Extruder Motor Getting Hot.

-

@Veti said in Extruder Motor Getting Hot.:

can you measure the resistance of one phase.

Model no.: 17HS4023

Size:424223mm

Phase: 2 Phase

Voltage: 12V

Current: 0.7 A/Phasefrom what i can see the motor is 0.7A so 500ma would be better

Well this has thrown a spanner in the works. it looks like there is 2 motors from the same company with the same model number.

1 is 0.7A and the other is 1.0A which is what I am certain I have but I just removed the motor from the BMG to see the label and the writting is rubbed out but looking at the pictures the labels are slightly different and mine looks like from what I can see is the same as the 1.0A

1.0A

https://images-na.ssl-images-amazon.com/images/I/61oCibxPEQL.SL1500.jpg0.7A

https://images-na.ssl-images-amazon.com/images/I/614OmoeLMLL.SL1120.jpg -

i believe this is the 1A version

https://www.amazon.com/Twotrees-Nema17-Stepper-42BYGH-Printer/dp/B07TGJSNJB/ -

@Veti this is definately the version I have which it says is the 1A version from this listing.

https://www.amazon.co.uk/Usongshine-Titanium-Extruder-Printing-17HS4023/dp/B07L8CGQMBI have one of the other motors that I use to drive the X,Y & Z Axis's would I be better off putting that in ?

-

try the motor with 500ma first

-

@Veti said in Extruder Motor Getting Hot.:

try the motor with 500ma first

Ok will do thanks for the help Veti

-

@Veti I dropped the current to 500 and it seems to have worked. before starting to print extruder motor temp was 21.5c and 36.7 by the end of the print which was a 1 hour 40 min print. I didn't change any of the other settings so that everything was the same as before.

