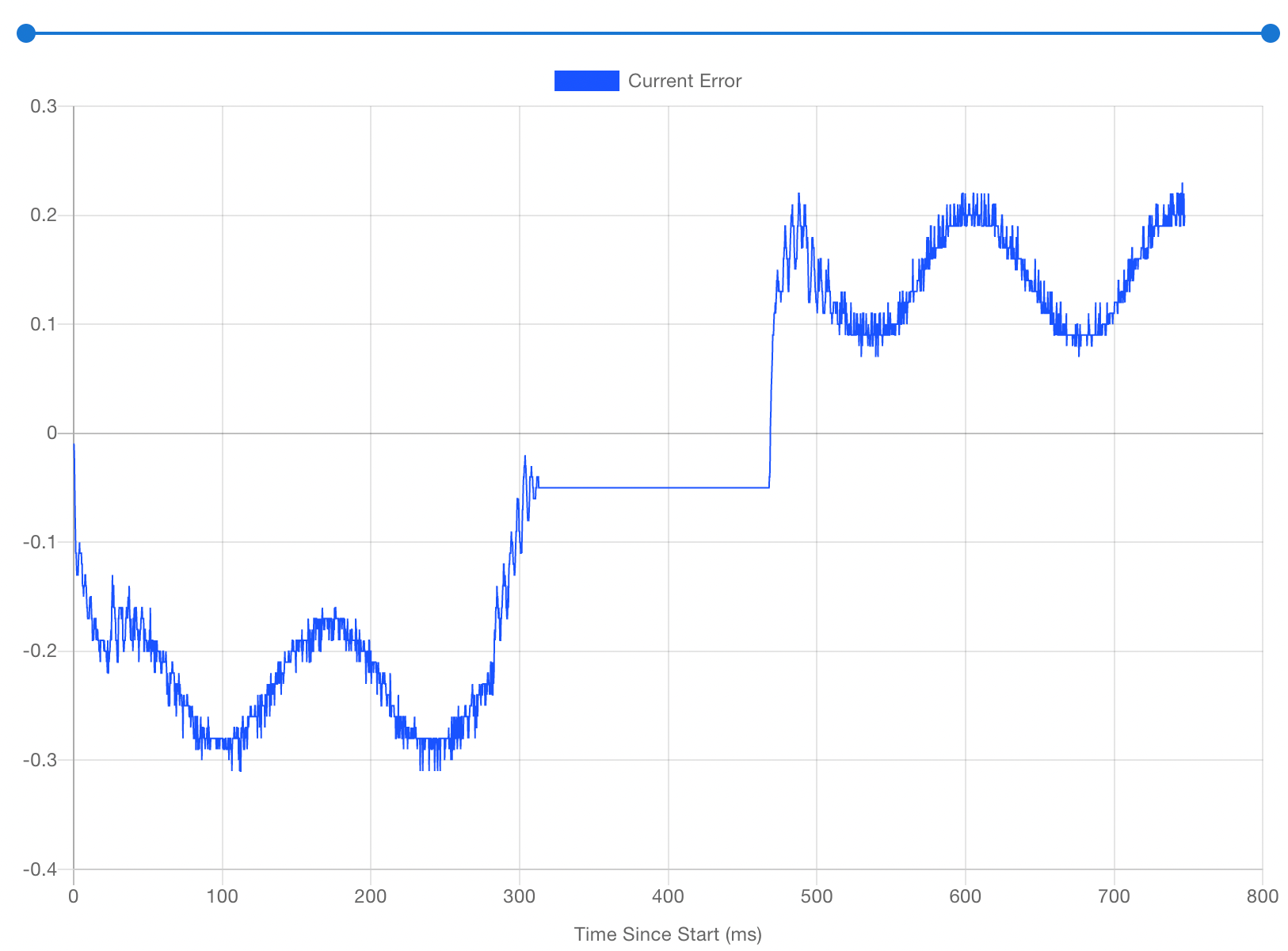

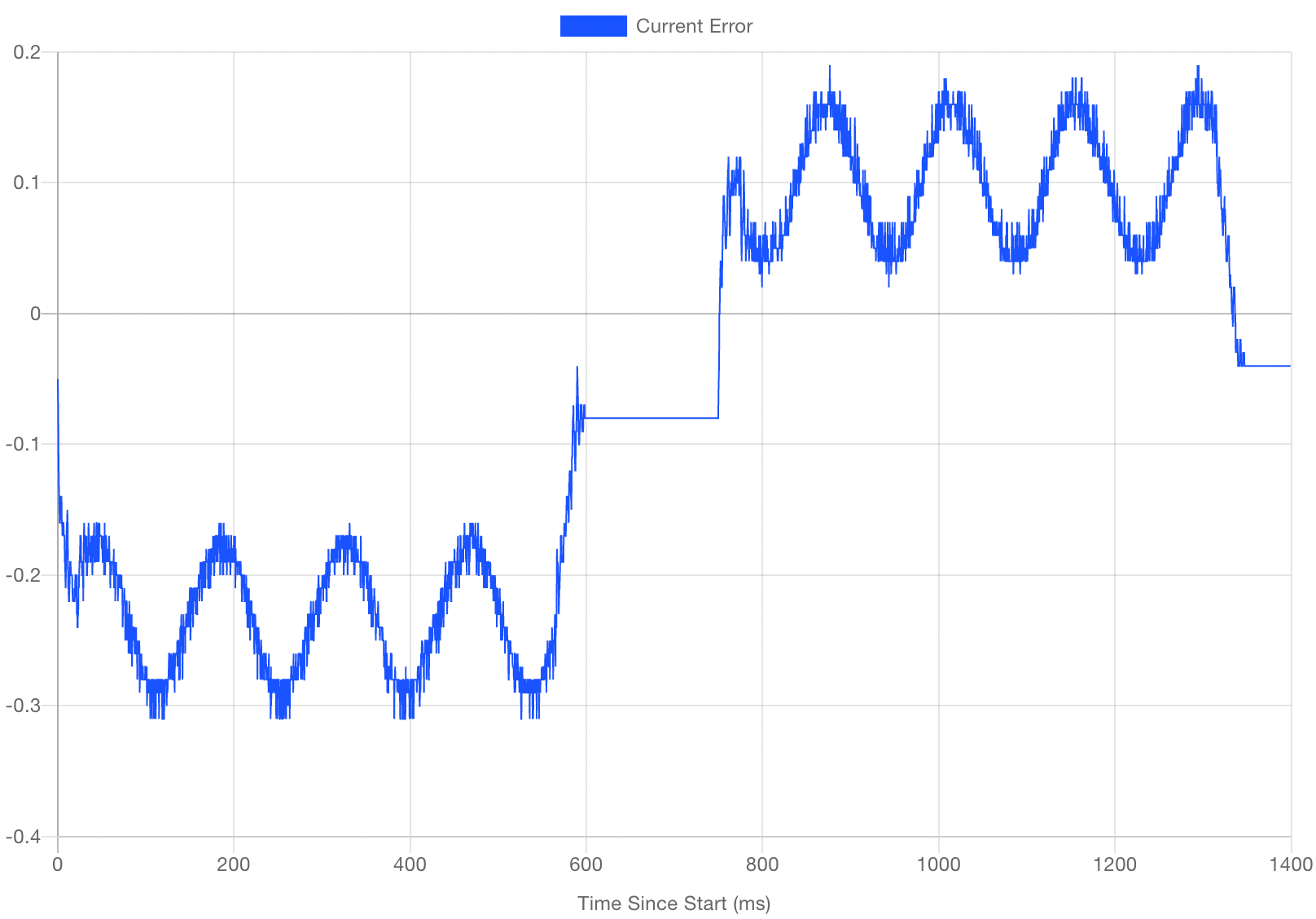

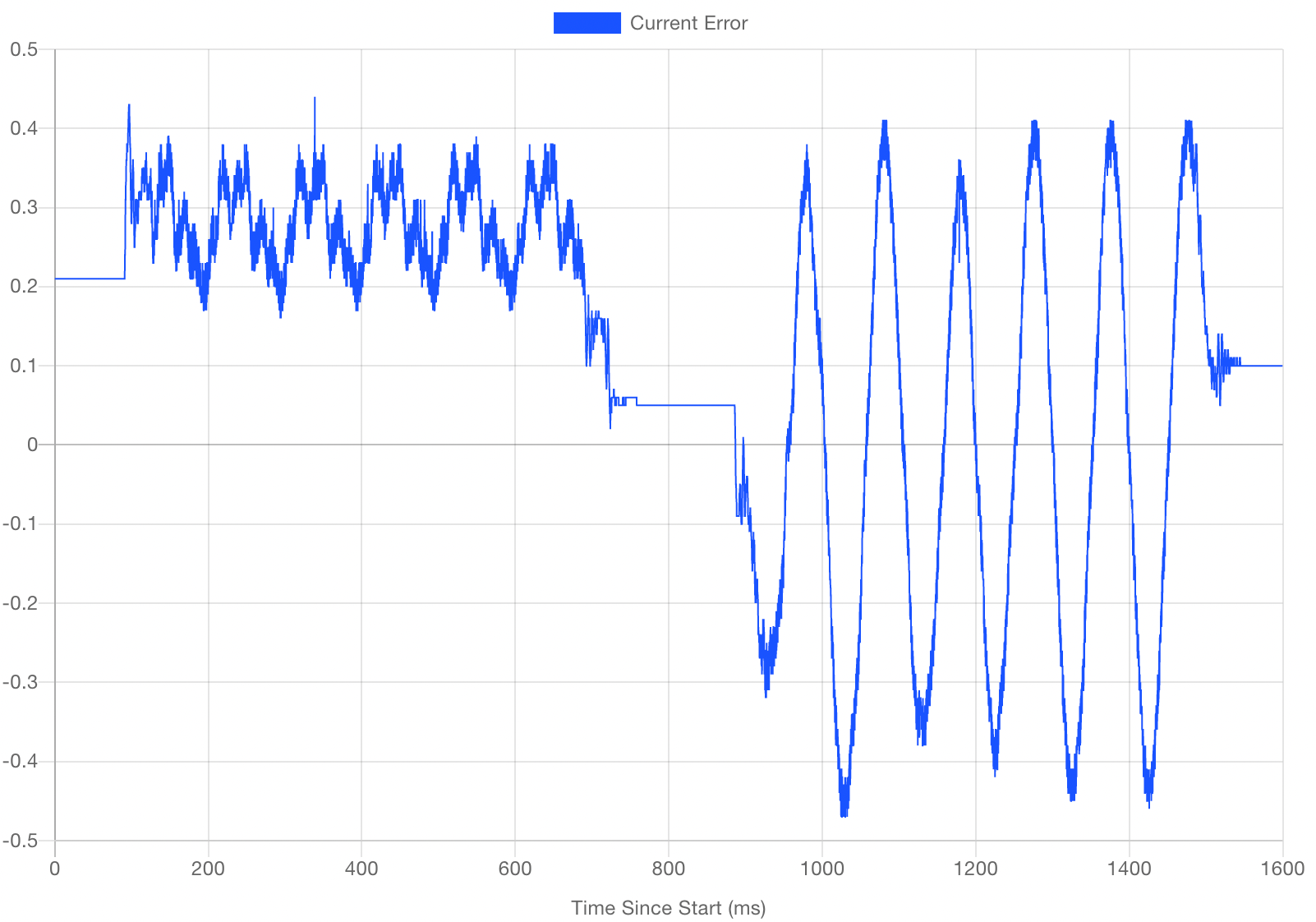

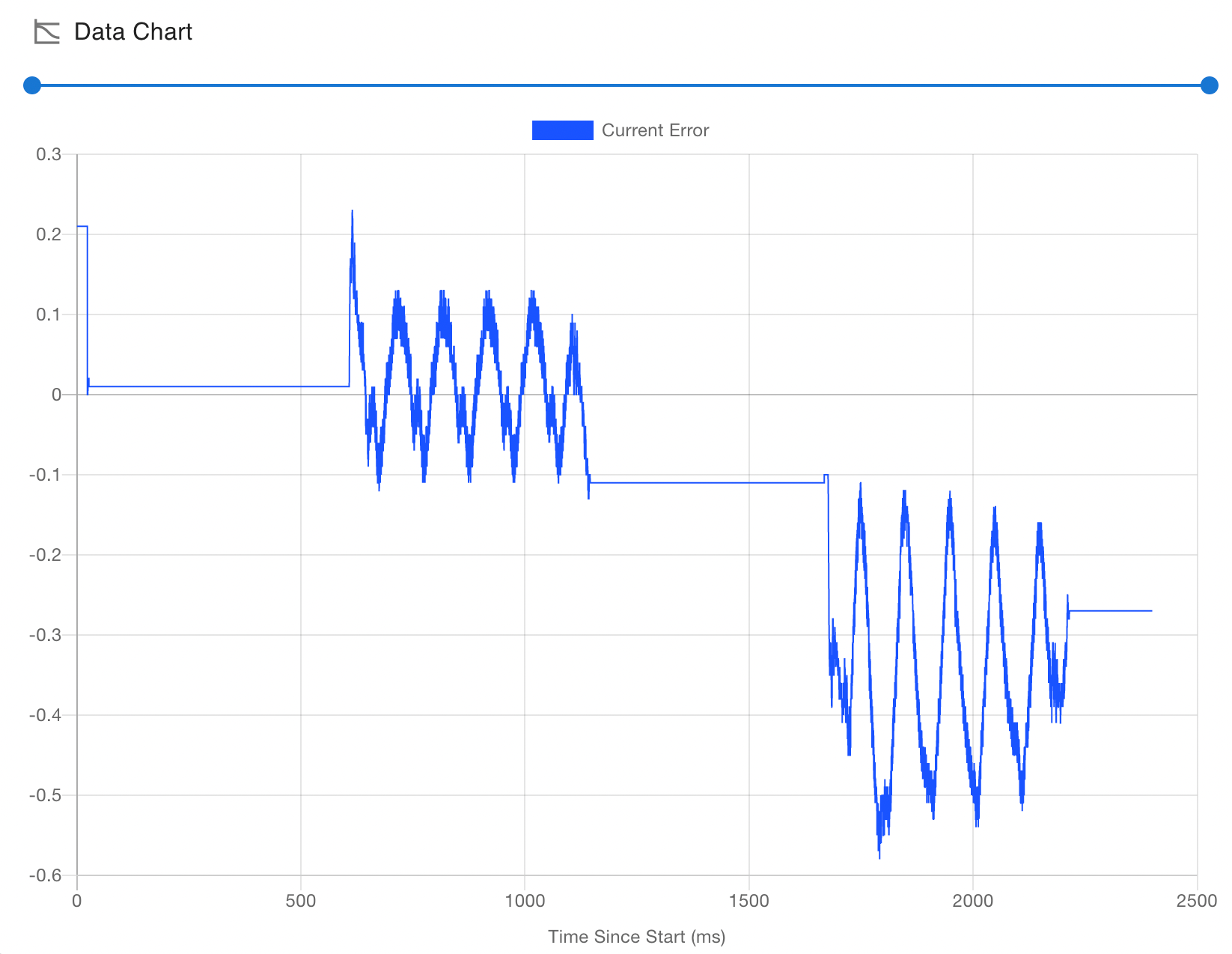

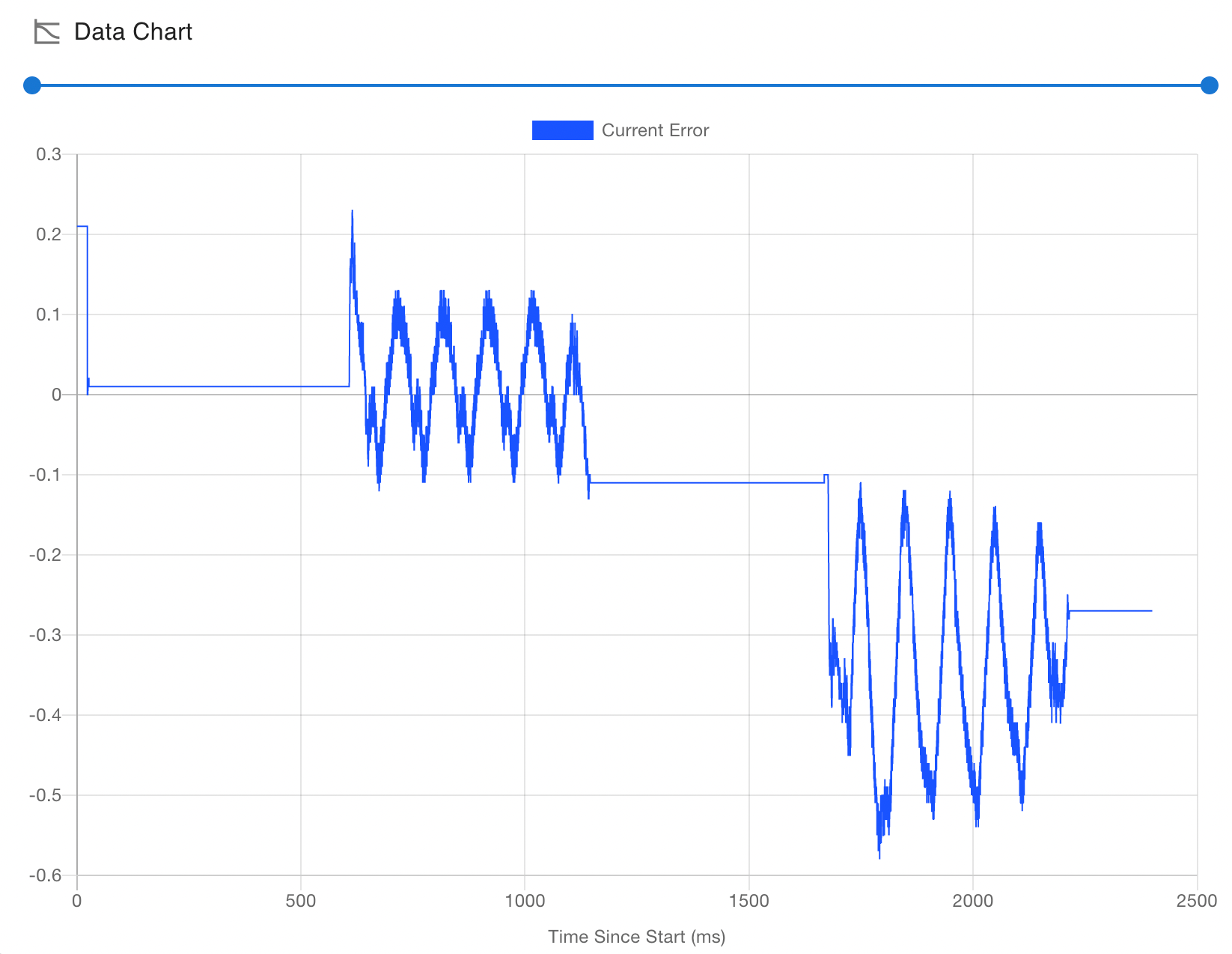

I've been spending time in the Closed Loop plugin tuning lately using 3.5.0beta1 and I keep seeing an oscillating "sawblade" pattern in the error during movement:

The movement above is a square at a 45° angle so that only one stepper moves at a time, since it's a CoreXY printer. It's just one stepper performing a straight movement, a pause, and a straight movement back. GCode here.

