ST3Di Modelsmart 280 - Duet Maestro repair/upgrade

-

the sleeve i linked

however the hotend is different from most other hotends so you will have to see how to fix it

maybe you could also mount a standard e3d block on there.

-

@Veti Sorry, I overlooked the 2nd link.

I did wonder about that. I'm going to take one apart and have a closer look.

-

Regarding the servo deployed probe. I'm looking for guidance or examples of how this is done. I'm looking a the guides and I cannot immediately see how I approach this.

This is the servo

https://emaxmodel.com/products/emax-es08ma-ii-12g-mini-metal-gear-analog-servo-for-rc-model-robot-pwm-servoSeems it needs 5v to power it. There are the three wires to power and deploy it. I then have the 2 for the microswitch to probe the bed level. My thought is I connect the servo to the Z probe on the board but do I then need to use an endstop to connect the probe switch? Could I use the +3.3v and Z Probe in for the switch? Thanks.

This looks a viable solution to me

-

I've been trying to get the probe working but for now I have decided to set my config with no z probe and use the manual option. Upon doing this I notice that when clicking to move the bed +25 it's not actually moving this distance.

My bed is on a lead screw which is connected to the stepper via a small belt. The mechanics of this are underneath the printer which will mean taking bit apart. Is there a way I can work out what I need to change to make this correct? Thanks.

-

can you post a picture of the belt assembly?

and you can wire the servo to the z probe connector.

use zprobe.mod for the servo signal line. just like for a bltouch.

