Haq XY

-

@dc42

I can't wait to try this when I get home from work!

Did you test the G29 in your test rig? -

@dc42

I can't wait to try this when I get home from work!

Did you test the G29 in your test rig?Not yet, but I hope to get the tests completed this afternoon.

The previous firmware got the positions wrong after homing. It was confusing to debug, because your original M669 command results in a matrix whose inverse was identical to itself! So for some time I thought that the matrix inversion code wasn't working.

-

I just did some more tests including G29. It looks to me that it is working properly.

-

@dc42 Great job! It seems to be working now, only updated the firmware and homing + G29 worked straight away!

-

@haggan90, thanks for confirming. I'm sorry it took so long to get it right. They say "premature optimisation is the root of all evil!" and I think there is some truth in that.

-

@dc42 No problem at all, I'm just thankfull for all the help

-

Can Haq XY-kinematics be used with RRF3/6HC mainboard?

I'm planning on changing from 3-axis (x,y,z) Corexy to Haq XY (x,u,y,z) but I need to be sure there is a working firmware for it. I use 6HC mainboard in my machine so I assume I cannot use binary posted several post above. -

Yes, RepRapFirmware supports any kinematics for which the movement of each axis is a linear combination of the movement of the motors.

-

Hi everyone,

Are you able to share how you set this up? I'm currently knew to RepRap Firmware, as I'm a long time user of Marlin but due to the fact Marlin doesn't support this type of configuration. I'm currently looking to move over to RepRap Firmware and purchase a Duet 3 6HC board.

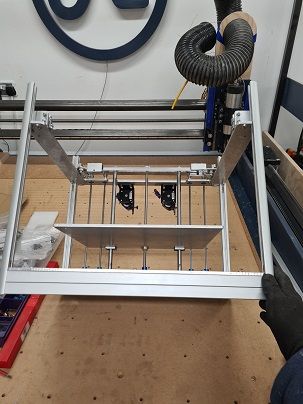

I've actually already built this printer, photos attached. Its still got a little bit of work todo and due to the nature of Duet, Reprap and the open source community I intend to share this project among my other projects (Root CNC).

I would much appreciate any help on configuring this type of kinematics as it looks like I'll be taking a big leap into the world of duet and RepRap firmware and I hope it'll soften the blow.

appreciate the help!

Thanks in advance! Pete from Root CNC

-

@RootCNC Hi,

Sure I can share how to set it up.

But I'm having a hard time understanding how you route your belts to make it a Haq-XY kinematics? -

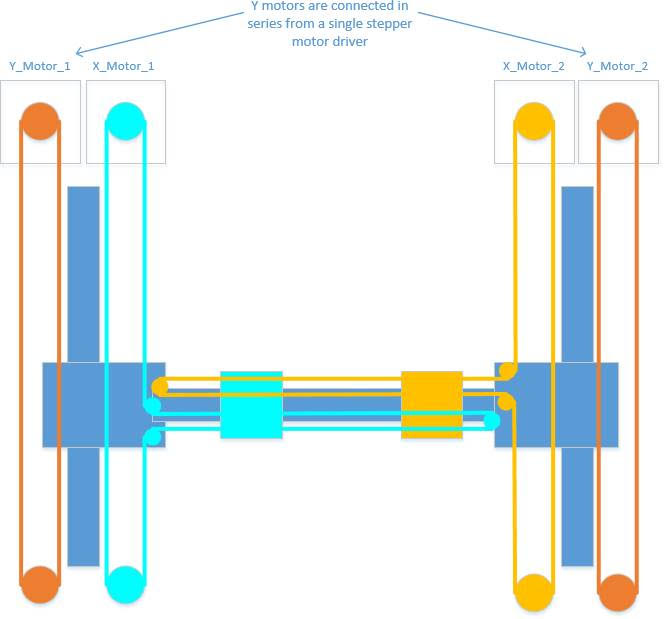

Ah sorry about that - Please see this photo.

I currently have two motors driving the Y axis - these shall be configured in a series configuration.

then two independent carriages driven from independent steppers.

Does that help?

Thanks

-

@RootCNC Aha I see!

I routed my 2 X belts on the same route but at different heights instead

And I used one stepper for the Y axis but with a rod connecting both sides of the Y axis.But the kinematics are exactly the same.

Btw, are you stepper mounted in the bottom with rods going to the top?

-

Yeah, to keep its low profile and symmetrical I went this way with the belts.

