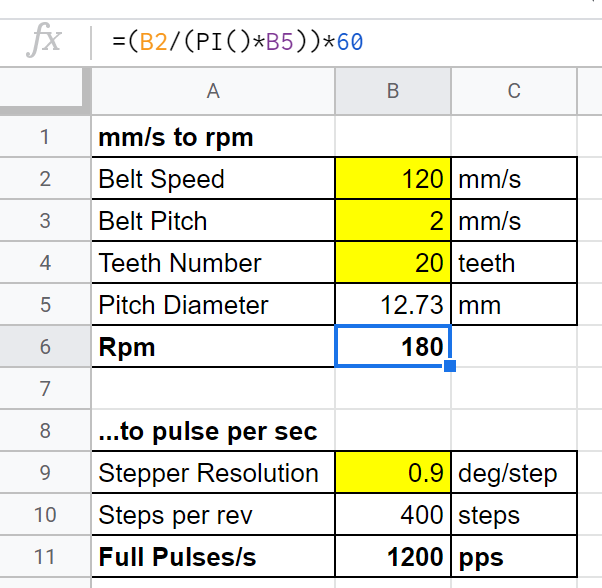

I made this little sheet; according to my calculation 120mm/s makes RPM and 1200pps

That should still be well within the envelope of this stepper?

Even twice that much pobably

-

@fractalengineer said in Duet 3 StealthChop 2 Tuning for Nema23:

Well again the steppers are running free; nothing connected to them

Have you tried connecting them to a load to see how they behave?

-

Hi @Phaedrux , yes mounting them was the first thing I did upon reception; when the problem occured I removed the belts to insulate the gantry binding possibility and kept testing this way to prevent crashing it due to the stalls

-

@dc42 did you get any insights from the torque curve?

Is there any chance of getting these steppers to work or is it just that the Duet3 can't drive Nema23?

-

I've been able to get some nice, big Moons MS23HA8L4360 NEMA23 steppers working well this weekend. I've tested them up to 400mm/sec with acceleration at 4000mm/sec², and suspect they could go higher if I drop microstepping down to x16.

Config looks like:

; Drives M569 P0.1 S1 D3 ; Y / Front 0.1 goes forwards 0.9° Moons MS23HA8L4360* M569 P0.2 S0 D3 ; X / Rear 0.2 goes backwards 0.9° Moons MS23HA8L4360* ... M350 X32 Y32 Z32 E32 I1 ; configure microstepping with interpolation ; Steps on X & Y ; = steps per rotation / (pulley teeth * belt spacing) * microstep multiplier ; 0.9° degree stepper has 400 steps per rotation, 1.8° stepper has 200 M92 X{400 / (18 * 2) * 32} Y{400 / (18 * 2) * 32} Z6400.00 E1674.00 ; set steps per mm ; Motor current ; = Max stepper rating in milliamps * 0.8 ; Adjust multiplier as desired. Lower is quieter, while higher means more torque, noise, and heat. ; ...but never over 1.0! (and even over 0.8 may lead to excess heat) M906 X{3600 * 0.8} Y{3600 * 0.8} Z{2000 * 0.8} E1100 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Speeds M203 X24000.00 Y24000.00 Z480.00 E3600.00 ; set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z80.00 E1500.00 ; set accelerations (mm/s^2) ; Jerk and accelerations ; M566 X500.00 Y500.00 Z20.00 E1500.00 ; set maximum jerk (instantaneous speed changes) (mm/min) M566 X300.00 Y300.00 Z20.00 E1500.00 ; set maximum jerk (instantaneous speed changes) (mm/min) M204 1000 T2000 ; use 1000mm/s² acceleration for print moves and 2000mm/s² for travel moves ; Trinamic Drive Tuning ; Tune tpwmthrs (V) so stealthchop runs at appropriate speeds ; and tune thigh (H) to avoid shifting into fullstep mode M569 P0.1 V40 H5 ; X - Set tpwmthrs so StealthChop runs up to 105.5mm/sec M569 P0.2 V40 H5 ; Y - Set tpwmthrs so StealthChop runs up to 105.5mm/sec ... M915 X Y T20000 ; Set CoolStep threshold super lowOne thing I've noticed is that using

M915 T...with low values to disable CoolStep leads to some nasty, loud noises. I suspect the current reduction that CoolStep does is beneficial in reducing back EMF. -

@evan38109 Yo Evan

Thanks a lot for this; very clever config file.

Looks like increasing Coolstep did help with speeds; I can go up to about 300mm/s before it stalls,

However Stealthchop doesn't seem to be running at any speed; it's all SpreadCycle now

-

Okay looks like lowering the M915 T value to the 50s reenables Stealthchop

Now the Stealthchop seizure speed is up to just below 100mm/s

I'm still confused as to how to setup the switch from StealthC to SpredC; looks like it's always choppy and noisy around the transition speed

-

@fractalengineer said in Duet 3 StealthChop 2 Tuning for Nema23:

StealthC to SpredC; looks like it's always choppy and noisy around the transition speed

the datasheet mentions that the transition between the two should be set to a speed that manages the Jerk caused by phase shift. Higher speed transition = more noticeable transition.

https://www.trinamic.com/fileadmin/assets/Products/ICs_Documents/TMC5160A_Datasheet_Rev1.14.pdf

see page 65

-

@T3P3Tony Hi Tony,

Yep I do remember reading that in the datasheet and I can reproduce this specific "caklonk" jerk when switching from M569 D3 to D2 or by changing M915 T value

What I'm referring to is more of a crackling sound around the transition speed

Here's how it runs currently; fastest speed is only 240mm/s