-

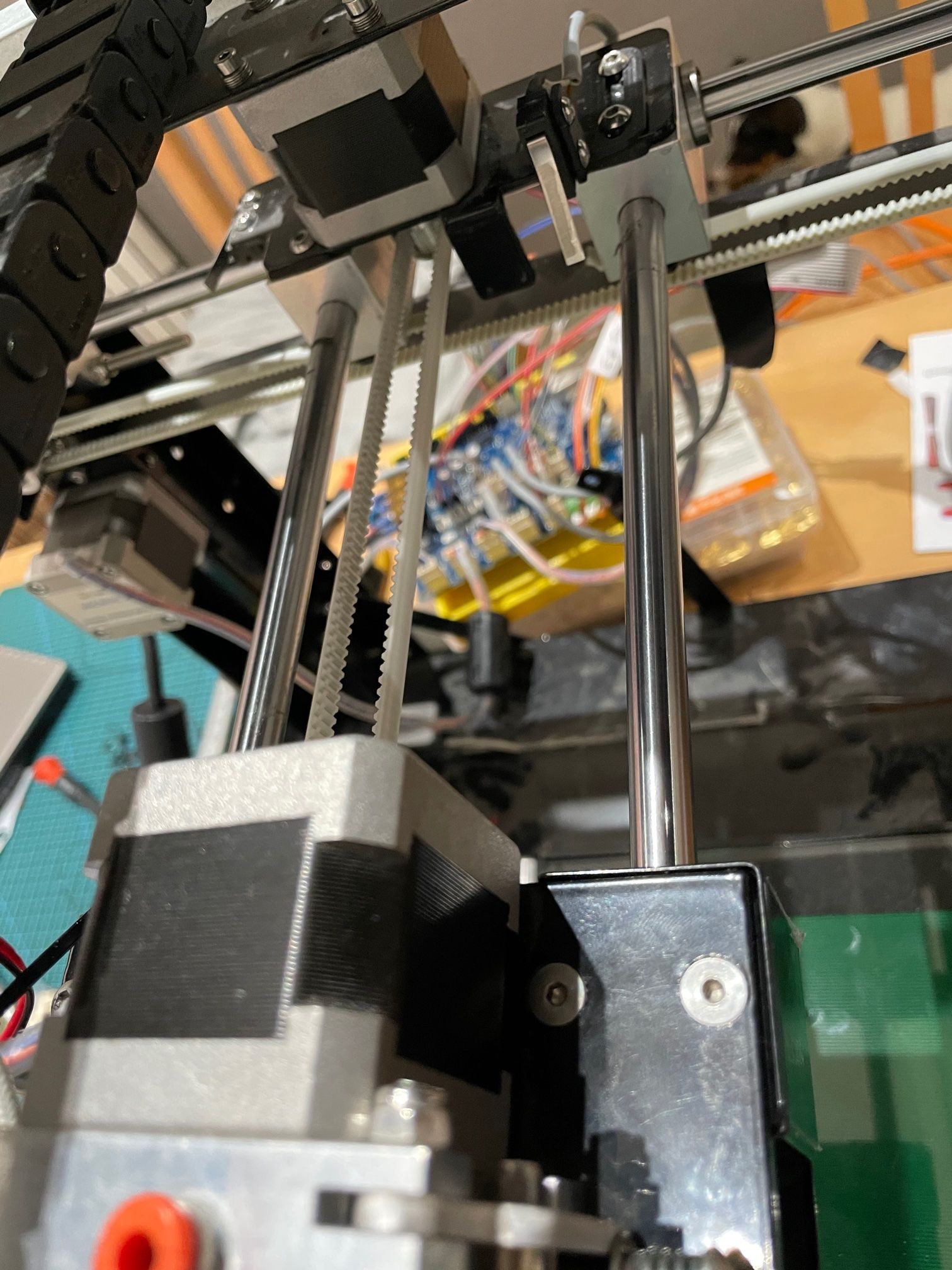

X Axis

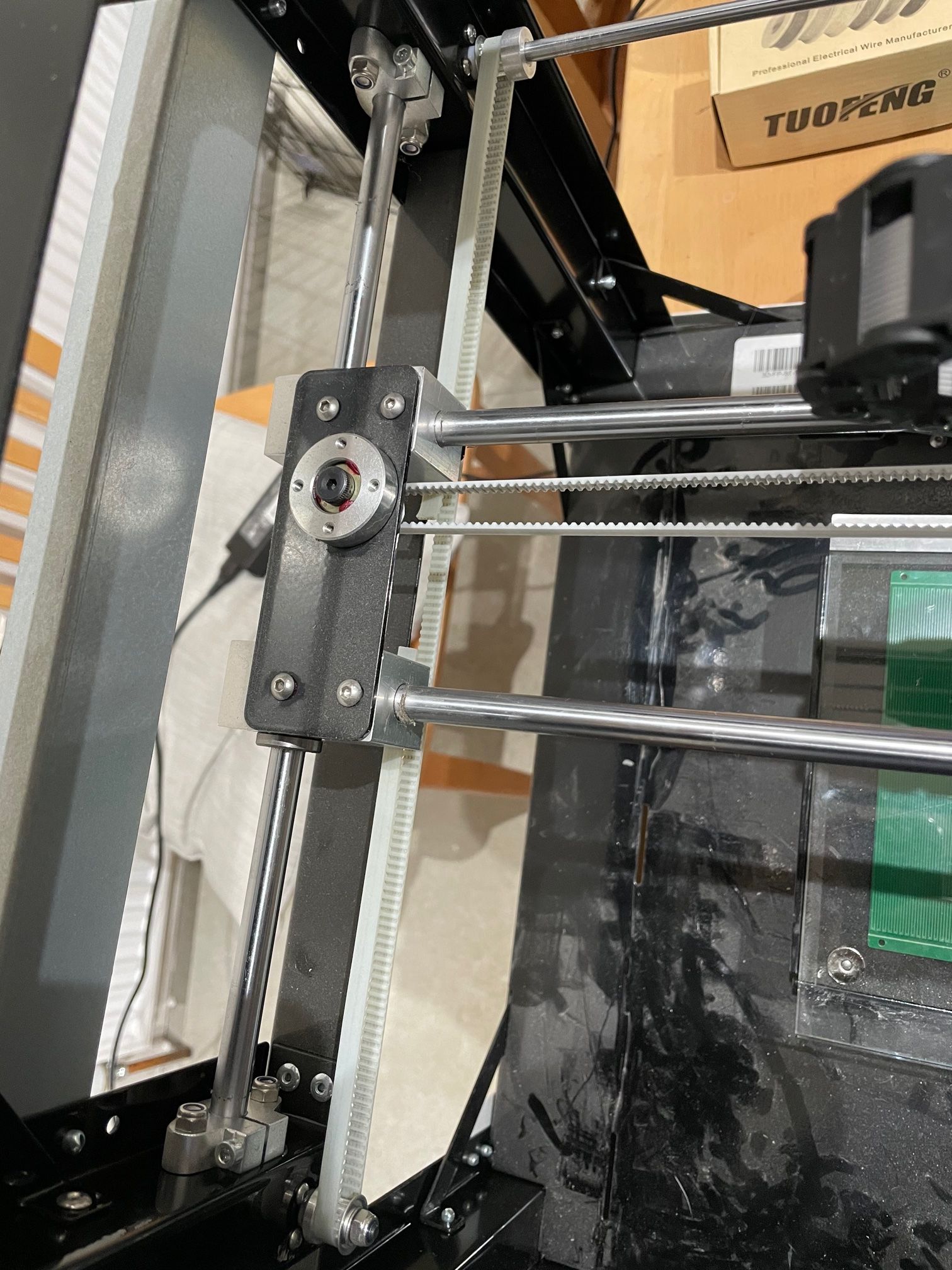

Y Axis - 2 belts and then a small belt to the stepper