I plan in the future to try a heated chamber, so keeping the motors below the 6mm plate seemed a good idea.

I just purchased my Duet 3 and LCD, hopefully it'll turn up soon and then we can get this printer moving!

Was the setup difficult?

-

@dc42 I just reversed the Y motor and when I do G1 X10 F1000 S2 the Y axis moves in the right direction (+10).

But I've noticed a new thing when homing.

This is my homeall.g now:G91 ; relative positioning G1 Z5 F6000 S2 ; lift Z relative to current position G1 S1 Y550 U540 X-540 F2500 ; move quickly to Y axis endstops and stop there (first pass) G1 S1 Y550 F2500 ; Home Y seperate G1 S1 X-540 F2500 ; Home X seperate G1 S1 U540 F2500 ; Home U seperate G1 Y-5 X5 U-5 F2000 ; Go back 5mm on all axis G1 S1 Y550 F600 ; slowly home Y G1 S1 X-100 F600 ; Slowly home X G1 S1 U100 F600 ; Slowly home U G90 ; absolute positioning G1 X300 Y310 F2500 ; go to first bed probe point and home Z G30 ; home Z by probing the bed G91 ; relative positioning G1 S2 Z5 F100 ; lift Z relative to current position G90 ; absolute positioningBut when it comes to G1 X300 Y310 F2500 the X axis just smashes into it's endstop.

It seems like both U and X looses their position somehow, or that X and U switches...so X becomes U and U becomes X.If I manually home Y first and then try to home X the U axis moves.

If I manually home U and X first, their postion is X0 U550.

If I then home Y manually X position is X1100.3 and U is U-560.Does this make any sense at all?

I am still having this bug, even after updating from the latest beta to 3.2 stable.

When I home one axis, the other two lose their position. Although I think the correct axis are moving when they are homing. -

I had problem where when doing homing U and X axes lost position during all axis homing. Those axes moved against endstops and lost steps/belt skipped.

This was because homeall.g included wrong move type: 1 motor move -type move (H2-command)

I switched it to H0. I think that you are also suppose to use H-command instead of S-commands.check: https://duet3d.dozuki.com/Wiki/Gcode#Section_G0_G1_Move

My corrected homeall.g

; Haq xy homing, U and X axes concurrently, Y axis after that and Z axis last G91 G1 H2 Z7 F200 ; raise head 7mm to keep it clear of the bed G1 H1 X-405 U405 F3000 ; coarse home X and U G1 H2 X5 U-5 F600 ; move 4mm away from the homing switches G1 H1 X-10 U10 F600 ; fine home X and U G1 H1 Y-420 F2000 G1 H0 Y5 F600 G1 H0 Y-5.5 F600 G1 H1 Z-380 F360 ; move Z down stopping at the endstop G90 -

@Visionary

Would you do me a favour and post your config file? I think with my setup there is more wrong than just the homing file.

-Cheers

Max -

-

Hey everyone,

last night I got my HAQ XY or markforged IDEX printer moving and homing correctly last night.

you can see it moving here: https://fb.watch/38agipCwQx/

Here is my config, once you get your head around the matrix manipulation it was easy to ensure it was moving in the correct direction.

The magic happens on M669 command....

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.2 on Tue Jan 19 2021 18:42:53 GMT+0000 (Greenwich Mean Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet3" ; set printer name ; Drives M569 P0.0 S0 ; (Y) physical drive 0.0 goes forwards M569 P0.1 S0 ; (X1) physical drive 0.1 goes forwards M569 P0.2 S1 ; (X2) physical drive 0.2 goes forwards M569 P0.3 S1 ; (Z) physical drive 0.3 goes forwards M569 P0.4 S1 ; (E1) physical drive 0.4 goes forwards M584 X0.1 U0.2 Y0.0 Z0.3 E0.4 ; set drive mapping M350 X64 U64 Y64 Z64 E16 I1 ; configure microstepping with interpolation M669 K1 X1:0:0:0 Y1:-1:0:1 Z0:0:1:0 U0:0:0:1; Matrix mapping for Axis - X:Y:Z:U M92 X400.00 U400.00 Y400.00 Z1600.00 E420.00 ; set steps per mm M566 X900.00 U900.00 Y900.00 Z180.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 U6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 U500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1200 U1200 Y1200 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-45 U45 Y0 Z0 S1 ; set axis minima M208 X220 U310 Y215 Z200 S0 ; set axis maxima ; Endstops M574 X1 S3 ; configure sensorless endstop for low end on X M574 Y1 S3 ; configure sensorless endstop for low end on Y M574 Z1 S3 ; configure sensorless endstop for low end on Z M574 U2 S3 ; configure sensorless endstop for high end on U M915 X U Y Z R0 F0 ; Configure motor stall detection ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters ; Fans M950 F0 C"out8" Q500 ; create fan 0 on pin out8 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out9" Q500 ; create fan 1 on pin out9 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDueHoming wise:

