oozeBot Elevate

-

@theruttmeister good point! I don't think we'll ever sell them - just point people to OptLaser's website instead. And the tool holder will just be a part we'll make available. Not sure if that carries any liability or not, but we'll make certain we comply! Thanks for pointing this out!

-

One more video of her running for today.. watch as she lays down a perfect honeycomb infill at 100mm/s!

I just bumped the print speed to 100mm/s and am now down from 59m where I started this AM to 44m total print time! That's over 25% faster.. I'm quite pleased.

And again, the rattling is the part cooling fan..

-

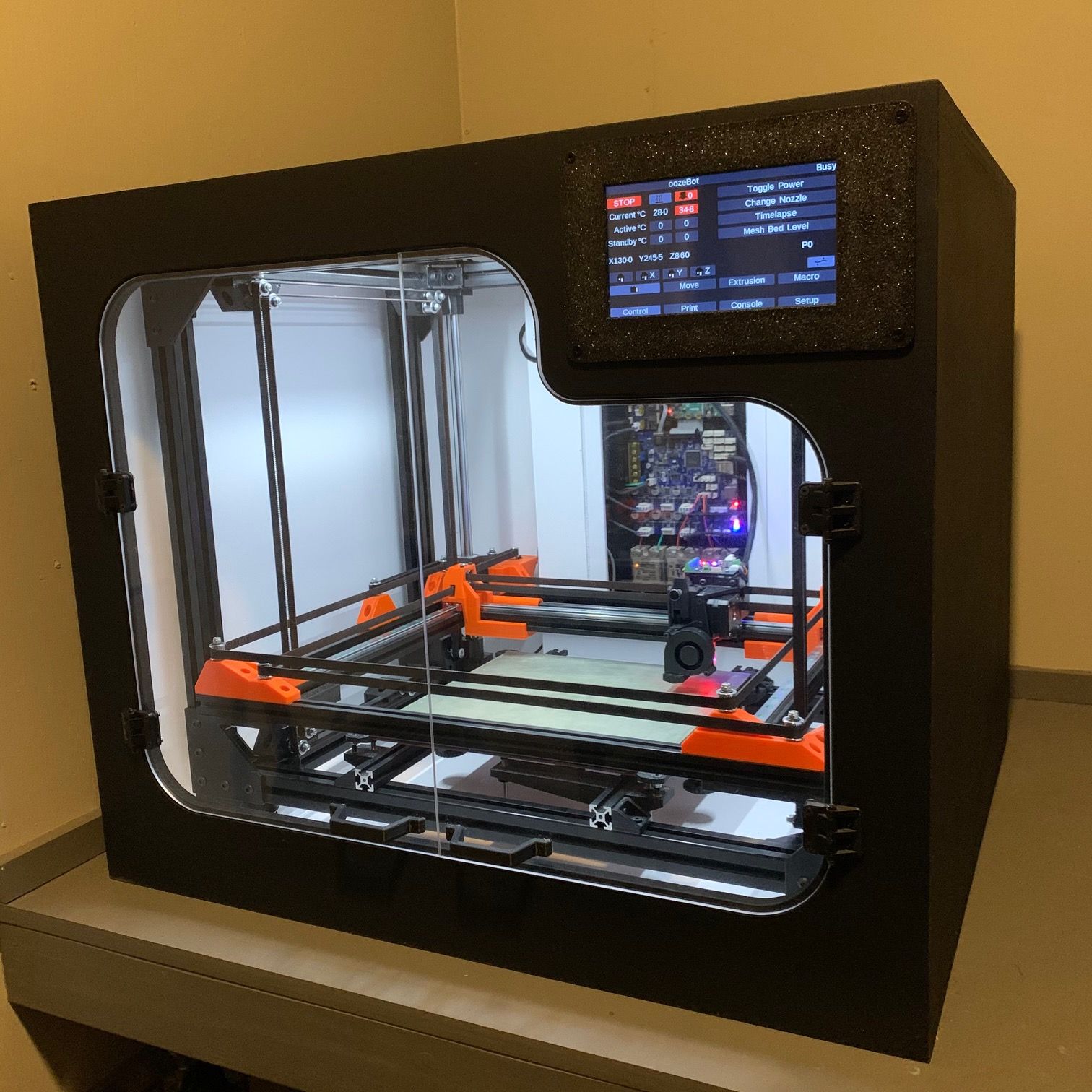

Sneak peak at the enclosure I’ve been throwing together in my spare time for our latest prototype.. am getting excited to wrap this up!

-

The electronics are coming together!

-

Here's a quick pic of our latest prototype in the enclosure I just finished..

-

Just an FYI, the little button with the bent line and two dots under the P0 on the PanelDue display will run bed.g, which could save you a macro slot for Mesh Bed Level that could be used for something else.