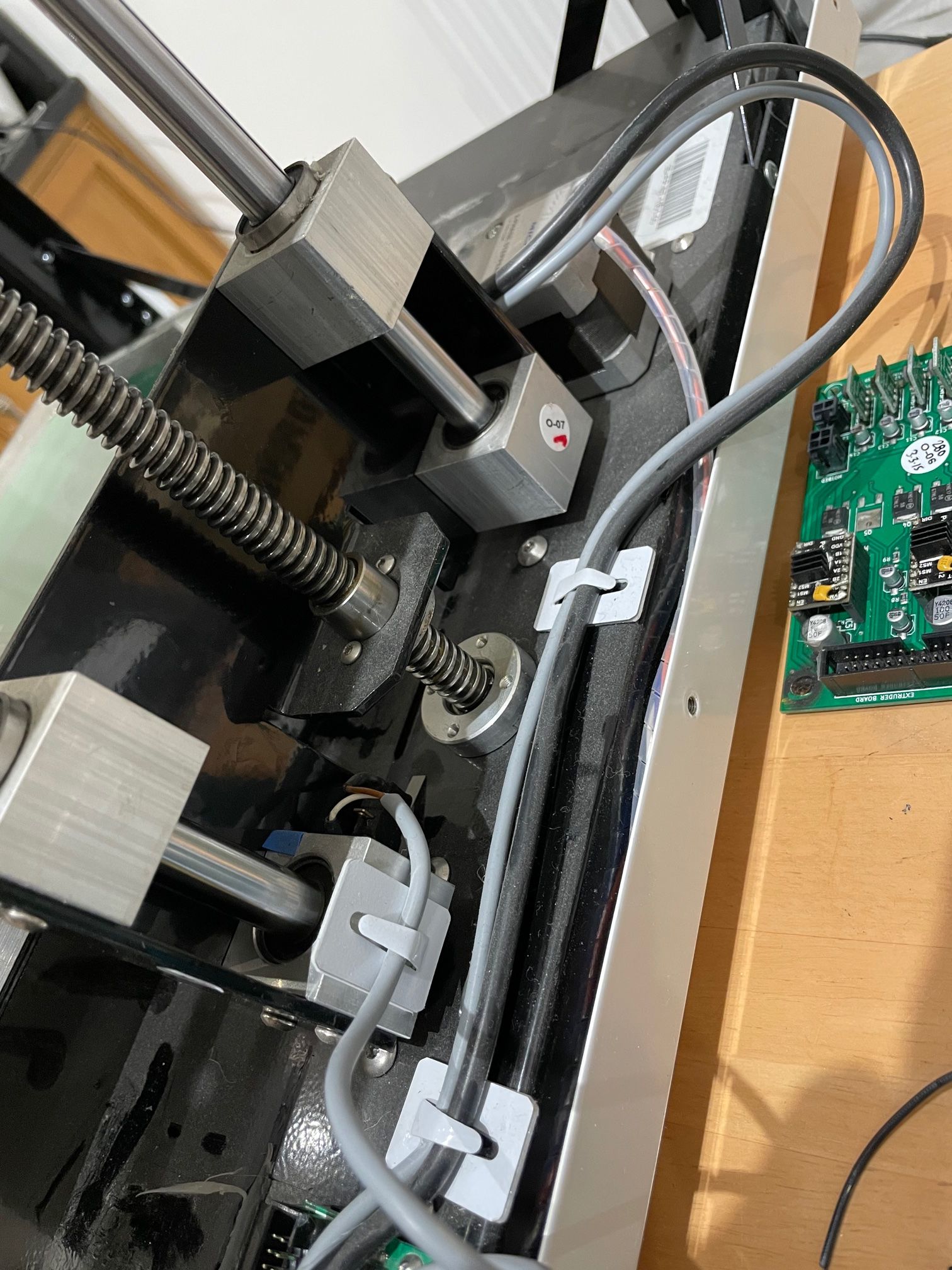

Z Axis - There must be a belt under the black base. I'll have to dismantle it to check.