here is an example of my homing script (the standard IDEX setup guild is very good); homex.g ; called to home the X axis M400 M913 X50 U50 Y50 ; drop motor current to 70% M400 G91; relative positioning ;G1 H2 Z10 F12000 ; lift Z relative to current position G1 H1 X-320.5 F10000 ; move quickly to X axis endstop and stop there (first pass) G1 H2 X5 F12000 ; go back a few mm G1 H1 X-320.5 F7000 ; move slowly to X axis endstop once more (second pass) ;G1 H2 Z-10 F6000 ; lower Z again G90 ; absolute positioning M400 M913 X100 U100 Y100 ; return current to 100% M400Please note I'm doing sensorless homing

-

@dc42 I just reversed the Y motor and when I do G1 X10 F1000 S2 the Y axis moves in the right direction (+10).

That will have changed the direction of X axis movement too.

I'm sorry, that would have been correct for CoreXY kinematics, not MarkForged kinematics. HaqXY is dual MarkForged.

-

Note that I'am too trying to get my printer working correctly. I have some problems for example with tool offsets. Please make sure that any parameters you take from it are correct for your machine.

my config at the moment:

; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K11 Y-1:-1:0:1 ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S1 ; physical drive 0.0 goes forwards X M569 P0.1 S1 ; physical drive 0.1 goes forwards U M569 P0.2 S1 ; physical drive 0.2 goes forwards Y M569 P0.3 S1 ; physical drive 0.3 goes forwards Z M569 P0.4 S1 ; physical drive 0.4 goes forwards E0 M569 P0.5 S1 ; physical drive 0.5 goes forwards E1 M584 X0.1 U0.0 Y0.2 Z0.3 E0.4:0.5 ; set drive mapping M350 X16 U16 Y16 Z16 E16:16 I1 ; configure microstepping without interpolation M92 X80.00 U80.00 Y80.00 Z640.00 E2700:208 ; set steps per mm M566 X600.00 U600.00 Y600.00 Z60.00 E40.00:300 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 U12000.00 Y12000.00 Z180.00 E1800.00:1000 ; set maximum speeds (mm/min) M201 X1000.00 U1000.00 Y1000.00 Z20.00 E120.00:600 ; set accelerations (mm/s^2) M906 X1200 U1200 Y1000 Z1000 E980:980 I45 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M569 P0.0 V25 H25 D3 M569 P0.1 V25 H25 D3 M569 P0.2 V25 H25 D3 M915 P0.0 S3 R0 H134 T25 F1 M915 P0.1 S3 R0 H134 T25 F1 M915 P0.2 S3 R0 H134 T25 F1 ; Axis Limits M208 X-42.3 U41 Y0 Z0 S1 ; set axis minima M208 X400 U439.6 Y400 Z375 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^io1.in" ; configure active-high endstop for low end on X via pin !^io2.in M574 U2 S1 P"!^io2.in" ; configure active-high endstop for high end on U via pin !^io1.in M574 Y1 S1 P"io5.in" ; configure active-high endstop for low end on Y via pin !^io3.in M574 Z1 S1 P"!^io4.in" ; configure active-high endstop for low end on Z via pin !^io4.in ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3974 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S130 ; set temperature limit for heater 0 to 120C M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp2 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H1 R2.399 C262.2 D5.02 S1 V23.8 M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp2 M950 H2 C"out2" T2 ; create nozzle heater output on out1 and map it to sensor 1 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M307 H2 R2.125 C261.6 D5.93 S1.00 V23.8 M143 H2 S280 ; set temperature limit for heater 1 to 280C M307 H0 A110 C180 D5 B1 ; Bed slow temperature rise ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools ; tool 0, X-axis M563 P0 D0 H1 X0 F0 ; define tool 0 G10 P0 R0 S0 X0 Y0 Z0 ; set tool 0 axis offsets ; tool 1, U-axis M563 P1 D1 H2 X3 F1 G10 P1 R0 S0 Y-0.1 U0 Z0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select tool