-

@Phaedrux just saw this.. thanks! but I am aware.. I actually don't even have 4 macros populating that just yet so I mocked those up for the picture.. lol

-

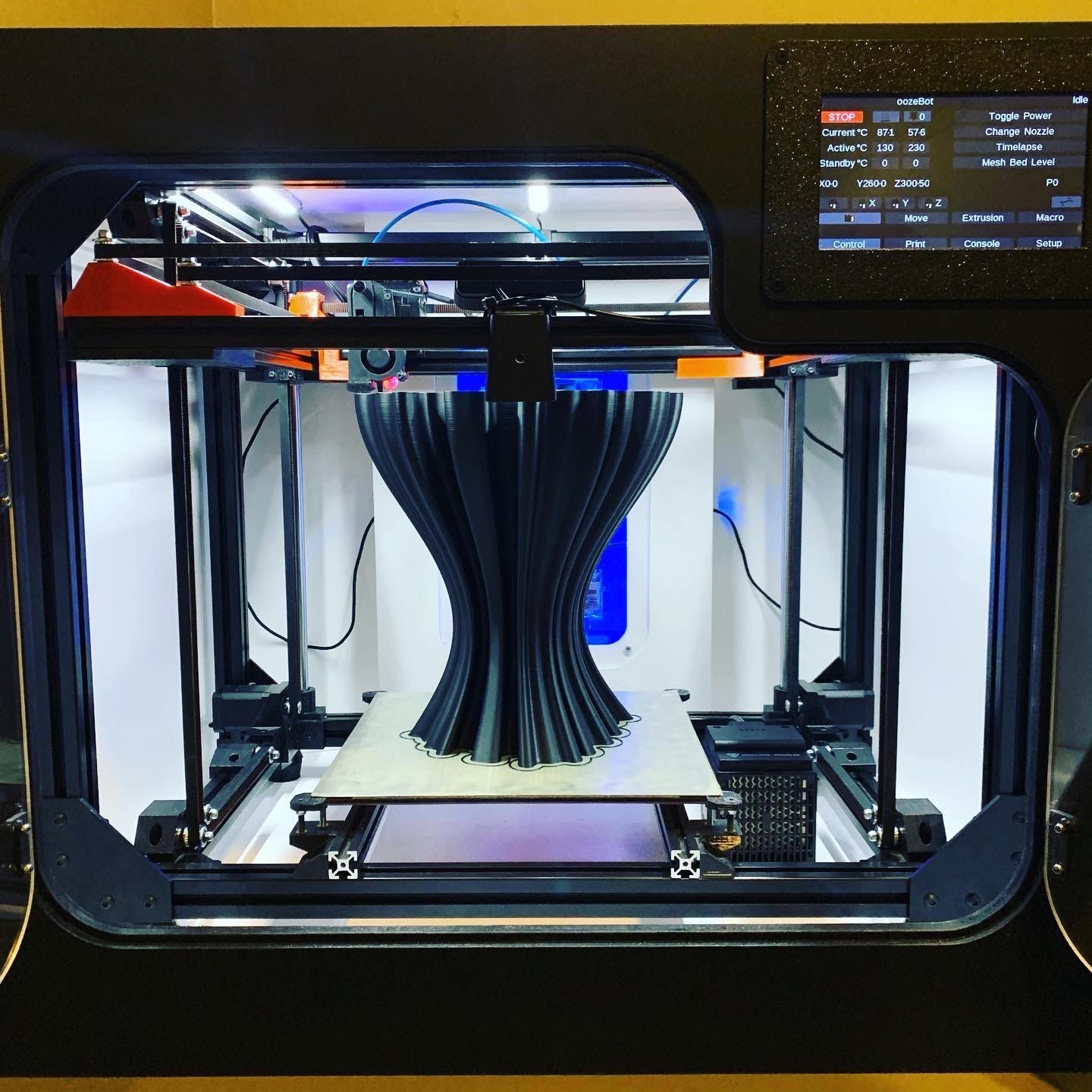

We just finished running a 300mm tall z-wobble test at 80mm/s and are very pleased with the results! It was done in ABS with a .6mm nozzle at .5mm layer height by .75 extrusion width in just a little over over 3 hours.

-

Here is the timelapse of it printing.

Note the bad spots in the rear as it prints (and the recovery!). Since this was in vase mode, I didn't use M400 in the timelapse script between layers. It was caused by the momentary stutter when the photos were triggered..