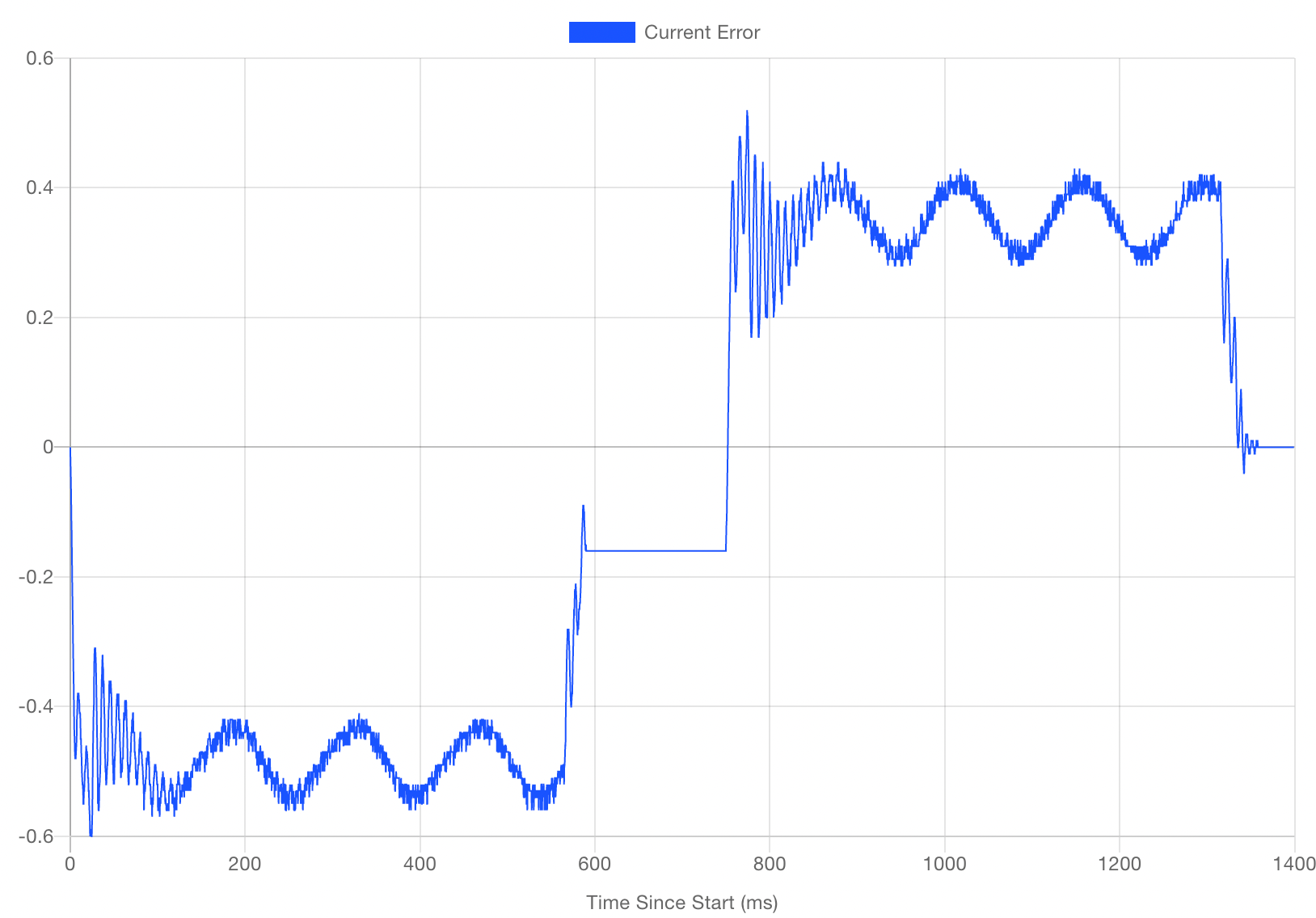

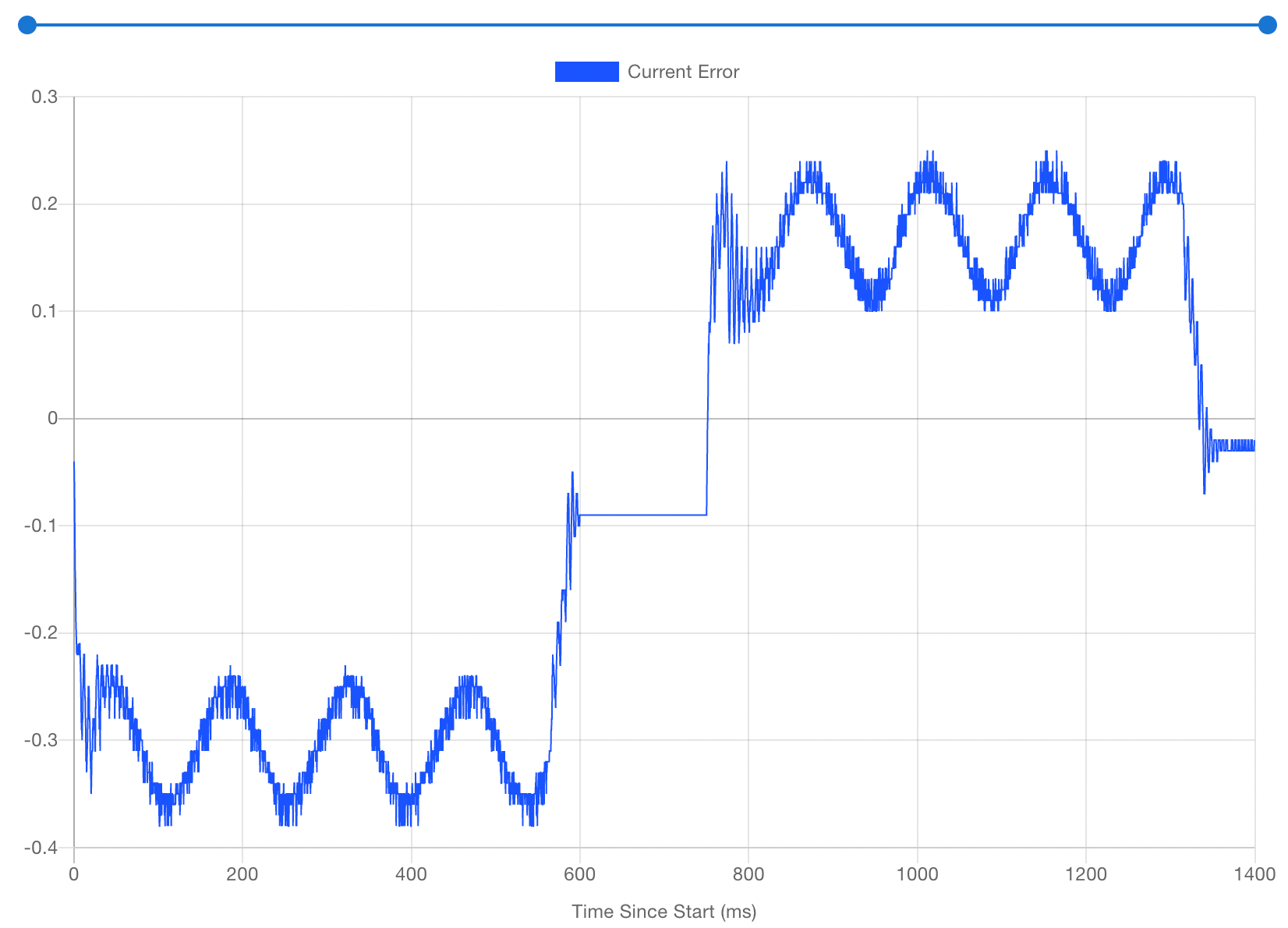

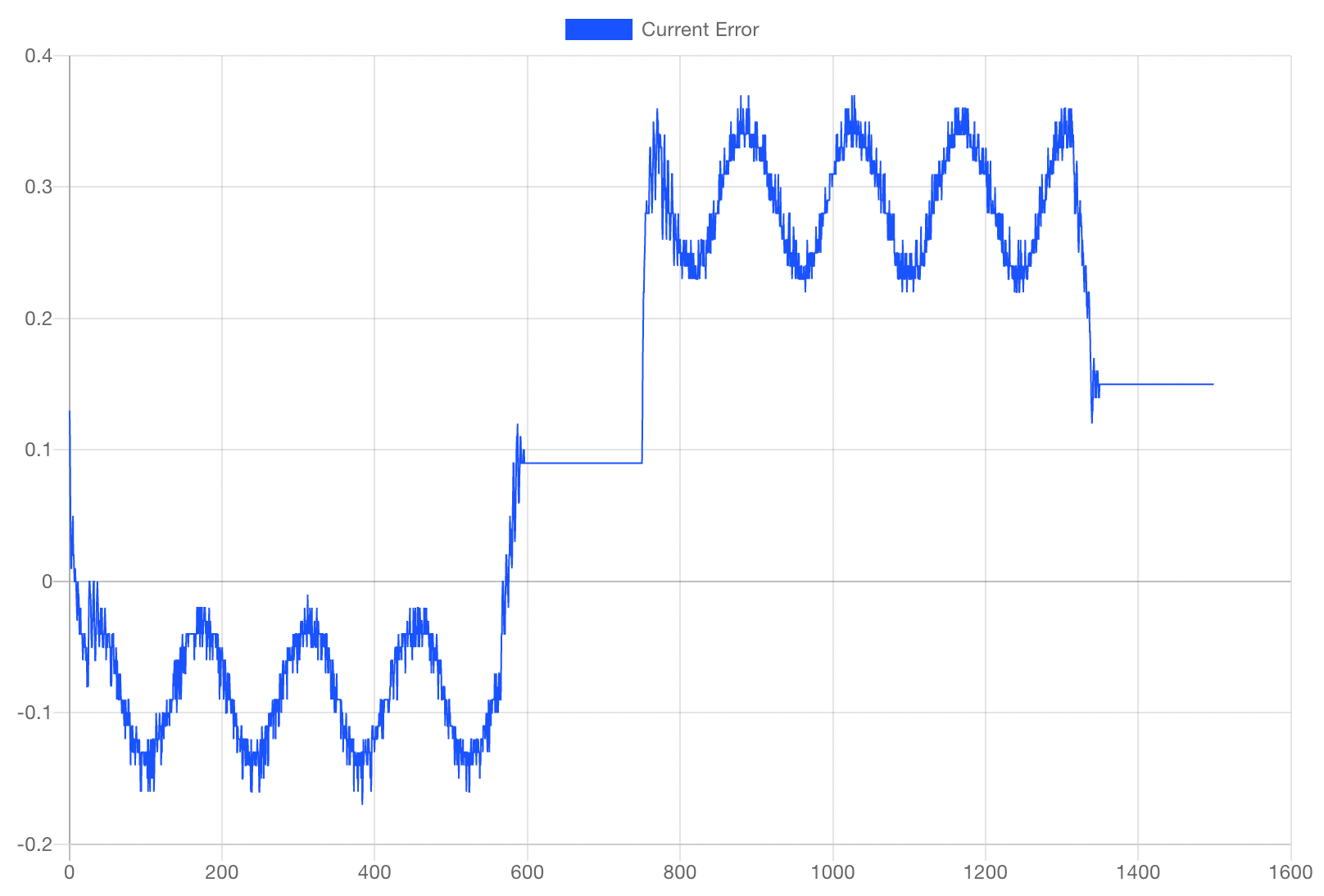

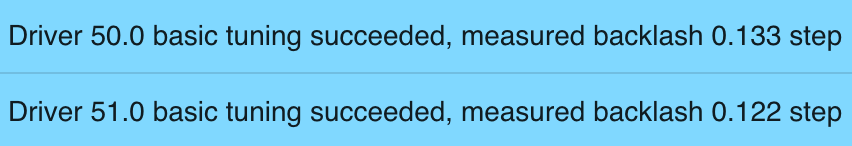

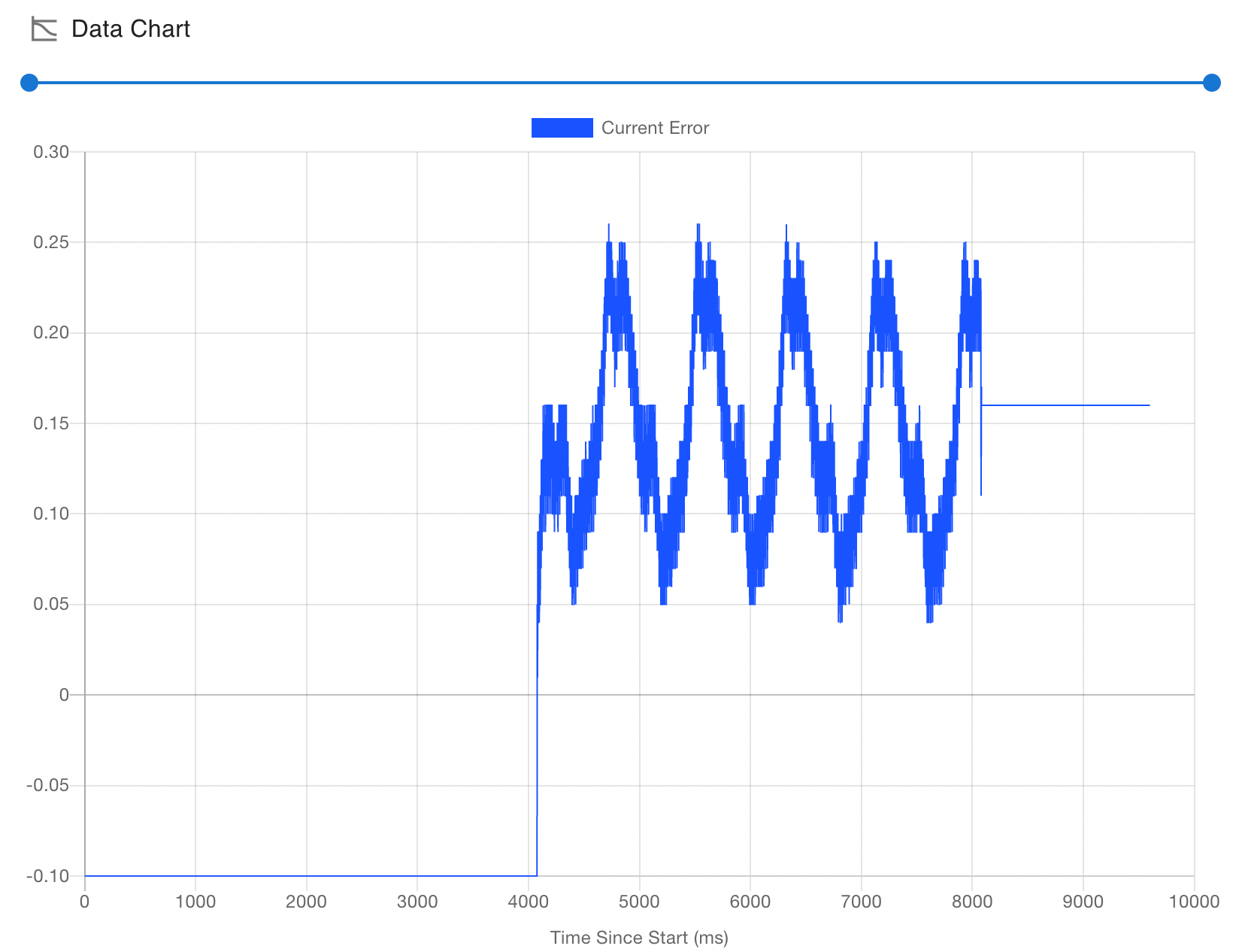

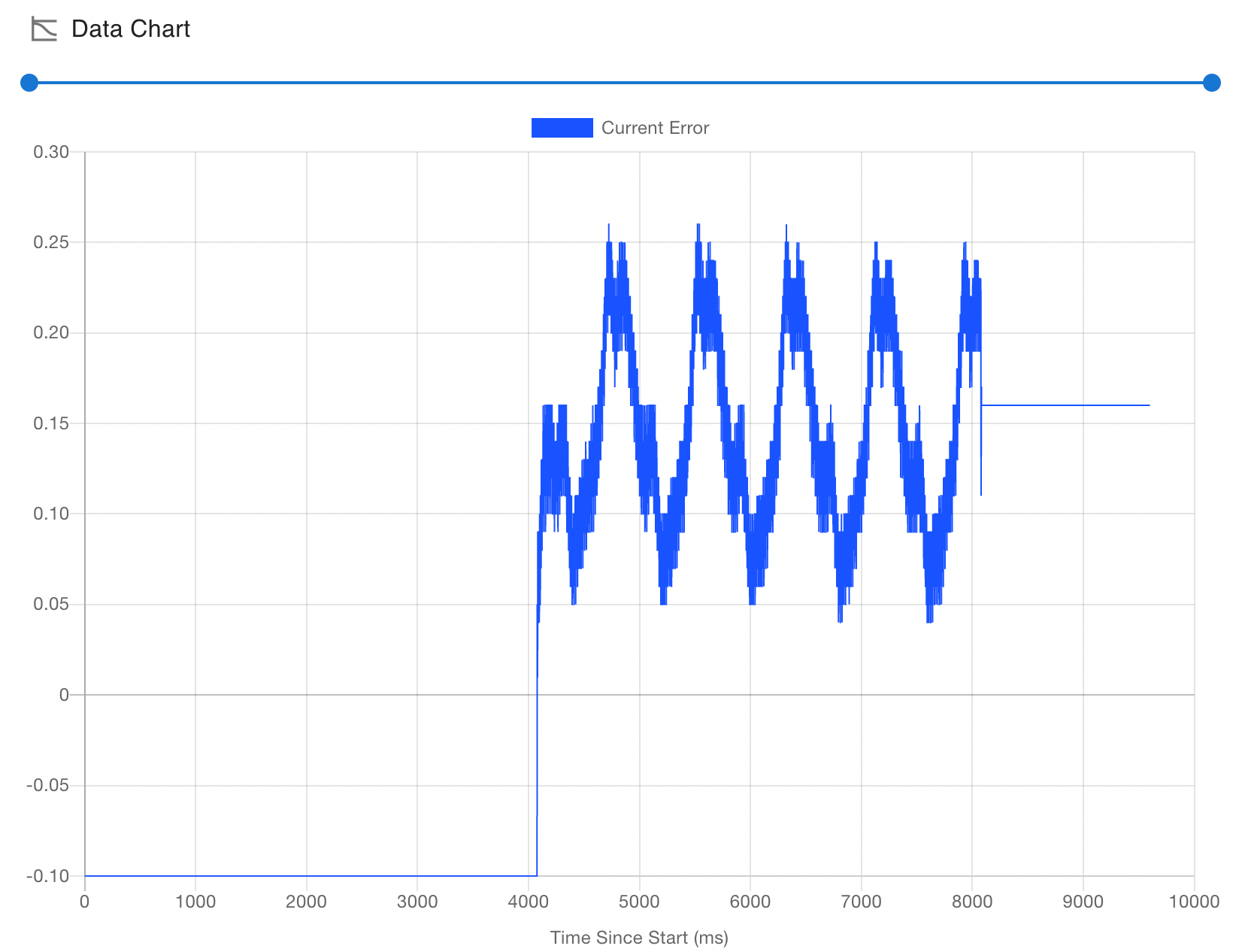

I can kinda-sorta tune it out with sufficiently aggressive PID parameters at the cost of overshoot, but it still bugged me. So I looked at the motion in open loop mode and, low and behold, the same sawblade error appears:

(P.S. - I love that I can use the 1HCL to view behavior of open loop steppers.)

