3 independent Z motors

-

Hi,

I have find this project, that seems very interesting... Seems a variation of Corexy printer, with 3 Z motors for autolevel bed...

Someone has do it? And can offer feedback?

Tjanks

-

I haven't come across that printer before. Using three separate Z motors for true bed levelling has been supported by RepRapFirmware for several years, see https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors. It's also used in standard configurations of the RailCore CoreXY printer.

-

As I wasn't very happy with the default V-Core bed design and had print quality issues I have modified my RatRig V-Core on my own to use linear rails and also to use a 3z level design based on that original HevORT ZR design:

https://www.thingiverse.com/thing:4387638I am very happy with the result and with the print quality now. Works fine for me.

-

its a very nice idea, but alas very badly executed.

I looked at the design and took the idea as inspiration for a non-planer design of my own.

The person(s) who designed the parts have little to no understanding of how to design printed parts that can be printed easily, it seems like they were designed look very nice and pretty in cad, but if you were to try to actually print them it soon becomes very apparent that its going to be a nightmare (as soon as you import a part into a slicer) as they rely far too heavily on printing them with way too much supports.

It is not cheating to break a component up in to smaller components that bolts together which can allow printing with little to no support due to being able to orientate things much better.

Go to their Thingiverse page and pick a part (almost any part ) and show me how it can be printed with next to no support..

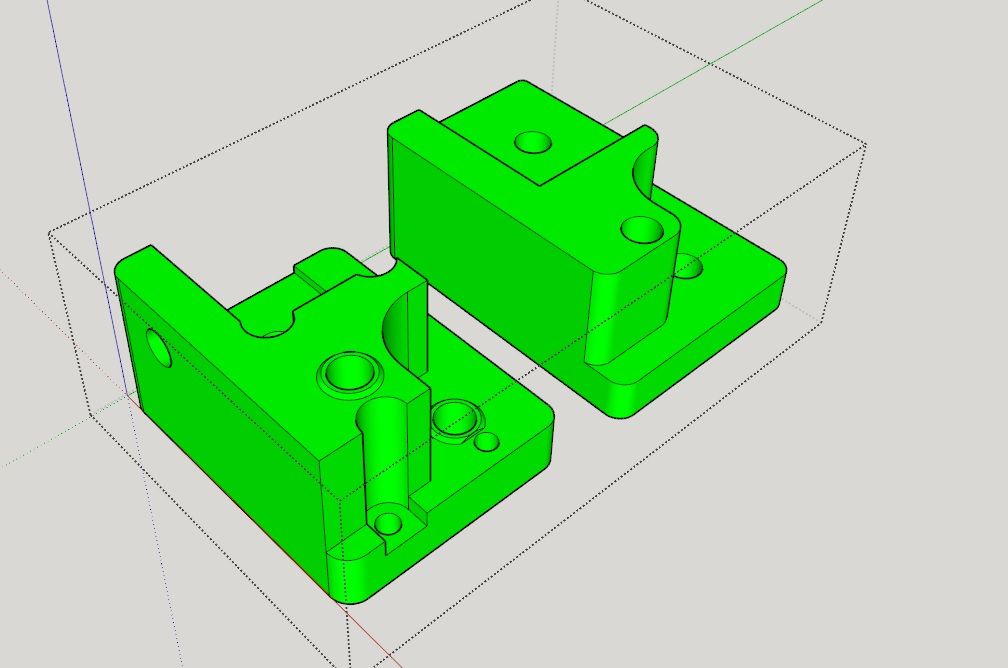

For example take a look at the X to Y carriage

Imagine trying to print that with NO support and keep dimensional accuracy

Now with a little bit of thought and a proper redesign, you can 100% print the part in multiple segments with ZERO supports

And the prototypes being tested for fit and strength

-

Yes, I do definitely prioritize layer orientation in function of functional load vectors when designing parts. 3D printers and slicers do have very good support functions. A well calibrated and good FDM machine can do supports

Zero support is not a decision factor to me.

All parts for HevORT will require support yes, where is the issue? We have now close to 20 functional HevORTs out there with and another 25 members have reported intention of actual progress in making one.

-

@CaLviNx

I know what you mean about "pretty" parts instead of simple, functional, printable designs.

A pet peeve of mine.

I wish I could afford a sintered nylon printer - lots of design freedom with that tech.

Frederick

-

@Mirage said in 3 independent Z motors:

Zero support is not a decision factor to me

Imagine printing the parts in nylon infused with carbon fiber (as I will print my final parts in) now while I am luckily in a position to be able to afford the filament I see it as a waste of money and time to print with so much unnecessary supports when it can be avoided with a little bit of understanding and thought, also post processing can be reduced to Zero,

how many hours is wasted during post process as the design stands?But if people don't know any different then I suppose they will be happy enough to follow on.

-

@Mirage It's a commonly accepted goal of design for FDM additive manufacturing to reduce/eliminate the need for supports. Less material used, shorter print time, greater chance of success, etc. To just rely on supports by default is a bit... inelegant? Lazy? (no offence)

-

@Phaedrux Yeah, that's it, I must be lazy...

-

@Mirage said in 3 independent Z motors:

@Phaedrux Yeah, that's it, I must be lazy...

You can't help it if you don't "get it"

There is a huge difference between being proficient with a CAD package and being proficient at design, and not everyone can differentiate between the two very separate skills, and many confuse being able to carry out one of them as automatically being proficient at the other, when nothing could be further from the truth