-

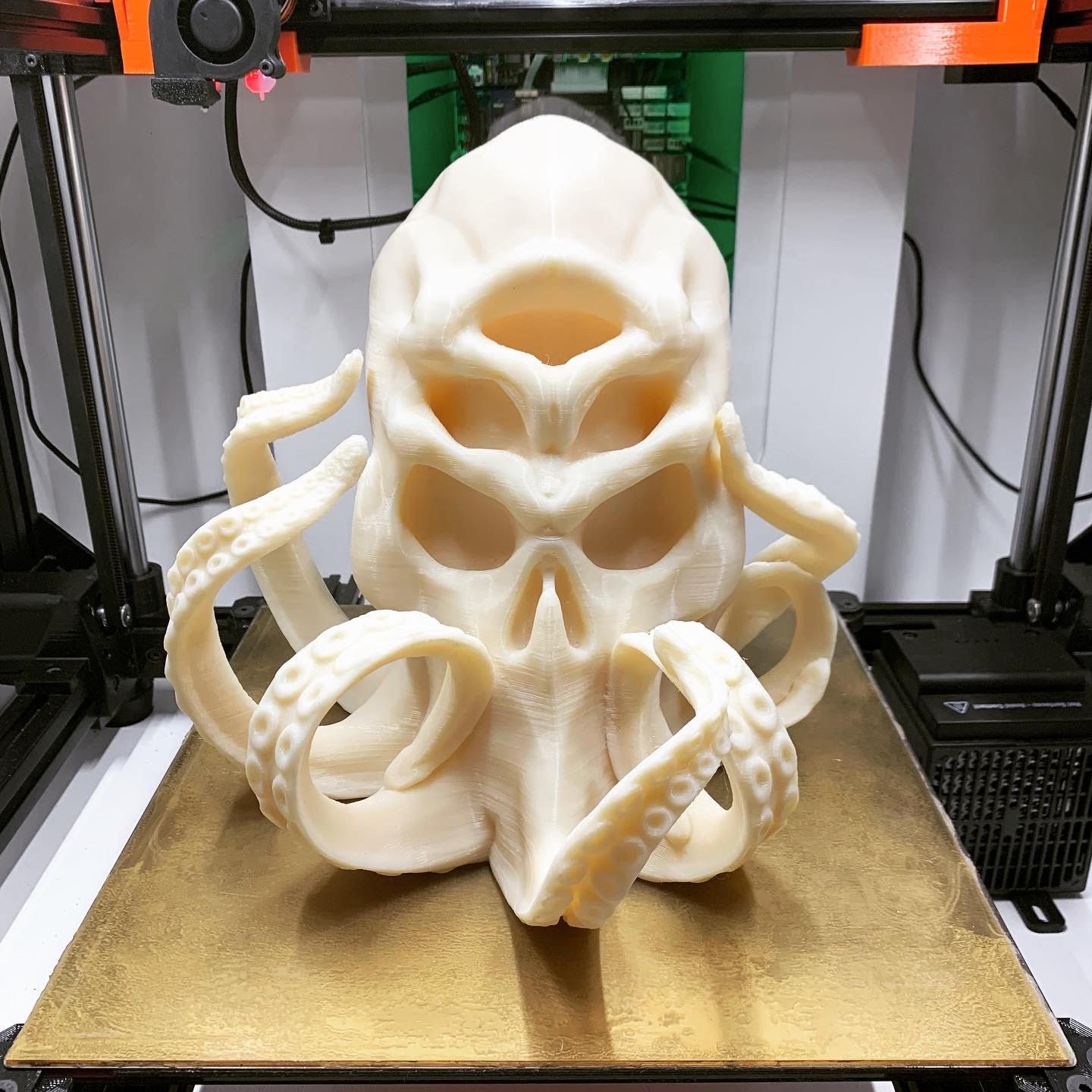

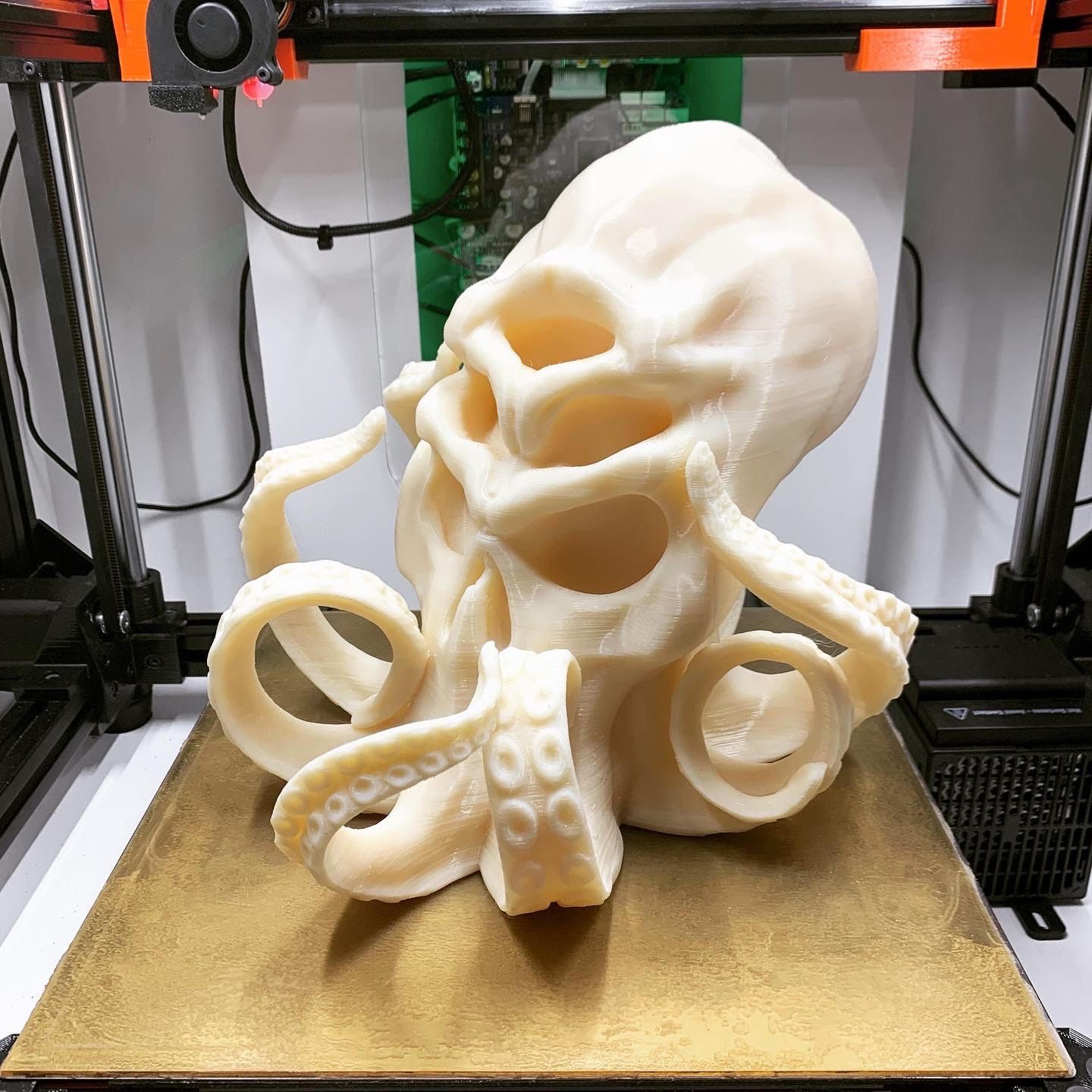

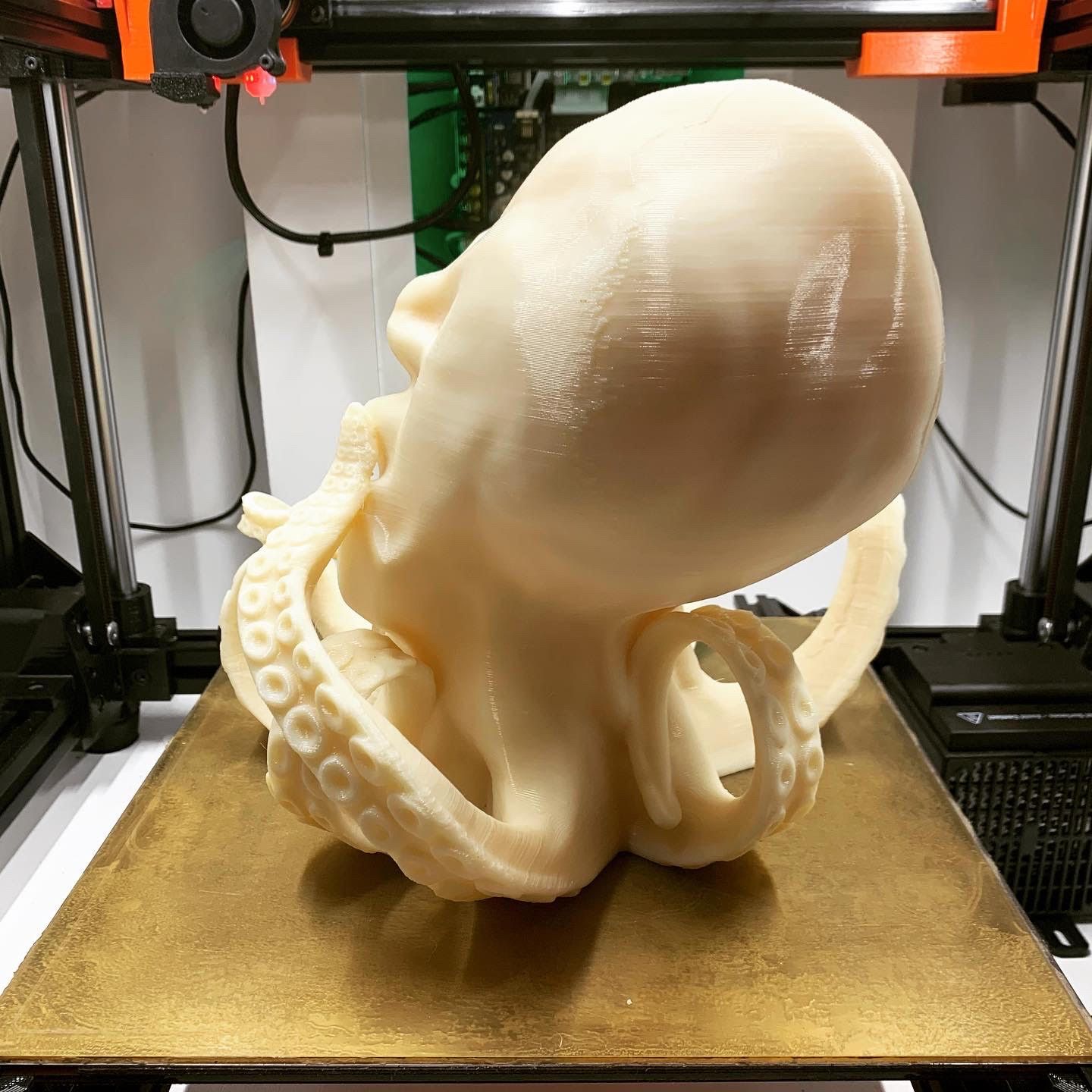

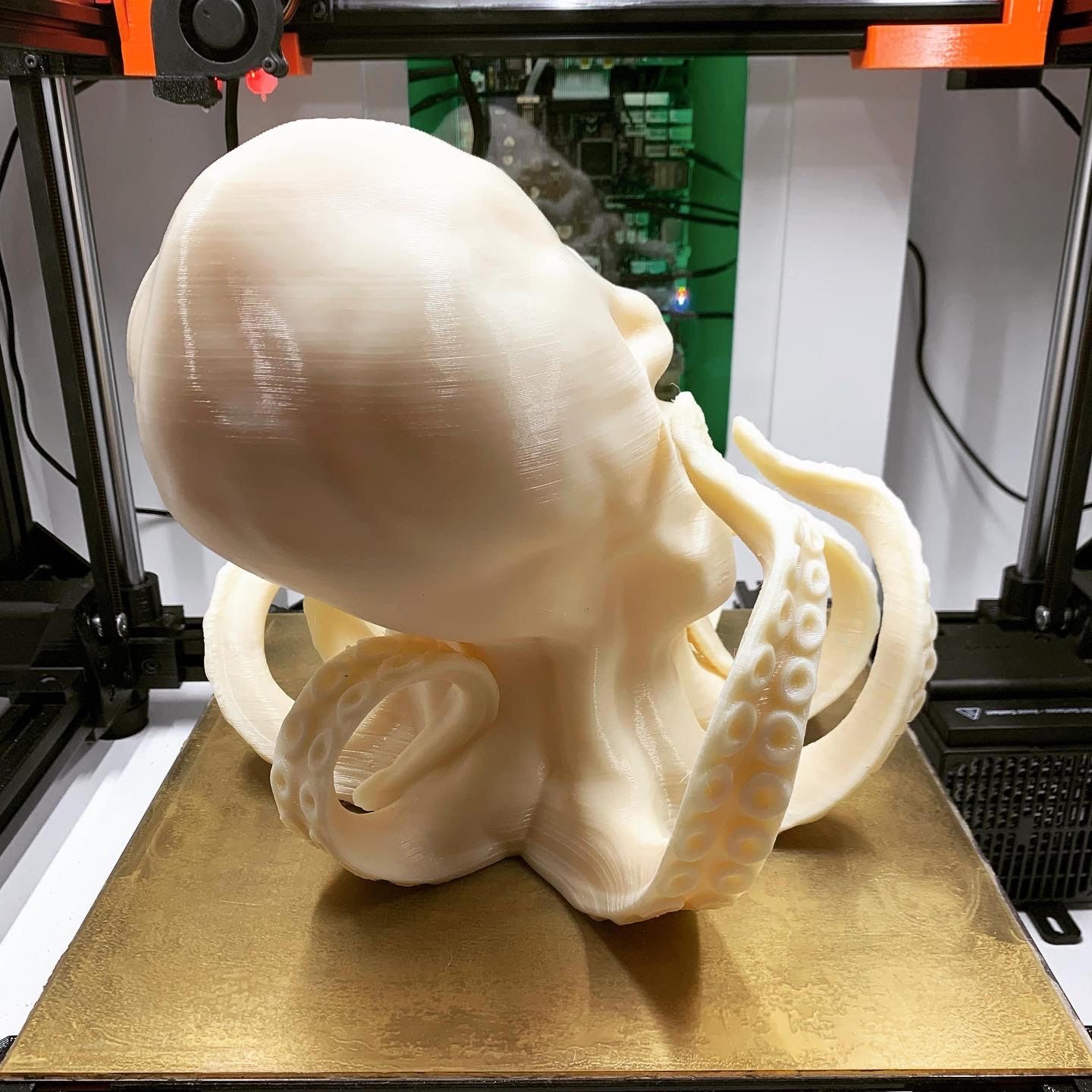

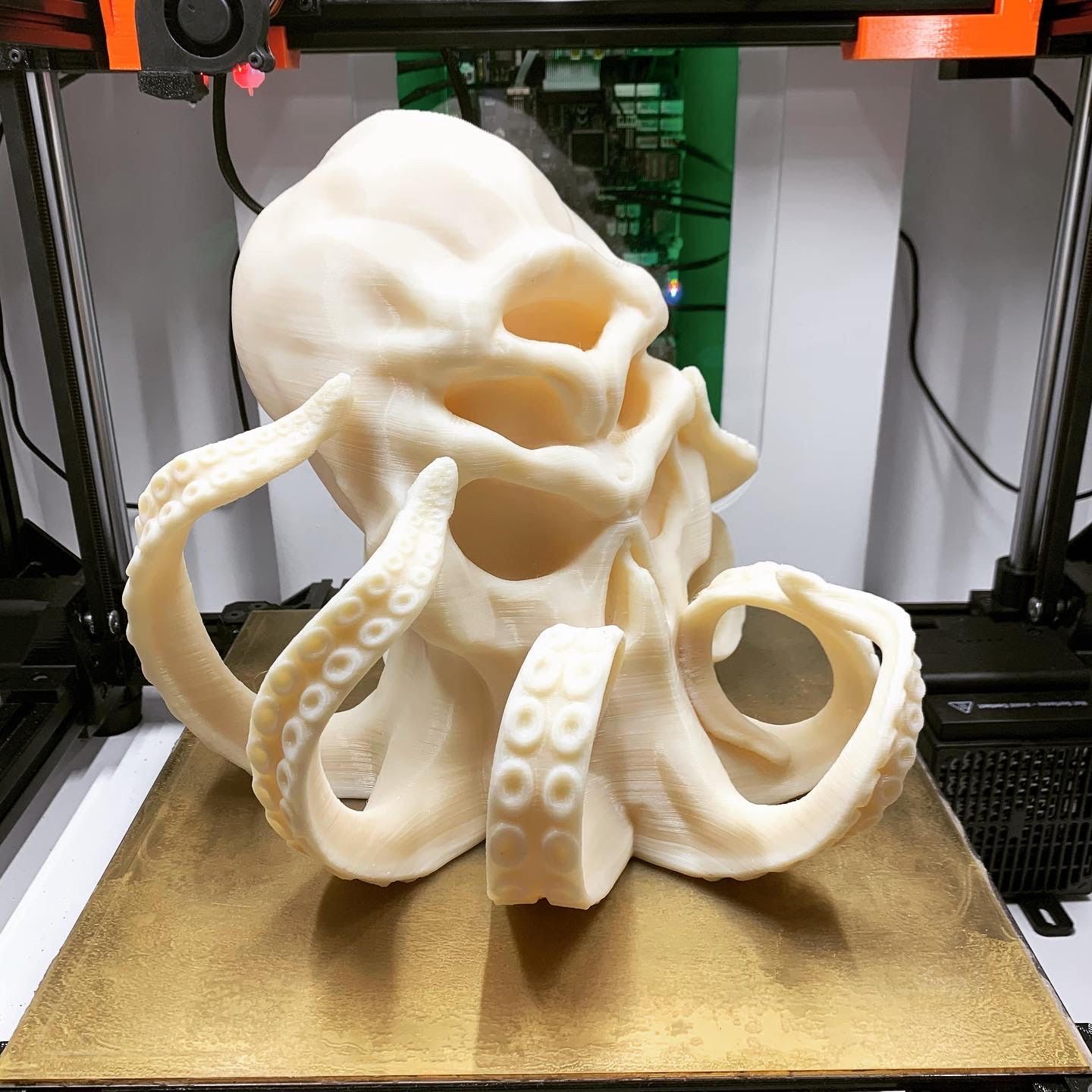

I wanted to post a few photos of a Halloween "torture test" we recently completed. This was printed in ABS, with no supports, using a 1.2mm nozzle. Extrusion width was 1.8mm and layer height was .4mm. It is 300mm deep x 264mm wide x 244mm high, was printed in ~17 hours, and weighs right at 3.5lbs.

This was our first time using a 1.2mm nozzle and getting the retraction settings right to (mostly) control stringing was a challenge, but firmware retraction made the changes easy! There was some mid-air printing near the base, but that was in the design and it recovered beautifully..

-

That's an impressive ABS print. well done.

-

yeah really nice!

-

Timelapse of the Cthulhu build.. You'll see the mid-air printing near the base as well as the stringing that we mostly got under control by about mid-way through the print.

-

Been following on instagram for a while now. Once this thing gets released I'm going to convince my work place to get one. We currently do not have a printer for ABS and this looks like it puts out great prints.

-

@doublec4 Fun fact - we don't even own any PLA or PETG! When I got into 3DP years back, I decided to go straight to ABS. But that will have to change soon for testing purposes..