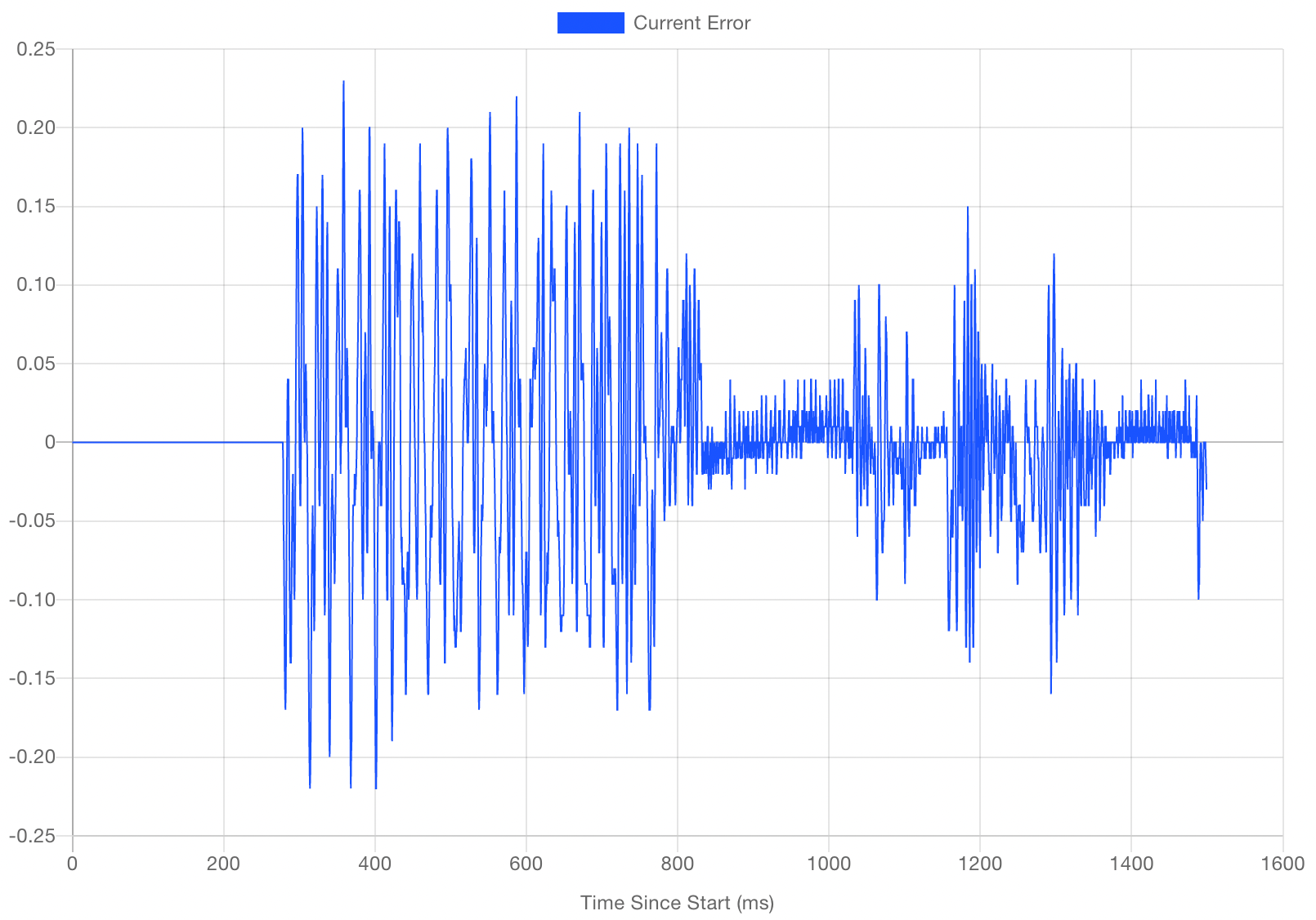

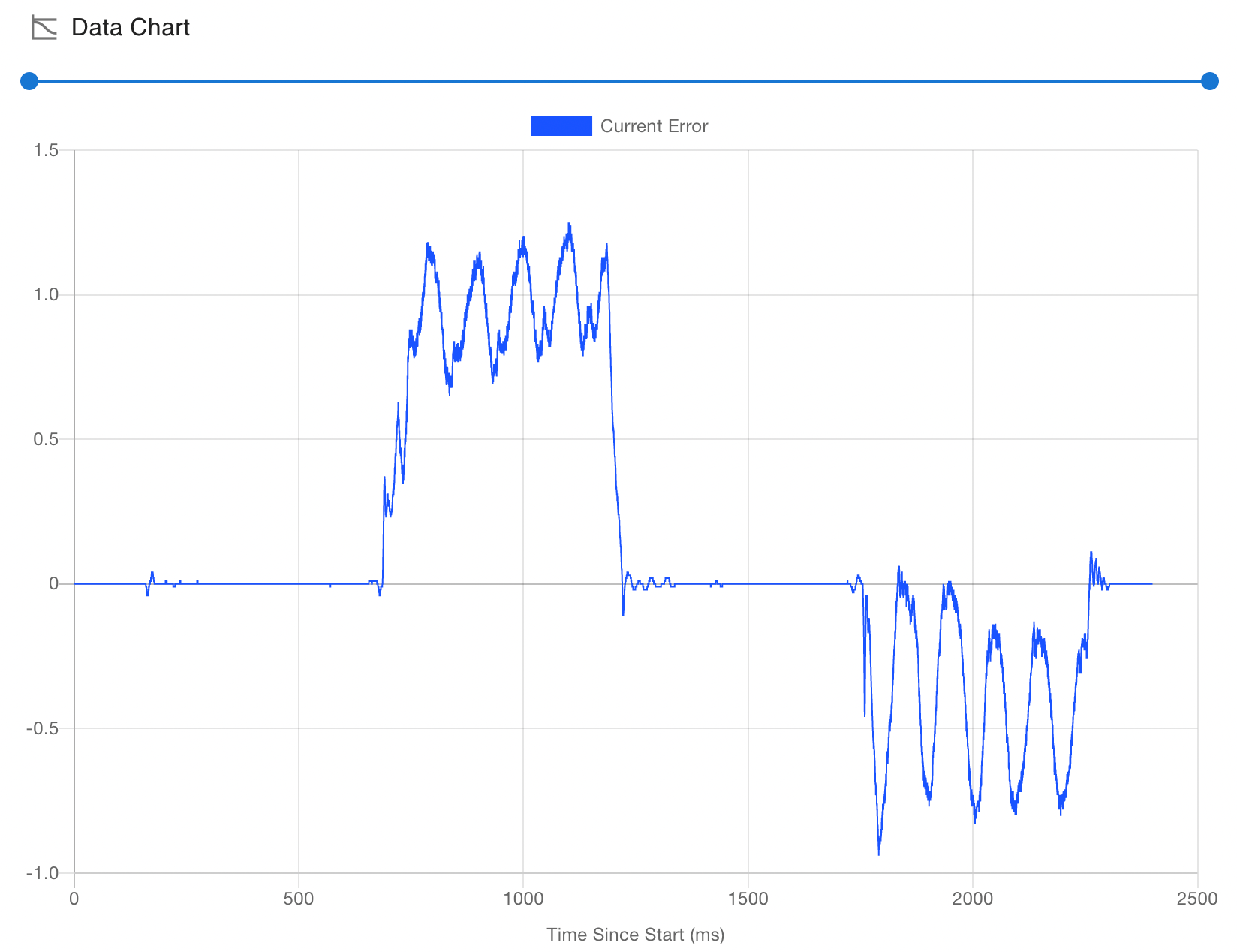

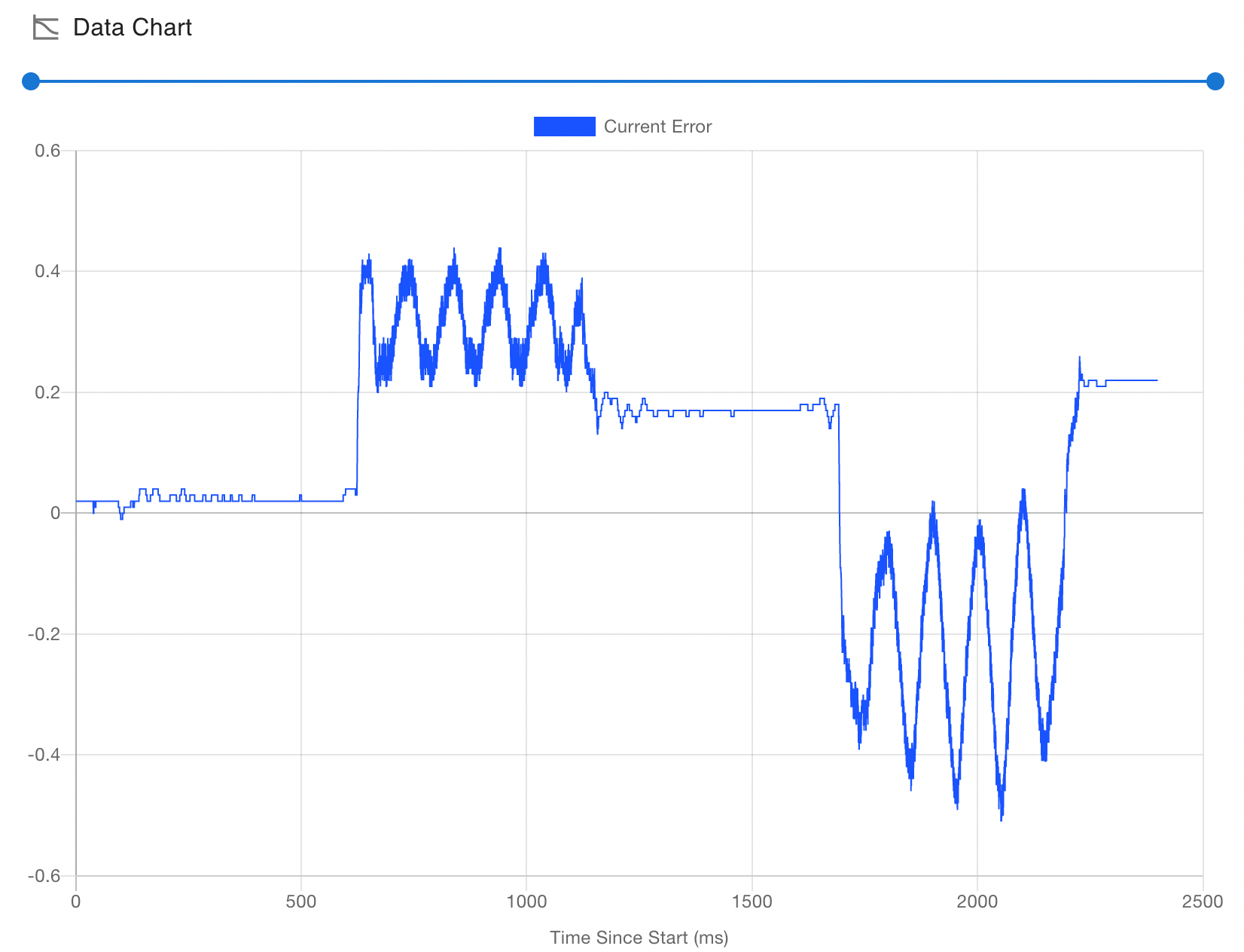

My first instinct was that I revealed some kind of stiction or other motion system issue, but then I took a look with the belts off. Same issue with both closed and open loop:

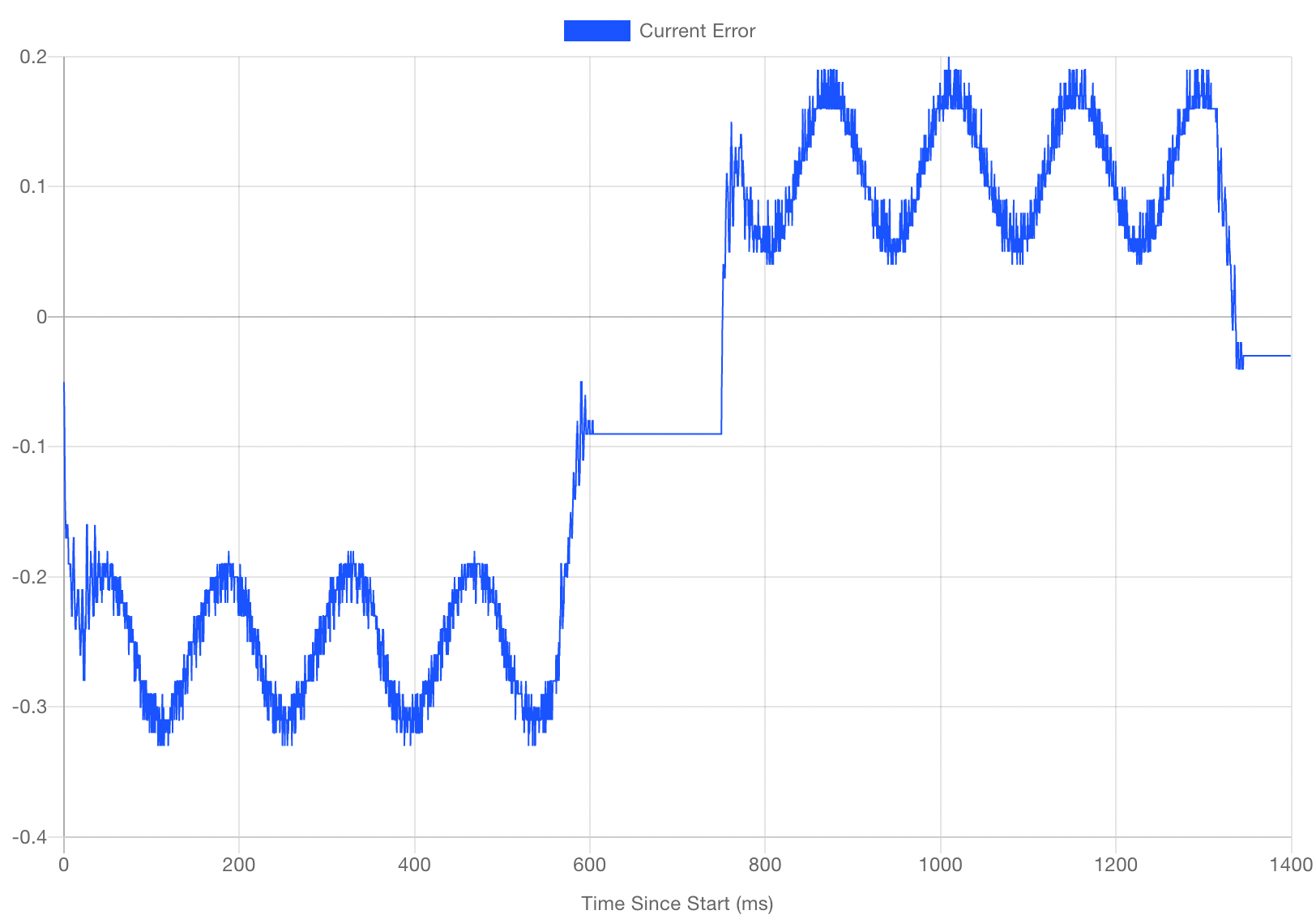

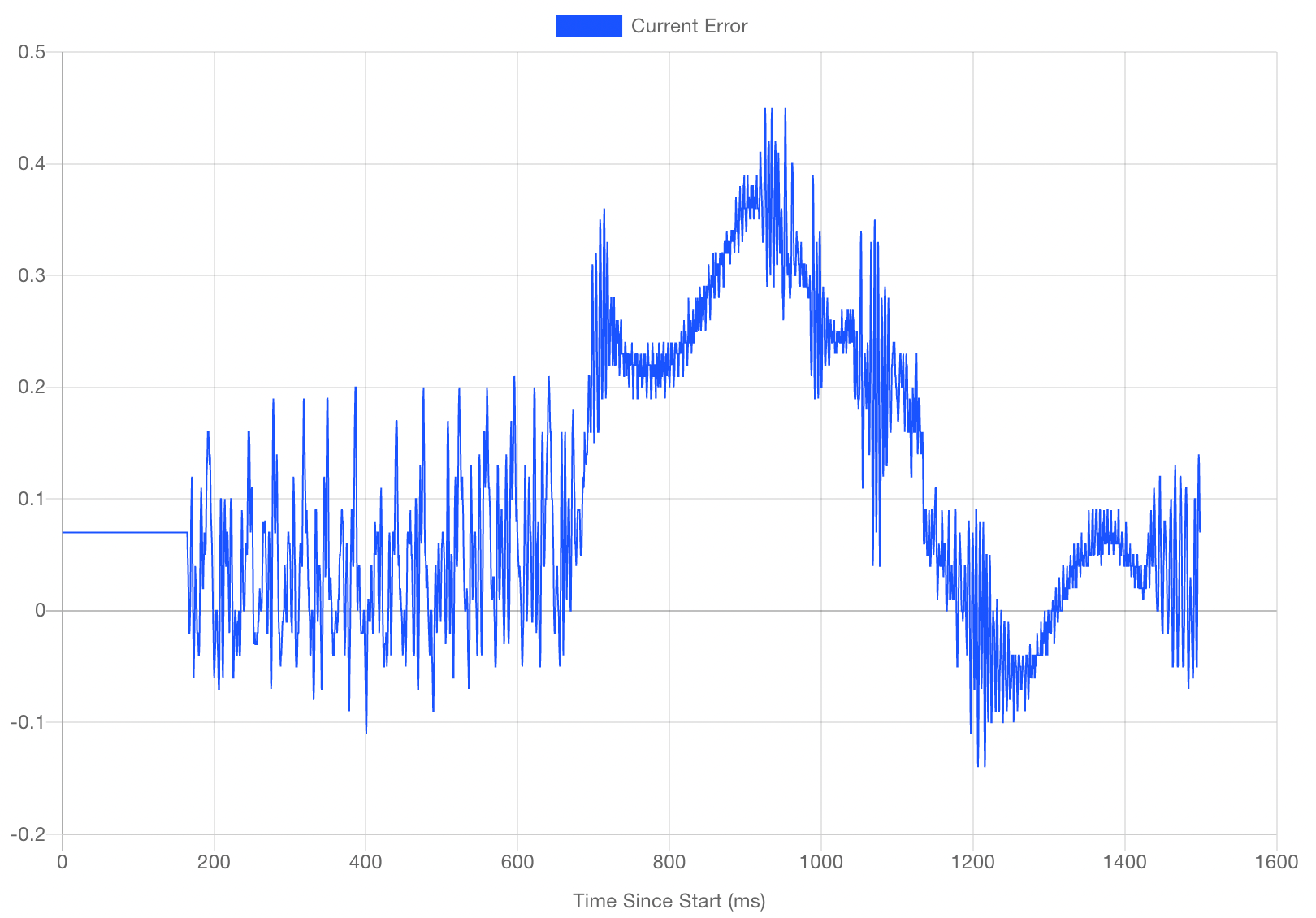

The previous were at 400mm/sec movement. The same pattern shows up at lower speeds as well, though. Here's 50mm/sec open loop:

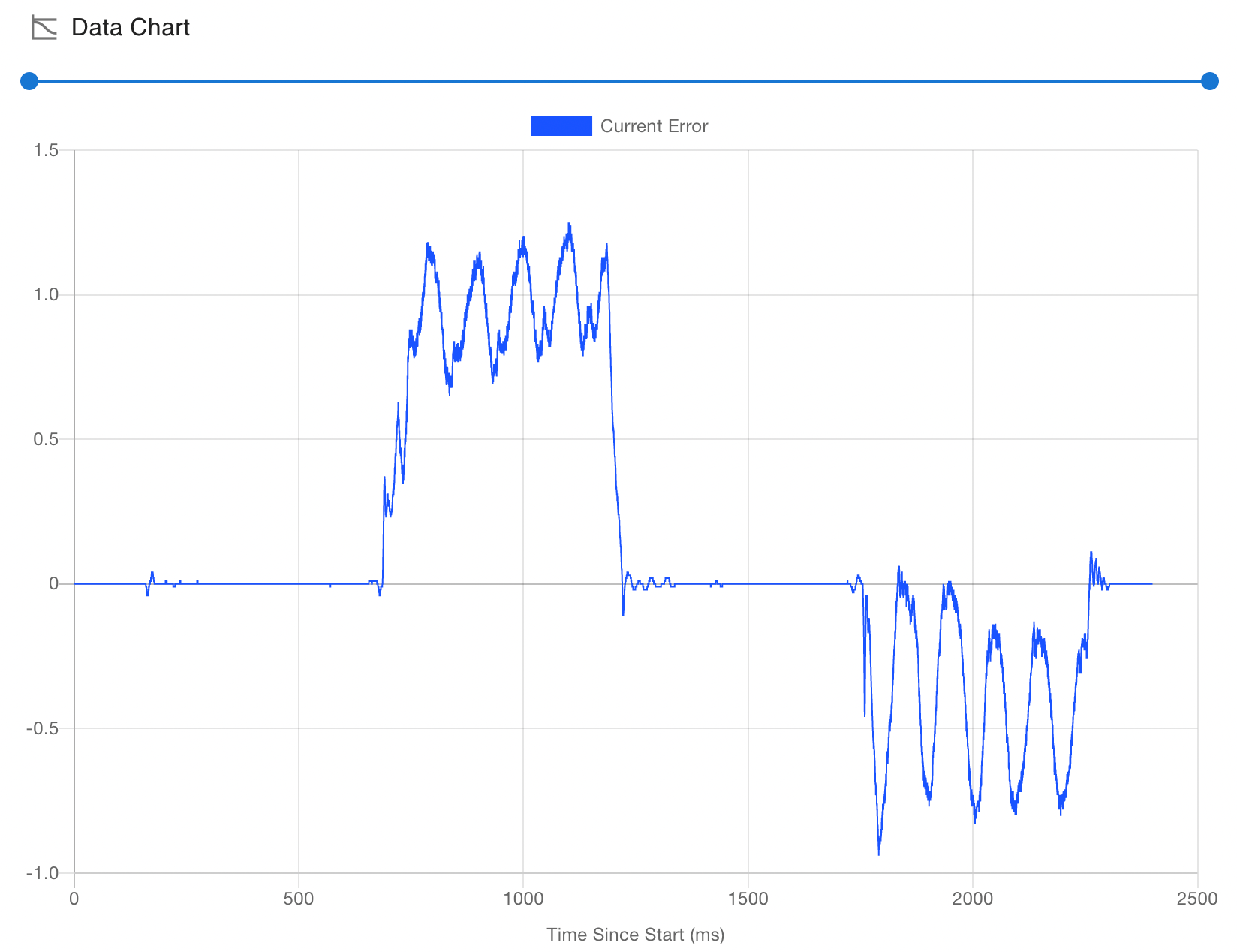

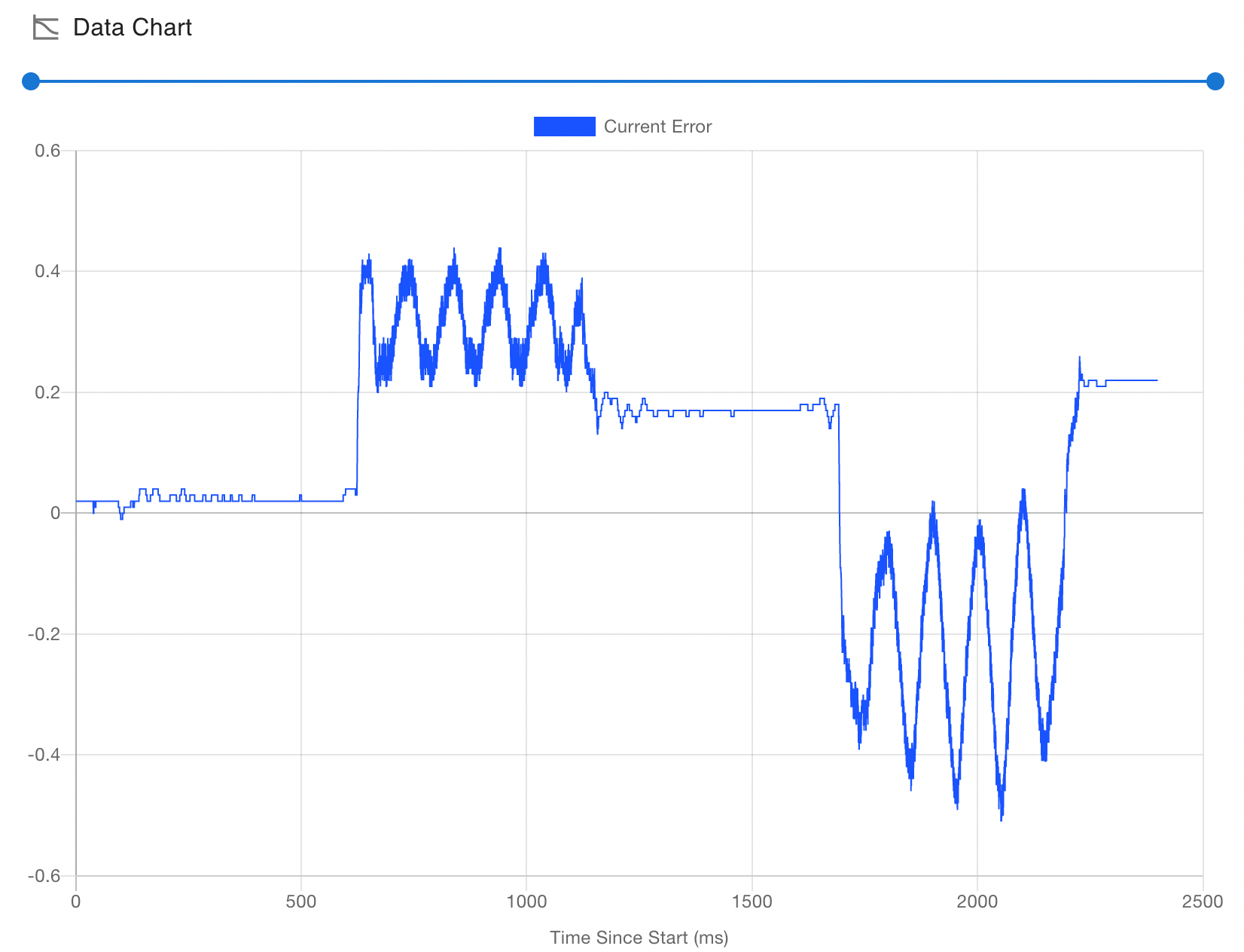

Machine is using Duet 3 6HC in SBC mode + 2 x 1HCL running 3.5 beta1.

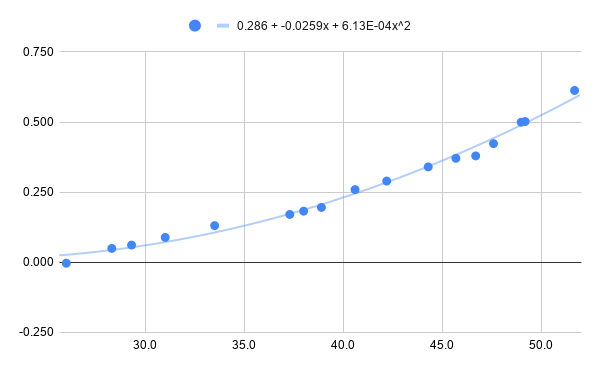

The above were with Trinamic TMCS-28-6.35-10k-AT-01 10,000 CPR / 40,000 PPR encoders on 1.8° ML23HS0L4350-E steppers at 48V. (Yes, overkill for this application.) I've seen similar with CUI AMT10E2 encoders at lower resolutions, and even tried 0.9° ML23HA0L4350-E steppers to see what I could see. Same behavior.

Why would there be a periodic error to movement like this, even in open-loop mode, and even with belts off the steppers? Am I doing something dumb? (I always assume I'm doing something dumb.)

For completeness, machine config is here, and here are the M122 diagnostics:

M122 B51

Diagnostics for board 51:

Duet EXP1HCL firmware version 3.5beta1 (2022-12-23 18:43:49)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 52392, free system stack 161 words

Tasks: Move(notifyWait,0.0%,108) HEAT(notifyWait,0.0%,88) CanAsync(notifyWait,0.0%,70) CanRecv(notifyWait,0.0%,79) CanClock(notifyWait,0.0%,70) TMC(notifyWait,37.0%,351) CLSend(notifyWait,0.0%,152) MAIN(running,60.9%,395) IDLE(ready,0.0%,30) AIN(notifyWait,2.0%,265), total 100.0%

Last reset 00:09:11 ago, cause: software

Last software reset data not available

Closed loop enabled: yes, pre-error threshold: 1.00, error threshold: 2.00, encoder type rotaryQuadrature, position -76033

Encoder reverse polarity: yes, raw count 10497

Tuning mode: 0, tuning error: 0, collecting data: no

Control loop runtime (ms): min=0.008, max=0.041, frequency (Hz): min=8242, max=16304

Driver 0: pos -158389, 320.0 steps/mm,ok, SG min 27, mspos 230, reads 6922, writes 64039 timeouts 0, steps req 384000 done 384000

Moves scheduled 23, completed 23, in progress 0, hiccups 0, step errors 0, maxPrep 65, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter 1/17, peak Rx sync delay 201, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 48.0, current 48.0, max 48.1

V12 voltage: min 12.1, current 12.1, max 12.1

MCU temperature: min 37.7C, current 37.9C, max 38.1C

Last sensors broadcast 0x00000000 found 0 118 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 2526, send timeouts 0, received 2821, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 307, adv 35645/37075

12/31/2022, 11:19:08 AM

M122 B50

Diagnostics for board 50:

Duet EXP1HCL firmware version 3.5beta1 (2022-12-23 18:43:49)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 52392, free system stack 167 words

Tasks: Move(notifyWait,0.0%,108) HEAT(notifyWait,0.0%,88) CanAsync(notifyWait,0.0%,70) CanRecv(notifyWait,0.0%,79) CanClock(notifyWait,0.0%,70) TMC(notifyWait,37.0%,351) CLSend(notifyWait,0.2%,122) MAIN(running,60.8%,395) IDLE(ready,0.0%,30) AIN(notifyWait,2.0%,265), total 100.0%

Last reset 00:09:09 ago, cause: software

Last software reset data not available

Closed loop enabled: yes, pre-error threshold: 1.00, error threshold: 2.00, encoder type rotaryQuadrature, position -94592

Encoder reverse polarity: yes, raw count 29056

Tuning mode: 0, tuning error: 0, collecting data: no

Control loop runtime (ms): min=0.008, max=0.055, frequency (Hz): min=7075, max=16667

Driver 0: pos 36801, 320.0 steps/mm,ok, SG min 28, mspos 290, reads 65125, writes 57829 timeouts 0, steps req 384000 done 384000