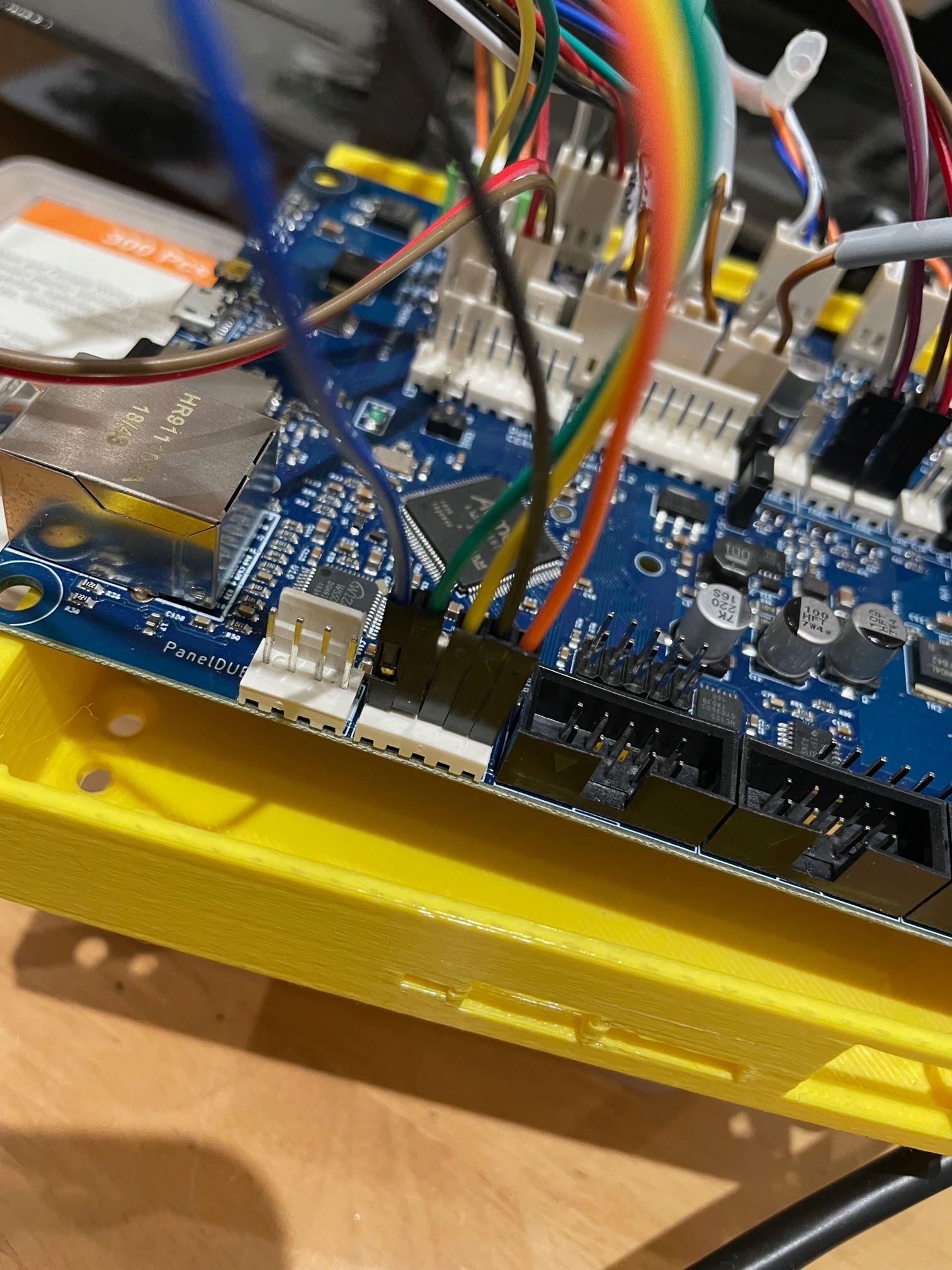

servo and probe wired up. Think this is right although the servo now doesn't respond. Temp wiring...

-

how is the motor connected to the lead screw? post a picture of that.

also you need to work out the pitch of the leadscrew.

-

@Veti I believe its a belt as that would be logical but I willhave to take the base off the printer as it's under the base I believe. Seems I can't avoid it?