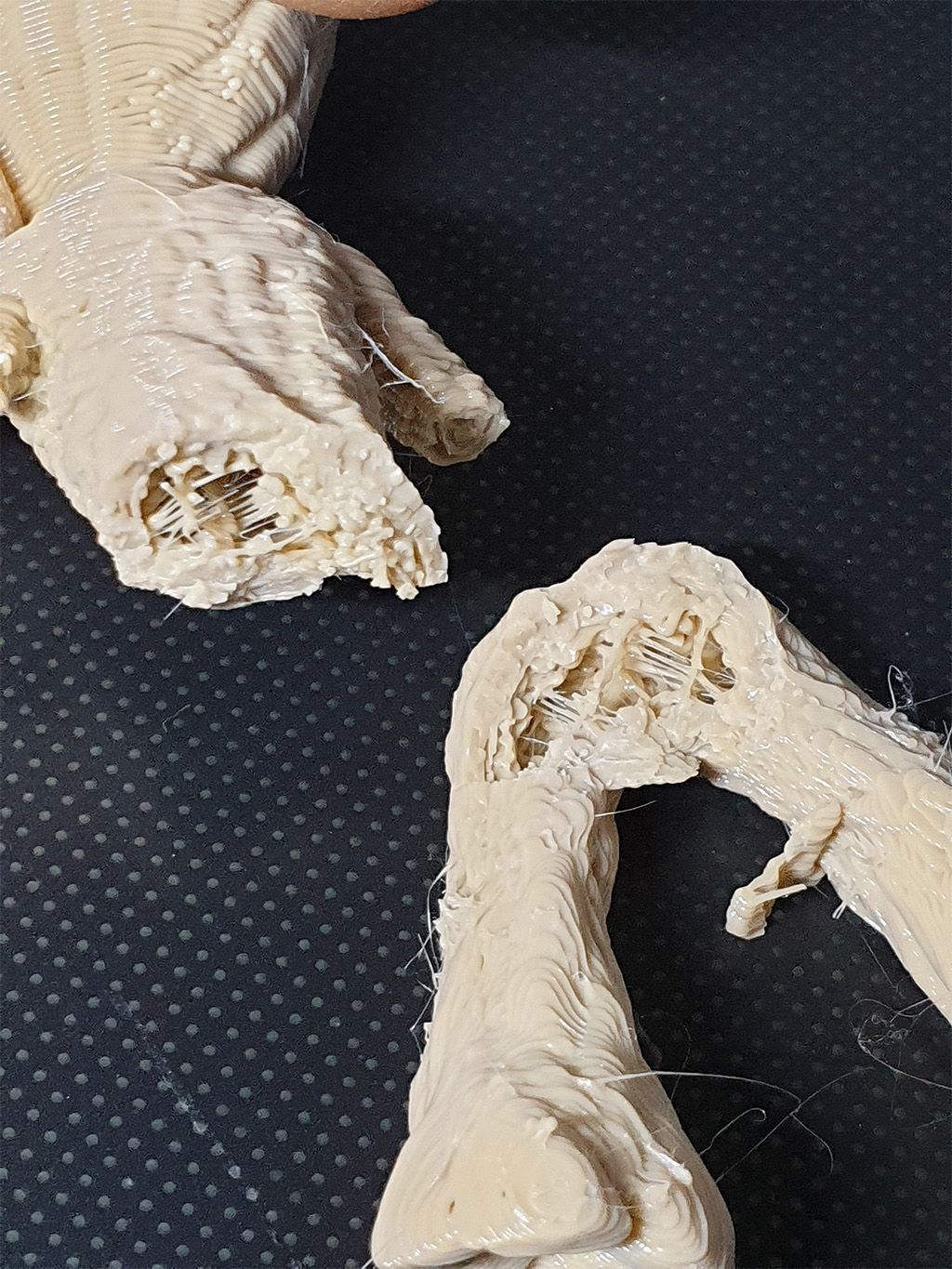

The print quality is not great though. the infill is still very poor and so is the surface finish.

Would you think it would be a good idea to do extruder and temperature calibrations again now that I have changed the current settings ?

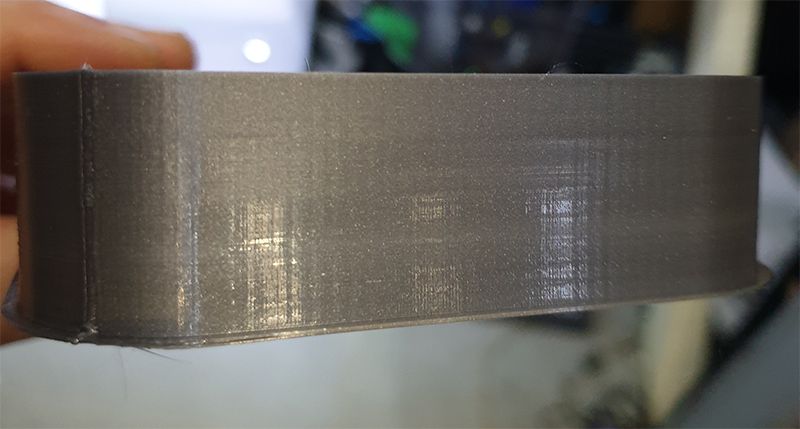

This is what the print came out like it is 60mm in height and was printed using .2 resolution.

If I did the same print on my other printer the quality would be a lot higher.

-

check all bearing and pulleys. everthing has to be very smooth without resistance.

-

@Veti everything seems to move ok and I don't have the belts to tight I made sure of that.

Is there a recommended way to check or is it more a case of feel ? -

start with something simple like a calibration cube.

then go to a retraction test print. -

@RAM said in Extruder Motor Getting Hot.:

Would you think it would be a good idea to do extruder and temperature calibrations again now that I have changed the current settings ?

Yes. I would say that looks over extruded and maybe printed too hot.