The ele^gant is the accumulation of everything we learned and yearned for over the years.. and we are finally close to making our vision a reality, but are about to go heads down on one last round of significant changes before calling version 1.0 complete. I'm excited to show what we have in store! We'll be starting the build of our final prototype within the next few weeks.

-

-

@Veti Yes - we've been using ASA lately, but not for our printer parts. It behaves extremely similar to ABS with a much higher UV resistance. Anything I print for outdoor use is in ASA. I've also had good luck with ABS outdoors with a top coat of clear UV spray paint, but ASA makes that step unnecessary..

I'm a big fan of a thin coat of ABS slurry over a PEI sheet on our build plate. ASA sticks just as good as ABS using it, which makes it even easier. Plus you can finish the parts in an acetone vapor bath just the same as ABS.

Our go-to ABS is made by IC3D. They are finally making the move into ASA. We've received samples, but will be exploring using it more once it's generally available.

-

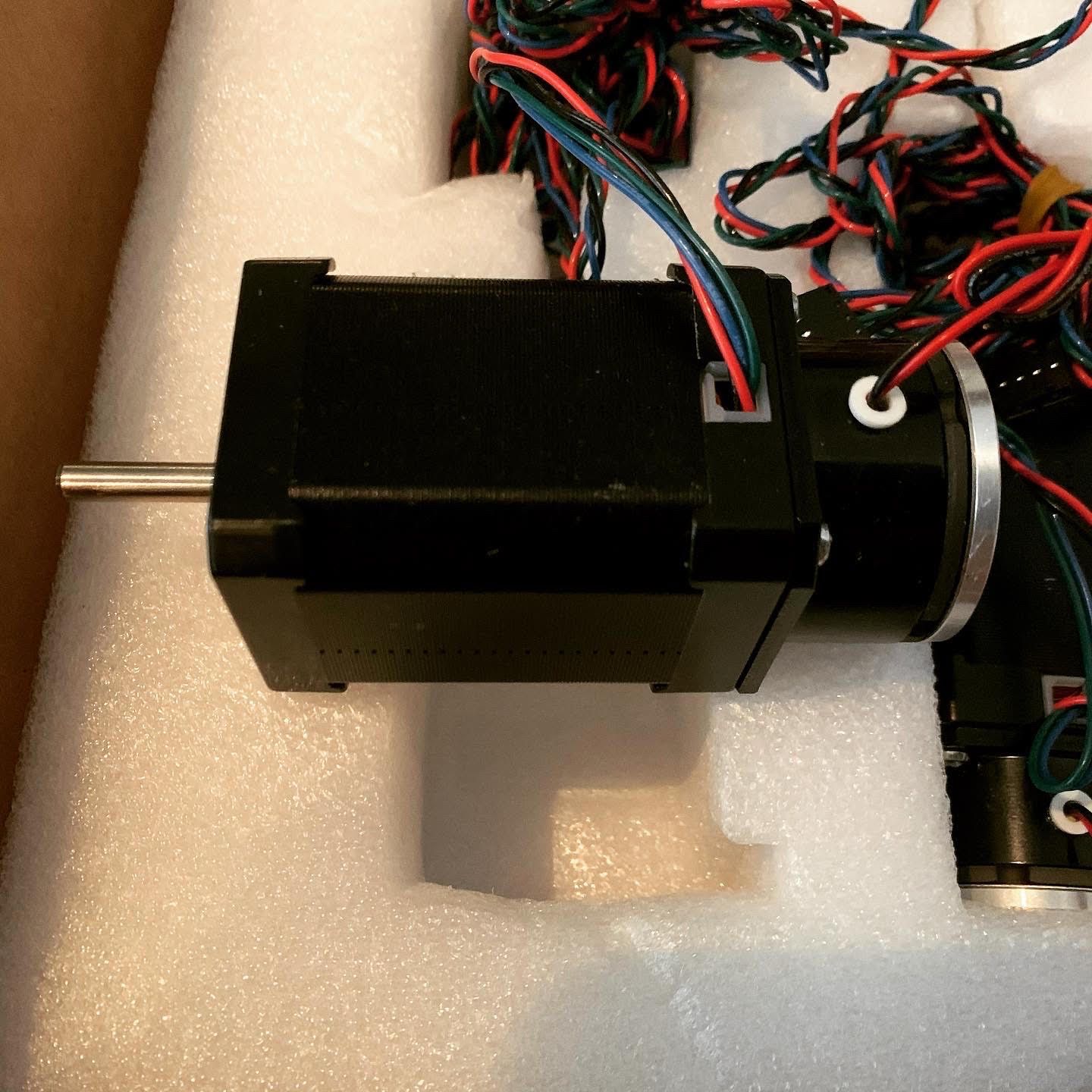

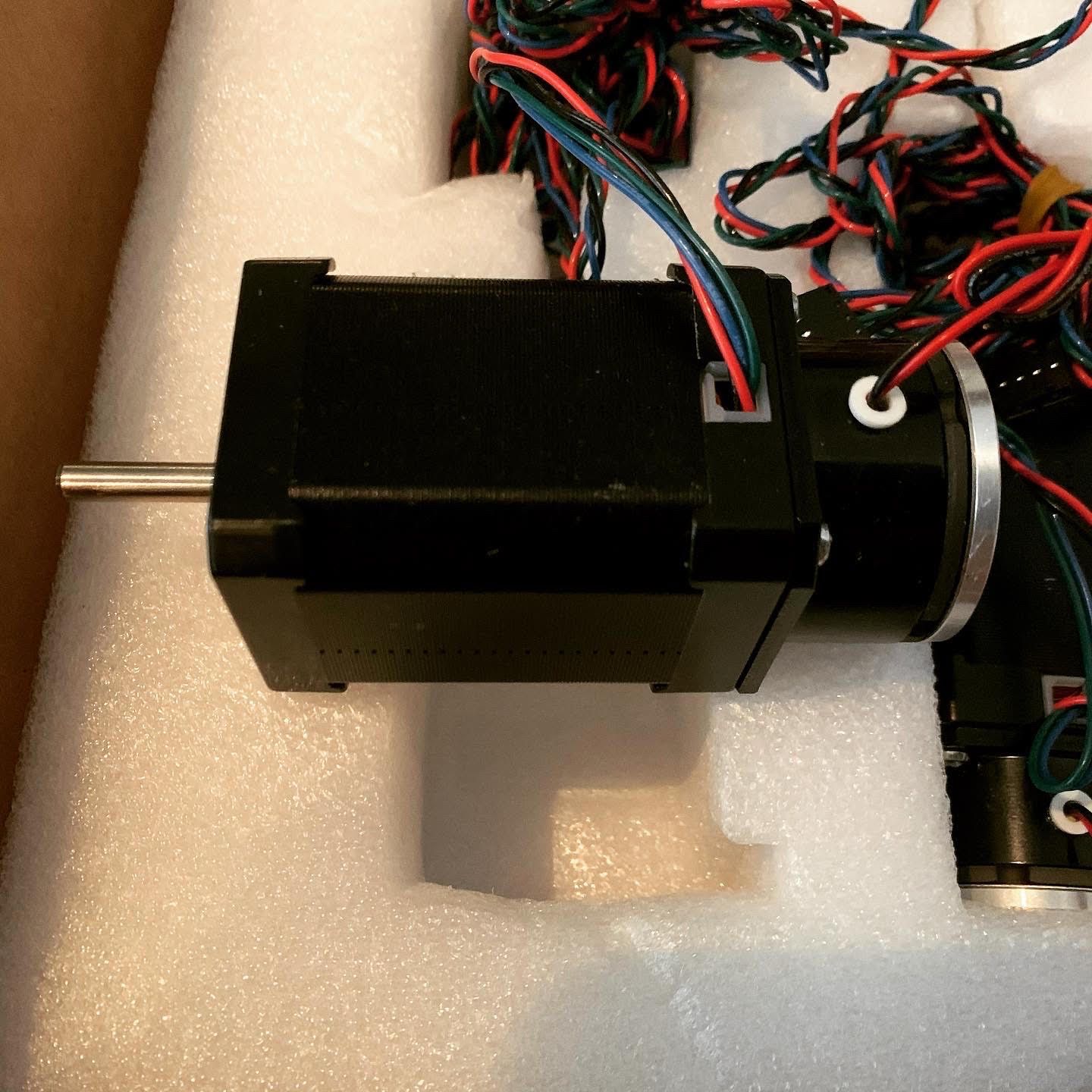

If you've followed along, our design uses a belt driven z-axis. Early designs incorporated a relay bank to act as a pseudo-brake. It worked, but not 100% and the concern for shorting out the Duet was significant.

So to resolve the issue once and for all, we worked with LDO to add an electromagnetic brake to our z-axis steppers. The samples just arrived this week and I finally had time to install them on a prototype. They work great! If Z is dropping at all when power is cut, I have not found a way to measure it.

Outside of our upcoming kits, these will be available in our parts store once it launches next year.

-

@oozeBot said in oozeBot ele^gant:

If you've followed along, our design uses a belt driven z-axis. Early designs incorporated a relay bank to act as a pseudo-brake. It worked, but not 100% and the concern for shorting out the Duet was significant.

So to resolve the issue once and for all, we worked with LDO to add an electromagnetic brake to our z-axis steppers. The samples just arrived this week and I finally had time to install them on a prototype. They work great! If Z is dropping at all when power is cut, I have not found a way to measure it.

Outside of our upcoming kits, these will be available in our parts store once it launches next year.

I would love to buy 3 of those! Where can I find them?

-

@Haggan90 We may be the only ones out there with this design as I worked with LDO on the specs for it. Testing is near complete and we will be placing an order soon. This will be something we stock in our parts store as soon as it launches.

And FYI, they work great!