Moves scheduled 22, completed 22, in progress 0, hiccups 0, step errors 0, maxPrep 66, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter 0/11, peak Rx sync delay 207, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 48.0, current 48.1, max 48.1

V12 voltage: min 12.1, current 12.2, max 12.2

MCU temperature: min 33.1C, current 33.1C, max 33.9C

Last sensors broadcast 0x00000000 found 0 161 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 7740, send timeouts 0, received 2897, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 310, adv 35769/36259

12/31/2022, 11:19:04 AM

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.5beta1 (2022-12-23 18:27:08) running on Duet 3 MB6HC v1.01 (SBC mode)

Board ID: 08DJM-956L2-G43S8-6J1DJ-3SJ6N-980LG

Used output buffers: 1 of 40 (17 max)

=== RTOS ===

Static ram: 151524

Dynamic ram: 74784 of which 0 recycled

Never used RAM 121364, free system stack 154 words

Tasks: SBC(ready,0.7%,458) HEAT(notifyWait,0.0%,321) Move(notifyWait,0.0%,255) CanReceiv(notifyWait,0.2%,763) CanSender(notifyWait,0.0%,335) CanClock(delaying,0.0%,340) TMC(notifyWait,7.8%,56) MAIN(running,91.0%,953) IDLE(ready,0.3%,30), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:09:06 ago, cause: software

Last software reset at 2022-12-31 17:09, reason: User, Platform spinning, available RAM 121160, slot 0

Software reset code 0x6000 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

Error status: 0x00

Step timer max interval 786

MCU temperature: min 52.3, current 52.7, max 52.8

Supply voltage: min 23.8, current 23.9, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0

Heap OK, handles allocated/used 99/17, heap memory allocated/used/recyclable 2048/744/496, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min n/a, mspos 4, reads 23289, writes 20 timeouts 0

Driver 1: standstill, SG min n/a, mspos 8, reads 23295, writes 14 timeouts 0

Driver 2: standstill, SG min n/a, mspos 8, reads 23295, writes 14 timeouts 0

Driver 3: standstill, SG min 43, mspos 8, reads 23284, writes 25 timeouts 0

Driver 4: standstill, SG min 84, mspos 8, reads 23284, writes 25 timeouts 0

Driver 5: standstill, SG min 85, mspos 8, reads 23284, writes 25 timeouts 0

Date/time: 2022-12-31 17:19:04

Slowest loop: 36.57ms; fastest: 0.04ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 6, maxWait 191256ms, bed compensation in use: none, comp offset 0.000

no step interrupt scheduled

=== DDARing 0 ===

Scheduled moves 31, completed 31, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x1000003

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== CAN ===

Messages queued 5059, received 17476, lost 0, boc 0

Longest wait 13ms for reply type 6018, peak Tx sync delay 445, free buffers 50 (min 46), ts 2731/2730/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 22960/22960

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x29b04

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.5.0-b1 (2022-12-23 20:41:36)

Failed to deserialize the following properties:

- ModelCollection`1 -> Int32 from 0.030

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 42.28, max time between full transfers: 84.0ms, max pin wait times: 68.7ms/16.0ms

Codes per second: 0.36

Maximum length of RX/TX data transfers: 7436/852

)

)