-

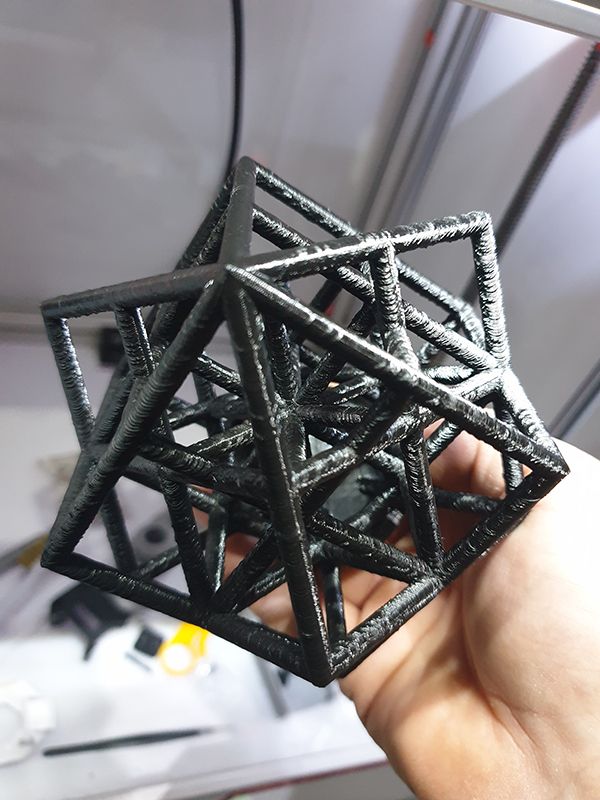

Hi @Phaedrux will do that once the test print has finished. I changed the S3D Printing profile and did the 40mm cube which came out quite nice so decided to do something a little more crazy which is going well so far but I'm not holding my breath.

Bet you hoped you would never have to deal with this printer again after all the issues I had at the very beginning lol.

-

Honest thoughts on this please with if there is anything that I could possibly do to improve the print quality.

it was printed with Black Real Filament PLA @ 210c & 60mms with 0.4 mm nozzel at 0.2 resolution. no supports, cooling fan set to maximum after 4th layer. Retraction distance 3.50, Retraction speed 150mms

-

the quality of the underside is determined by the quality of the part cooling.

this print needs a lot of cooling and it has to be focused cooling.

put some water in a shallow container underneath and see where the airflow is directed when the part cooling fan is on.

-

It also looks very glossy which can mean it's printed too hot.

Look into doing a temp tower test where the temp gets changed at certain points up a tower so you can visually see the results. If the thermistor isn't very accurate when you think you are using 210 it could actually be 240. So in absence of accurate measurements, you can still determine a good set point experimentally. In other words, it doesn't matter if you use 190 or 220 so long as the results look good.

-

@Veti said in Extruder Motor Getting Hot.:

the quality of the underside is determined by the quality of the part cooling.

this print needs a lot of cooling and it has to be focused cooling.

put some water in a shallow container underneath and see where the airflow is directed when the part cooling fan is on.

It looks like the fan is blowing where it should be from what i can see

-

@Phaedrux said in Extruder Motor Getting Hot.:

It also looks very glossy which can mean it's printed too hot.

Look into doing a temp tower test where the temp gets changed at certain points up a tower so you can visually see the results. If the thermistor isn't very accurate when you think you are using 210 it could actually be 240. So in absence of accurate measurements, you can still determine a good set point experimentally. In other words, it doesn't matter if you use 190 or 220 so long as the results look good.

Not sure what you think but 205c looks ok to me and it is also what is recommended on the filament.

-

Calibrate the extruder.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

-

the water looks like you have two places where the part fans are blowing and its not underneath the nozzle.

also it does not seem that strong -

@Phaedrux said in Extruder Motor Getting Hot.:

Calibrate the extruder.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

Thanks for that guide, I went through the steps and it seems to be a lot nicer than I have ever had it before.

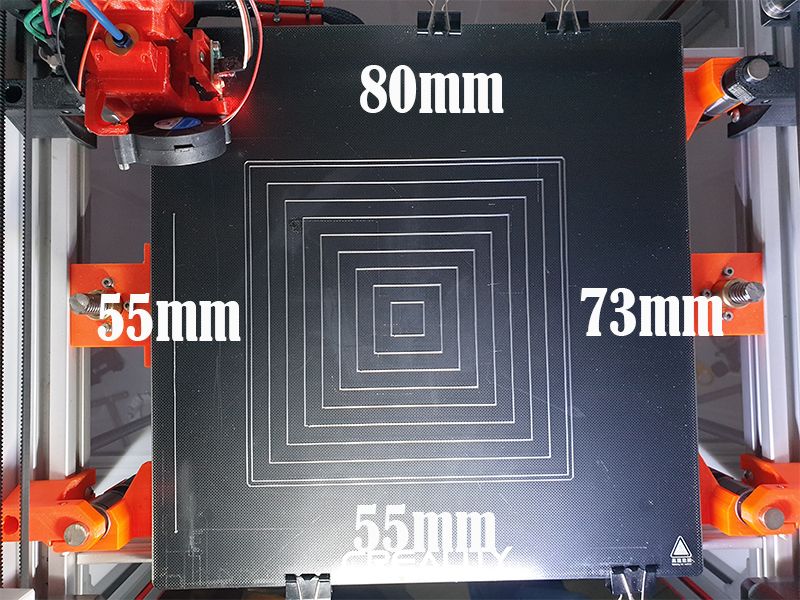

only thing I did notice when doing the bed leveling test was that the print seems to be way off center for some reason. How do I go about moving the head to more to the center as I can't seem to remember how I did it the 1st time around and have no idea what has changed.