-

well if its 1:1 transmition then no

so work out the pitch of the leadscrew and use this to calculate the steps

https://blog.prusaprinters.org/calculator_3416/ -

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

well if its 1:1 transmition then no

so work out the pitch of the leadscrew and use this to calculate the steps

https://blog.prusaprinters.org/calculator_3416/Thanks. I would think it is. Pitch looks to be 2mm. Stepper is 1.8 degrees from the spec sheet. stepper at x16 so I think we're looking at 1600 for the Z

-

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

well if its 1:1 transmition then no

so work out the pitch of the leadscrew and use this to calculate the steps

https://blog.prusaprinters.org/calculator_3416/Thanks. I would think it is. Pitch looks to be 2mm. Stepper is 1.8 degrees from the spec sheet. stepper at x16 so I think we're looking at 1600 for the Z

I take this back. I know that the build height is 150. I've tried manual Z definition and it's come at 120. If I look at the Y axis then the teeth on the two pullys the motor one is 12 teeth. Harder to count the other but looks to be 16.

-

12:16 ratio with 120 would give you 160. so...

if its a 16:20 with 120 would give you 150.

you ought to open it up and count -

@Veti said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

12:16 ratio with 120 would give you 160. so...

if its a 16:20 with 120 would give you 150.

you ought to open it up and countI will. A job for tomorrow. Thanks again, I do appreciate the help.

-

Thanks to a lot of help I finally managed to get everything hooked up and in theory working. I just wanted to link to the separate thread I created for completeness.

https://forum.duet3d.com/topic/20803/servo-deployed-probe-on-duet-maestro

I need to tidy my wiring up, mount the board, bracket for the power cables etc.

The next task is getting a successful first print.

-

Can't thank the people who have helped me enough. Still lots of work to do in terms of getting the printer calibrated properly and playing with settings but to get to this stage I'm extremely happy.

It's smushing layers a little and over extruding I think. The part fan is disconnected as I need to cut the shroud that directs the air to the part so it fits around the new probe.

-

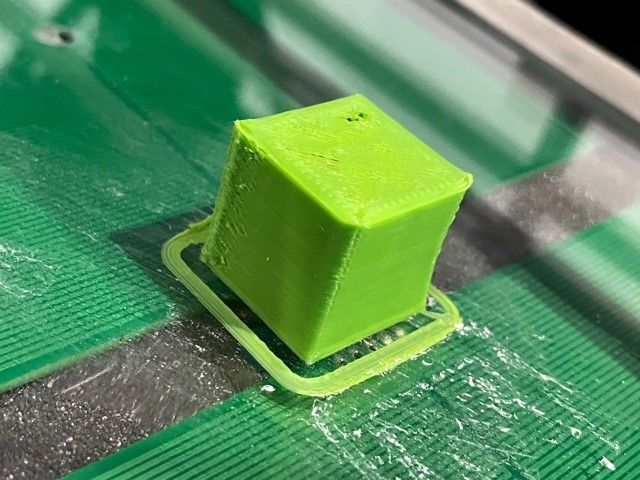

Not a bad first print on a conversion.

Maybe give this calibration guide a go.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

-

I'm getting some decent test prints now. The calibration cube looks so much better and measures accurately.

I'm starting to focus on the dual nozzles and try get them working together for dual colour prints. I've measured the nozzle to nozzle as 28mm. I just wondered if there were some techniques I can use to calibrate them?

I'm set the printer up with centre of the bed as 0,0 and defined the centre of the tool head to align with that.

-

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

defined the centre of the tool head to align with that.

It'll keep things simpler if you use your tool0 nozzle as the reference point. Then the second nozzle is offset from that.

So if the center of your bed is 0,0, and your nozzle0 is touching that point, the offset for the second nozzle is easily found by jogging the print head to move the second nozzle so that it's now at the 0,0 center point. Now you can use the current X Y position as the offset for your second tool.

-

@Phaedrux said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

defined the centre of the tool head to align with that.

It'll keep things simpler if you use your tool0 nozzle as the reference point. Then the second nozzle is offset from that.

So if the center of your bed is 0,0, and your nozzle0 is touching that point, the offset for the second nozzle is easily found by jogging the print head to move the second nozzle so that it's now at the 0,0 center point. Now you can use the current X Y position as the offset for your second tool.

Thanks. That makes sense. Does it make most sense to define the tool closest to the probe as the one at 0,0?

-

@Blacksheep99 said in ST3Di Modelsmart 280 - Duet Maestro repair/upgrade:

Does it make most sense to define the tool closest to the probe as the one at 0,0?

I don't know if that will matter really since they are all related distances anyway. My brains thinks left to right in ascending order, but it doesn't have to be like that.