When I measured the spacings with the print on the bed it is off as it shows in the picture.

It needs to be moved up and to the right. But for the life of me I have tried to follow the guide for setting the bed center but nothing seems to make a difference.Would like to say thanks for all the help you guys have given me with sorting this out I am starting to get a smile back on my face when it comes to this printer.

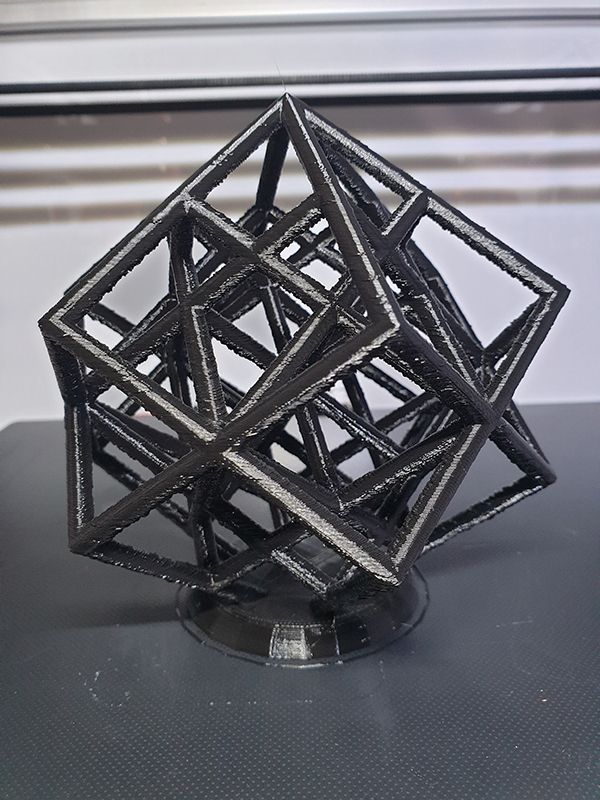

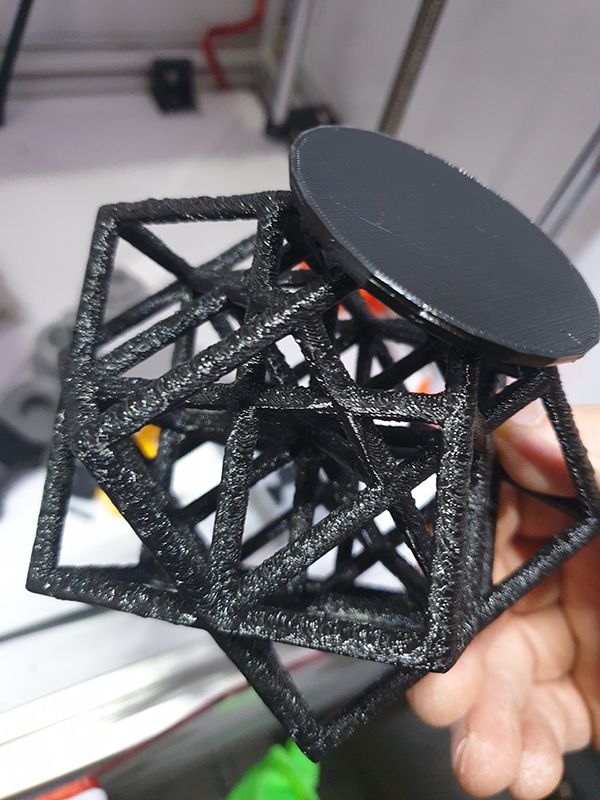

This is the result I am getting when printing the rounded cube test

@Veti I am not sure if I had the fan set to maximum or not, I will redo the picture with it set to maximum I was a bit worried about blowing water out and all over the printer.

-

move go X0 Y0 (G0 X0 Y0)

then measure the distance to real X0 and Y0

and adjust

M208 with the measured values.